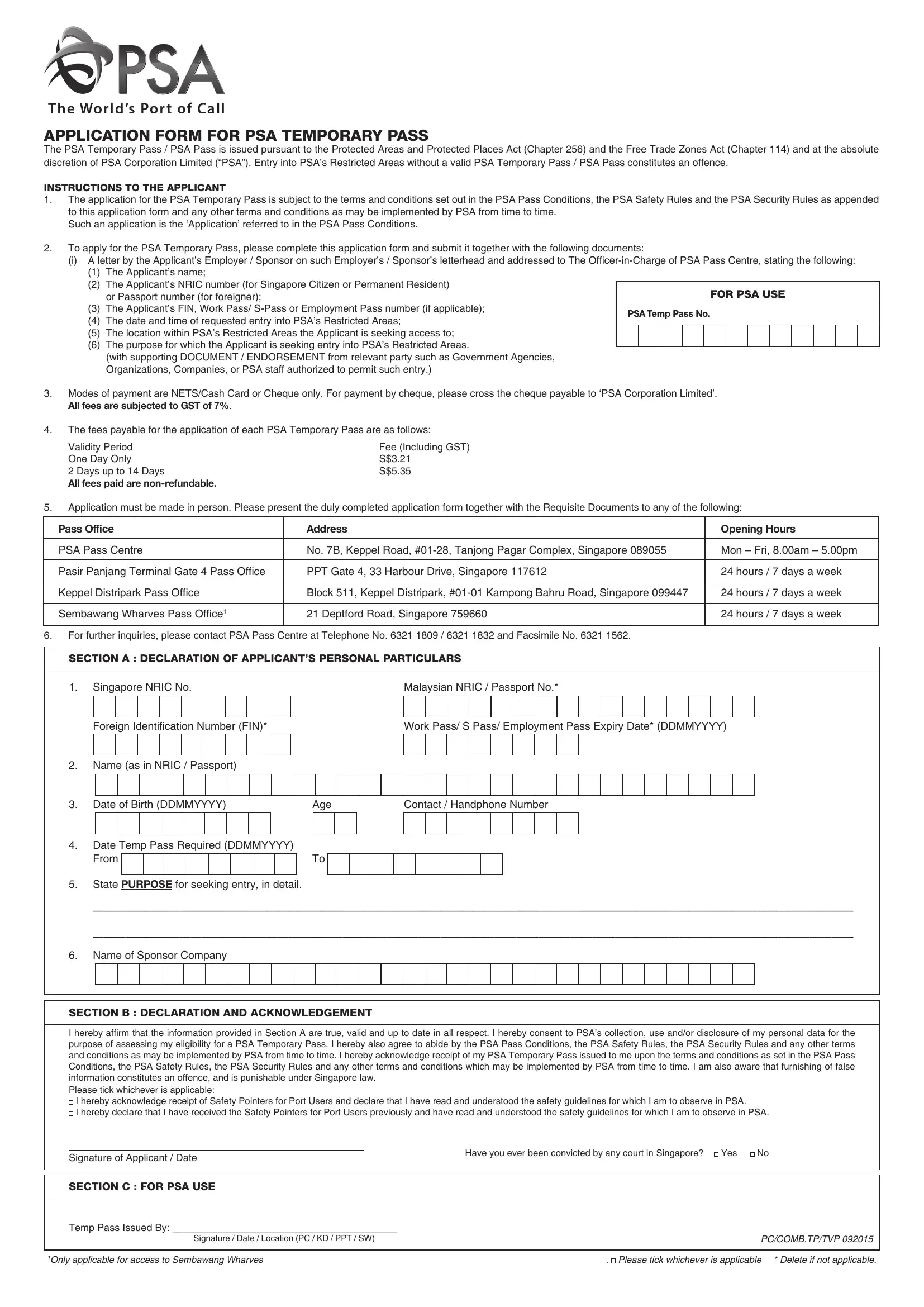

INDIVIDUAL SAFETY SYSTEM

Any breach by an individual of the Safety Rules (Individual) shall result in demerit points accruing to, and enforcement charges levied on, such individual, as set out in the table below in relation to less serious offences (indicated by an “L” preix to the safety rule number), serious offences (indicated by an “S” preix to the safety rule number) and very serious offences (indicated by a “V” preix to the safety rule number):

Type of Safety & Trafic Offence |

Penalty |

Less Serious Offence (L) |

2 demerit points + $75 enforcement charge |

Serious Offence (S) |

4 demerit points + $150 enforcement charge |

Very Serious Offence (V) |

8 demerit points + $300 enforcement charge |

|

|

|

On accumulation of 24 demerit points or more for offences committed within a 24-month period :- |

1st infringement period |

|

3 months debarment & Safety Refresher Course |

|

2nd infringement period |

|

6 months debarment & Safety Refresher Course |

3rd infringement period |

|

Permanent debarment (immediate) |

|

|

|

Serious infringement resulting in |

|

Fine and immediate debarment irrespective of whether or not it is the irst |

death or serious injuries or serious |

|

infringement. (The Offender must attend a Safety Refresher Course and |

damage to equipment or property |

|

the PSA Pass may be re-issued to such offender thereafter.) |

|

|

|

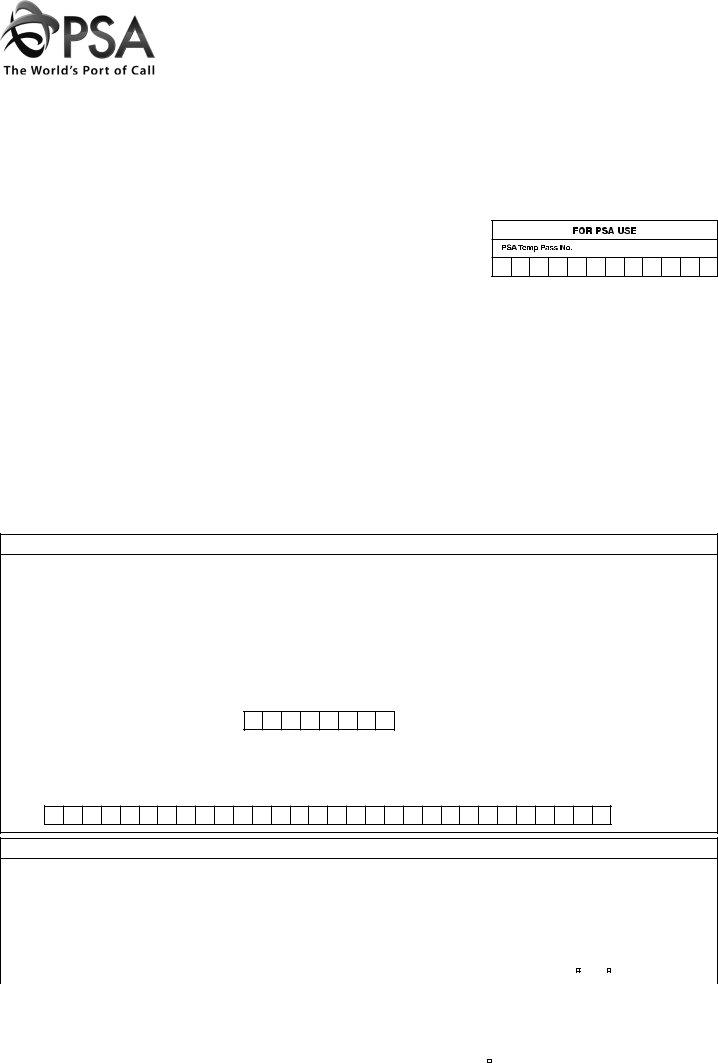

SAFETY RULES (INDIVIDUAL)

1Proper Protective Apparel

L101 To ensure that a safety helmet is properly worn in compulsory “Safety Helmet” areas at all times.

L102 To ensure that suitable protective footwear acceptable to PSA are properly worn at all times.

V103 To ensure that a safety belt/harness is properly worn at all times when working from heights or when riding

on quay crane spreaders.

V104 To ensure that a seat belt is properly worn at all times when driving any equipment/vehicle.

S106 To ensure that a high visibility vest acceptable to PSA is properly worn at all times.

V107 To ensure that a life jacket acceptable to PSA is properly worn at all times when working at all ship edge/ wharf edge.

L149 To ensure that all other suitable protective apparels acceptable to PSA are properly worn at all times.

2Safe Lifting Equipment/Slinging Operations

L201 To ensure that proper guide ropes of adequate length are used when handling heavy or lengthy loads.

S202 To ensure that only lifting machines/appliances/gear marked with “SWL” and with valid test certiicates are used.

S203 To ensure that appropriate lifting machines/appliances/gear/method e.g. self-locking spreaders, etc. are used for container-handling.

S204 To ensure that lifting machines/appliances/gear and pallets used for the slinging,

loading and stacking of goods/materials are free from defects and properly used.

S205 To ensure that the 3-step lifting operational procedure is properly observed and that loads are lifted with due care and attention.

S206 To ensure that lifting operations are properly guided by a signaller, lifting supervisor and/ or Ship Trafic Assistant and Wharf Operations Supervisor.

S207 To ensure that any person performing the duties of a signaller, lifting supervisor, Ship

Trafic Assistant or Wharf Operations Supervisor is stationed at the proper vantage position.

S208 To ensure that the handling of heavy equipment, including overheight containers, hatch cover, etc., is properly supervised.

V209 To ensure that no lifting equipment/gear/machine is to be loaded beyond the safe working load.

V210 To ensure that no load is suspended over or near any person at all times and that no person is allowed to work under or near a suspended load.

S249 To ensure that lifting machines/appliances/gear are operated in a safe manner and compliant with relevant safety requirements at law and/or stipulated by PSA.

3Safe Equipment Operations

(Including Prime Movers, Forklifts, Mobile Cranes, etc.)

S301 To ensure that any equipment used is installed with proper and standard safety features e.g. brakes, horns, meter gauges, blinker lights, reverse buzzer, etc.

S302 To ensure that headlights of all equipment are switched on when operating in or around the warehouse/ freight station/vessel between 7.00 p.m. and 7.00 a.m. and whenever visibility is poor.

S303 To ensure that only proper equipment for the intended work purpose is used and that such equipment is used carefully according to its function and operational instructions.

S304 To ensure that the engine of a piece of equipment is promptly switched off and the hand brake is engaged during refuelling or before leaving the cabin.

S305 To ensure that loads are lifted or transported in a stable and safe manner and within the load limit.

L349 To ensure that all equipment are driven or operated with due care and attention and compliant with safety procedures/guidelines/instructions of the law and/or stipulated by PSA

