In the realm of construction and energy efficiency, the FORM 405-10, under the auspices of the Florida Department of Business and Professional Regulation, emerges as a pivotal document for residential construction projects in Florida aiming to meet or exceed the Florida Energy Efficiency Code for Building Construction. This comprehensive form serves not only as a testament to a project's adherence to stringent energy efficiency standards but also as a blueprint detailing numerous facets of the building's design and expected performance characteristics. For instance, it encompasses a wide array of information, from basic project identification, such as the project name and builder details, to intricate data about the construction, including wall and ceiling types, insulation levels, window specifications, cooling and heating systems, and more. Crucial for both new constructions and existing building assessments, the form meticulously breaks down energy-related attributes, addressing everything from ductwork and air leakage tests to cooling system efficiency and hot water systems, thereby guiding builders, owners, and officials through the meticulous process of certifying a building's energy compliance. Furthermore, it underscores the necessity of various certifications and tests, like envelope leakage and roof absorption tests, to ensure compliance with the Florida Energy Code, ultimately underscoring the form's integral role in fostering energy-efficient residential environments in Florida.

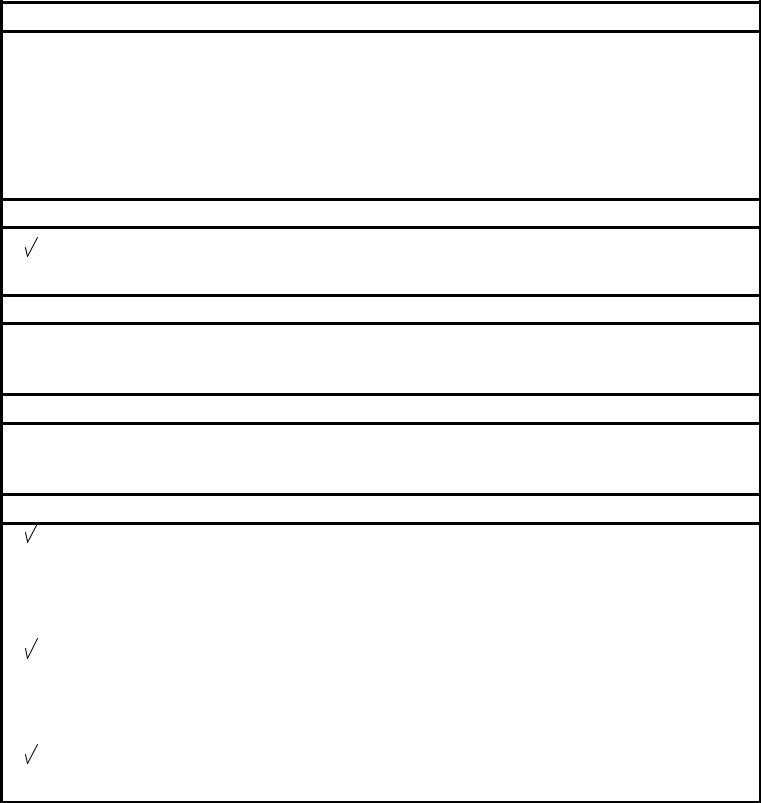

| Question | Answer |

|---|---|

| Form Name | Form 405 10 |

| Form Length | 6 pages |

| Fillable? | No |

| Fillable fields | 0 |

| Avg. time to fill out | 1 min 30 sec |

| Other names | 405 florida building, 405 form, form r405, r405 form |

FORM

FLORIDA ENERGY EFFICIENCY CODE FOR BUILDING CONSTRUCTION

Florida Department of Business and Professional Regulation - Residential Performance Method

