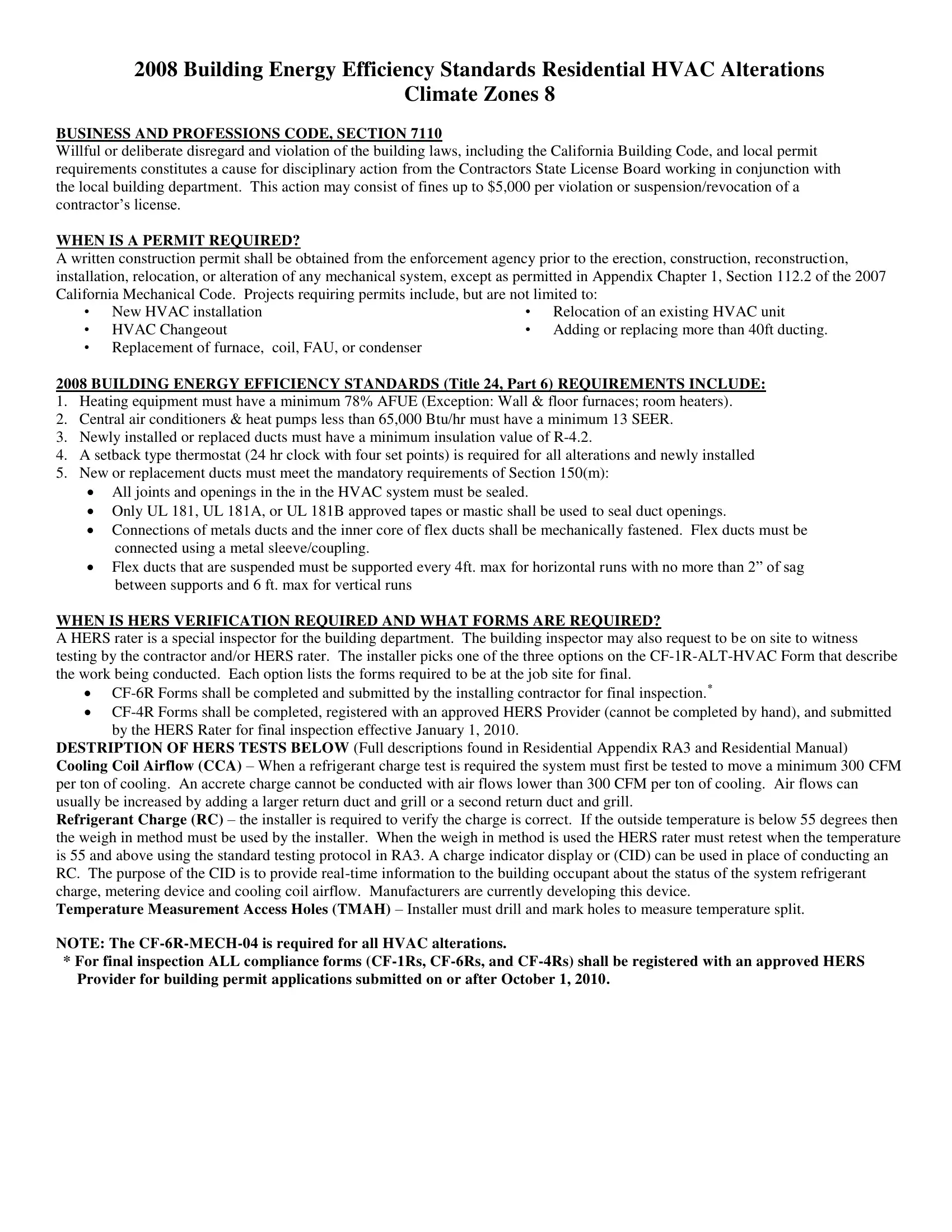

2008 Building Energy Efficiency Standards Residential HVAC Alterations

Climate Zones 8

BUSINESS AND PROFESSIONS CODE, SECTION 7110

Willful or deliberate disregard and violation of the building laws, including the California Building Code, and local permit requirements constitutes a cause for disciplinary action from the Contractors State License Board working in conjunction with

the local building department. This action may consist of fines up to $5,000 per violation or suspension/revocation of a contractor’s license.

WHEN IS A PERMIT REQUIRED?

