Working with PDF forms online is very easy using our PDF tool. You can fill out form u vfs global here within minutes. The editor is consistently improved by our team, acquiring new awesome functions and becoming greater. Here's what you will need to do to get started:

Step 1: Access the PDF doc inside our editor by pressing the "Get Form Button" at the top of this webpage.

Step 2: Once you open the tool, you will notice the document ready to be filled out. Apart from filling in various blanks, you might also do many other things with the file, including putting on any textual content, changing the initial text, adding graphics, signing the PDF, and more.

It really is simple to complete the form with this practical guide! This is what you must do:

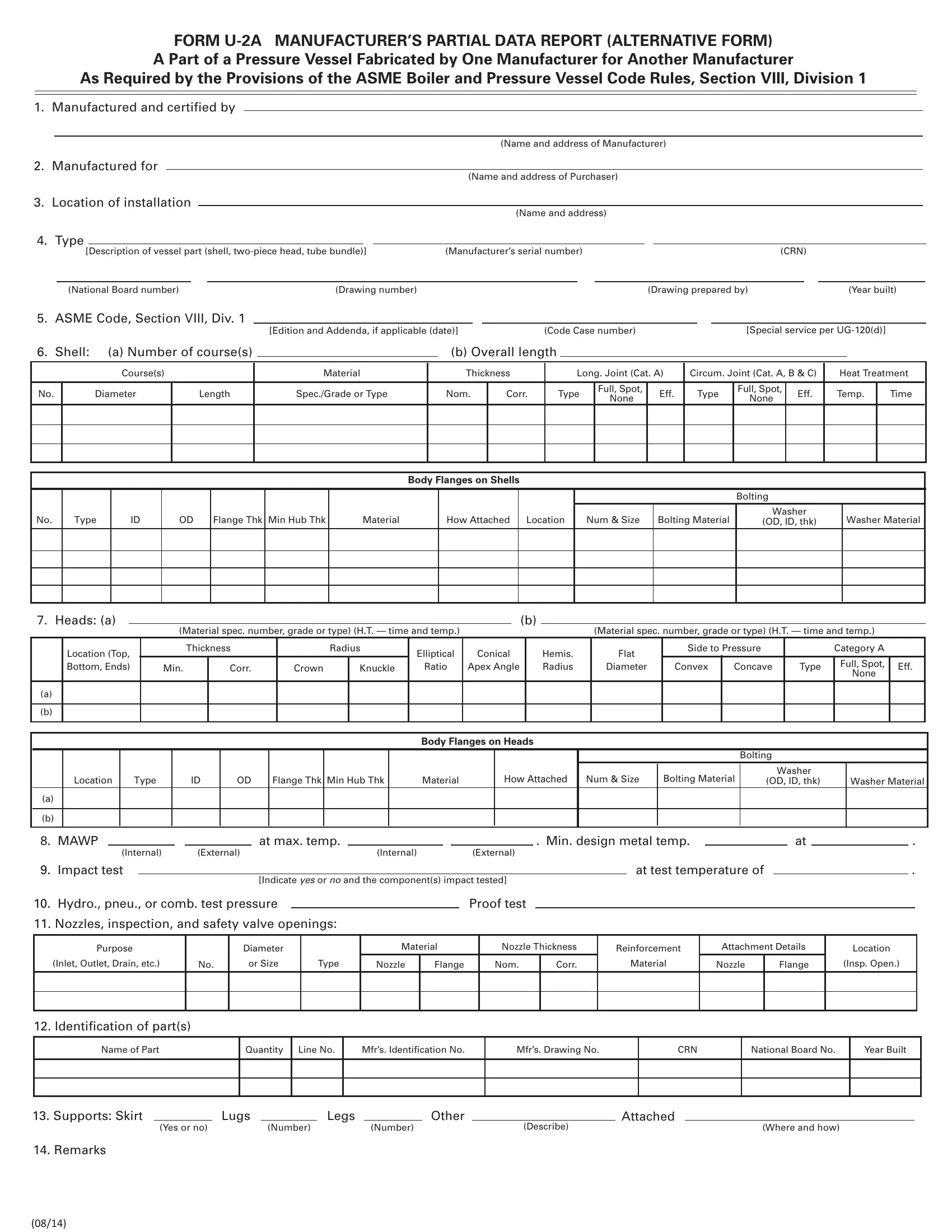

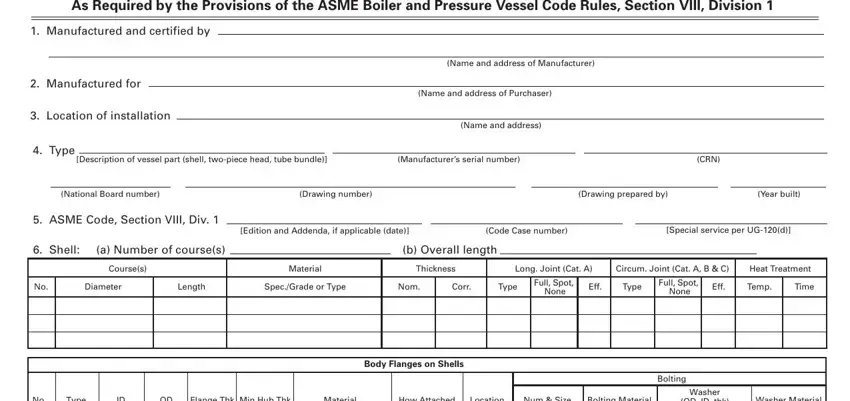

1. You should complete the form u vfs global correctly, hence be mindful when working with the sections that contain these particular blank fields:

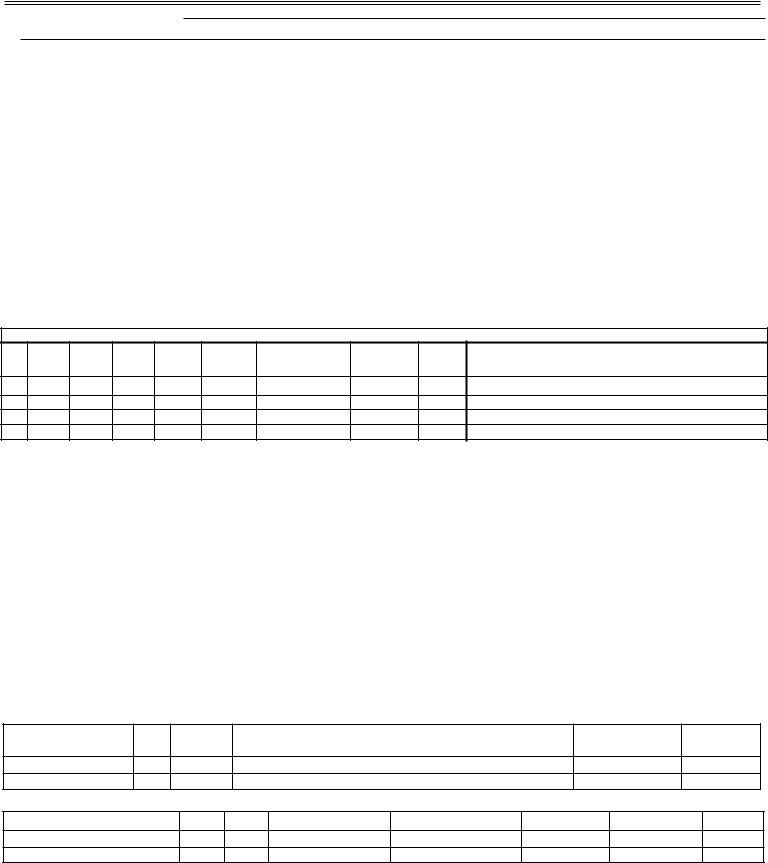

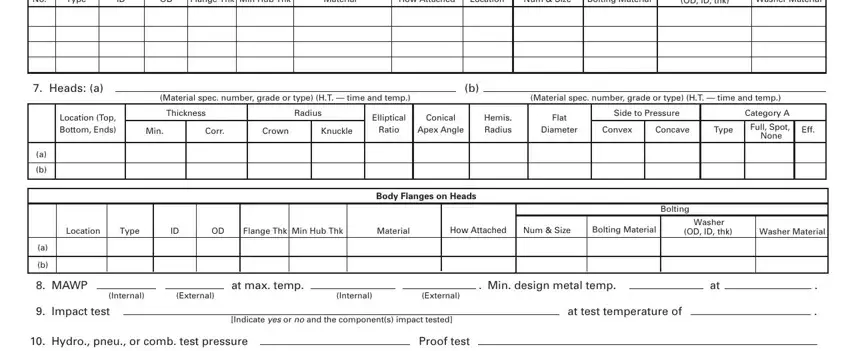

2. Soon after filling in this section, go to the next step and fill out the essential details in these blank fields - Type, Flange Thk, Min Hub Thk, Material, How Attached, Location, Num Size, Bolting Material, OD ID thk, Washer Material, Heads a, Location Top Bottom Ends, Material spec number grade or type, Material spec number grade or type, and Thickness.

You can certainly make a mistake while filling out the Location, thus you'll want to look again prior to deciding to finalize the form.

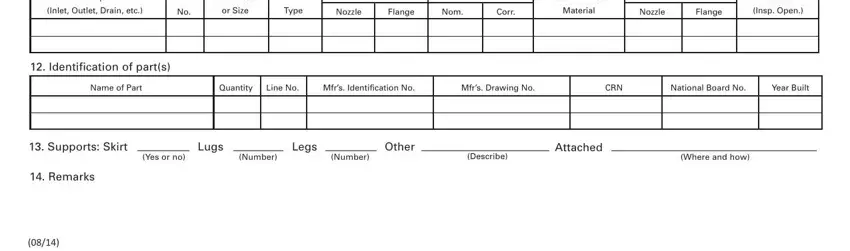

3. Completing Purpose, Inlet Outlet Drain etc, Diameter, or Size, Type, Material, Nozzle Thickness, Reinforcement, Attachment Details, Nozzle, Flange, Nom, Corr, Material, and Nozzle is essential for the next step, make sure to fill them out in their entirety. Don't miss any details!

