With the online tool for PDF editing by FormsPal, it is possible to complete or change Form Fda 3511 2 right here. To maintain our editor on the cutting edge of efficiency, we aim to integrate user-driven capabilities and enhancements regularly. We are always looking for suggestions - help us with revolutionizing the way you work with PDF documents. Here is what you will want to do to get going:

Step 1: Access the PDF doc inside our tool by clicking on the "Get Form Button" above on this page.

Step 2: When you start the file editor, you will find the form ready to be filled in. Aside from filling in various blank fields, you may as well do many other actions with the PDF, particularly writing your own textual content, modifying the initial textual content, adding images, signing the document, and a lot more.

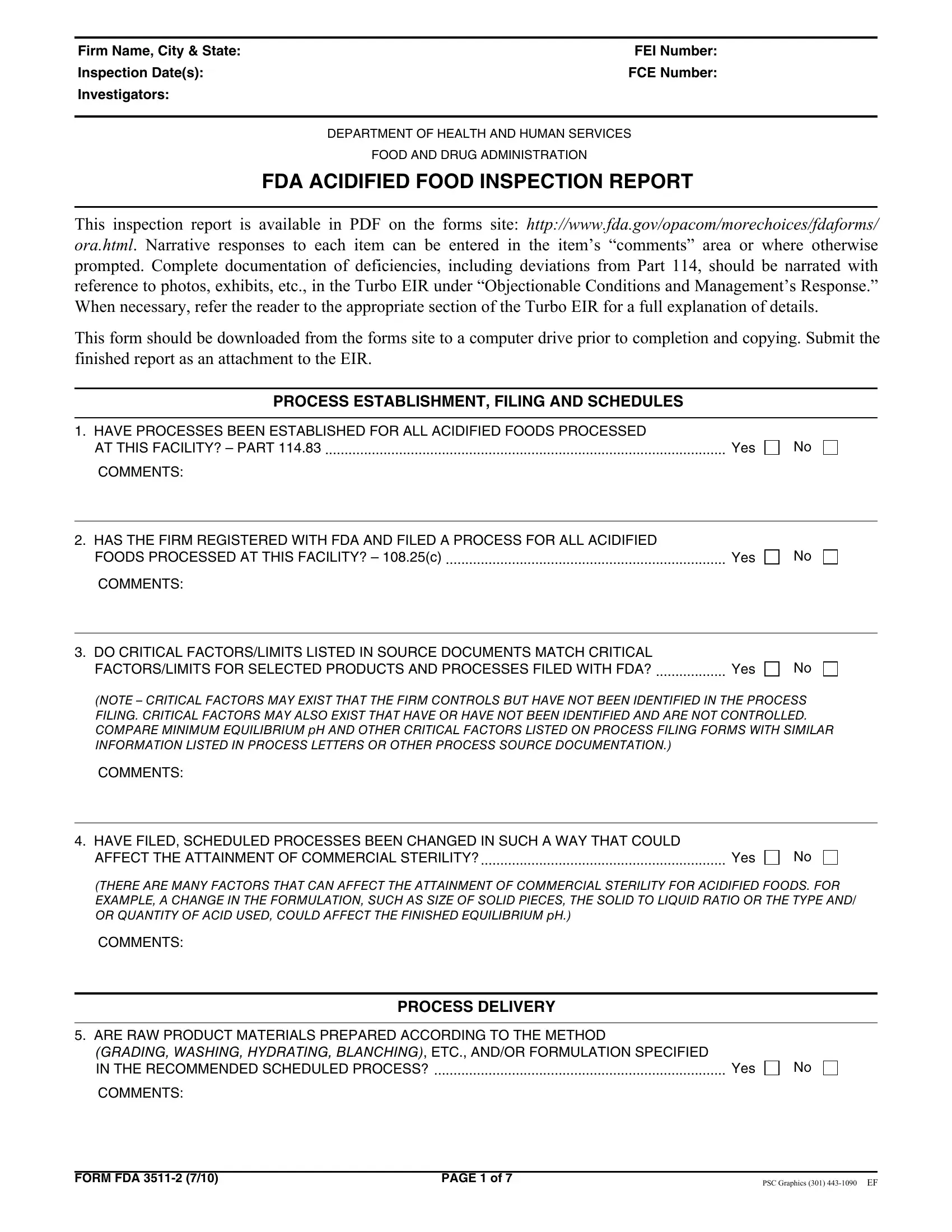

This PDF form will require particular info to be filled out, therefore you need to take your time to enter precisely what is expected:

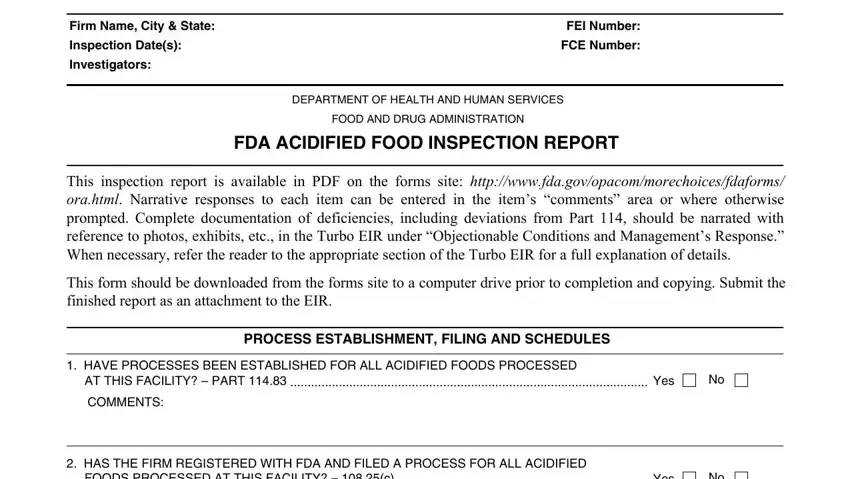

1. The Form Fda 3511 2 needs particular information to be inserted. Make sure the subsequent blank fields are complete:

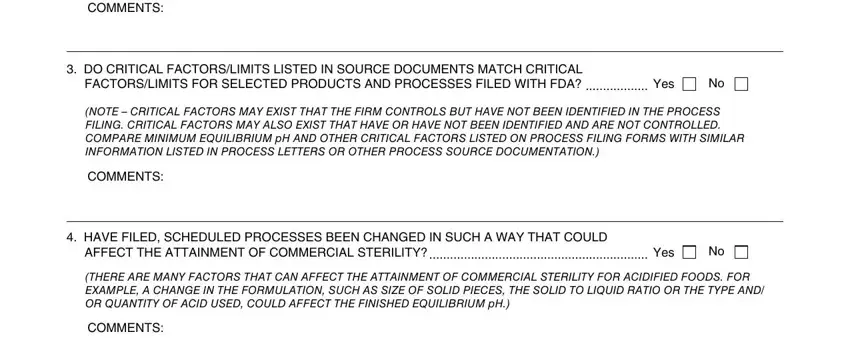

2. Once your current task is complete, take the next step – fill out all of these fields - COMMENTS, DO CRITICAL FACTORSLIMITS LISTED, Yes, NOTE CRITICAL FACTORS MAY EXIST, COMMENTS, HAVE FILED SCHEDULED PROCESSES, AFFECT THE ATTAINMENT OF, Yes, THERE ARE MANY FACTORS THAT CAN, and COMMENTS with their corresponding information. Make sure to double check that everything has been entered correctly before continuing!

3. The next part is generally hassle-free - fill out all of the form fields in ARE RAW PRODUCT MATERIALS, GRADING WASHING HYDRATING, Yes, COMMENTS, FORM FDA, PAGE of, and PSC Graphics EF to complete the current step.

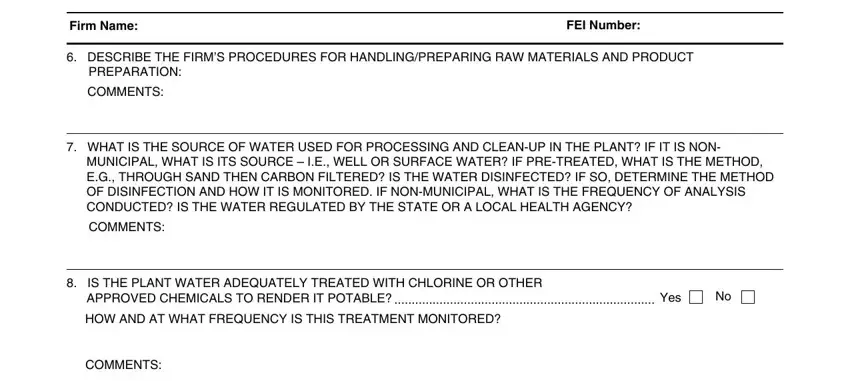

4. The form's fourth section comes with the next few blank fields to fill out: Firm Name, FEI Number, DESCRIBE THE FIRMS PROCEDURES FOR, PREPARATION, COMMENTS, WHAT IS THE SOURCE OF WATER USED, MUNICIPAL WHAT IS ITS SOURCE IE, COMMENTS, IS THE PLANT WATER ADEQUATELY, APPROVED CHEMICALS TO RENDER IT, Yes, HOW AND AT WHAT FREQUENCY IS THIS, and COMMENTS.

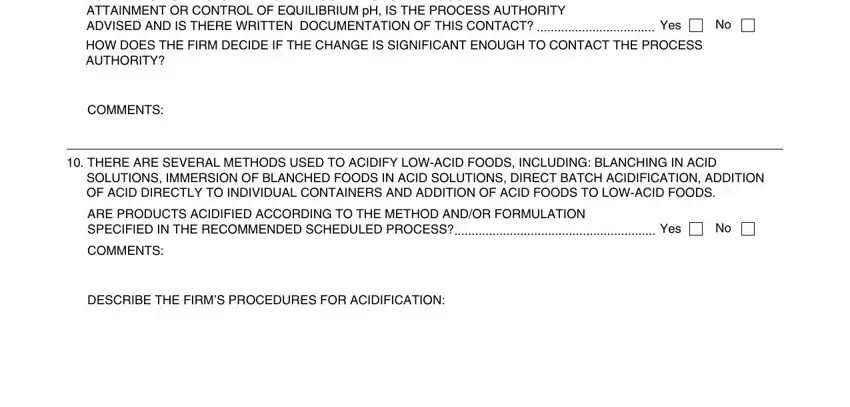

5. The very last section to finalize this PDF form is essential. You must fill in the displayed form fields, particularly ACIDIFYING AGENTS OR ANY OTHER, Yes, HOW DOES THE FIRM DECIDE IF THE, COMMENTS, THERE ARE SEVERAL METHODS USED TO, SOLUTIONS IMMERSION OF BLANCHED, ARE PRODUCTS ACIDIFIED ACCORDING, Yes, COMMENTS, and DESCRIBE THE FIRMS PROCEDURES FOR, before submitting. If not, it might produce an unfinished and potentially unacceptable form!

It's very easy to make an error when filling in the COMMENTS, consequently make sure you reread it before you submit it.

Step 3: Immediately after looking through the entries, hit "Done" and you are all set! After setting up afree trial account at FormsPal, you will be able to download Form Fda 3511 2 or send it via email at once. The PDF document will also be at your disposal via your personal account menu with your every change. We don't sell or share the details that you type in when filling out forms at FormsPal.