A written construction permit shall be obtained from the enforcement agency prior to the erection, construction, reconstruction, installation, relocation, or alteration of any mechanical system, except as permitted in Appendix Chapter 1, Section 112.2 of the 2007 California Mechanical Code. Projects requiring permits include, but are not limited to:

• |

New HVAC installation |

• |

Relocation of an existing HVAC unit |

• |

HVAC Changeout |

• |

Adding or replacing more than 40ft ducting. |

•Replacement of furnace, coil, FAU, or condenser

2008 BUILDING ENERGY EFFICIENCY STANDARDS (Title 24, Part 6) REQUIREMENTS INCLUDE:

1.Heating equipment must have a minimum 78% AFUE (Exception: Wall & floor furnaces; room heaters).

2.Central air conditioners & heat pumps less than 65,000 Btu/hr must have a minimum 13 SEER.

3.Newly installed or replaced ducts must have a minimum insulation value of R-4.2.

4.A setback type thermostat (24 hr clock with four set points) is required for all alterations and newly installed

5.New or replacement ducts must meet the mandatory requirements of Section 150(m):

∙All joints and openings in the in the HVAC system must be sealed.

∙Only UL 181, UL 181A, or UL 181B approved tapes or mastic shall be used to seal duct openings.

∙Connections of metals ducts and the inner core of flex ducts shall be mechanically fastened. Flex ducts must be

connected using a metal sleeve/coupling.

∙Flex ducts that are suspended must be supported every 4ft. max for horizontal runs with no more than 2” of sag between supports and 6 ft. max for vertical runs

WHEN IS HERS VERIFICATION REQUIRED AND WHAT FORMS ARE REQUIRED?

A HERS rater is a special inspector for the building department. The building inspector may also request to be on site to witness testing by the contractor and/or HERS rater. The installer picks one of the three options on the CF-1R-ALT-HVAC Form that describe the work being conducted. Each option lists the forms required to be at the job site for final.

∙CF-6R Forms shall be completed and submitted by the installing contractor for final inspection.*

∙CF-4R Forms shall be completed, registered with an approved HERS Provider (cannot be completed by hand), and submitted

by the HERS Rater for final inspection effective January 1, 2010.

DESTRIPTION OF HERS TESTS BELOW (Full descriptions found in Residential Appendix RA3 and Residential Manual) Cooling Coil Airflow (CCA) – When a refrigerant charge test is required the system must first be tested to move a minimum 300 CFM per ton of cooling. An accrete charge cannot be conducted with air flows lower than 300 CFM per ton of cooling. Air flows can usually be increased by adding a larger return duct and grill or a second return duct and grill.

Refrigerant Charge (RC) – the installer is required to verify the charge is correct. If the outside temperature is below 55 degrees then the weigh in method must be used by the installer. When the weigh in method is used the HERS rater must retest when the temperature is 55 and above using the standard testing protocol in RA3. A charge indicator display or (CID) can be used in place of conducting an RC. The purpose of the CID is to provide real-time information to the building occupant about the status of the system refrigerant charge, metering device and cooling coil airflow. Manufacturers are currently developing this device.

Temperature Measurement Access Holes (TMAH) – Installer must drill and mark holes to measure temperature split.

NOTE: The CF-6R-MECH-04 is required for all HVAC alterations.

*For final inspection ALL compliance forms (CF-1Rs, CF-6Rs, and CF-4Rs) shall be registered with an approved HERS Provider for building permit applications submitted on or after October 1, 2010.

Conditioned Floor Area

Thermostat

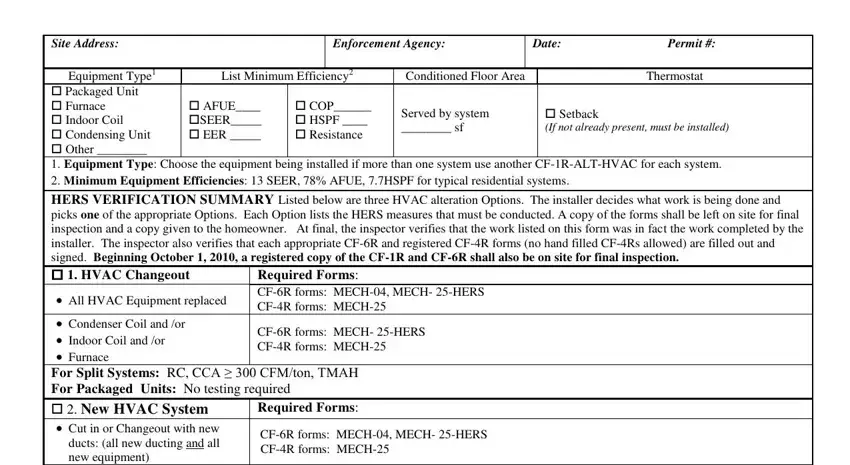

Simplified Prescriptive Certificate of Compliance: 2008 Residential HVAC Alterations |

CF-1R-ALT-HVAC |

Climate Zones 8

|

Packaged Unit |

|

|

|

|

|

Furnace |

AFUE____ |

COP______ |

Served by system |

Setback |

|

Indoor Coil |

SEER_____ |

HSPF ____ |

|

________ sf |

(If not already present, must be installed) |

|

Condensing Unit |

EER _____ |

Resistance |

|

|

|

|

Other ________ |

|

|

|

|

1.Equipment Type: Choose the equipment being installed if more than one system use another CF-1R-ALT-HVAC for each system.

2.Minimum Equipment Efficiencies: 13 SEER, 78% AFUE, 7.7HSPF for typical residential systems.

HERS VERIFICATION SUMMARY Listed below are three HVAC alteration Options. The installer decides what work is being done and picks one of the appropriate Options. Each Option lists the HERS measures that must be conducted. A copy of the forms shall be left on site for final inspection and a copy given to the homeowner. At final, the inspector verifies that the work listed on this form was in fact the work completed by the installer. The inspector also verifies that each appropriate CF-6R and registered CF-4R forms (no hand filled CF-4Rs allowed) are filled out and signed. Beginning October 1, 2010, a registered copy of the CF-1R and CF-6R shall also be on site for final inspection.

|

1. HVAC Changeout |

Required Forms: |

|

|

|

|

∙ All HVAC Equipment replaced |

CF-6R forms: MECH-04, MECH- 25-HERS |

|

CF-4R forms: MECH-25 |

|

|

|

∙ Condenser Coil and /or |

CF-6R forms: MECH- 25-HERS |

|

∙ Indoor Coil and /or |

|

CF-4R forms: MECH-25 |

|

∙ Furnace |

|

|

|

For Split Systems: RC, CCA ≥ 300 CFM/ton, TMAH |

|

For Packaged Units: No testing required |

2. New HVAC System |

|

Required Forms: |

∙ Cut in or Changeout with new |

|

CF-6R forms: MECH-04, MECH- 25-HERS |

ducts: (all new ducting and all |

|

|

CF-4R forms: MECH-25 |

new equipment) |

|

|

|

|

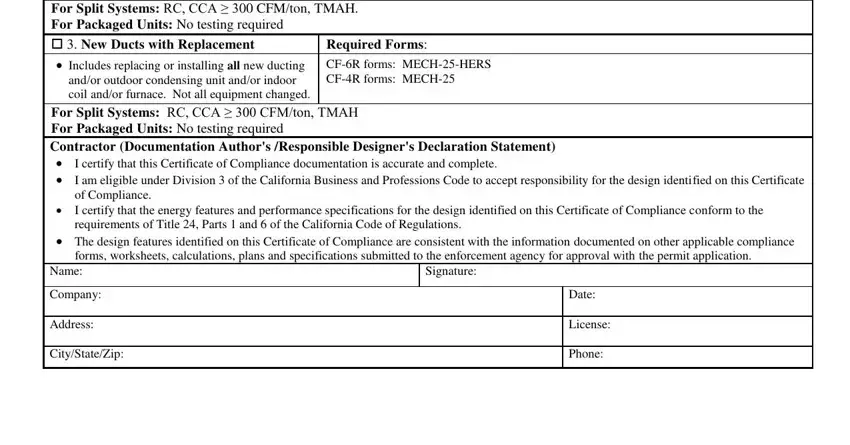

For Split Systems: RC, CCA ≥ 300 |

CFM/ton, TMAH. |

For Packaged Units: No testing required |

|

3. New Ducts with Replacement |

|

Required Forms: |

∙ Includes replacing or installing all new ducting |

CF-6R forms: MECH-25-HERS |

and/or outdoor condensing unit and/or indoor |

CF-4R forms: MECH-25 |

coil and/or furnace. Not all equipment changed. |

|

|

|

|

|

For Split Systems: RC, CCA ≥ 300 CFM/ton, TMAH

For Packaged Units: No testing required

Contractor (Documentation Author's /Responsible Designer's Declaration Statement)

∙I certify that this Certificate of Compliance documentation is accurate and complete.

∙I am eligible under Division 3 of the California Business and Professions Code to accept responsibility for the design identified on this Certificate of Compliance.

∙I certify that the energy features and performance specifications for the design identified on this Certificate of Compliance conform to the requirements of Title 24, Parts 1 and 6 of the California Code of Regulations.

∙The design features identified on this Certificate of Compliance are consistent with the information documented on other applicable compliance forms, worksheets, calculations, plans and specifications submitted to the enforcement agency for approval with the permit application.

2008 Residential Compliance Forms |

March 2010 |