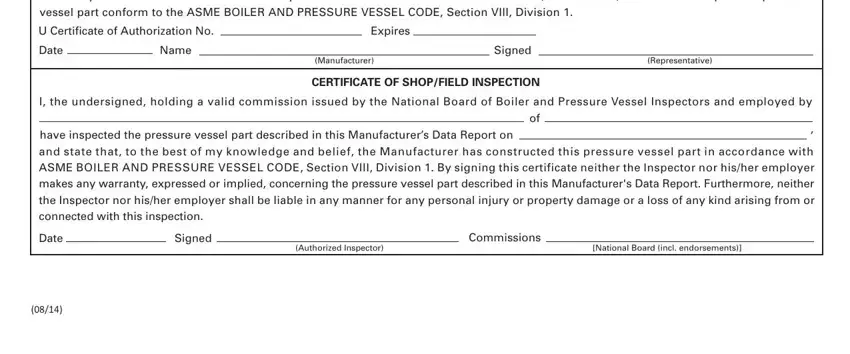

4. The form's fourth section comes next with the next few form blanks to complete: We certify that the statements, vessel part conform to the ASME, U Certificate of Authorization No, Expires, Date, Name, Signed, Manufacturer, Representative, CERTIFICATE OF SHOPFIELD INSPECTION, I the undersigned holding a valid, have inspected the pressure vessel, and state that to the best of my, ASME BOILER AND PRESSURE VESSEL, and makes any warranty expressed or.

Step 3: Prior to moving forward, it's a good idea to ensure that form fields were filled out right. When you are satisfied with it, press “Done." Make a 7-day free trial subscription with us and get immediate access to form u vfs global - accessible inside your FormsPal cabinet. FormsPal guarantees protected form editing without data recording or distributing. Rest assured that your information is secure with us!