|

Project Name: |

Sample 2 zone home |

|

|

|

Builder Name: BUILDER |

|

|

|

|

|

|||||

|

Street: |

123 Main Street |

|

|

|

Permit Office: |

|

|

|

|

|

|||||

|

City, State, Zip: |

Orlando , FL , 32922- |

|

|

|

Permit Number: |

|

|

|

|

|

|||||

|

Owner: |

OWNER |

|

|

|

Jurisdiction: |

|

|

|

|

|

|||||

|

Design Location: |

FL, Orlando |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

1. |

New construction or existing |

New (From Plans) |

9. Wall Types (2350.0 sqft.) |

Insulation |

Area |

|||||||||||

2. |

Single family or multiple family |

a. Frame - Wood, Exterior |

R=13.0 |

1230.00 ft² |

||||||||||||

b. Concrete Block - Int Insul, Exterior |

R=5.0 |

944.00 ft² |

||||||||||||||

3. |

Number of units, if multiple family |

1 |

|

|

||||||||||||

|

|

c. Frame - Wood, Adjacent |

R=13.0 |

176.00 ft² |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||

4. Number of Bedrooms |

|

6 |

|

|

d. N/A |

R= |

|

|

² |

|

||||||

|

|

|

|

|

|

|

|

|

||||||||

5. |

Is this a worst case? |

|

No |

|

|

10. Ceiling Types (1200.0 sqft.) |

Insulation |

Area |

||||||||

|

|

|

a. Under Attic (Vented) |

R=30.0 |

1200.00 ft² |

|||||||||||

|

|

|

|

|

|

|

|

|||||||||

6. |

Conditioned floor area above grade (ft²) |

2400 |

|

|

b. N/A |

R= |

|

|

ft ² |

|||||||

|

Conditioned floor area below grade (ft²) |

0 |

|

|

c. N/A |

R= |

|

|

ft ² |

|||||||

|

|

|

11. Ducts |

|

|

R |

² |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||

7. |

Windows(416.0 sqft.) |

Description |

|

Area |

a. Sup: Main, Ret: Main, AH: Main |

|

|

6 |

240 |

|

||||||

|

a. |

|

Dbl, U=0.75 |

|

276.00 ft² |

b. Sup: Attic, Ret: Attic, AH: 2nd Floor |

|

|

6 |

240 |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

S H G C : |

|

SHGC=0.40 |

|

|

|

12. Cooling systems |

k B |

u h r |

Efficiency |

||||||

|

b. |

|

Dbl, U=0.60 |

|

40.00 ft² |

|||||||||||

|

|

|

a. Central Unit |

|

20.0 |

SEER:13.00 |

||||||||||

|

S H G C : |

|

SHGC=0.30 |

|

|

|

|

|||||||||

|

|

|

|

|

b. Central Unit |

|

18.0 |

SEER:13.00 |

||||||||

|

c. |

|

Dbl, U=0.50 |

|

40.00 ft² |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

S H G C : |

|

SHGC=0.35 |

|

|

|

13. Heating systems |

k B |

u h r |

Efficiency |

||||||

|

d. |

|

other (see details) |

60.00 ft² |

a. Electric Heat Pump |

|

20.0 |

HSPF:7.70 |

||||||||

|

S H G C : |

|

other (see details) |

|

|

b. Natural Gas Furnace |

|

18.0 |

AFUE:0.78 |

|||||||

|

Area Weighted Average Overhang Depth: |

|

2.000 ft. |

|

|

|

|

|

|

|

|

|||||

|

Area Weighted Average SHGC: |

|

0.406 |

|

14. Hot water systems |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

||||||

8. |

Floor Types (2400.0 |

sqft.) |

Insulation |

Area |

a. Electric |

|

Cap: 50 gallons |

|||||||||

|

|

|

|

|

EF: 0.9 |

|||||||||||

|

a. |

R=0.0 |

1200.00 ft² |

|

|

|

|

|

||||||||

|

b. Conservation features |

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

b. Interior Floor |

|

|

R=0.0 |

1200.00 ft² |

None |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

c. N/A |

|

|

R= |

² |

|

15. Credits |

|

|

|

Pstat |

|||||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Glass/Floor Area: |

0.173 |

Total Proposed Modified Loads: 47.03 |

PASS |

|

|

|||||||||||

|

Total Baseline Loads: 58.94 |

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

I hereby certify that the plans and specifications covered by |

Review of the plans and |

|

|

|

|

|

||||||||||

this calculation are in compliance with the Florida Energy |

specifications covered by this |

|

|

|

|

|

||||||||||

Code. |

|

|

|

|

|

calculation indicates compliance |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

with the Florida Energy Code. |

|

|

|

|

|

|||

PREPARED BY: |

|

|

|

|

|

Before construction is completed |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|||||||

