sample welding procedure specification form can be filled in online very easily. Just make use of FormsPal PDF editing tool to do the job in a timely fashion. The tool is consistently upgraded by us, acquiring powerful features and growing to be even more convenient. This is what you would want to do to begin:

Step 1: Click the "Get Form" button at the top of this page to access our editor.

Step 2: The editor helps you modify almost all PDF documents in various ways. Modify it with your own text, correct original content, and put in a signature - all manageable within a few minutes!

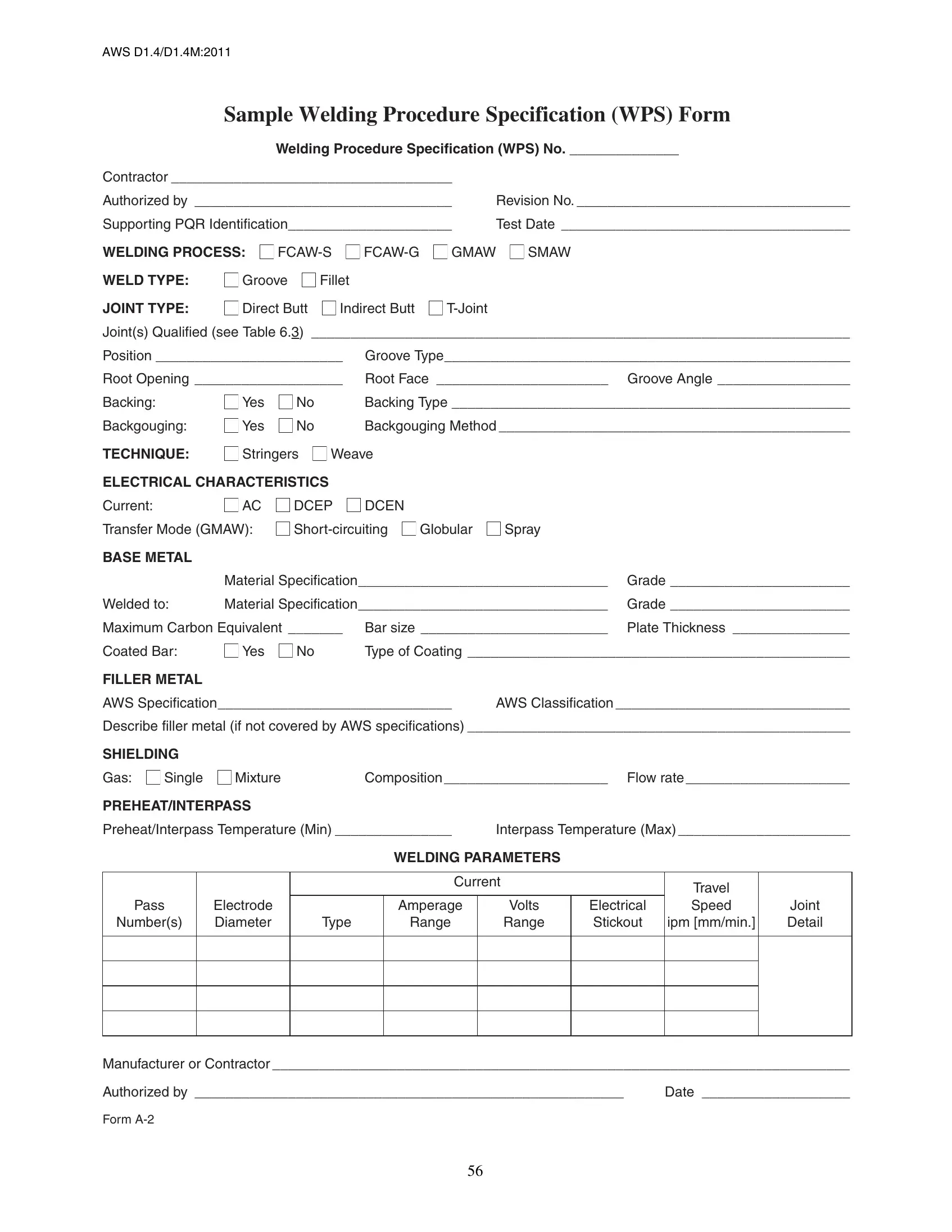

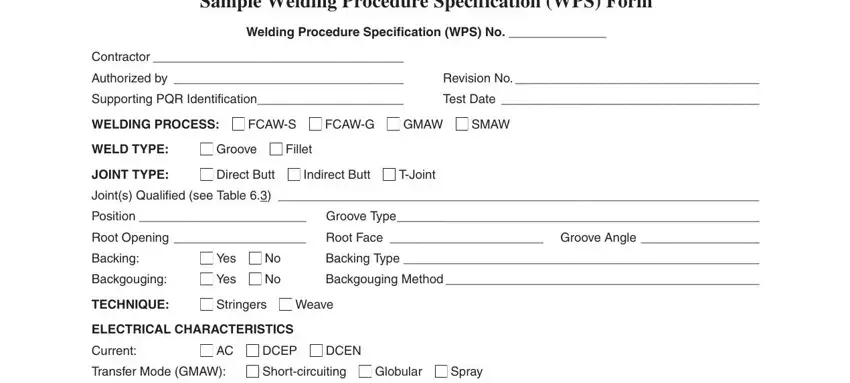

This document will need specific details; in order to ensure correctness, you should heed the next suggestions:

1. When completing the sample welding procedure specification form, be sure to complete all necessary blank fields in their corresponding area. It will help hasten the work, enabling your information to be handled quickly and properly.

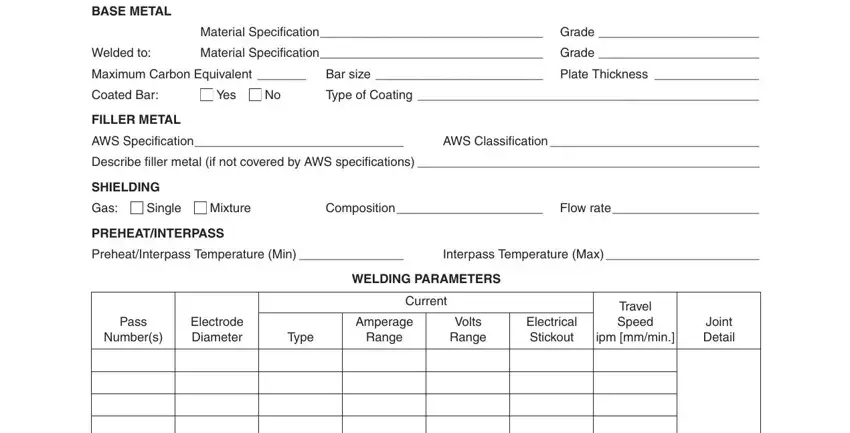

2. After the last section is done, you're ready to add the required specifics in BASE METAL, Material Specification Grade, Welded to, Material Specification Grade, Maximum Carbon Equivalent, Bar size, Plate Thickness, Coated Bar, Yes, Type of Coating, FILLER METAL, AWS Specification, AWS Classification, Describe filler metal if not, and SHIELDING allowing you to move forward to the 3rd step.

You can easily make a mistake when filling out your Type of Coating, consequently you'll want to reread it before you'll finalize the form.

3. The third part is normally easy - complete every one of the blanks in Manufacturer or Contractor, Authorized by, Date, and Form A in order to complete this part.

Step 3: Right after rereading the entries, click "Done" and you're all set! Sign up with FormsPal right now and easily get access to sample welding procedure specification form, available for downloading. All modifications made by you are kept , so that you can change the pdf at a later stage when necessary. FormsPal is focused on the personal privacy of all our users; we make sure that all information entered into our tool remains confidential.