Manifolded can be completed online in no time. Simply make use of FormsPal PDF tool to accomplish the job right away. To retain our editor on the forefront of practicality, we strive to put into operation user-oriented features and enhancements on a regular basis. We are at all times glad to get suggestions - play a vital role in reshaping the way you work with PDF docs. If you're looking to begin, here's what it takes:

Step 1: Click on the "Get Form" button at the top of this webpage to open our tool.

Step 2: With the help of our online PDF editing tool, it's possible to do more than simply complete blanks. Try all the features and make your documents appear high-quality with customized text put in, or tweak the file's original input to perfection - all that supported by an ability to insert any kind of photos and sign it off.

It is an easy task to finish the document with our detailed tutorial! This is what you need to do:

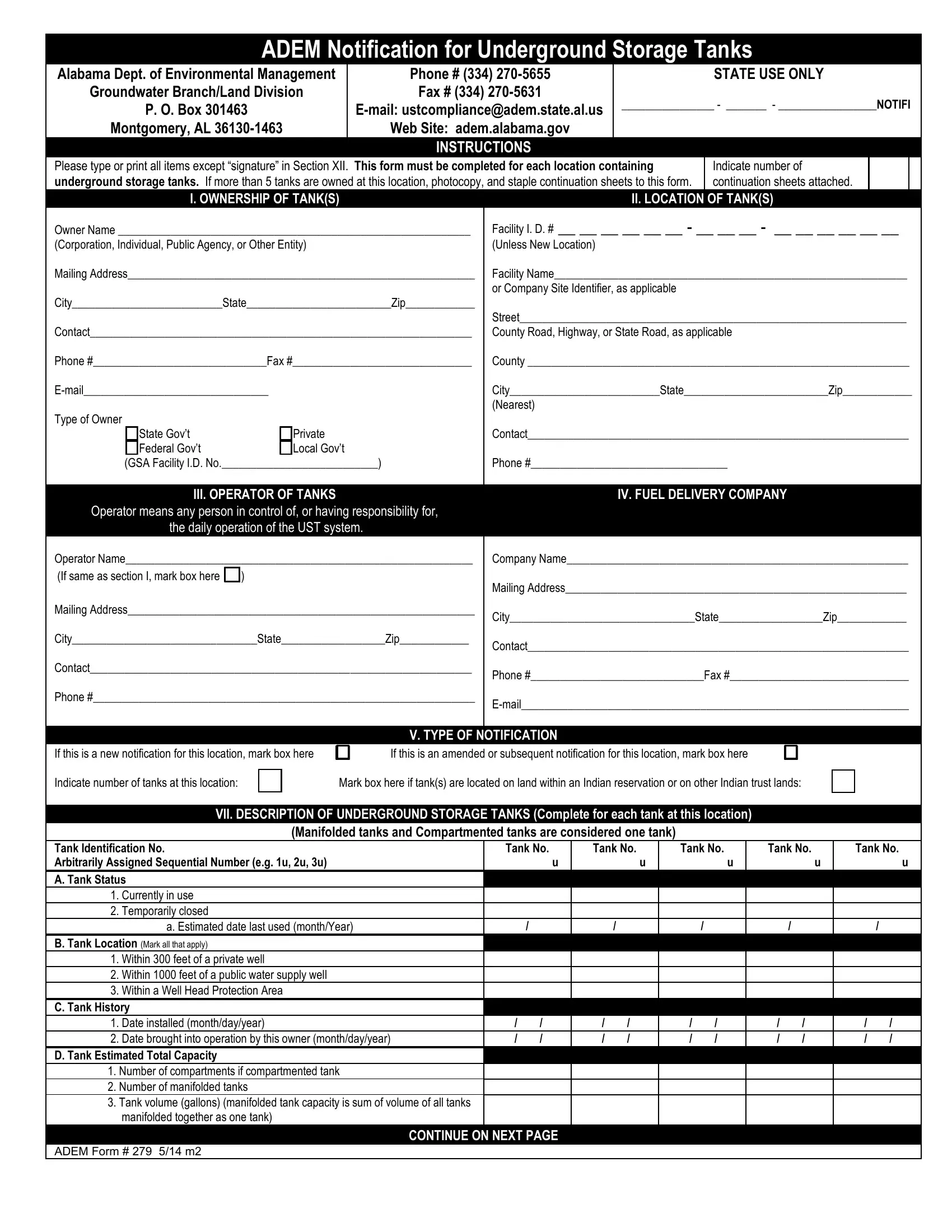

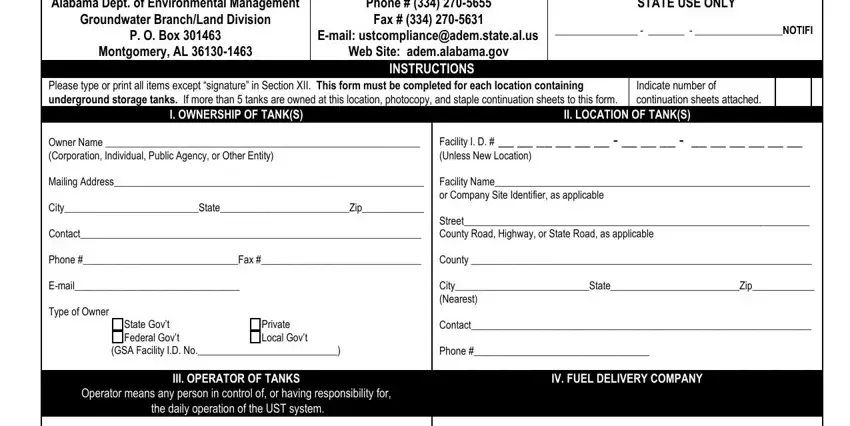

1. The Manifolded will require certain information to be typed in. Ensure the next fields are filled out:

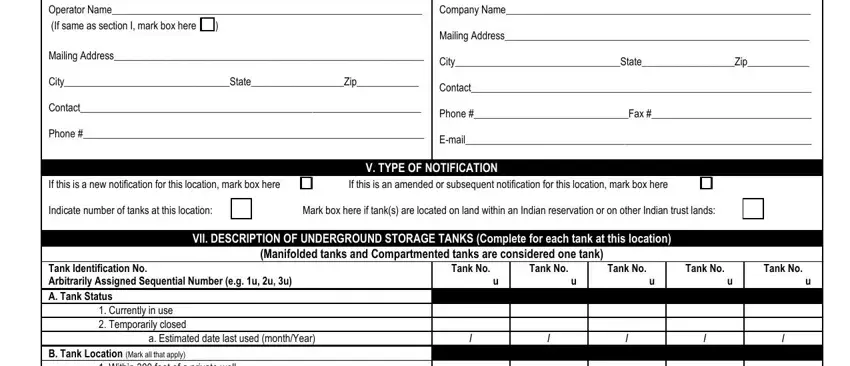

2. Right after this part is done, proceed to enter the applicable details in all these: Operator Name If same as section I, Company Name Mailing Address, If this is a new notification for, If this is an amended or, Indicate number of tanks at this, VII DESCRIPTION OF UNDERGROUND, Manifolded tanks and Compartmented, V TYPE OF NOTIFICATION, a Estimated date last used, Currently in use Temporarily, Tank Identification No Arbitrarily, Within feet of a private well , Tank No, Tank No, and Tank No.

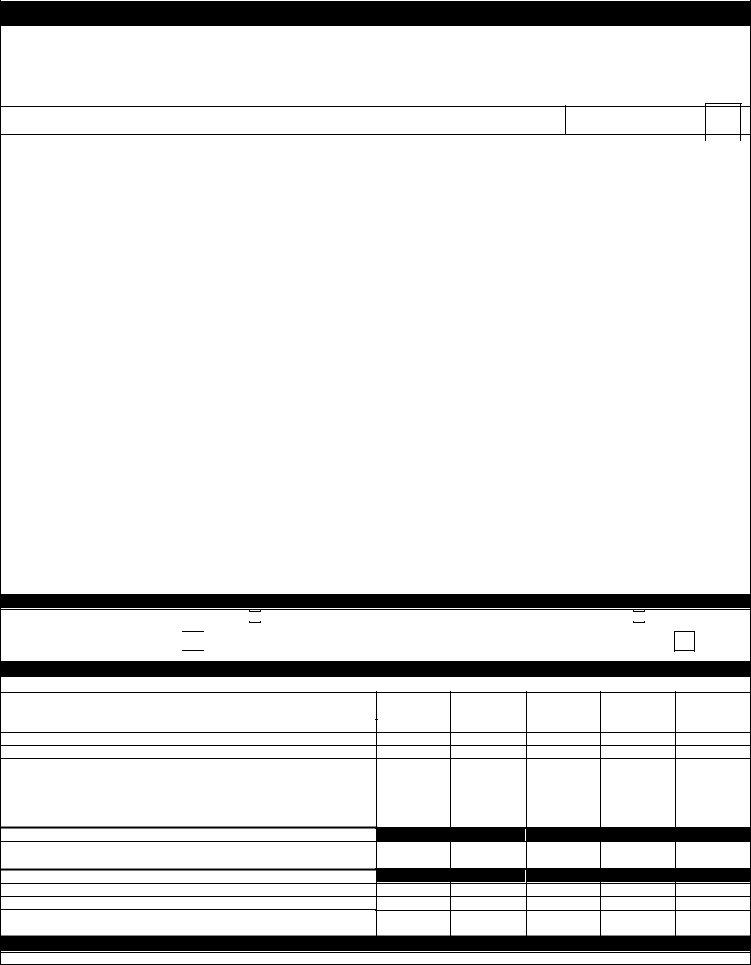

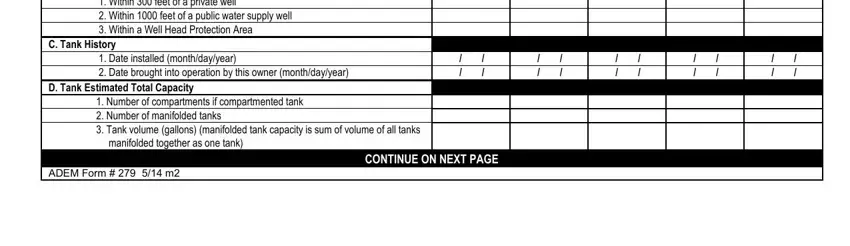

3. This next segment will be focused on Tank Identification No Arbitrarily, Within feet of a private well , Date installed monthdayyear Date, ADEM Form m, and CONTINUE ON NEXT PAGE - type in all these fields.

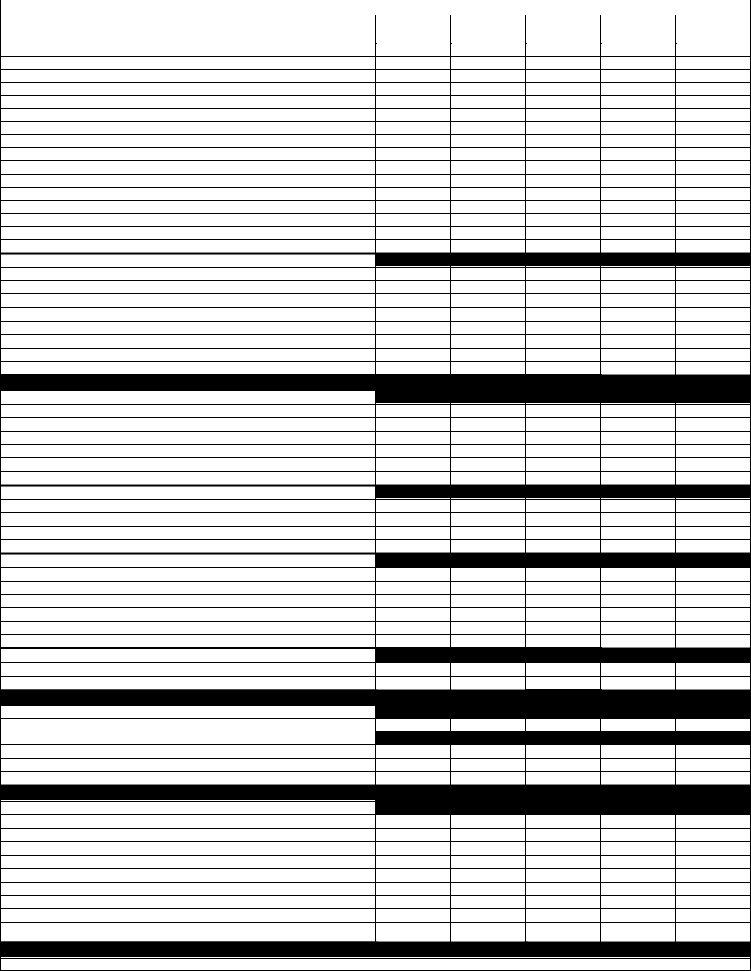

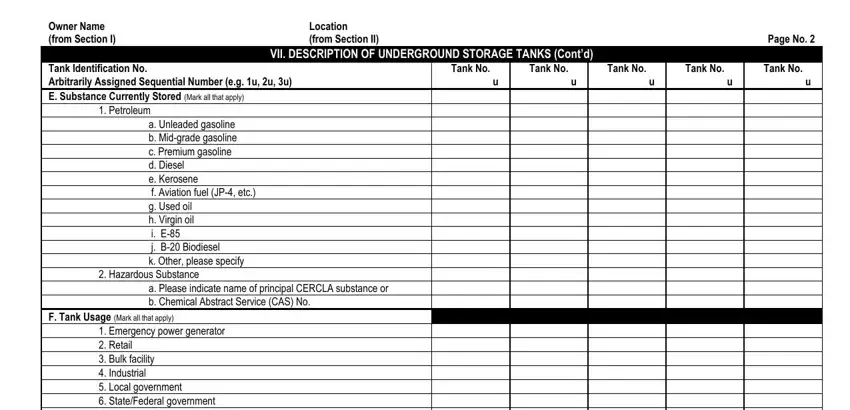

4. This next section requires some additional information. Ensure you complete all the necessary fields - Owner Name from Section I, Location from Section II, VII DESCRIPTION OF UNDERGROUND, Page No , Tank No, Tank No, Tank No, Tank No, Tank No, Petroleum, a Unleaded gasoline b Midgrade, Tank Identification No Arbitrarily, Emergency power generator Retail, Hazardous Substance, and k Other please specify - to proceed further in your process!

It's easy to get it wrong when filling out your Emergency power generator Retail, for that reason be sure you take another look prior to deciding to submit it.

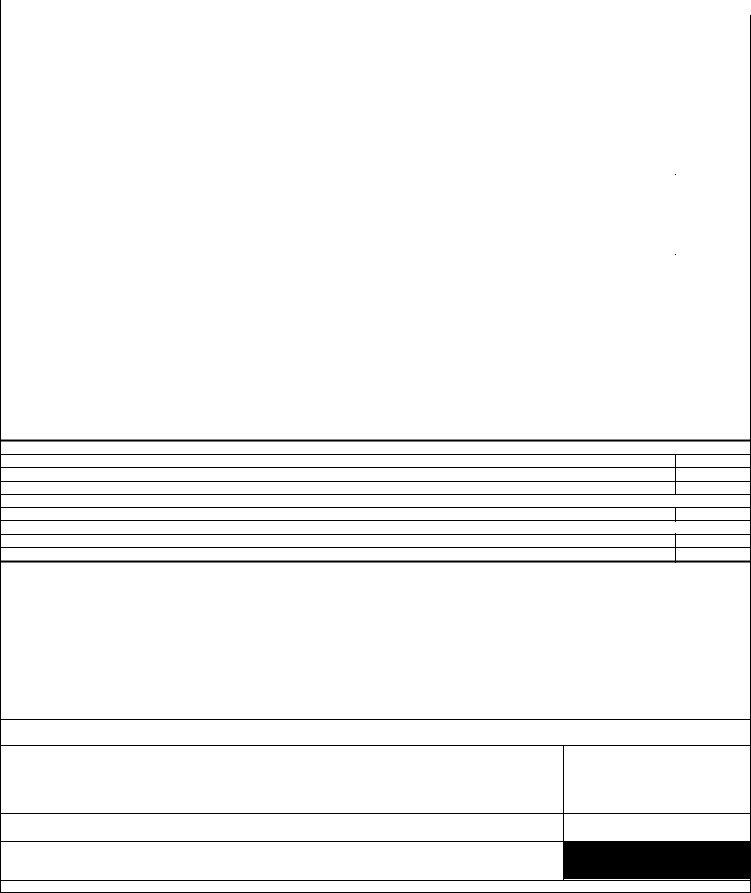

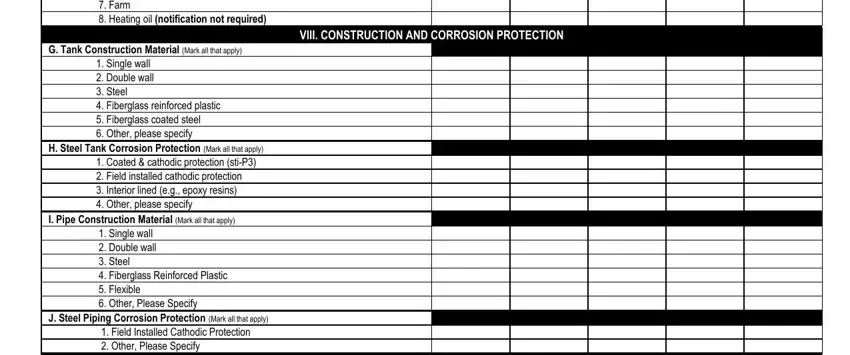

5. Finally, this last section is precisely what you have to wrap up prior to closing the document. The fields at issue include the following: Tank Identification No Arbitrarily, Emergency power generator Retail, VIII CONSTRUCTION AND CORROSION, G Tank Construction Material Mark, Field Installed Cathodic, Steel Fiberglass Reinforced, and IX SPILLOVERFILL PREVENTION.

Step 3: After you've looked over the details provided, simply click "Done" to conclude your document creation. Make a free trial subscription with us and gain immediate access to Manifolded - download or modify in your FormsPal cabinet. FormsPal provides secure form editing with no personal information recording or any kind of sharing. Rest assured that your details are secure here!