DATE: |

|

|

|

|

|

|

this building will be inspected for |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

compliance with Section 553.908 |

|

|

|

|

|

|||

I hereby certify that this building, as designed, is in compliance |

Florida Statutes. |

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|||||||||

with the Florida Energy Code. |

|

|

|

|

|

|

|

|

|

|

|

|||||

OWNER/AGENT: |

|

|

|

|

|

BUILDING OFFICIAL: |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

||||||

DATE: |

|

|

|

|

|

|

DATE: |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-Compliance requires certification by the air handler unit manufacturer that the air handler enclosure qualifies as certified

-Compliance requires an envelope leakage test report, by a Florida Class 1 Rater, in accordance with Table

-Compliance requires a roof absorptance test and a roof emittance test in accordance with 405.6.2

-Compliance requires an air distribution system test report, by a Florida Class 1 Rater, confirming system leakage to outdoors tested at 25 pascals pressure difference in accordance with 403.2.2.1. is not greater than (36 cfm:Duct#1) (36 cfm:Duct#2)

10/31/2011 5:40 PM |

EnergyGauge® USA - FlaRes2010 Section 405.4.1 Compliant Software |

Page 1 of 6 |

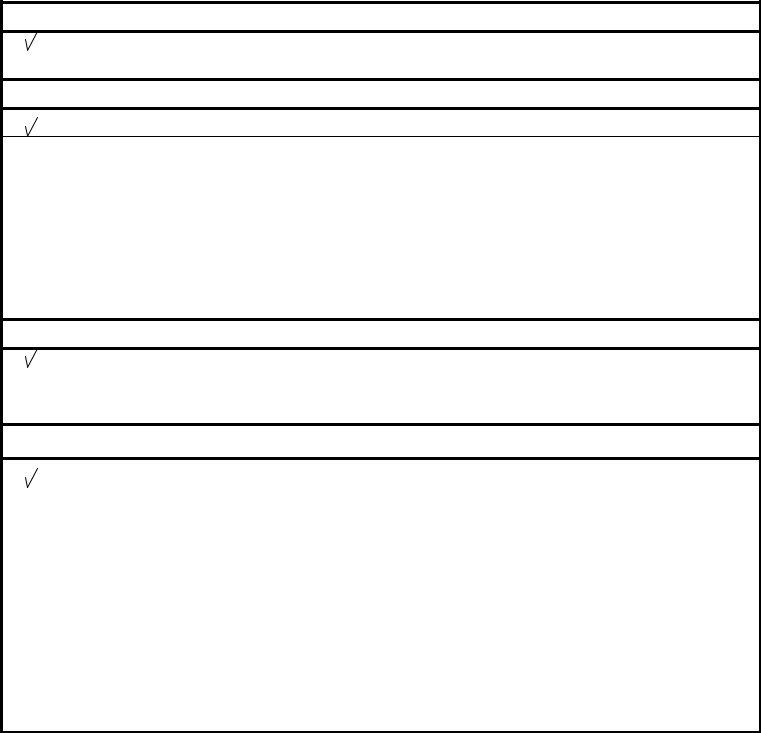

PROJECT

Title: |

Sample 2 zone home |

Bedrooms: |

6 |

Adress Type: |

Street Address |

|

Building Type: |

FLProp2010 |

Conditioned Area: |

2400 |

Lot # |

|

|

Owner: |

OWNER |

Total Stories: |

2 |

Block/SubDivision: |

|

|

# of Units: |

1 |

Worst Case: |

No |

PlatBook: |

|

|

Builder Name: |

BUILDER |

Rotate Angle: |

0 |

Street: |

123 Main Street |

|

Permit Office: |

|

Cross Ventilation: |

No |

County: |

Orange |

|

Jurisdiction: |

|