S349

V349

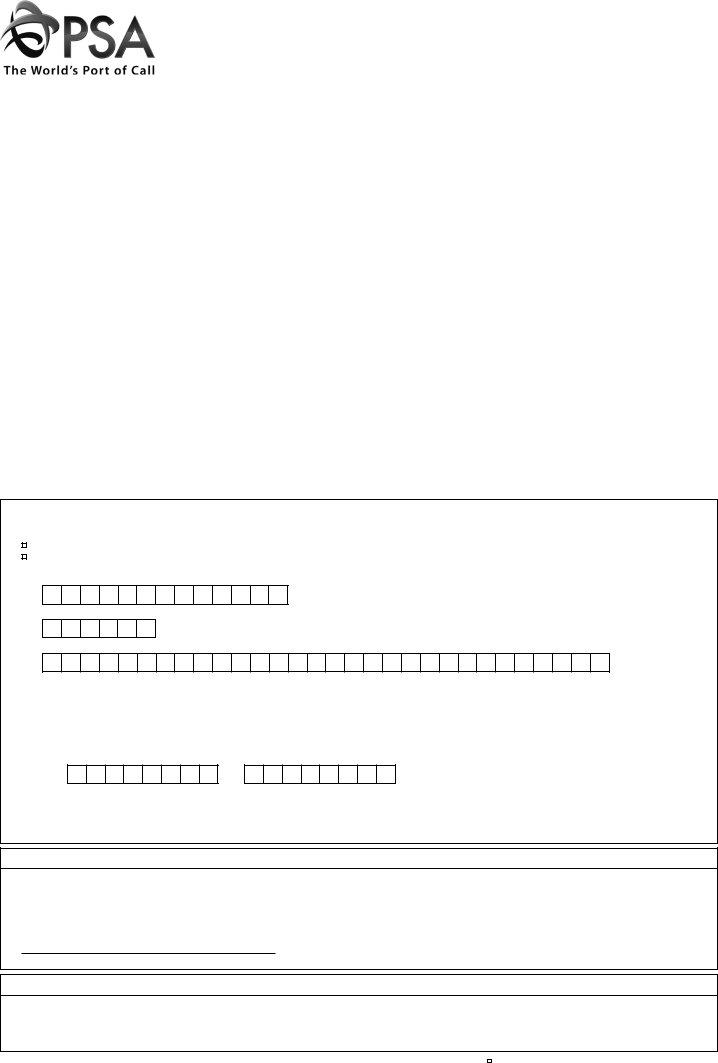

4Safe Work Method/Procedures

L401 To ensure that means of access and ire/life-saving appliances are free from obstruction at all times.

L402 To ensure that work areas are kept free from obstruction and tripping hazards at all times.

S403 To ensure that work areas or any unguarded openings are adequately illuminated/barricaded before work. S404 To ensure that safety warning signs/devices, including trafic cones/blinkers, etc., as required by PSA are

placed in appropriate places.

S405 To ensure that prompt action is taken to rectify any unstable stacking, obstruction to ire ighting/life saving equipment and means of access, and any other sub-standard condition.

S406 To ensure that wheel chocks and/or proper support stands are used for vehicles or other equipment under repair.

S407 To ensure that there is compliance with all ire safety requirements, safety instructions, permit to work system and hot work procedures required at law and as stipulated by PSA.

S408 To ensure that safe work practices are adopted when working at a height.

S409 To ensure that signallers, Ship Trafic Assistants or Wharf Operations Supervisors are to remain at the relevant work stations during operation at all times unless there are suitable and proper replacement.

S410 To ensure that all trailer twistlocks are properly unlocked before ofloading of containers and properly locked after loading of containers.

S411 To ensure that no person is to perform work for more than 12 continuous hours.

S412 To ensure that save-all nets are properly rigged at the shipside as required by PSA.

S413 To ensure that safety devices are not tampered with and suitable and proper tools and equipment are used. V414 To ensure that proper and safe means are used to access to and from high work places.

S415 To ensure that no tool, gear or equipment and means of access (e.g. ladder, platform, man-cage, gondola, scaffold, etc.) which is defective, untested or uncertiied is put into use, and any such item is immediately removed from PSA premises.

S416 To ensure that proper tools, receptacles and aids for lashing/unlashing are used.

S417 To ensure that there is a suficient number of trained workers to handle each stevedoring/lashing/berthing

operation.

S418 To ensure that all loose items on the surfaces of, or which are not properly secured to, the hatch covers or containers are removed before such hatch covers or containers are handled.

S419 To ensure that no equipment or tool is thrown or dropped from any worksite at a height.

S420 To ensure that only quay crane spreaders are used to get to and from container tops and workers using such spreaders are properly secured within the man-cage by safety belt/harness before such spreaders are activated. No more than 2 workers are to use one such spreader at any one time.

