Understanding the Material Safety Data Sheet (MSDS) is crucial for handling chemicals safely in the workplace. This document, with its comprehensive details, aids in identifying chemical properties, health and safety hazards, and measures for first aid, handling, and storage. For instance, the MSDS No. 0009 Rev. 4 for TSP-90 Heavy Duty Cleaner outlines critical information including the product’s composition, which mainly consists of Sodium Metasilicate, Pentahydrate, highlighting the absence of hazardous Prop 65 ingredients. It also details the emergency contact numbers, manufacturer information, and addresses potential hazards such as corrosiveness to eyes and skin. The form further advises on first aid measures in case of exposure, fire fighting techniques if the material is involved in a fire, and accidental release measures emphasizing on spill management. Additionally, it provides guidelines for safe handling and storage, exposure controls/personal protection to minimize risks, and disposal considerations to comply with environmental regulations. The sheet also covers the product’s physical and chemical properties and regulatory information, ensuring that users are well informed of any risks and comply with safety standards. Such a detailed MSDS ensures that safety is not compromised, making it an essential tool for promoting workplace health and safety.

| Question | Answer |

|---|---|

| Form Name | Material Safety Data Sheet Form |

| Form Length | 3 pages |

| Fillable? | No |

| Fillable fields | 0 |

| Avg. time to fill out | 45 sec |

| Other names | Oklahoma, Metasilicate, OSHA, material safety data sheet templates |

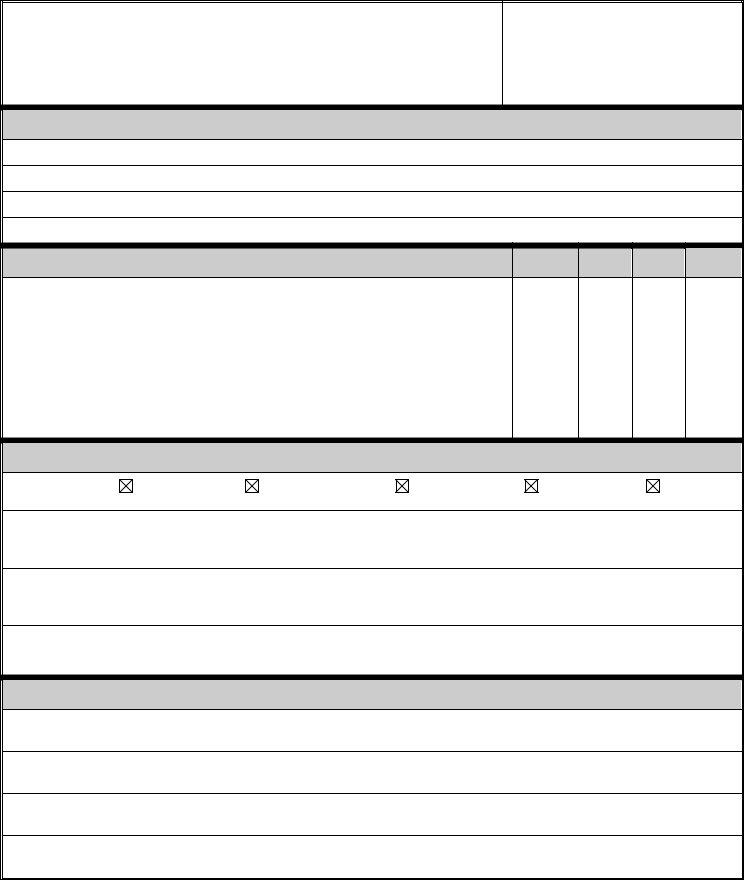

Material Safety Data Sheet

MSDS No. 0009 Rev. 4 |

Emergency Phone No.

SECTION 1 – PRODUCT NAME & MANUFACTURER INFORMATION

PRODUCT NAME

MANUFACTURER’S NAME & |

Red Devil, Inc. |

|

TELEPHONE NUMBER |

STREET ADDRESS

4175 Webb Street

CITY / STATE / ZIP

Pryor, Oklahoma 74361

SECTION 2 – COMPOSITION / HAZARDOUS INGREDIENTS

PRODUCT CONSISTS OF:

Sodium Metasilicate, Pentahydrate

*Unlisted ingredients are not considered hazardous under the OSHA Hazard Communication Standard (29 CFR 1910.1200).

Calculated VOC: 0%/wt, 0 g/L. CARB Compliance: Yes. Prop 65 Ingredients: None.

% |

100

0

TLV |

NE

NE

PEL |

NE

NE

UNITS |

SECTION 3 – HAZARDS IDENTIFICATION

PRIMARY

ROUTE(S) OF

ENTRY

EMERGENCY

OVERVIEW

EFFECTS OF OVEREXPOSURE

MEDICAL CONDITIONS AGGRAVATED BY EXPOSURE

Skin Contact |

Skin Absorption |

Eye Contact |

Inhalation |

Ingestion |

White, odorless, granular powder. Corrosive to eyes, skin & digestive tract. Dust corrosive to respiratory tract. Due to high pH of product, release into surface water is harmful to aquatic life. Noncombustible. Reacts w/ acids & some organics.

Eye Contact: Corrosive, causes eye burns. Skin Contact: Corrosive, causes skin burns. Inhalation: Dust corrosive to

respiratory tract. Ingestion: Corrosive, causes burns to mouth, esophagus & stomach. Chronic Hazards: None known. Not

listed by NTP, IARC or OSHA as a carcinogen. Physical Hazards: Can etch glass if not promptly removed.

None known.

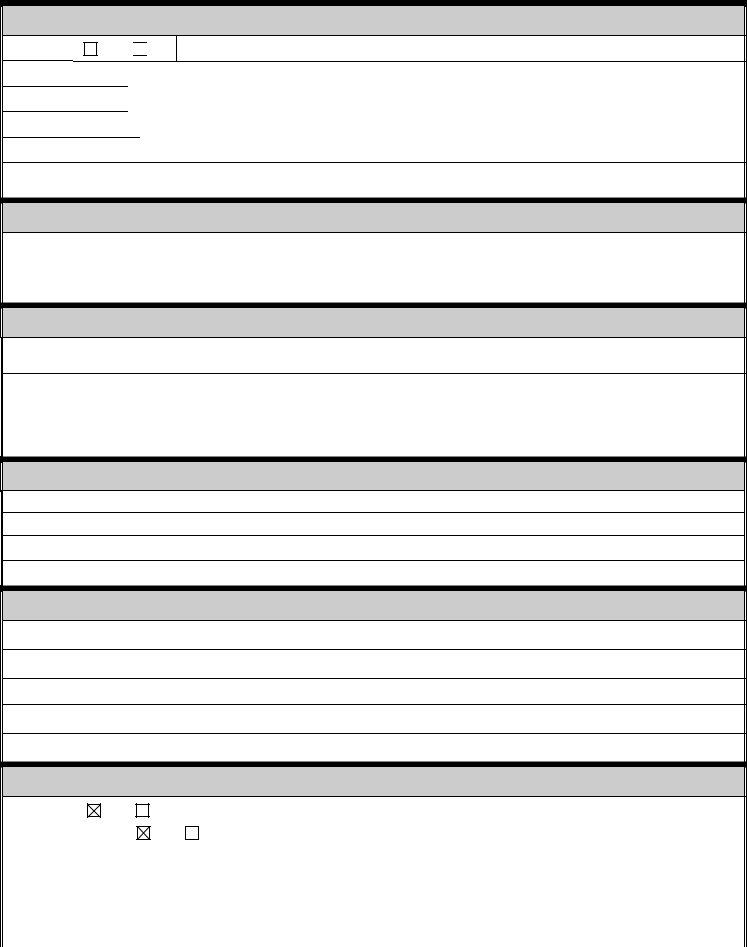

SECTION 4 – FIRST AID MEASURES

SKIN CONTACT

Immediately flush skin w/ plenty of water for @ least 15 minutes, while removing contaminated clothing & shoes. Seek medical attention immediately. Wash clothing before reuse. Thoroughly clean shoes before reuse.

EYE CONTACT

Immediately flush eyes w/ plenty of water for @ least 15 minutes. If easy to do, remove contact lenses, if worn. Seek medical attention immediately.

INHALATION

Remove to fresh air. If not breathing, give artificial respiration. If breathing difficult, give oxygen. Seek medical attention.

INGESTION

DO NOT INDUCE VOMITING. Seek medical attention immediately. If person is fully conscious, give cupful of water. Never give anything by mouth to an unconscious person.

1

SECTION 5 – FIRE FIGHTING MEASURES

FLAMMABLE

EXTINGUISHING MEDIA

Yes No

Material compatible w/ all extinguishing media.

FLASHPOINT (°F) &

METHOD

LOWER EXPLOSIVE LIMIT (% BY VOLUME)

UNUSUAL FIRE & EXPLOSION HAZARDS

Material noncombustible. |

UPPER EXPLOSIVE LIMIT |

NA |

|

|

|

(% BY VOLUME) |

|

NA |

AUTOIGNITION |

NA |

|

|

|

TEMPERTURE (°F) |

|

See Section 3 for information on hazards when material is present in area of a fire.

SPECIAL FIREFIGHTING PROCEDURES

When material present in the area of a fire: chemical goggles,

SECTION 6 – ACCIDENTAL RELEASE MEASURES

PROCEDURES

SECTION 7 – HANDLING & STORAGE

HANDLING PROCEDURES & EQUIPMENT

STORAGE REQUIREMENTS

Do not get in eyes, on skin or on clothing. Do not breathe dust. Keep container closed. Promptly clean up spills. Wash thoroughly after handling.

Store @ temperatures below 150F. Keep containers closed. Store in clean, tightly closed steel, fiber or plastic containers. Separate from acids, reactive metals & ammonium salts. Do not store in aluminum, fiberglass, copper, brass, zinc or galvanized containers. Product can absorb water from the air. In high humidity or storage for extended periods, use plastic bags to enclose product containers to avoid caking.

RESPIRATORY

EYEWEAR

CLOTHING / GLOVES

HYGENIC PRACTICES

SECTION 8 – EXPOSURE CONTROL / PERSONAL PROTECTION

Use a

Wear chemical goggles.

Wear

Take appropriate measures to prevent all contact. Wash thoroughly before breaks & after workday.

SECTION 9 – PHYSICAL AND CHEMICAL PROPERTIES

PHYSICAL STATE

Granular powder

ODOR &

APPEARANCE

Odorless or musty odor. White powder.

SPECIFIC GRAVITY

NE

VAPOR DENSITY (AIR=1)

NE

EVAPORATION RATE

NE |

BOILING RANGE (°F) |

NE |

|

pH

Approximately 14

SOLUBILITY IN |

Soluble. |

|

WATER |

||

|

VAPOR PRESSURE (MM Hg)

NE

%/WT VOLATILE (TNV)

NE

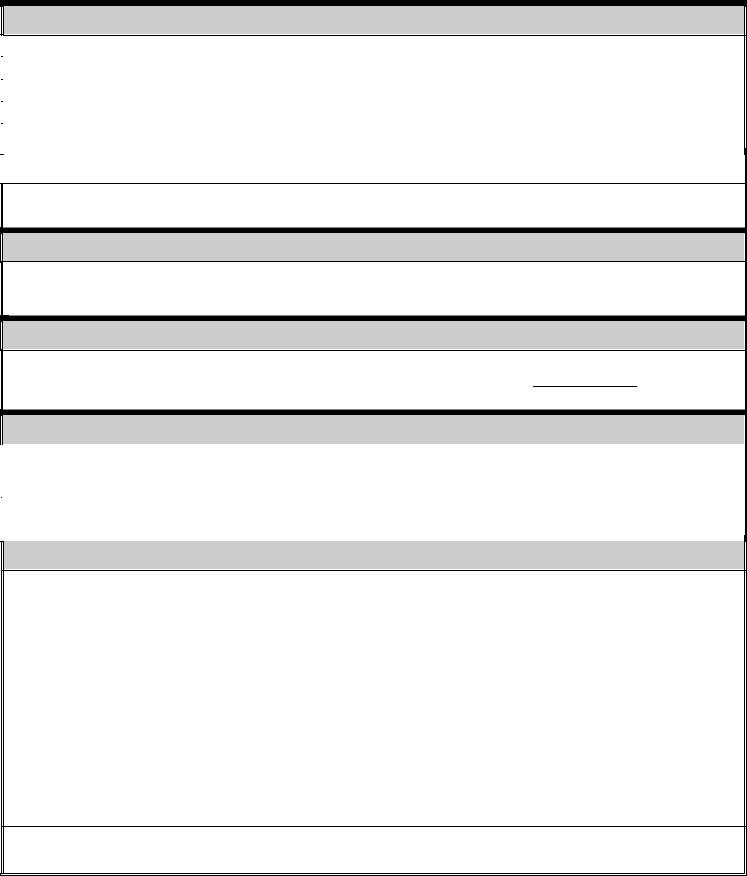

SECTION 10 – STABILITY AND REACTIVITY

STABILITY |

Yes |

No |

Material stable under conditions of normal use & storage. |

|

|

||||

INCOMPATABILITY |

|

Yes |

No |

Generates heat when mixed w/ acid. May react w/ ammonium salt solutions resulting in |

|

|

|||

|

|

|

ammonia gas. Flammable hydrogen gas may be produced on contact w/ aluminum, tin, lead |

|

|

|

|

& zinc. Carbon monoxide gas may result on contact w/ reducing sugars. |

|

|

CONDITIONS |

None. |

|

|

|

TO AVOID |

|

|

|

|

|

|

|

|

|

HAZARDOUS |

|

Hazardous decomposition products: Hydrogen. |

|

|

POLYMERIZATION/HAZARDOUS |

|

||

|

|

|

||

|

DECOMPOSITION PRODUCTS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

SECTION 11 – TOXICOLOGICAL INFORMATION / CARCINOGENICITY

ACGIH |

NE |

|

|

|

|

OSHA |

Not listed as a carcinogen. Toxicity has not been tested. |

|

|

|

|

IARC |

Not listed as a carcinogen. Toxicity has not been tested. |

|

|

|

|

NTP |

Not listed as a carcinogen. Toxicity has not been tested. |

|

|

|

|

DATA WITH POSSIBLE |

Sodium Metasilicate, Pentahydrate is corrosive to eyes, skin & respiratory tract. |

|

RELEVANCE TO HUMANS |

|

|

|

|

|

|

|

|

|

SECTION 12 – ECOLOGICAL INFORMATION |

|

|

|

|

AQUATIC TOXICITY

Due to high pH, release into surface water is harmful to aquatic life. Material sinks & dissolves in water.

SECTION 13 – DISPOSAL CONSIDERATIONS

WASTE DISPOSAL

EPA WASTE CODE IF DISCARDED (40CFR Sec.261)

Dispose in accordance w/ Local, State & Federal Regulations. Disposed dry/solid material is not classified as a RCRA Hazardous Waste. However, disposed water/wet solutions containing this material are classified as a RCRA Hazardous Waste, if they exhibit the corrosive characteristic (pH greater than or equal to 12.5) as defined by EPA.

SECTION 14 – TRANSPORT INFORMATION

SPECIAL SHIPPING INFORMATION

DOT UN Status: A regulated hazardous material. UN Proper Shipping Name: Disodium Trioxosilicate,

Pentahydrate. UN Hazard Class/Division: 8. UN Identification No.: UN3253. UN Packing Group: PG III.

SECTION 15 – REGULATORY INFORMATION

CERCLA – SARA |

No CERCLA Reportable Quantity has been |

U.S. |

See Section 16. |

|

HAZARD |

STATE |

|||

|

|

|||

CATEGORY |

established for this material. SARA Title III: Not |

REGS |

|

|

|

an extremely hazardous substance under 302. |

|

|

|

SARA 313 |

Not a toxic chemical under 313. Hazard categories |

TSCA |

All ingredients of this material listed on TSCA |

|

|

|

|||

|

under 311/312: Acute. |

|

Inventory. |

|

|

|

|

|

SECTION 16 – OTHER INFORMATION / SPECIAL PRECAUTIONS / LEGEND

FDA: The use of sodium metasilicate is authorized by FDA as a boiler water additive for the production of steam that will contact food pursuant to 21 CFR 173.310; & as a GRAS substance pursuant to 21 CFR 184.1769a for use in washing & lye peeling of fruits, vegetables

&nuts; as a denuding agent for tripe; a hog scald agent in removing hair; & as a corrosion preventative in canned & bottled water. WARNING: This product contains Sodium Metasilicate, Pentahydrate. Material is corrosive to eyes, skin & respiratory tract. INTERNATIONAL EMERGENCY NUMBER:

LEGEND: NA – Not Applicable, NE – Not Established, UN – Unavailable, VOC – Volatile Organic Compound, PEL – Permissible Exposure Limit, TLV – Threshold Limit Value, STEL – Short Term Exposure Limit, MSDS – Material Safety Data Sheet, ACGIH – American Conference of Governmental Industrial Hygienists, SARA – Superfund Amendments & Reauthorization Act of 1986, OSHA – Occupational Safety & Health Administration, HMIS – Hazardous Materials Identification System, NTP – National Toxicology Program, CEIL – Ceiling Exposure Limit, CASRN (CAS Number) – Chemical Abstracts Service Registry Number, TSCA – Toxic Substances Control Act

Reviewed By

Larry Brandon |

Vice President Technology & General Manager |

March 6, 2012 |

NAME |

TITLE |

DATE |

The information contained herein has been developed based upon currently available scientific data. New information may be developed from time to time which may render the conclusions of this report obsolete. Therefore, no warranty is extended as to the applicability of this information to the user’s intended purpose or for the consequences of its use or misuse.

3