FAA can be filled out with ease. Simply make use of FormsPal PDF tool to accomplish the job in a timely fashion. To make our tool better and easier to work with, we consistently implement new features, with our users' suggestions in mind. All it takes is just a few easy steps:

Step 1: Simply click the "Get Form Button" at the top of this page to launch our pdf file editor. Here you will find everything that is required to work with your document.

Step 2: This editor lets you customize PDF forms in many different ways. Enhance it by including your own text, correct what is already in the PDF, and place in a signature - all within a couple of clicks!

As for the blanks of this precise document, here is what you should know:

1. The FAA will require particular details to be entered. Ensure the following fields are complete:

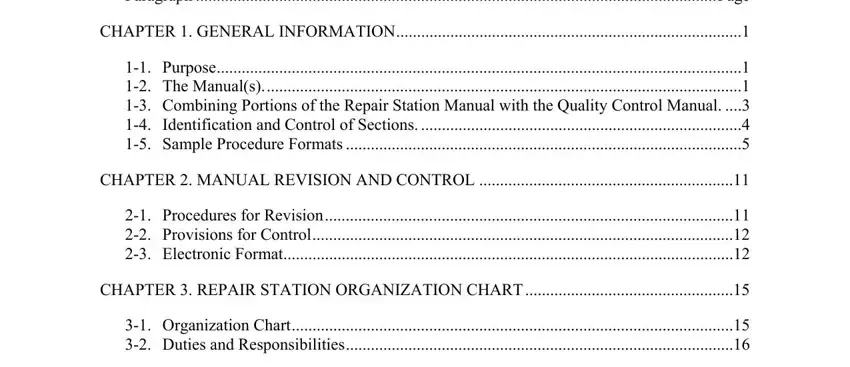

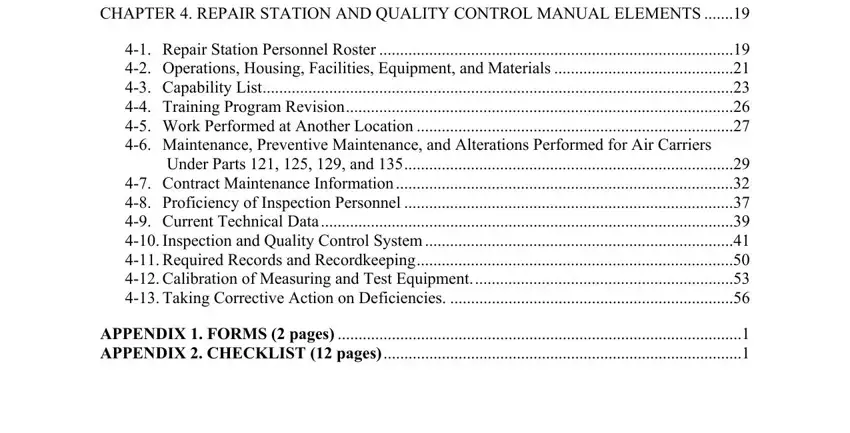

2. Once your current task is complete, take the next step – fill out all of these fields - CHAPTER REPAIR STATION AND, Repair Station Personnel Roster , Under Parts and Contract, and APPENDIX FORMS pages APPENDIX with their corresponding information. Make sure to double check that everything has been entered correctly before continuing!

When it comes to APPENDIX FORMS pages APPENDIX and Under Parts and Contract, be certain that you double-check them in this current part. Both these are viewed as the most important fields in the file.

Step 3: Immediately after taking another look at your fields and details, press "Done" and you are done and dusted! Try a free trial subscription with us and obtain instant access to FAA - which you may then use as you want in your personal account page. FormsPal ensures your data privacy by having a protected method that in no way records or distributes any type of sensitive information used in the form. Be assured knowing your documents are kept protected when you work with our tools!