QBE European Operations – Hot work permit | 2

Issuer guidance notes

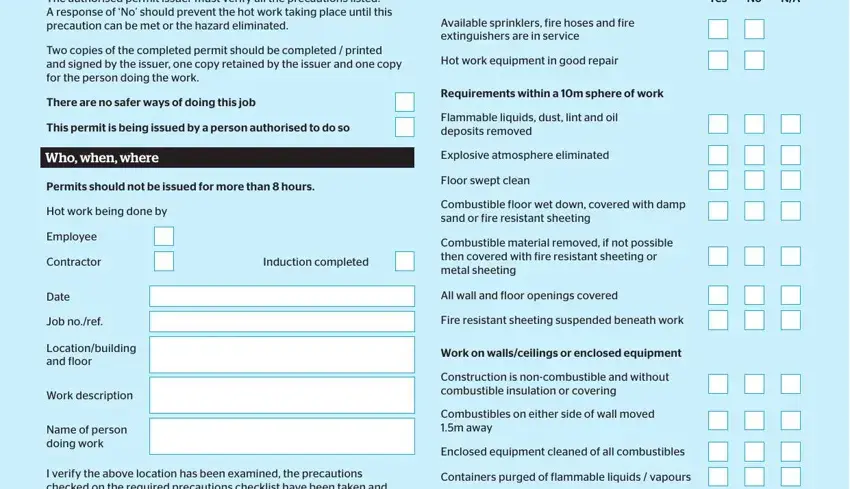

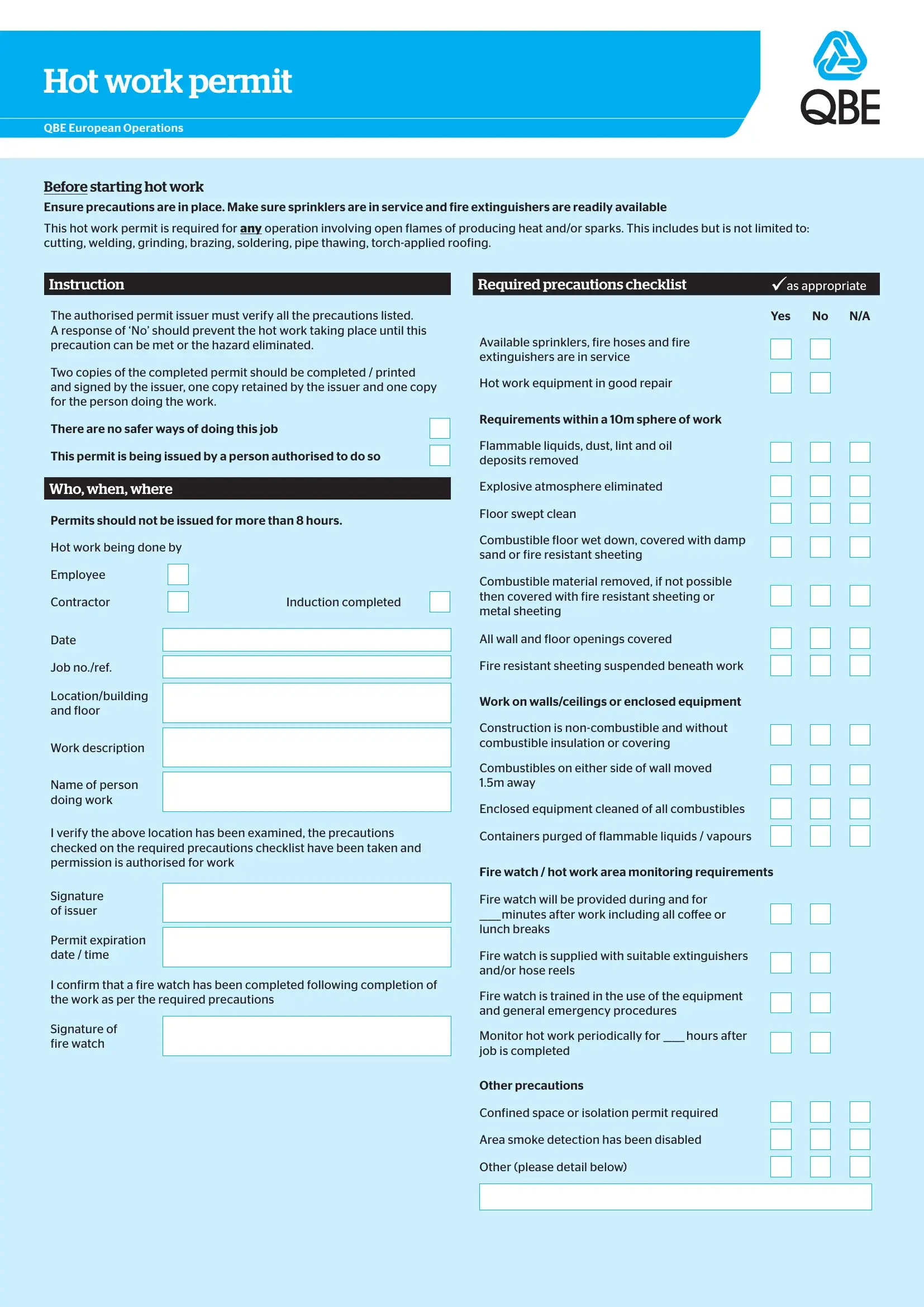

Application and scope:

A Hot Work Permit should be used during use of equipment such as:

•Blow lamps

•Cutting and welding equipment

•Brazing and soldering equipment

•Bitumen boilers

•Temporary open flame heaters

•Any other equipment producing heat, flames or sparks.

The hot work permit will be needed whilst work is carried out within or on any part of the premises, except permanent facilities designed for use of such equipment, such as welding bays within maintenance work shops.

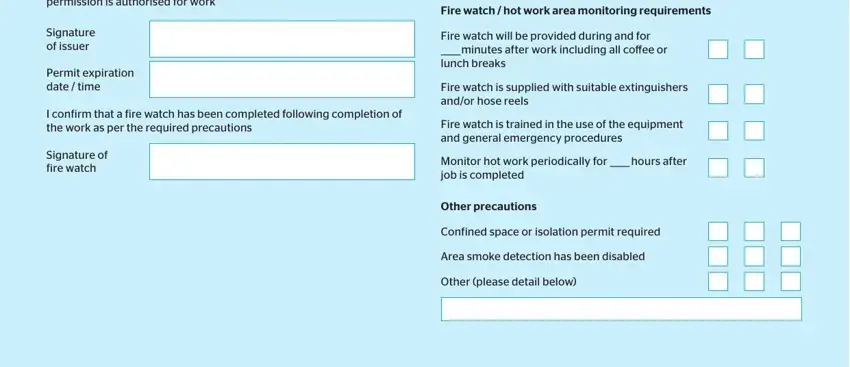

The Permit to Work should be issued to either own staf or to contractors, and should not be issued for lengthy or prolonged periods.

The Permit must be issued and returned to the authorising oficial and retained on file for future inspection.

User notes:

Many large fires have been caused in industrial premises in recent years by the careless or inappropriate use of Hot Work and the problem appears to be escalating. For property insurance purposes, Insurers expect that the Hot Work Permit System to be followed with care and diligence by all concerned, to avoid the danger of fire outbreak.

The Third Party Insurance cover held by any contractors working must be checked for adequacy with reference made to the Insurers or Insurance Broker where such cover is limited or low, before the work is undertaken.

It is best practice, particularly where major ongoing projects are concerned, that in addition to issue of hot work permits, that a “method statement” be produced. Before the work commences, this will involve a senior or competent person preparing and recording relevant details such as the nature and purpose of the project; the time scales involved; the equipment to be used; the area/location of work; details of the persons carrying out the work and the personnel in charge; details of the particular fire hazards presented from carrying out this work in this location; the fire precautions taken; the fire protection equipment available; with details of inspections after work is completed.

It is preferable in all cases to conduct work either by a safer method not involving the application of heat, or to take the work to a safe location, such as an open area or maintenance workshop. The experience and competence of the contractors or employee must always be established before the work is authorised and equipment checked for safety and condition. Fire protection/detection equipment should be checked to ensure that it is functioning properly and is not impaired. (NB - fire detection in the immediate vicinity may need to be isolated, but it should not be isolated in adjoining areas and must be reactivated immediately the work finishes).

A hot work permit should only be issued by personnel authorised and trained to do so and a list of these persons should be maintained. The precautions listed as part of the Hot work permit should be strictly observed, and common sense applied where there is doubt. Areas should be kept clean and tidy during the work, combustible waste produced during operations regularly removed to a safe location, and premises NO SMOKING rules strictly observed at all times, particularly where contractors are involved.

If the work causes a small fire which is extinguished, work must nevertheless cease and the incident reported to the issuer of the permit for immediate investigation. Only after full investigation should work be permitted to recommence.

When the work is complete, it is essential that a check is made after work is finished, to look for glowing embers, smoke, areas of residual heat etc. The extent of this check is a function of the area of the hot work (in areas of low or no combustible loading it may be shortened, or lengthened in areas of high combustible loading) but is nominally recommended for up to 90 minutes, with continuous monitoring for the first 30 minutes and periodic checking (every 10-15 minutes) for a further 60 minutes. Where such checks cannot be carried out, issue of the permit should be deferred or delayed.

Any indications of an outbreak of fire should be treated immediately as an emergency, and the Fire Brigade summoned.

QBE European Operations Plantation Place 30 Fenchurch Street London EC3M 3BD tel +44 (0)20 7105 4000 www.QBEeurope.com