You can complete asme u1a easily by using our online PDF tool. The editor is constantly improved by our staff, acquiring new features and becoming better. It just takes several basic steps:

Step 1: First of all, open the pdf editor by pressing the "Get Form Button" at the top of this site.

Step 2: The editor lets you modify PDF files in a variety of ways. Improve it by adding customized text, correct existing content, and place in a signature - all when you need it!

It is actually easy to finish the document using out practical tutorial! This is what you have to do:

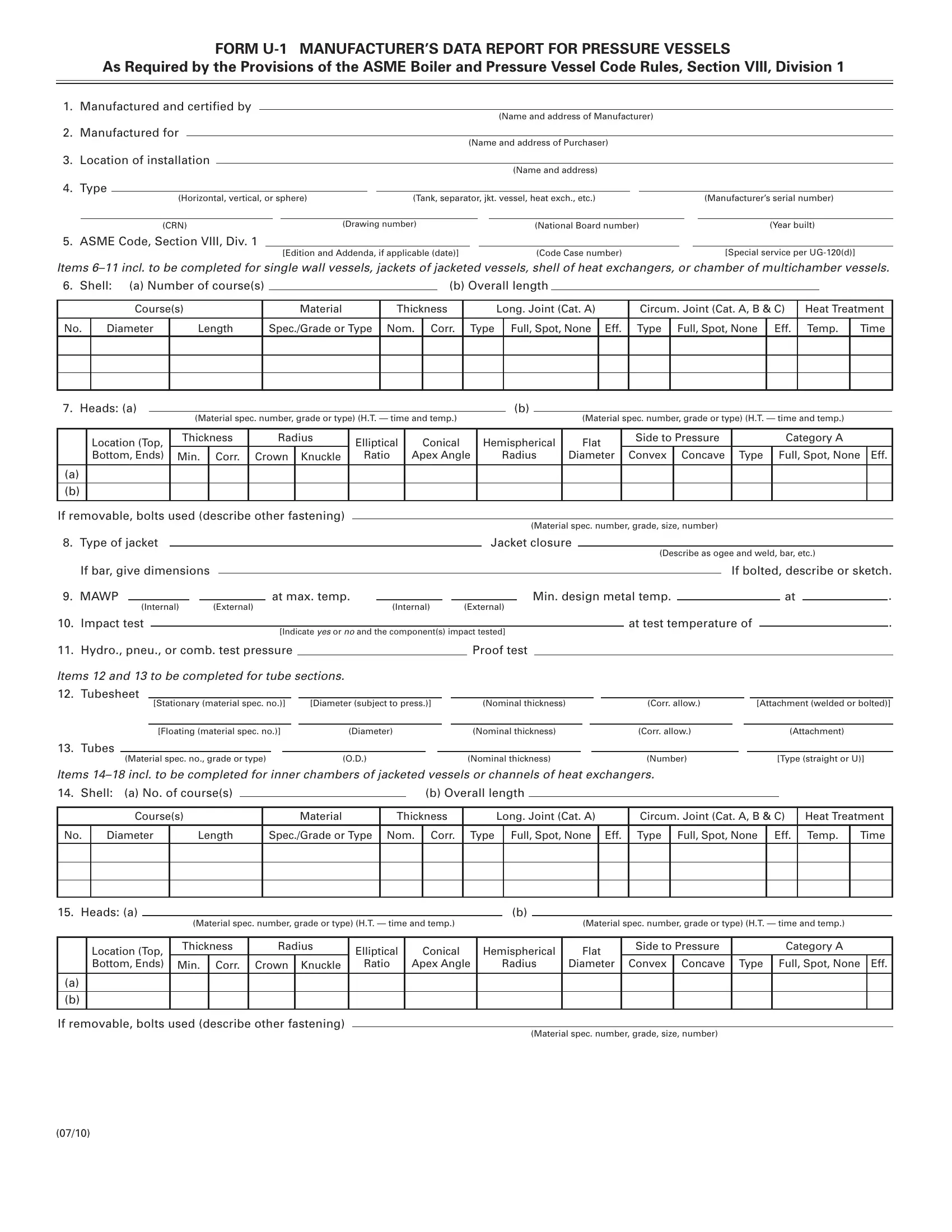

1. Start filling out the asme u1a with a group of essential blank fields. Collect all of the necessary information and make sure absolutely nothing is omitted!

