The STI SP001 AST Record form is a comprehensive tool designed to assist owners and operators of Aboveground Storage Tanks (ASTs) in maintaining and documenting the condition and compliance status of their tanks. This form encompasses vital information including owner, facility, and installer details, alongside specifications regarding the tank's design, manufacturer, contents, dimensions, capacity, and construction material. It extends to cover the dates of key events such as installation, last repair or reconstruction, and any changes in service. The form lays out specifics about the tank's construction, whether it's bare steel, cathodically protected, coated steel, or made from concrete, plastic/fiberglass, among other materials, and details regarding containment features like earthen dikes, steel dikes, concrete synthetic liners, etc. Moreover, it includes a monthly inspection checklist to ensure ongoing compliance with safety standards, highlighting areas such as tank containment, leak detection, tank attachments, and other conditions crucial for safe operation and adherence to the Spill Prevention, Control, and Countermeasure (SPCC) plan. The meticulousness of the STI SP001 AST Record form underscores the seriousness with which tank integrity, environmental protection, and regulatory compliance are treated, serving as an essential document for responsible AST management.

| Question | Answer |

|---|---|

| Form Name | Sti Sp001 Ast Record Form |

| Form Length | 10 pages |

| Fillable? | No |

| Fillable fields | 0 |

| Avg. time to fill out | 2 min 30 sec |

| Other names | sti sp001 6th edition inspection checklist, sti sp001 6th edition pdf, SPCC, sti sp001 monthly inspection checklist |

STI SP001 AST Record

|

|

OWNER INFORMATION |

|

|

|

FACILITY INFORMATION |

|

|

INSTALLER INFORMATION |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Name |

|

|

|

|

|

|

|

Name |

|

|

|

|

|

|

|

Name |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Number and Street |

|

|

|

|

|

|

|

Number and Street |

|

|

|

Number and Street |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

City, State, Zip Code |

|

|

|

|

|

City, State, Zip Code |

|

|

|

City, State, Zip Code |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TANK ID |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SPECIFICATION: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Design: |

UL |

|

|

SWRI |

|

|

|

Horizontal |

Vertical |

Rectangular |

||||||||

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

API |

|

|

|

Other |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Unknown |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Manufacturer: |

|

|

|

|

Contents: |

|

|

|

Construction Date: |

|

|

Last Repair/Reconstruction Date: |

||||||

|

Dimensions: |

|

|

|

|

Capacity: |

|

|

|

Last Change of Service Date: |

|

|

|||||||

|

Construction: |

Bare Steel |

|

|

Cathodically Protected (Check one: A. Galvanic or B. |

Impressed Current) Date Installed: _______________ |

|||||||||||||

|

|

|

Coated Steel |

|

|

Concrete |

|

|

Plastic/Fiberglass |

|

Other |

|

|

||||||

|

|

|

Double Bottom |

|

|

Double Wall |

|

Lined Date Installed: _______________ |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Containment: |

Earthen Dike |

|

Steel Dike |

Concrete |

|

Synthetic Liner |

Other |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

CRDM: |

|

|

Date Installed: |

|

|

|

Type: |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Release Prevention Barrier: |

Date Installed: |

|

|

|

Type: |

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TANK ID

SPECIFICATION: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Design: |

UL |

|

|

SWRI |

|

|

|

Horizontal |

Vertical |

Rectangular |

||||||||||

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

API |

|

|

|

Other |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Unknown |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Manufacturer: |

|

|

|

|

Contents: |

|

|

Construction Date: |

|

|

Last Repair/Reconstruction Date: |

|||||||||

Dimensions: |

|

|

|

|

Capacity: |

|

|

Last Change of Service Date: |

|

|

|

|||||||||

Construction: |

Bare Steel |

|

|

Cathodically Protected (Check one: A. |

|

Galvanic or B. |

Impressed Current) Date Installed: _______________ |

|||||||||||||

|

|

Coated Steel |

|

|

Concrete |

|

|

Plastic/Fiberglass |

|

Other |

|

|

|

|||||||

|

|

Double Bottom |

|

|

Double Wall |

Lined Date Installed: _______________ |

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Containment: |

Earthen Dike |

|

Steel Dike |

Concrete |

|

Synthetic Liner |

Other |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

CRDM: |

|

|

Date Installed: |

|

|

|

Type: |

|

|

|

|

|

|

|

|

|||||

Release Prevention Barrier: |

Date Installed: |

|

|

|

Type: |

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TANK ID |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SPECIFICATION: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Design: |

