Navigating the intricacies of mix design in road construction projects necessitates a thorough understanding of various components and their interplay. Within this realm, the Federal Highway Administration (FHWA) Form 1607, titled "Worksheet for a Hveem Mix Design," stands as a pivotal document. This comprehensive form guides contractors and engineers through the meticulous process of designing a Hveem mix, which is crucial for ensuring the durability and reliability of pavement structures. It encompasses a wide array of parameters, including the percentage of asphalt by mass of the total mix, air voids, voids in mineral aggregate, maximum specific gravity, and recommended plant mixing temperature amongst others. Moreover, it delves into aggregate sourcing, asphalt grading, and the specifics of the testing laboratory involved. By integrating elements like the stabilization value, specific gravity of binders and fillers, and moisture susceptibility tests, the form facilitates a systematic approach to defining the job-mix formula. Such a formula is essential for achieving the desired pavement performance, highlighting the importance of precision in each step, from selecting materials to specifying mixing temperatures and assessing potential moisture-induced vulnerabilities. The FHWA 1607 form plays a crucial role in aligning project specifications with industry standards, thereby influencing the structural integrity and lifespan of roadways.

| Question | Answer |

|---|---|

| Form Name | Form Fhwa 1607 |

| Form Length | 5 pages |

| Fillable? | No |

| Fillable fields | 0 |

| Avg. time to fill out | 1 min 15 sec |

| Other names | 1607_v28 aashto and hveem mix design form |

U.S. Department of Transportation

Federal Highway Administration

Federal Lands Highway

|

|

|

|

|

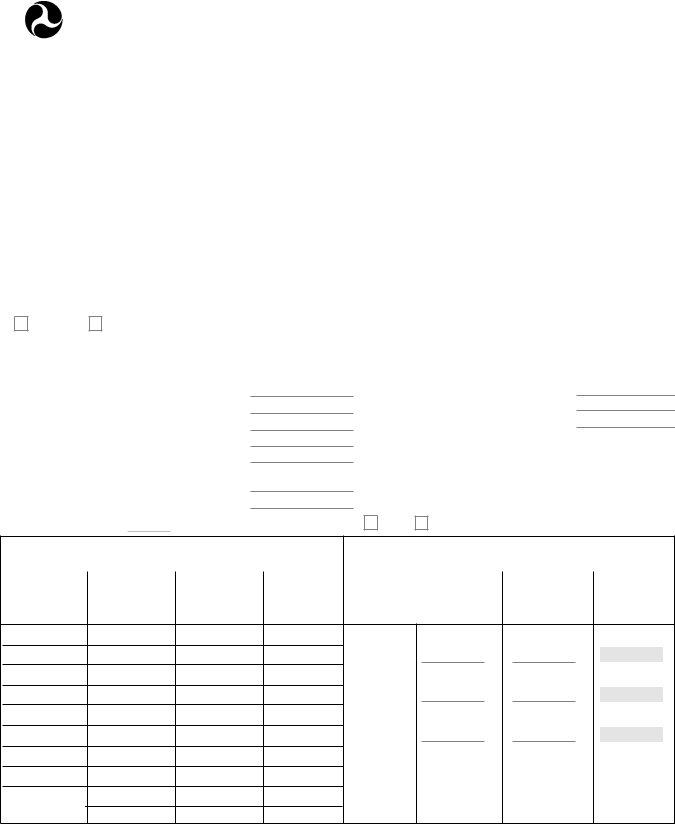

WORKSHEET FOR A HVEEM MIX DESIGN |

|

|||||||||

|

|

|

|

|

AASHTO T 246 |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Project: |

|

|

|

|

|

|

Date: |

|

|

|

|||||

Contractor: |

|

|

|

|

|

Class & Grading of mixture: |

|

|

|

||||||

Asphalt supplier: |

|

|

Grade of asphalt: |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||

Sources for: |

Aggregates: |

|

|

Mineral filler: |

|

|

|||||||||

Testing laboratory name: |

|

|

|

Phone: |

|

|

|||||||||

Testing performed by: |

|

|

|

|

|

|

|

|

|

|

|

|

|||

Testing reported by: |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

English |

Metric |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

SUMMARY OF THE PROPOSED |

|

|||||||||

1.Percent asphalt by mass of total mix1, (Pb)

2.Air voids (Va)

3.Voids in mineral aggregate (VMA)

4.Maximum specific gravity (Gmm )

5.Recommended plant mixing temperature,

(Attach Temperature Viscosity Curve)

6.Effective specific gravity of aggregate (Gse)

7.Stabilometer value

Gradation Designation:

8.Specific gravity of binder (Gb)

9.Specific gravity of mineral filler

10.

11. Moisture susceptibility test results: 2 a. Dry strength, b. Wet strength, c. Index of retained strength, %

|

GRADATION TARGET VALUES AND |

SPECIFIC GRAVITY AND ABSORPTION |

|||||

|

ALLOWABLE DEVIATIONS |

|

|||||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Job Mix |

Target Value |

Allowable |

Fine |

Coarse |

Combined |

|

Sieve Sizes |

Formula |

Specification |

Deviation4 |

Aggregate |

Aggregate |

||

Aggregate |

|||||||

|

Target Value 3 |

Range % |

% |

(AASHTO T 84) |

(AASHTO T 85) |

||

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bulk SG (Gsb )

Bulk SSD SG

Apparent SG (Gsb)

Absorption |

|

% |

|

% |

|

% |

1Establish asphalt cement content (percent by mass of mix) to the nearest 0.01 percent.

2See contract for moisture susceptibility test method: AASTHO T 165/T 167 or AASTHO T 283.

3 Establish target values to the nearest 0.1 percent as a part of the job mix formula. 4 Allowable deviations plus or minus from established target values.

Form FHWA 1607 (Rev |

Page 1 of 5 |

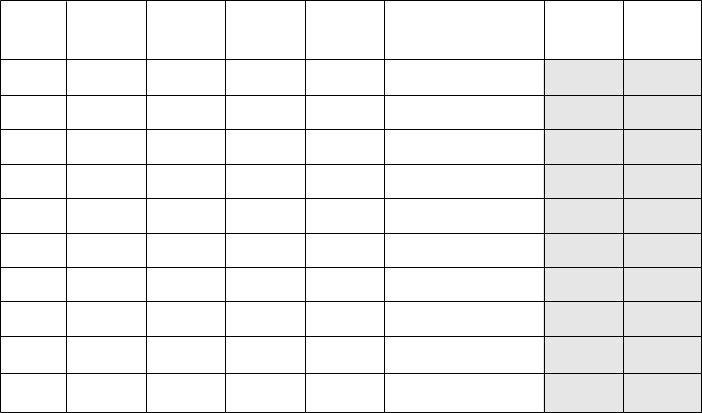

WORKSHEET FOR A HVEEM MIX DESIGN (Continued)

Material |

Stockpile Description |

|

Blend Ratio |

|||||

Stockpile |

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

% |

||

B |

|

|

|

|

|

% |

||

C |

|

|

|

|

|

|

% |

|

D |

|

|

|

|

|

% |

||

E |

|

|

|

|

|

% |

||

|

|

Total |

|

|||||

|

|

|

|

% |

||||

|

|

|

||||||

|

|

Stockpile Gradation |

|

|

|

|||

Sieve

Size

Stockpile

A

%

Stockpile

B

%

Stockpile

C

%

Stockpile

D

%

Stockpile |

Blended |

|

E |

Stockpile |

|

|

% |

Gradation |

|

|

|

|

|

|

|

|

|

Job Mix

Formula

Target Values

Specification

Limits

Aggregate Properties

Property |

Result |

Specification |

Property |

Result |

Specification |

||||

|

|

|

|

|

|

|

|

|

|

LA Abrasion, % - Grading |

|

|

|

|

Fractured Faces, % - |

|

|

|

|

|

|

|

|

|

|

|

|

||

AASHTO T 96 |

|

|

ASTM D 5821 |

|

|

|

|

||

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

Sodium Sulfate Soundness, % |

|

|

Sand Equivalent |

|

|

||||

|

|

AASHTO T 176, Alt method |

|

|

|||||

AASHTO T 104 |

|

|

|

|

|||||

|

|

#2, reference method |

|

|

|||||

|

|

|

|

|

|

|

|||

Durability index (Coarse) |

|

|

Other: |

|

|

||||

AASHTO T 210 |

|

|

|

|

|||||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

Durability index (Fine) |

|

|

Other: |

|

|

||||

AASHTO T 210 |

|

|

|

|

|||||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

Form FHWA 1607 (Rev |

Page 2 of 5 |

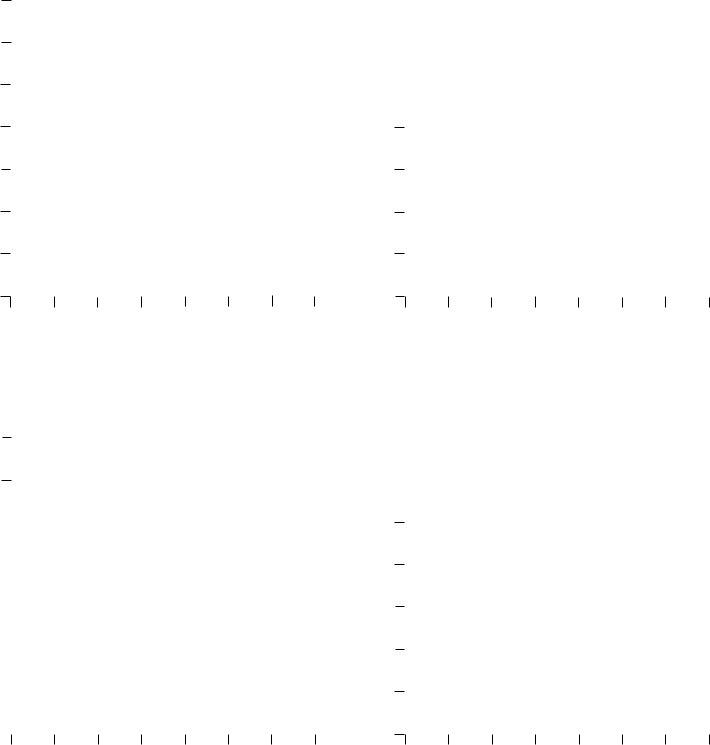

WORKSHEET FOR A HVEEM MIX DESIGN (Continued)

Trial Number |

1 |

|

2 |

|

3 |

|

|||

% Asphalt by mass of total mix, (Pb) |

|

|

|

|

|

|

|

|

|

Effective Binder Content (Pbe) |

|

|

|

|

|

|

|

|

|

Specimen height, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Stabilometer value |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bulk specific gravity, (Gmb) |

|

|

|

|

|

|

|

|

|

Bulk unit mass, |

|

|

|

|

|

|

|

|

|

Max. specific gravity, (Gmm ) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

% Air voids, (Va) |

|

|

|

|

|

|

|

|

|

% Voids in mineral aggregate, (VMA) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Average Stabilometer value |

|

|

|

|

|

|

|

|

|

Average % Air voids, (Va) |

|

|

|

|

|

|

|

|

|

Average % Voids in mineral aggregate, (VMA) |

|

|

|

|

|

|

|

|

|

Average Bulk Unit Mass |

|

|

|

|

|

|

|

|

|

Trial Number |

4 |

|

5 |

|

6 |

|

|||

% Asphalt by mass of total mix, (Pb) |

|

|

|

|

|

|

|

|

|

Effective Binder Content (Pbe) |

|

|

|

|

|

|

|

|

|

Specimen height, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Stabilometer value |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bulk specific gravity, (Gmb) |

|

|

|

|

|

|

|

|

|

Bulk unit mass, |

|

|

|

|

|

|

|

|

|

Max. specific gravity, (Gmm ) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

% Air voids, (Va) |

|

|

|

|

|

|

|

|

|

% Voids in mineral aggregate, (VMA) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Average Stabilometer value |

|

|

|

|

|

|

|

|

|

Average % Air voids, (Va) |

|

|

|

|

|

|

|

|

|

Average Voids in mineral aggregate, (VMA) |

|

|

|

|

|

|

|

|

|

Average Bulk Unit Mass |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Test Results for Each of the Individual Moisture Susceptibility Test Specimens |

|

||||||||||

Percent asphalt binder: |

|

|

AASHTO T 165/T 167 |

AASHTO T 283 |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

Specimen Dia: |

6 inch |

4 inch |

|||

Antistrip, type, amount: |

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

Freeze cycle: |

Yes |

No |

||||||

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sample I.D. |

|

|

|

|

|

|

|

|

|

|

|

Average |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Height |

|

Dry |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wet |

|

|

|

|

|

|

|

|

|

|

|

|

Bulk Specific |

|

Dry |

|

|

|

|

|

|

|

|

|

|

|

|

Gravity |

|

Wet |

|

|

|

|

|

|

|

|

|

|

|

|

Air |

|

Dry |

|

|

|

|

|

|

|

|

|

|

|

|

Voids |

|

Wet |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dry |

|

|

|

|

|

|

|

|

|

|

|

|

Strength |

|

Wet |

|

|

|

|

|

|

|

|

|

|

|

|

Retained Strength, % |

|

|

|

|

|

|

|

||||||

Form FHWA 1607 |

Page 3 of 5 |

WORKSHEET FOR A HVEEM MIX DESIGN (Continued)

Design Curves for Proposed Job Mix Formula (JMF)

AIR VOIDS (Va) |

|

UNIT MASS |

|

|

|

|

|

|

|

|

|

% Air voids (Va )

% Asphalt binder (Pb)

% Asphalt binder (Pb)

SVALUE |

|

VMA |

|

|

|

|

|

|

Stabilometer values |

|

|

Voids in mineral aggregate |

|

|

||

|

|||

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

% Asphalt binder (Pb) |

% Asphalt binder (Pb) |

Form FHWA 1607 (Rev |

Page 4 of 5 |

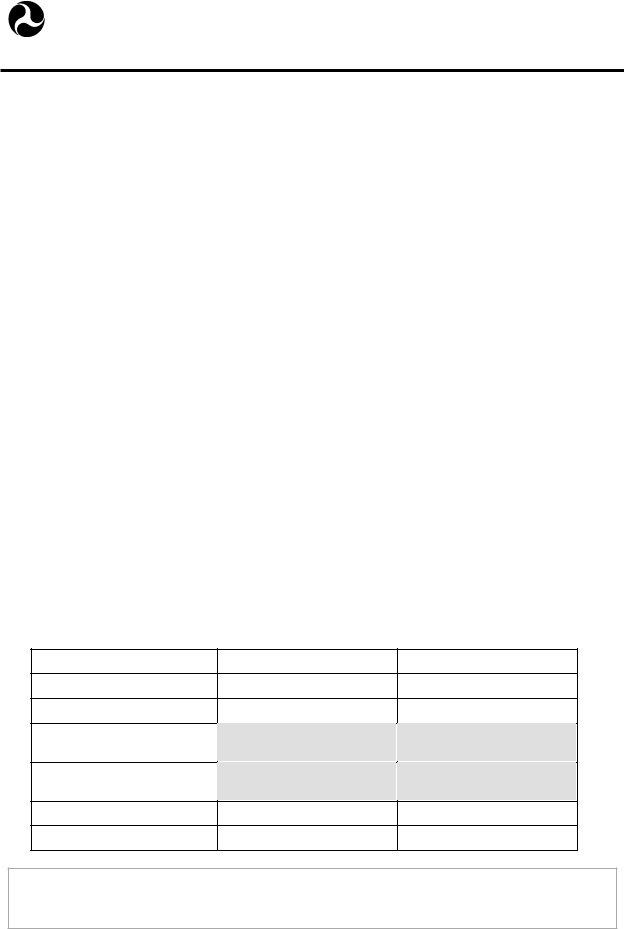

U.S. Department of Transportation

Federal Highway Administration

Federal Lands Highway

RECLAIMED ASPHALT PAVEMENT (RAP) DATA SHEET

Location: |

|

|

|

|

|

Sampled by: |

|

||||||

Tested by: |

|

|

|

|

Date: _____________________ |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RAP 1 |

|

|

RAP 2 |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

% of RAP in Mixture |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dry |

T 308 |

|

|

Dry |

|

T 308 |

|

|

|

|

|

|

Sieve Size |

Burned |

|

|

|

|

|

|

|||

|

|

|

Gradation |

|

|

Gradation |

|

Burned |

|

|

|||

|

|

|

|

Gradation |

|

|

Gradation |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AC by % mix, Pb

Specific Gravity |

Specific Gravity |

Gmm

Gse

Gse = (100 – Pb)/(10/Gmm – Pb/Gb)

Gsb

Gsb = Gse/(((Pba*Gse)/(100*Gb)) + 1)

Pba = (assumed)

Gb = (assumed)

Remarks:

Form FHWA 1607 (Rev |

Page 5 of 5 |