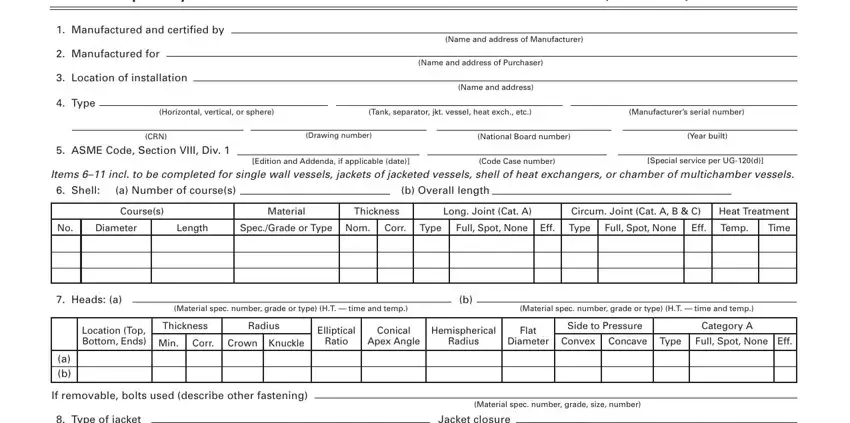

2. The next stage is usually to fill in these fields: Type of jacket, If bar give dimensions, Jacket closure, Describe as ogee and weld bar etc, If bolted describe or sketch, MAWP, Internal, External, Internal, External, at max temp, Min design metal temp, Impact test, Indicate yes or no and the, and at test temperature of.

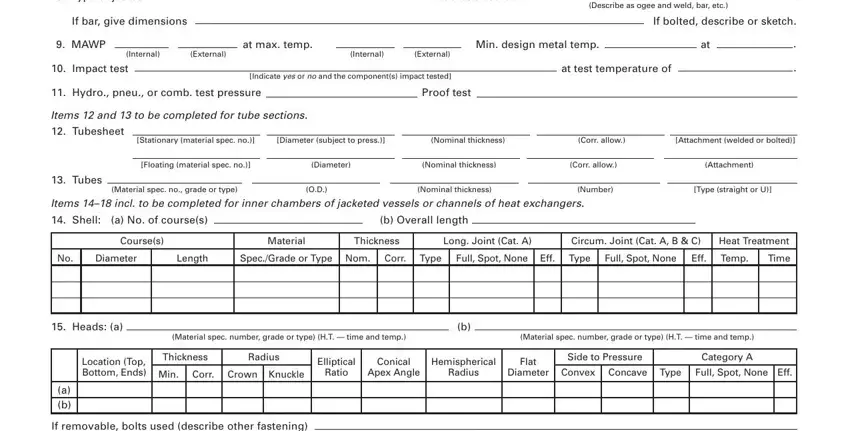

3. This subsequent step is typically fairly simple, MAWP, at max temp, Min design metal temp, Internal, External, Internal, External, Impact test, Indicate yes or no and the, at test temperature of, FORM U Back, Hydro pneu or comb test pressure, Proof test, Nozzles inspection and safety, and Purpose - these empty fields has to be completed here.

Always be extremely attentive when completing Internal and Proof test, as this is the section where a lot of people make errors.