Whole House Fan: |

No |

City, State, Zip: |

Orlando , |

|

Family Type: |

|

|

|

FL , |

32922- |

|

New/Existing: |

New (From Plans) |

|

|

|

|

|

Comment: |

High Performance Florida Home |

|

|

|

|

|

CLIMATE

|

|

|

IECC |

Design Temp |

Int Design Temp |

Heating |

Design |

Daily Temp |

||

|

Design Location |

TMY Site |

Zone |

97.5 % |

2.5 % |

Winter |

Summer |

Degree Days |

Moisture |

Range |

|

|

|

|

|

|

|

|

|

|

|

______ |

FL, Orlando |

FL_ORLANDO_INTL_AR |

2 |

41 |

91 |

75 |

70 |

526 |

44 |

Medium |

BLOCKS

Number |

Name |

Area |

Volume |

|

|

|

|

1 |

Zone1 |

1200 |

9600 |

2 |

Zone2 |

1200 |

9600 |

SPACES

Number |

Name |

Area |

Volume |

Kitchen |

Occupants |

Bedrooms |

Infil ID |

Cooled |

Heated |

|

|

|

|

|

|

|

|

|

|

1 |

Main |

1200 |

9600 |

Yes |

3.5 |

3 |

1 |

Yes |

Yes |

2 |

2nd Floor |

1200 |

9600 |

No |

3.5 |

3 |

2 |

Yes |

Yes |

FLOORS

|

# |

Floor Type |

Room |

Perimeter |

Perimeter |

Area |

Joist |

Tile |

Wood |

Carpet |

||

______ |

1 |

140 ft |

|

0 |

1200 ft² |

- - - - |

|

0.2 |

0 |

0.8 |

||

______ |

2 |

Interior Floor |

2nd Floor |

- - - - |

- - |

- - |

1200 ft² |

0 |

|

0 |

0 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ROOF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Roof |

Gable |

Roof |

Solar |

SA |

Emitt |

Emitt |

Deck |

Pitch |

|

# |

Type |

Materials |

Area |

Area |

Color |

Absor. |

Tested |

|

Tested |

Insul. |

(deg) |

|

|

|

|

|

|

|

|

|

|

|

|

|

______ |

1 |

Hip |

Composition shingles |

1300 ft² |

0 ft² |

White |

0.85 |

Yes |

0.9 |

Yes |

0 |

22.6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ATTIC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

# |

Type |

Ventilation |

Vent Ratio (1 in) |

Area |

RBS |

IRCC |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

______ |

1 |

Full attic |

Vented |

|

150 |

|

1200 ft² |

N |

N |

|

|

|

10/31/2011 5:40 PM |

EnergyGauge® USA - FlaRes2010 Section 405.4.1 Compliant Software |

Page 2 of 6 |

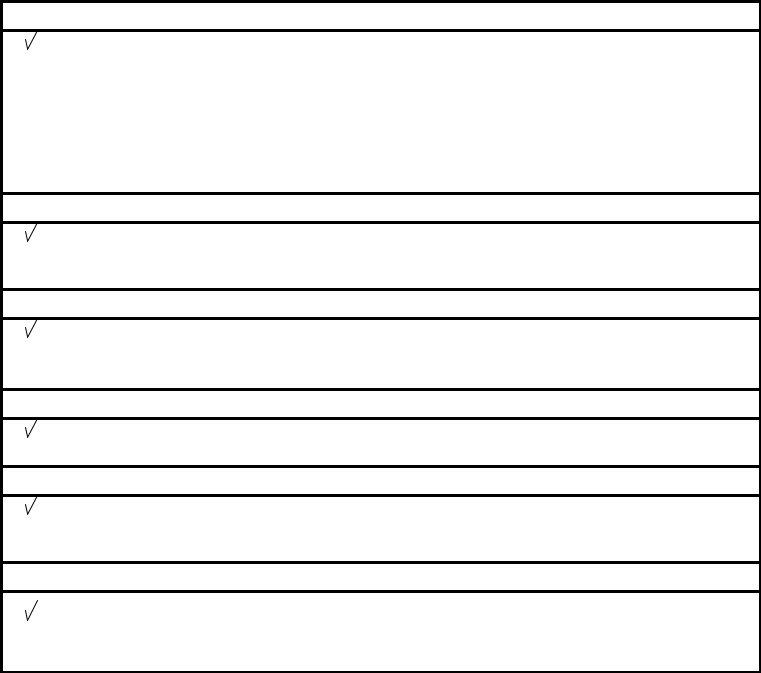

CEILING

|

# |

Ceiling Type |

Space |

Area |

Framing Frac |

Truss Type |

|

|

|

|

|

|

|

|

|

______ |

1 |

Under Attic (Vented) |

2nd Floor |

30 |

1200 ft² |

0.11 |

Wood |

WALLS

|

|

Adjacent |

Space |

Cavity |

Width |

Height |

|

Sheathing Framing |

Solar |

Below |

|||

# |

Ornt |

To |

Wall Type |

Ft In |

Ft In |

Area |

Fraction |

Absor. |

Grade% |

||||

|

|||||||||||||

______ 1 |

N |

Exterior Concrete Block - Int Insul |

Main |

5 |

40 |

8 |

320 ft² |

0 |

0 |

0.5 |

0 |

||

______ 2 |

E |

Exterior |

Concrete Block - Int Insul |

Main |

5 |

30 |

8 |

240 ft² |

0 |

0 |

0.5 |

0 |

|

______ 3 |

S |

Exterior |

Concrete Block - Int Insul |

Main |

5 |

40 |

8 |

320 ft² |

0 |

0 |

0.5 |

0 |

|

______ 4 |

W |

Exterior Concrete Block - Int Insul |

Main |

5 |

8 |

8 |

64 ft² |

0 |

0 |

0.5 |

0 |

||

______ 5 |

W |

Garage Frame - Wood |

Main |

13 |

22 |

8 |

176 ft² |

0 |

0 |

0.01 |

0 |

||

______ 6 |

N |

Exterior Frame - Wood |

2nd Floor |

13 |

40 |

9 |

360 ft² |

0 |

0.23 |

0.5 |

0 |

||

______ 7 |

E |

Exterior Frame - Wood |

2nd Floor |

13 |

30 |

9 |

270 ft² |

0 |

0.23 |

0.5 |

0 |

||

______ 8 |

S |

Exterior Frame - Wood |

2nd Floor |

13 |

40 |

9 |

360 ft² |

0 |

0.23 |

0.5 |

0 |

||

______ 9 |

W |

Exterior Frame - Wood |

2nd Floor |

13 |

30 |

8 |

240 ft² |

0 |

0.23 |

0.5 |

0 |

||

DOORS

|

# |

Ornt |

Door Type |

Space |

Storms |

Width |

|

Height |

Area |

||

|

|

|

|

|

|

|

Ft |

In |

Ft |

In |

|

______ |

1 |

N |

Insulated |

Main |

None |

0.2 |

3 |

|

6 |

8 |

20 ft² |

______ |

2 |

S |

Insulated |

Main |

None |

0.2 |

3 |

|

6 |

8 |

20 ft² |

WINDOWS

Orientation shown is the entered, Proposed orientation.

|

|

|

|

|

|

|

|

|

|

Overhang |

|

|

|

|

# |

Ornt |

Frame |

Panes |

NFRC |

SHGC |

Storms |

Area |

Depth |

Separation |

Int Shade |

Screening |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

______ |

1 |

N |

Vinyl |

Yes |

0.75 |

0.4 |

N |

48 ft² |

2 ft 0 in |

10 ft 4 in |

HERS 2006 |

None |

|

______ |

2 |

N |

None |

Glazed Block |

No |

0.6 |

0.6 |

N |

24 ft² |

2 ft 0 in |

10 ft 4 in |

HERS 2006 |

None |

______ |

3 |

E |

Vinyl |

Yes |

0.75 |

0.4 |

N |

24 ft² |

2 ft 0 in |

10 ft 4 in |

HERS 2006 |

None |

|

______ |

4 |

E |

Vinyl |

Yes |

0.75 |

0.4 |

N |

24 ft² |

2 ft 0 in |

10 ft 4 in |

HERS 2006 |

None |

|

______ |

5 |

S |

Vinyl |

Yes |

0.75 |

0.4 |

N |

36 ft² |

2 ft 0 in |

10 ft 4 in |

HERS 2006 |

None |

|

______ |

6 |

S |

Vinyl |

Yes |

0.5 |

0.35 |

N |

40 ft² |

2 ft 0 in |

10 ft 4 in |

HERS 2006 |

None |

|

______ |

7 |

W |

Vinyl |

Yes |

0.6 |

0.3 |

N |

16 ft² |

2 ft 0 in |

10 ft 4 in |

HERS 2006 |

None |

|

______ |

8 |

N |

Vinyl |

Yes |

0.75 |

0.5 |

N |

36 ft² |

2 ft 0 in |

1 ft 4 in |

HERS 2006 |

None |

|

______ |

9 |

E |

Vinyl |

Yes |

0.75 |

0.4 |

N |

48 ft² |

2 ft 0 in |

1 ft 4 in |

HERS 2006 |

None |

|

______ |

10 |

S |

Vinyl |

Yes |

0.75 |

0.4 |

N |

48 ft² |

2 ft 0 in |

1 ft 4 in |

HERS 2006 |

None |

|

______ |

11 |

S |

Vinyl |

Yes |

0.75 |

0.4 |

N |

48 ft² |

2 ft 0 in |

1 ft 4 in |

HERS 2006 |

None |

|

______ |

12 |

W |

Vinyl |

Yes |

0.6 |

0.3 |

N |

24 ft² |

2 ft 0 in |

1 ft 4 in |

HERS 2006 |

None |

|

10/31/2011 5:40 PM |

EnergyGauge® USA - FlaRes2010 Section 405.4.1 Compliant Software |

Page 3 of 6 |

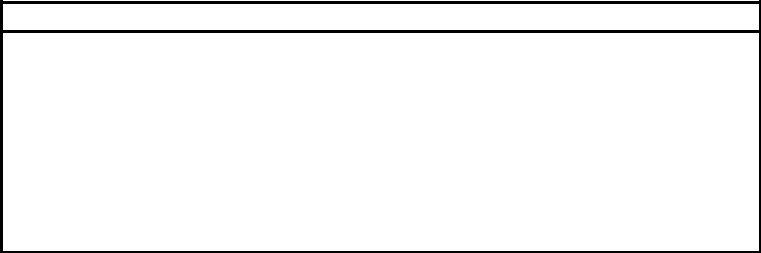

GARAGE

|

|

# |

Floor Area |

Ceiling Area |

Exposed Wall Perimeter |

Avg. Wall Height |

Exposed Wall Insulation |

||

|

|

|

|

|

|

|

|

|

|

______ |

1 |

384 ft² |

384 ft² |

|

64 ft |

|

8 ft |

13 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INFILTRATION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

# |

|

Scope |

Method |

SLA |

CFM 50 |

ELA |

EqLA |

ACH |

ACH 50 |

|

|

|

|

|

|

|

|

|

|

1 |

BySpaces |

Proposed ACH(50) |

0.000360 |

1133.1 |

62.208 |

116.99 |

0.3235 |

7.0821 |

|

2 |

BySpaces |

Proposed ACH(50) |

0.000355 |

1120 |

61.486 |

115.63 |

0.3197 |

7 |

|

HEATING SYSTEM

|

# |

System Type |

Subtype |

Efficiency |

Capacity |

Block |

Ducts |

|

|

|

|

|

|

|

|

______ |

1 |

Electric Heat Pump |

None |

HSPF: 7.7 |

20 kBtu/hr |

1 |

sys#1 |

______ |

2 |

Natural Gas Furnace |

None |

HSPF: 0.78 |

18 kBtu/hr |

2 |

sys#2 |

COOLING SYSTEM

|

# |

System Type |

Subtype |

Efficiency |

Capacity |

Air Flow |

SHR |

Block |

Ducts |

||

|

|

|

|

|

|

|

|

|

|

|

|

______ |

1 |

Central Unit |

None |

SEER: 13 |

20 |

kBtu/hr |

600 |

cfm |

0.75 |

1 |

sys#1 |

______ |

2 |

Central Unit |

None |

SEER: 13 |

18 |

kBtu/hr |

540 |

cfm |

0.75 |

2 |

sys#2 |

HOT WATER SYSTEM

|

# |

System Type |

EF |

Cap |

Use |

SetPnt |

Conservation |

|

|

|

|

|

|

|

|

______ |

1 |

Electric |

0.9 |

50 gal |

90 gal |

120 deg |

None |

SOLAR HOT WATER SYSTEM

|

FSEC |

|

|

|

Collector |

Storage |

|

|

Cert # |

Company Name |

System Model # |

Collector Model # |

Area |

Volume |

FEF |

|

|

|

|

|

|

|

|

______ |

None |

None |

|

|

² |

|

|

DUCTS

|

|

|

|

Air |

Percent |

|

|

HVAC # |

|||||

|

# |

Location |

Area |

Location |

Area |

Leakage Type |

Handler CFM 25 |

Leakage |

QN |

RLF |

Heat |

Cool |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

______ |

1 |

Main |

6 |

240 ft² |

Main |

60 ft² |

Proposed Qn |

Main 36.0 cfm |

6.00 % |

0.03 |

0.50 |

1 |

1 |

______ |

2 |

Attic |

6 |

240 ft² |

Attic |

60 ft² |

Proposed Qn |

2nd Floor 36.0 cfm |

6.67 % |

0.03 |

0.50 |

2 |

2 |

10/31/2011 5:40 PM |

EnergyGauge® USA - FlaRes2010 Section 405.4.1 Compliant Software |

Page 4 of 6 |

TEMPERATURES

Programable Thermostat: Y |

|

|

Ceiling Fans: |

|

|

|

|

|

|

|

|

|||

Cooling |

[X] Jan |

[X] Feb |

[X] Mar |

[X] Apr |

|

[X] May |

[X] Jun |

[X] Jul |

[X] Aug |

[X] Sep |

|

[X] Oct |

[X] Nov |

[X] Dec |

Heating |

[X] Jan |

[X] Feb |

[X] Mar |

[X] Apr |

|

[X] May |

[X] Jun |

[X] Jul |

[X] Aug |

[X] Sep |

|

[X] Oct |

[X] Nov |

[X] Dec |

Venting |

[X] Jan |

[X] Feb |

[X] Mar |

[X] Apr |

|

[X] May |

[X] Jun |

[X] Jul |

[X] Aug |

[X] Sep |

|

[X] Oct |

[X] Nov |

[X] Dec |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Thermostat Schedule: |

HERS 2006 Reference |

|

|

|

|

Hours |

|

|

|

|

|

|

||

Schedule Type |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cooling (WD) |

|

AM |

78 |

78 |

78 |

78 |

78 |

78 |

78 |

78 |

80 |

80 |

80 |

80 |

|

|

PM |

80 |

80 |

78 |

78 |

78 |

78 |

78 |

78 |

78 |

78 |

78 |

78 |

Cooling (WEH) |

AM |

78 |

78 |

78 |

78 |

78 |

78 |

78 |

78 |

78 |

78 |

78 |

78 |

|

|

|

PM |

78 |

78 |

78 |

78 |

78 |

78 |

78 |

78 |

78 |

78 |

78 |

78 |

Heating (WD) |

|

AM |

66 |

66 |

66 |

66 |

66 |

68 |

68 |

68 |

68 |

68 |

68 |

68 |

|

|

PM |

68 |

68 |

68 |

68 |

68 |

68 |

68 |

68 |

68 |

68 |

66 |

66 |

Heating (WEH) |

AM |

66 |

66 |

66 |

66 |

66 |

68 |

68 |

68 |

68 |

68 |

68 |

68 |

|

|

|

PM |

68 |

68 |

68 |

68 |

68 |

68 |

68 |

68 |

68 |

68 |

66 |

66 |

10/31/2011 5:40 PM |

EnergyGauge® USA - FlaRes2010 Section 405.4.1 Compliant Software |

Page 5 of 6 |