V421 To ensure that no Ship Trafic Assistant performs Ship Trafic Assistant duties and worker duties

simultaneously.

V422 To ensure that deep tanks or conined spaces are properly ventilated and certiied safe before allowing workers to enter.

L449 To ensure that all necessary precautionary measures are taken at all times when working in PSA premises. S449

V449

5Safe Stacking/Unstacking Operations

L501 To ensure that goods are stacked within safe height limits.

L502 To ensure that adequate space clearance is provided between stacks and between stacks and walls.

S503 To ensure that adequate space clearance is provided between incompatible goods/materials.

S549 To ensure that goods/materials are properly stacked and compliant with safe work practices required by PSA.

6Authorised/Trained Workers

S601 To ensure that any person who performs or is permitted to perform stevedoring works is properly trained and within the authorised age limit.

S602 To ensure that the requisite authorisation is obtained before any person performs or is permitted to perform wharinger duties and/or berthing/unberthing.

S603 To ensure that the requisite authorisation is obtained before any person performs or is permitted to perform the duties of a Safety Supervisor, Foreman or Ship Checker.

S604 To ensure that any person who performs or is permitted to perform plug/unplug jobs onboard vessel and/or in the yard is properly trained and has obtained the prior requisite authorisation.

S605 To ensure that the requisite authorisation is obtained before any person performs or is permitted to perform the duties of Ship Trafic Assistant or Wharf Operations Supervisor.

S606 To ensure that the requisite authorisation is obtained before any person performs or is permitted to perform engineering or hot work only after obtaining the requisite authorisation.

V607 To ensure that the requisite authorisation is obtained before any person drives or operates or is permitted to drive or operate forklifts, machines, vehicles, prime movers or other port equipment.

V608 To ensure that the requisite authorisation is obtained before any person operates or is permitted to operate winches, cranes or other lifting equipment.

V609 To ensure that any person who performs or is permitted to perform stevedoring works, including lashing/ unlashing works, etc., is properly trained and obtains the requisite authorisation before performing such works.

S649 To ensure that only persons authorised by PSA perform or are permitted to perform work in PSA premises.

7Submission Of Documents

L701 To ensure that an accurate and current checklist of safety measures and other requisite measures is submitted in the form, and within the time, required by PSA.

L702 To ensure that an accurate and current Labour Attendance Sheet is submitted in the form, and within the time, required by PSA.

L703 To ensure that any safety document, report or plan as required by PSA is promptly updated at all times. V703

8Safety Behaviour/Conduct

L801 To ensure that a safe distance from equipment gantry paths is maintained at all times.

L802 To ensure no cycling except in authorised operational areas.

L803 To ensure that discipline and order are properly maintained at the work areas at all times.

S804 To ensure that rest is taken only at places authorised by PSA.

S805 To ensure that any person who climbs ladders, stairs, containers, stacks, spreaders or equipment does so in

a proper and safe manner.

V806 To ensure that a safe distance from a container which is lifted or lowered is maintained.

S807 To ensure that a safe position is maintained at the edge of ships, hatches, cargo stacks, container tops, unguarded openings, wharf aprons, equipment or work areas at all times.

S808 To ensure that all persons are kept clear from all areas between suspended load and stationary object. V809 To ensure that all persons are kept clear from any suspended load, path of suspended load, unstable stack

or path of moving equipment at all times.

V810 To ensure that persons who are permitted to work are not under the inluence of alcohol or drug or any substance which may impair their judgment or action at work.

V811 To ensure that no smoking is allowed at all times, except in smoking areas.

S812 To ensure that no port or other property is vandalised or otherwise tampered with, damaged, impaired

or destroyed.

S813 To ensure that there is no littering or spitting at all times.

S849 To ensure that a safe position is maintained in and around the operational areas at all times.