UL |

|

|

SWRI |

|

|

|

Horizontal |

Vertical |

Rectangular |

||||||||||

|

|

API |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Unknown |

|

|

Other |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Manufacturer: |

|

|

|

|

Contents: |

|

|

Construction Date: |

|

|

Last Repair/Reconstruction Date: |

|||||||||

Dimensions: |

|

|

|

|

Capacity: |

|

|

Last Change of Service Date: |

|

|

|

|||||||||

Construction: |

Bare Steel |

|

|

Cathodically Protected (Check one: A. |

|

Galvanic or B. |

Impressed Current) Date Installed: _______________ |

|||||||||||||

|

|

Coated Steel |

|

|

Concrete |

|

|

Plastic/Fiberglass |

|

Other |

|

|

|

|||||||

|

|

Double Bottom |

|

|

Double Wall |

Lined Date Installed: _______________ |

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Containment: |

Earthen Dike |

|

Steel Dike |

Concrete |

|

Synthetic Liner |

Other |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

CRDM: |

|

|

Date Installed: |

|

|

|

Type: |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Release Prevention Barrier: |

Date Installed: |

|

|

|

Type: |

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TANK ID

SPECIFICATION: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Design: |

UL |

|

|

SWRI |

|

|

|

Horizontal |

Vertical |

Rectangular |

||||||||

|

|

API |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Unknown |

|

|

Other |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Manufacturer: |

|

|

|

|

Contents: |

|

Construction Date: |

|

|

Last Repair/Reconstruction Date: |

||||||||

Dimensions: |

|

|

|

|

Capacity: |

|

Last Change of Service Date: |

|

|

|||||||||

Construction: |

Bare Steel |

|

|

Cathodically Protected (Check one: A. |

|

Galvanic or B. |

Impressed Current) Date Installed: _______________ |

|||||||||||

|

|

Coated Steel |

|

|

Concrete |

|

|

Plastic/Fiberglass |

|

Other |

|

|

||||||

|

|

Double Bottom |

|

|

Double Wall |

Lined Date Installed: _______________ |

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Containment: |

Earthen Dike |

|

Steel Dike |

Concrete |

|

Synthetic Liner |

Other |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

CRDM: |

|

|

Date Installed: |

|

|

|

Type: |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Release Prevention Barrier: |

Date Installed: |

|

|

|

Type: |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TANK ID |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SPECIFICATION: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Design: |

UL |

|

|

SWRI |

|

|

|

Horizontal |

Vertical |

Rectangular |

||||||||

|

|

|

|

|

|

|

|

|

||||||||||

|

|

API |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Unknown |

|

|

Other |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Manufacturer: |

|

|

|

|

Contents: |

|

Construction Date: |

|

|

Last Repair/Reconstruction Date: |

||||||||

Dimensions: |

|

|

|

|

Capacity: |

|

Last Change of Service Date: |

|

|

|||||||||

Construction: |

Bare Steel |

|

|

Cathodically Protected (Check one: A. |

|

Galvanic or B. |

Impressed Current) Date Installed: _______________ |

|||||||||||

|

|

Coated Steel |

|

|

Concrete |

|

|

Plastic/Fiberglass |

|

Other |

|

|

||||||

|

|

Double Bottom |

|

|

Double Wall |

Lined Date Installed: _______________ |

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Containment: |

Earthen Dike |

|

Steel Dike |

Concrete |

|

Synthetic Liner |

Other |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

CRDM: |

|

|

Date Installed: |

|

|

|

Type: |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Release Prevention Barrier: |