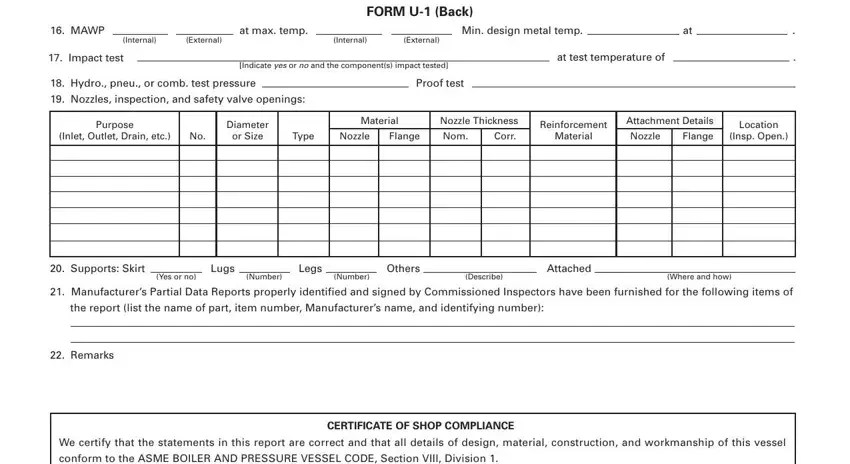

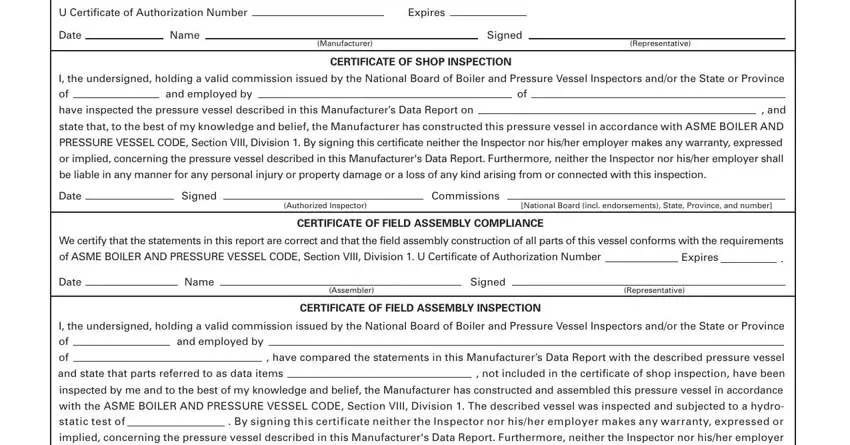

4. The subsequent subsection requires your input in the subsequent places: conform to the ASME BOILER AND, U Certificate of Authorization, Expires, Date, Name, Manufacturer, Signed, Representative, CERTIFICATE OF SHOP INSPECTION, I the undersigned holding a valid, and employed by, have inspected the pressure vessel, and, state that to the best of my, and PRESSURE VESSEL CODE Section VIII. Make sure that you type in all of the requested info to go onward.

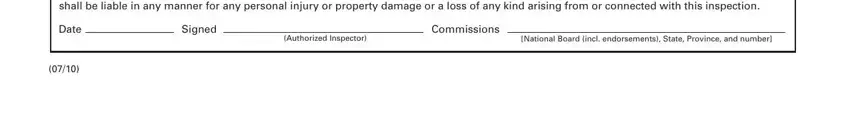

5. This last notch to conclude this document is integral. You'll want to fill in the necessary blanks, for instance shall be liable in any manner for, Date, Signed, Commissions, Authorized Inspector, and National Board incl endorsements, prior to using the pdf. Failing to accomplish that could give you an unfinished and potentially invalid document!

Step 3: Soon after going through your fields you have filled in, hit "Done" and you're all set! Right after registering a7-day free trial account with us, you'll be able to download asme u1a or send it through email without delay. The PDF document will also be easily accessible in your personal account with your every single change. FormsPal ensures your data privacy by having a secure method that never saves or distributes any kind of personal data provided. You can relax knowing your documents are kept safe when you work with our service!