In the realm of infrastructure development and maintenance, the integration of robust materials and meticulous planning plays a pivotal role in ensuring the longevity and sustainability of road surfaces. The Federal Highway Administration (FHWA), a division of the U.S. Department of Transportation, recognizes the critical importance of selecting and testing materials for Superpave asphalt concrete mix designs, instrumental in paving safer and more durable roads. The FHWA 1641 form, developed for this exact purpose, serves as a comprehensive worksheet guiding engineers and contractors through the intricate process of Superpave mix design for federal lands highways. This detailed form encompasses various critical aspects of mix design, including but not limited to, the selection and proportions of aggregates, binder specifications, target values for mix components, and the necessary laboratory tests to determine moisture susceptibility and other vital properties of the asphalt mix. Moreover, it meticulously records project details, contractor information, aggregate and asphalt suppliers, and the specifics of the job mix formula, aiming to standardize the mix design process and assure quality control across federal highway projects. By facilitating a uniform approach to asphalt mix design, the FHWA 1641 form plays a crucial role in enhancing road quality, safety, and performance on federal lands, contributing significantly to the infrastructure's enduring reliability.

| Question | Answer |

|---|---|

| Form Name | Form Fhwa 1641 |

| Form Length | 5 pages |

| Fillable? | No |

| Fillable fields | 0 |

| Avg. time to fill out | 1 min 15 sec |

| Other names | 1641_v14 superpave bituminous concrete mix form |

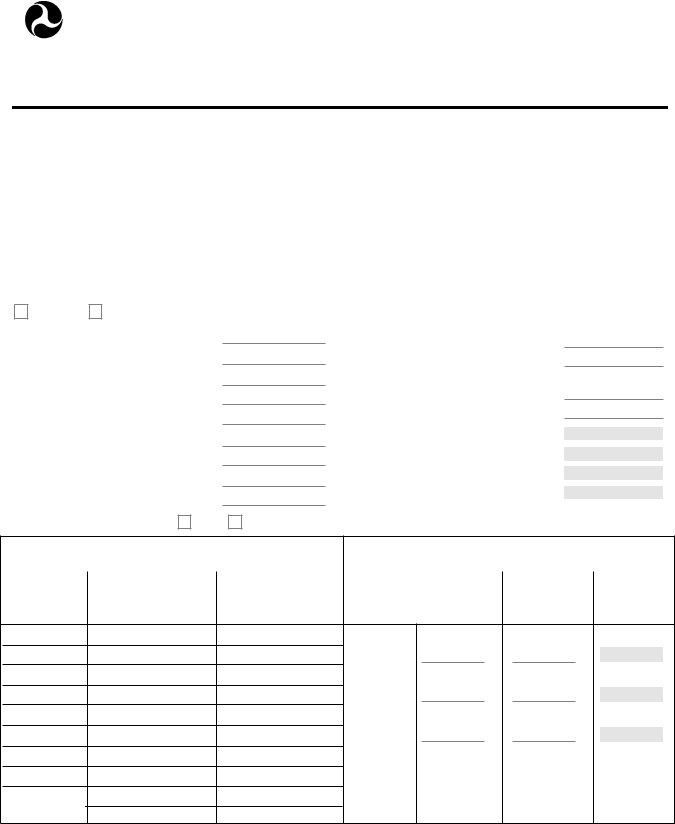

U.S. Department of Transportation

Federal Highway Administration

Federal Lands Highway

WORKSHEET FOR SUPERPAVE ASPHALT CONCRETE MIX DESIGN

AASHTO R 35

Project: |

|

|

|

|

|

Date: |

|

|

|

|||||

Contractor: |

|

|

|

|

Nominal Maximum Aggregate Size, : |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||

Asphalt supplier: |

|

|

Grade of asphalt: |

|

|

|||||||||

Sources for: |

Aggregates: |

|

Mineral filler: |

|

|

|||||||||

Testing laboratory name: |

|

|

Phone: |

|

|

|||||||||

Testing performed by: |

|

|

|

|

|

|

|

|

|

|

|

|||

Testing reported by: |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

English |

Metric |

SUMMARY OF THE PROPOSED |

|

|||||||||||

1.Number of gyrations (Nint,/ Ndes,/ Nmax)

2.Percent binder by mass of total mix (Pb)1

3.Percent binder by mass of aggregate

4.Air voids (Va) at Ndes

5.Voids in mineral aggregate (VMA) at Ndes

6.Voids filled with asphalt (VFA) at Ndes

7.Maximum unit mass (Gmm)

8.Effective specific gravity of aggregate (Gse)

9.

10.Specific gravity of binder (Gb)

11.Recommended plant mixing temperature, (Attach Temperature Viscosity Curve)

12.Percent compaction at Nmax

13.Hveem stabilometer value (If specified)

14.Moisture Susceptibility:

a.Dry strength,

b.Wet strength,

c.Index of Retained Strength, %

|

GRADATION TARGET VALUES AND |

SPECIFIC GRAVITY AND ABSORPTION |

||||

|

ALLOWABLE DEVIATIONS |

|||||

|

|

|

|

|||

|

|

|

|

|

|

|

|

Job Mix |

Allowable |

Fine |

Coarse |

Combined |

|

Sieve Sizes |

Formula |

Deviation3 |

Aggregate |

Aggregate |

||

Aggregate |

||||||

|

Target Value2 |

% |

(AASHTO T 84) |

(AASHTO T 85) |

||

|

|

|||||

|

|

|

|

|

|

|

Bulk SG (Gsb )

Bulk SSD SG

Apparent SG (Gsb)

Absorption |

|

% |

|

% |

|

% |

1Establish asphalt cement content (percent by mass of mix) to the nearest 0.01 percent.

2 Establish target values to the nearest 0.1 percent as a part of the job mix formula. 3 Allowable deviations plus or minus from established target values.

Form FHWA 1641 (Rev |

Page 1 of 5 |

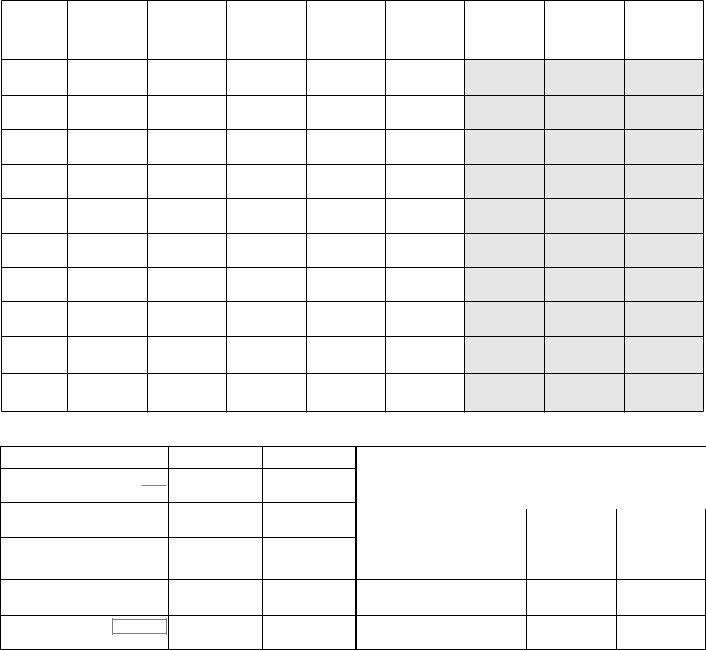

WORKSHEET FOR A SUPERPAVE MIX DESIGN (Continued)

Material |

Stockpile Description |

|

Blend Ratio |

|||||

Stockpile |

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

% |

||

B |

|

|

|

|

|

% |

||

C |

|

|

|

|

|

|

% |

|

D |

|

|

|

|

|

% |

||

E |

|

|

|

|

|

% |

||

|

|

TOTAL |

|

|||||

|

|

|

|

% |

||||

|

|

|

||||||

|

|

Stockpile Gradation |

|

|

|

|||

Sieve

Size

Stockpile

A

%

Stockpile

B

%

Stockpile

C

%

Stockpile

D

%

Stockpile

E

%

Blended

Stockpile

Gradation

Job Mix

Formula

Target Values

Specification

Limits

Aggregate Properties

Property |

Result |

Specification |

LA Abrasion, % - Grading

AASHTO T 96

Sodium Sulfate Soundness, %

AASHTO T 104

Durability index (Coarse)

AASHTO T 210

Durability index (Fine)

AASHTO T 210

Fractured Faces, % -

ASTM D 5821

Property |

|

|

|

Result |

Specification |

|

|

|

|

|

|

Fine aggregate angularity, |

|

|

|

||

AASHTO T 304 - method A |

|

|

|

||

|

|

|

|

|

|

Flat and elongated particles, |

|

|

|

||

|

|

||||

ASTM D 4791 - 1: |

|

ratio |

|

||

|

|

|

|

|

|

Sand Equivalent |

|

|

|

|

|

AASHTO T 176, Alt method #2, reference method

Other:

Other:

Form FHWA 1641 (Rev |

Page 2 of 5 |

WORKSHEET FOR A SUPERPAVE MIX DESIGN (Continued)

TRIAL NUMBER |

1 |

AVG |

2 |

AVG |

3 |

AVG |

|

|||

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

% Asphalt by mass of total mix (Pb) |

|

|

|

|

|

|

|

|

|

|

Specimen height, |

|

|

|

|

|

|

|

|

|

|

Effective Binder Content (Pbe) |

|

|

|

|

|

|

|

|

|

|

Bulk specific gravity at Ndes (Gmb) |

|

|

|

|

|

|

|

|

|

|

% compaction at Nint |

|

|

|

|

|

|

|

|

|

|

% Air voids at Ndes (VA) |

|

|

|

|

|

|

|

|

|

|

Max. unit mass Gmm |

|

|

|

|

|

|

|

|

|

|

Voids in mineral aggregate (VMA) at Ndes |

|

|

|

|

|

|

|

|

|

|

Voids filled with asphalt (VFA) at Ndes |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hveem Stabilometer value |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TRIAL NUMBER |

4 |

AVG |

5 |

AVG |

6 |

AVG |

|

|||

|

|

|

|

|

|

|

|

|

|

|

% Asphalt by mass of total mix (Pb) |

|

|

|

|

|

|

|

|

|

|

Specimen height, |

|

|

|

|

|

|

|

|

|

|

Effective Binder Content (Pbe) |

|

|

|

|

|

|

|

|

|

|

Bulk specific gravity at Ndes (Gmb) |

|

|

|

|

|

|

|

|

|

|

% compaction at Nint |

|

|

|

|

|

|

|

|

|

|

% Air voids at Ndes (VA) |

|

|

|

|

|

|

|

|

|

|

Max. unit mass Gmm |

|

|

|

|

|

|

|

|

|

|

Voids in mineral aggregate (VMA) at Ndes |

|

|

|

|

|

|

|

|

|

|

Voids filled with asphalt (VFA) at Ndes |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hveem Stabilometer value |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