Date Installed: |

|

|

|

Type: |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

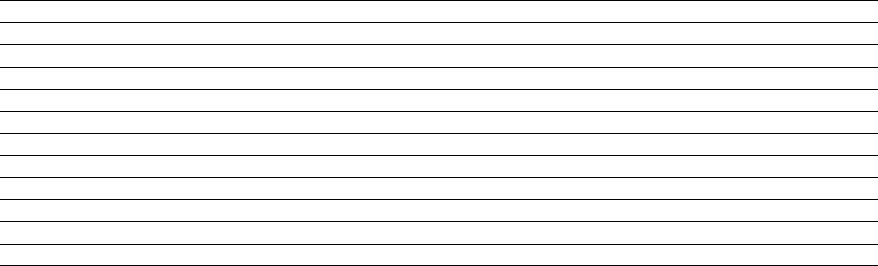

STI SP001 Monthly Inspection Checklist

General Inspection Information:

Inspection Date: |

|

Retain Until Date: |

|

(36 months from inspection date) |

||

Prior Inspection Date: |

Inspector Name: |

|

|

|

||

|

|

|

||||

|

|

|

|

|

|

|

Tanks Inspected (ID #’s): |

|

|

|

|

||

|

|

|

|

|

|

|

Inspection Guidance:

ᄒ For equipment not included in this standard, follow the manufacturer recommended inspection/testing schedules and procedures.

ᄒ The periodic AST Inspection is intended for monitoring the external AST condition and its containment structure. This visual inspection does not require a certified inspector. It shall be performed by an owner’s inspector who is familiar with the site and can identify changes and developing problems.

ᄒ Upon discovery of water in the primary tank, secondary containment area, interstice, or spill container, remove promptly or take other corrective action. Before discharge to the environment, inspect the liquid for regulated products or other contaminants and disposed of it properly.

ᄒ (*) designates an item in a

ᄒ

ᄒ Retain the completed checklists for 36 months.

ᄒ In the event of severe weather (snow, ice, wind storms) or maintenance (such as painting) that could affect the operation of critical components (normal and emergency vents, valves), an inspection of these components is required immediately following the event.

Item |

|

Status |

Comments |

1.0 Tank Containment |

|

|

|

1.1Water in primary tank, |

Yes* |

No |

|

secondary containment, |

|

|

|

interstice, or spill |

|

|

|

container? |

|

|

|

1.2 Debris or fire hazard in |

Yes* |

No |

|

containment? |

|

|

|

1.3 Drain valves operable |

Yes |

No* |

|

and in a closed |

|

|

|

position? |

|

|

|

1.4Containment egress |

Yes |

No* |

|

pathways clear |

|

|

|

and gates/doors |

|

|

|

operable? |

|

|

|

2.0 |

Leak Detection |

|

|

|

2.1 |

Visible signs of |

Yes* |

No |

|

|

leakage around the tank, |

|

|

|

|

concrete pad, |

|

|

|

|

containment, ringwall or |

|

|

|

|

ground? |

|

|

|

3.0 |

Tank Attachments and Appurtances |

|

|

|

3.1 |

Ladder and platform |

Yes |

No* |

|

|

structure secure with no |

|

|

|

|

sign of severe corrosion |

|

|

|

|

or damage? |

|

|

|

3.2 |

Tank Liquid level gauge |

Yes |

No* |

|

readable and in good |

|

|

|

|

condition? |

|

|

|

|

3.3 |

Check all tank openings |

Yes |

No* |

|

|

are properly sealed |

|

|

|

|

|

|

|

|

4.0 |

Other Conditions |

|

|

|

4.1 |

Are there other conditions |

Yes* |

No |

|

|

that should be addressed |

|

|

|

|

for continued safe |

|

|

|

|

operation or that may |

|

|

|

|

affect the site SPCC plan? |

|

|

|

Additional Comments: