Using the online editor for PDFs by FormsPal, you'll be able to fill out or edit concrete mix design submittal right here. FormsPal expert team is continuously endeavoring to develop the tool and enable it to be even easier for people with its extensive functions. Take full advantage of present-day progressive prospects, and discover a myriad of unique experiences! With a few easy steps, you'll be able to begin your PDF editing:

Step 1: Click on the orange "Get Form" button above. It will open our pdf editor so you can start filling in your form.

Step 2: Once you open the online editor, you will notice the document prepared to be filled out. Apart from filling in various blanks, you may also perform some other things with the file, including writing custom words, editing the original textual content, inserting graphics, putting your signature on the document, and much more.

It really is simple to fill out the document using out practical tutorial! This is what you want to do:

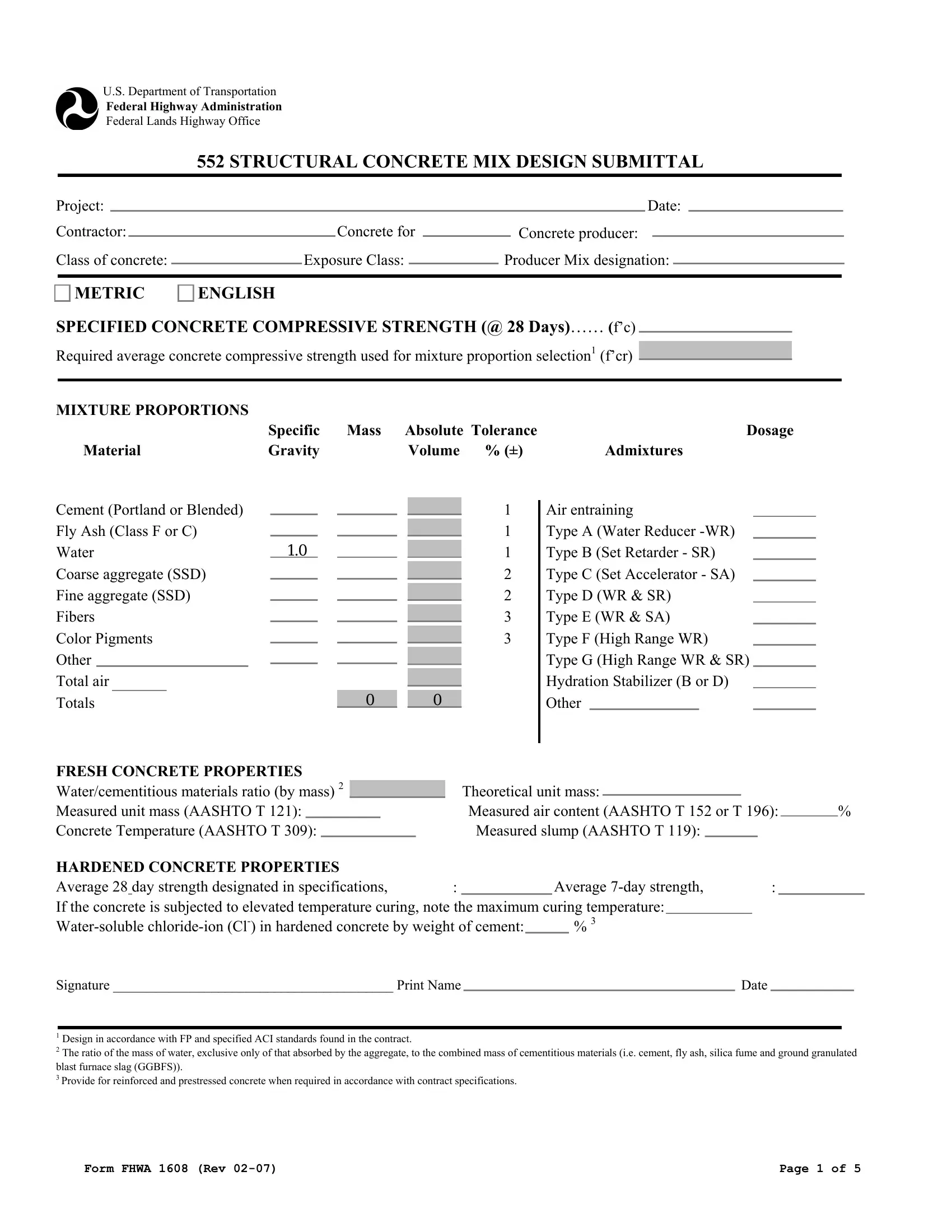

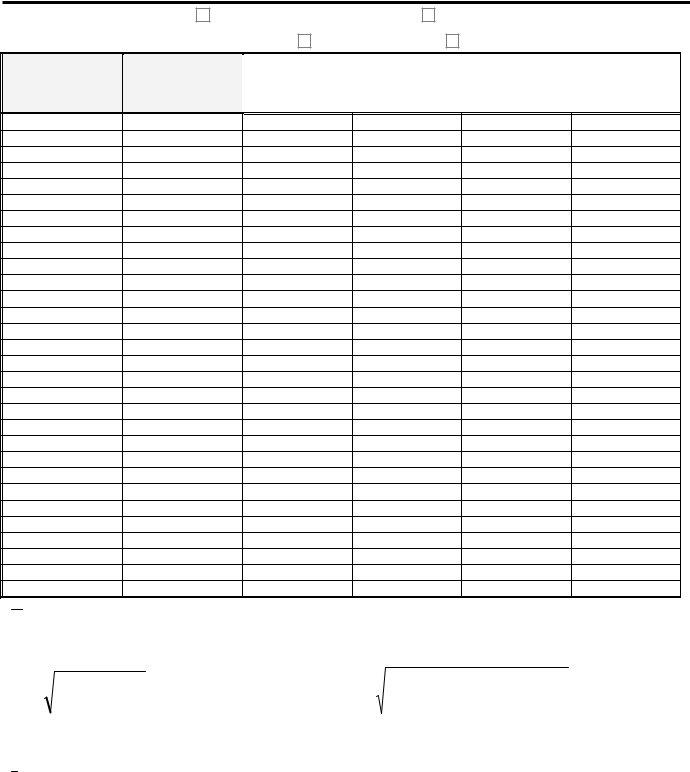

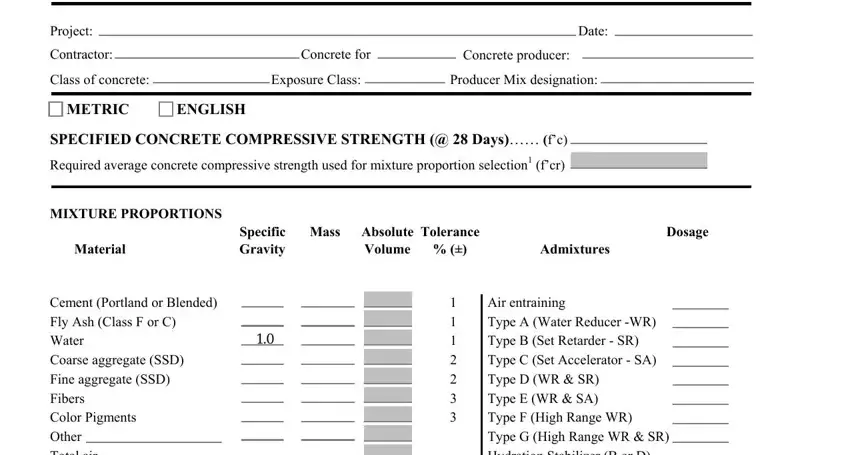

1. You should complete the concrete mix design submittal accurately, so be mindful when filling out the segments including all these blank fields:

2. Once your current task is complete, take the next step – fill out all of these fields - Total air, Totals, Hydration Stabilizer B or D, Other, FRESH CONCRETE PROPERTIES, Theoretical unit mass Measured air, Measured slump AASHTO T, Average day strength, Signature Print Name Design in, Date, Form FHWA Rev, and Page of with their corresponding information. Make sure to double check that everything has been entered correctly before continuing!

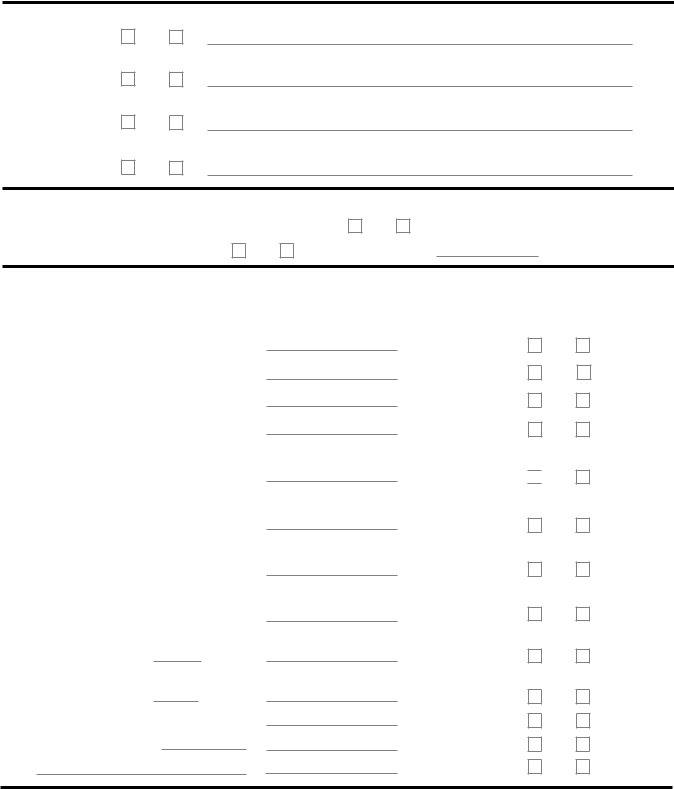

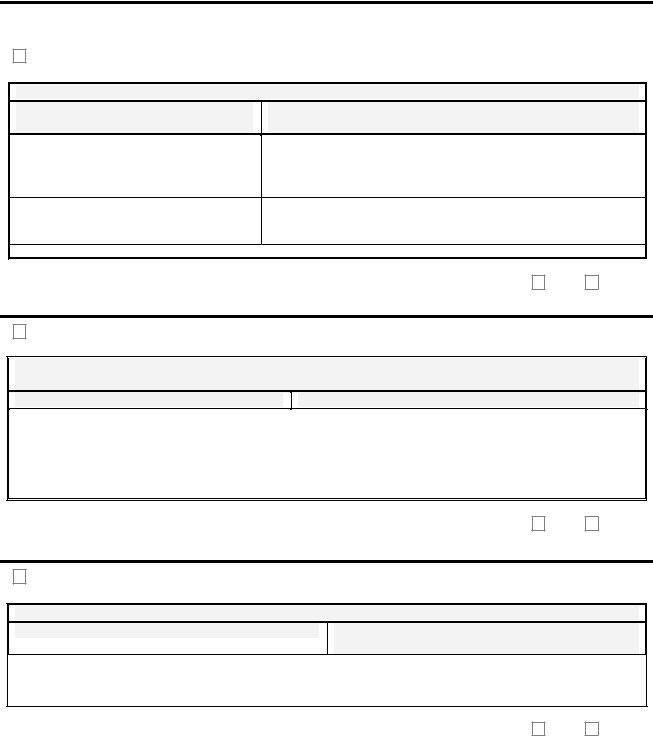

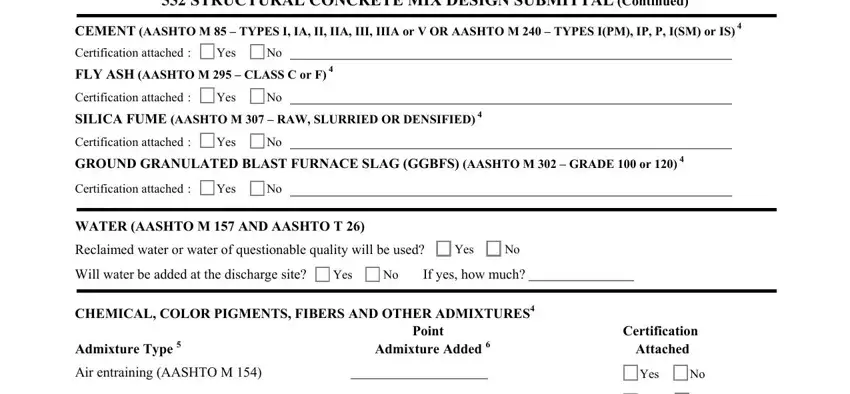

3. The following segment will be focused on STRUCTURAL CONCRETE MIX DESIGN, CEMENT AASHTO M TYPES I IA II, WATER AASHTO M AND AASHTO T, Reclaimed water or water of, CHEMICAL COLOR PIGMENTS FIBERS AND, Admixture Type, Air entraining AASHTO M, Point Admixture, Added, Certification Attached, and Yes No Yes No Yes No Yes No - fill in these fields.

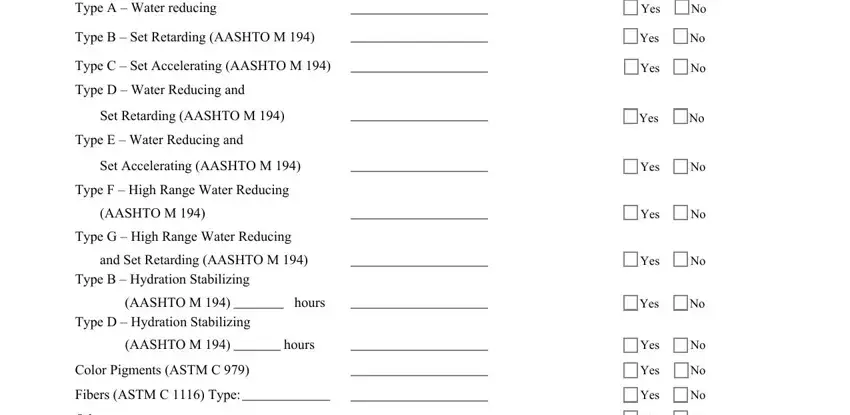

4. This next section requires some additional information. Ensure you complete all the necessary fields - Type A Water reducing, Type B Set Retarding AASHTO M, Type C Set Accelerating AASHTO M, Type D Water Reducing and, Set Retarding AASHTO M, Type E Water Reducing and, Set Accelerating AASHTO M, Type F High Range Water Reducing, AASHTO M, Type G High Range Water Reducing, and Set Retarding AASHTO M, Type B Hydration Stabilizing, AASHTO M, Type D Hydration Stabilizing, and hours - to proceed further in your process!