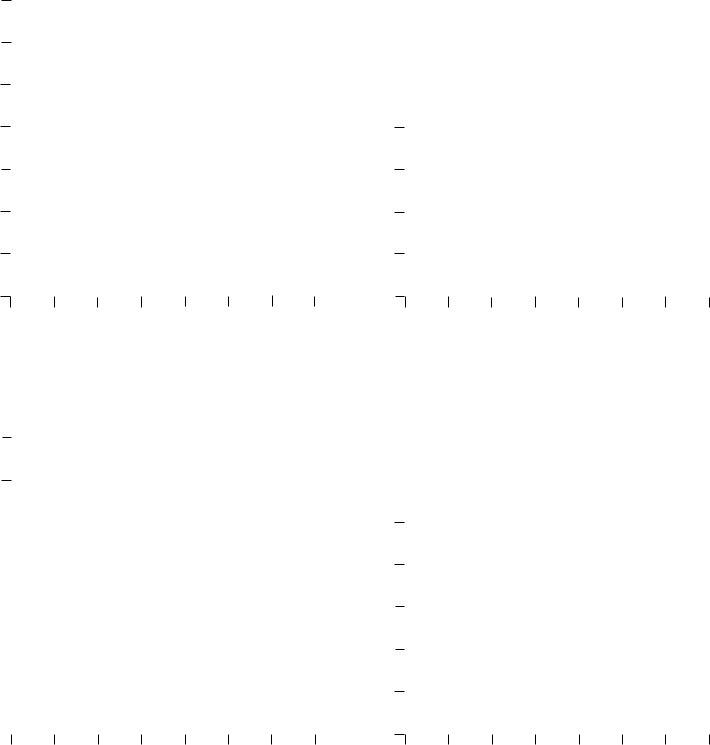

Test Results for Each of the Individual Moisture Susceptibility Test Specimens |

|

|||||||||

Percent asphalt binder: |

|

|

|

AASHTO T 283 |

|

|

|

||||||

|

|

|

|

|

|

|

|

Specimen Dia: |

6 inch |

4 inch |

|||

Antistrip, type, amount: |

|

|

|

|

|

||||||||

|

|

|

|

|

Freeze cycle: |

Yes |

No |

||||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sample I.D. |

|

|

|

|

|

|

|

|

|

|

Average |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Height |

|

Dry |

|

|

|

|

|

|

|

|

|

|

|

|

|

Wet |

|

|

|

|

|

|

|

|

|

|

|

Bulk Specific |

|

Dry |

|

|

|

|

|

|

|

|

|

|

|

Gravity |

|

Wet |

|

|

|

|

|

|

|

|

|

|

|

Air |

|

Dry |

|

|

|

|

|

|

|

|

|

|

|

Voids |

|

Wet |

|

|

|

|

|

|

|

|

|

|

|

|

|

Dry |

|

|

|

|

|

|

|

|

|

|

|

Strength |

|

Wet |

|

|

|

|

|

|

|

|

|

|

|

Retained Strength, % |

|

|

|

|||||||||

Form FHWA 1641 |

Page 3 of 5 |

WORKSHEET FOR A SUPERPAVE MIX DESIGN (Continued)

Design Curves for Proposed Job Mix Formula (JMF)

AIR VOIDS (Va) |

|

UNIT MASS |

|

|

|

|

|

|

|

|

|

% Air voids (Va )

% Asphalt binder (Pb)

% Asphalt binder (Pb)

VFA |

|

VMA |

|

|

|

|

|

|

Voids filled with asphalt |

|

|

Voids in mineral aggregate |

|

|

||

|

|||

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

% Asphalt binder (Pb) |

% Asphalt binder (Pb) |

Form FHWA 1641 (Rev |

Page 4 of 5 |

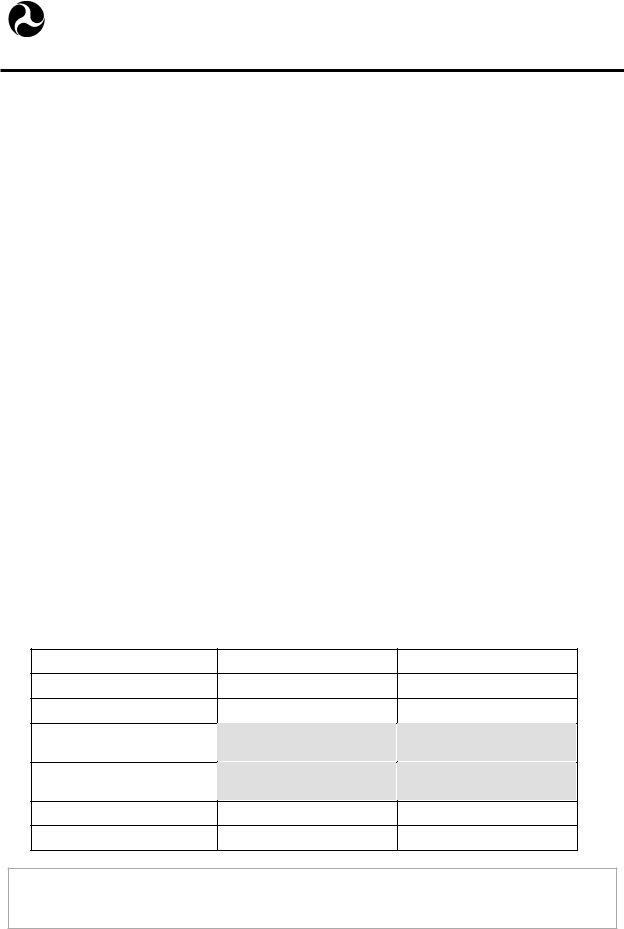

U.S. Department of Transportation

Federal Highway Administration

Federal Lands Highway

RECLAIMED ASPHALT PAVEMENT (RAP) DATA SHEET

Location: |

|

|

|

|

|

Sampled by: |

|

||||||

Tested by: |

|

|

|

|

Date: _____________________ |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RAP 1 |

|

|

RAP 2 |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

% of RAP in Mixture |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dry |

T 308 |

|

|

Dry |

|

T 308 |

|

|

|

|

|

|

Sieve Size |

Burned |

|

|

|

|

|

|

|||

|

|

|

Gradation |

|

|

Gradation |

|

Burned |

|

|

|||

|

|

|

|

Gradation |

|

|

Gradation |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AC by % mix, Pb

Specific Gravity |

Specific Gravity |

Gmm

Gse

Gse = (100 – Pb)/(10/Gmm – Pb/Gb)

Gsb

Gsb = Gse/(((Pba*Gse)/(100*Gb)) + 1)

Pba = (assumed)

Gb = (assumed)

Remarks:

Form FHWA 1641 (Rev |

Page 5 of 5 |