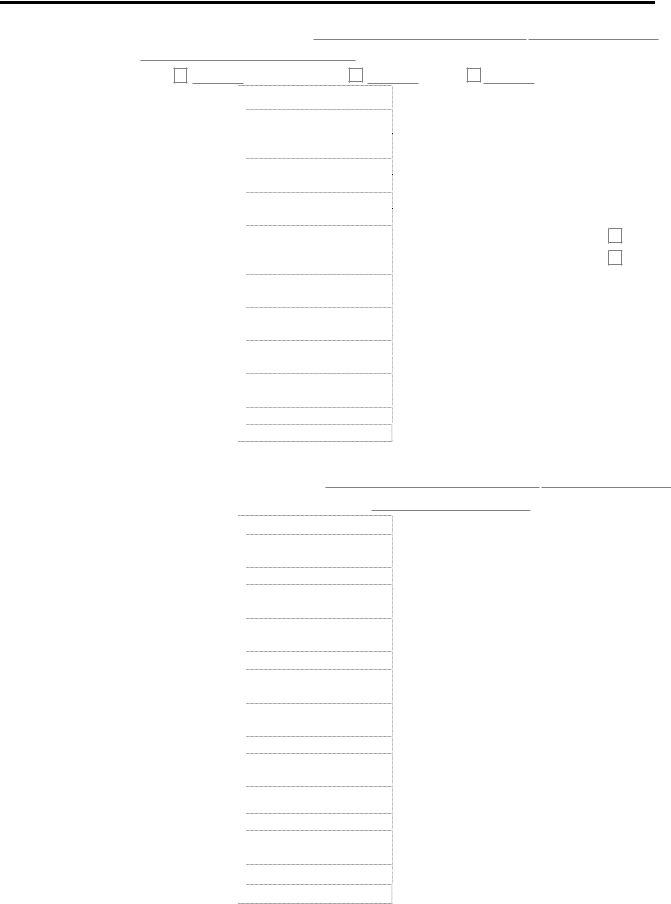

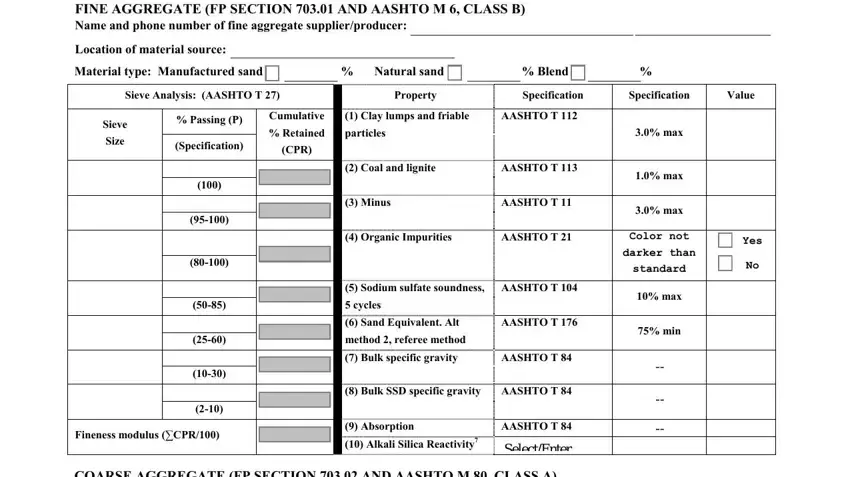

5. The very last stage to submit this document is integral. You must fill out the mandatory form fields, which includes FINE AGGREGATE FP SECTION AND, Location of material source, Natural sand Blend, Sieve Analysis AASHTO T, Property, Specification, Specification, Value, Sieve, Size, Passing P, Cumulative, Clay lumps and friable, AASHTO T, and Specification, before finalizing. Neglecting to do this might lead to an incomplete and possibly incorrect document!

As for Sieve Analysis AASHTO T and Passing P, make sure you don't make any mistakes here. Both of these are the key fields in the document.

Step 3: Immediately after looking through the fields and details, hit "Done" and you're good to go! Go for a free trial plan with us and obtain immediate access to concrete mix design submittal - with all transformations preserved and accessible inside your personal account. At FormsPal.com, we strive to be certain that all of your details are maintained secure.