undersigned can be filled in online in no time. Simply make use of FormsPal PDF editing tool to do the job quickly. Our tool is constantly evolving to grant the very best user experience possible, and that's due to our resolve for continual development and listening closely to customer opinions. With some simple steps, you may start your PDF editing:

Step 1: Open the form inside our editor by pressing the "Get Form Button" above on this webpage.

Step 2: As you launch the editor, you will get the document made ready to be filled out. In addition to filling out various blanks, you could also perform some other things with the form, including writing your own text, modifying the original textual content, adding illustrations or photos, affixing your signature to the form, and a lot more.

Be attentive while filling in this form. Make certain each and every blank is done properly.

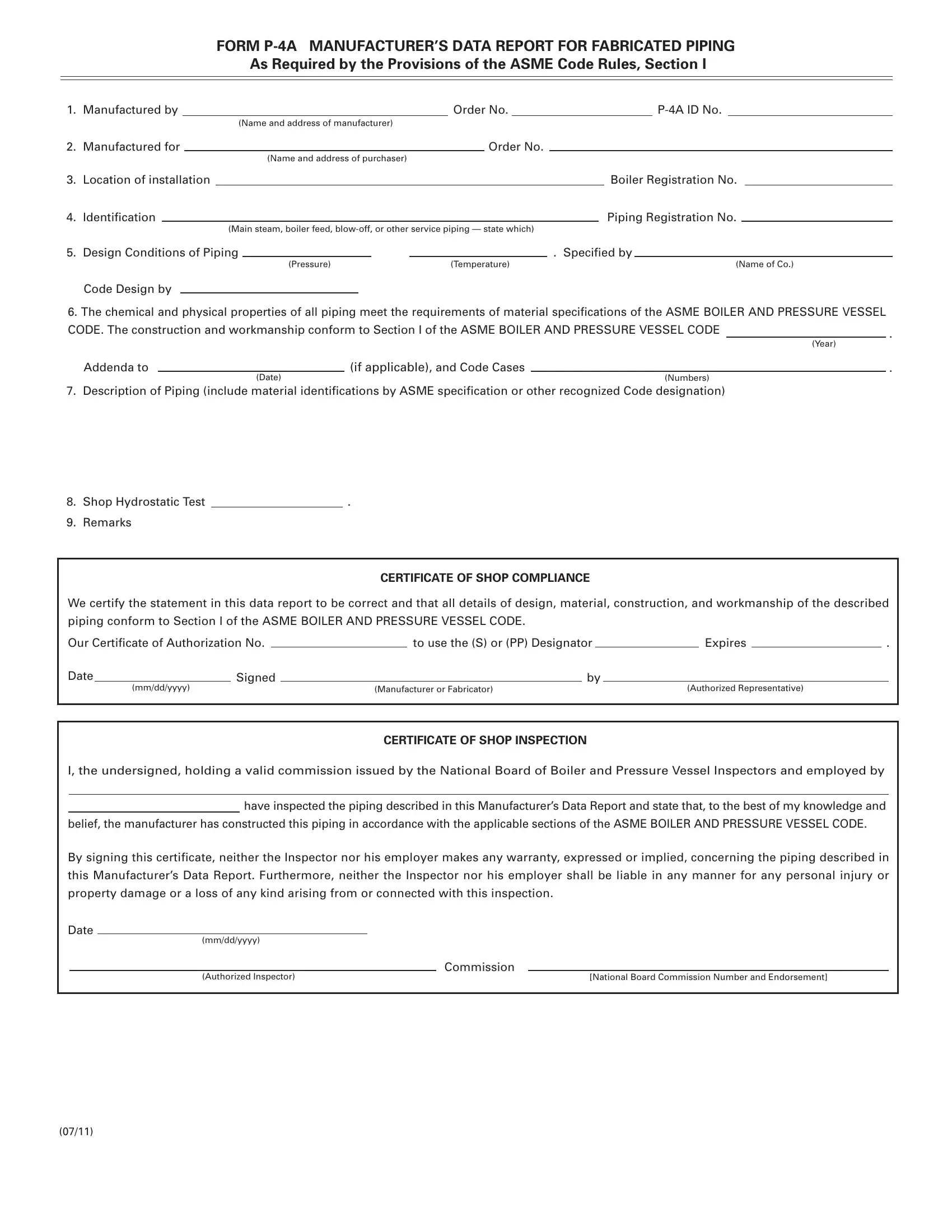

1. For starters, once filling out the undersigned, start with the section containing following blank fields:

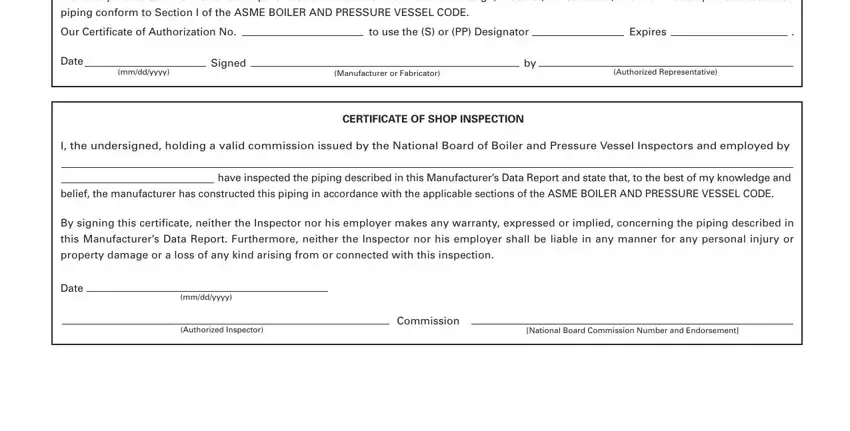

2. Once your current task is complete, take the next step – fill out all of these fields - We certify the statement in this, piping conform to Section I of the, Our Certificate of Authorization No, to use the S or PP Designator, Expires, Date, mmddyyyy, Signed, Manufacturer or Fabricator, Authorized Representative, CERTIFICATE OF SHOP INSPECTION, I the undersigned holding a valid, belief the manufacturer has, have inspected the piping, and By signing this certificate with their corresponding information. Make sure to double check that everything has been entered correctly before continuing!

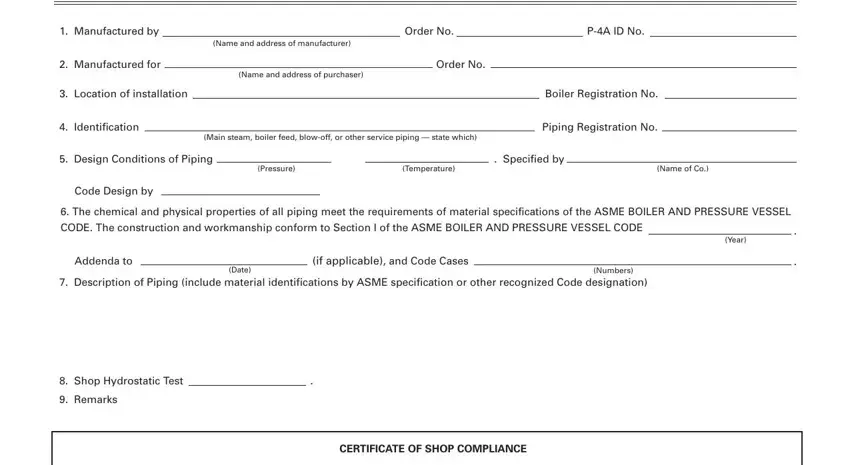

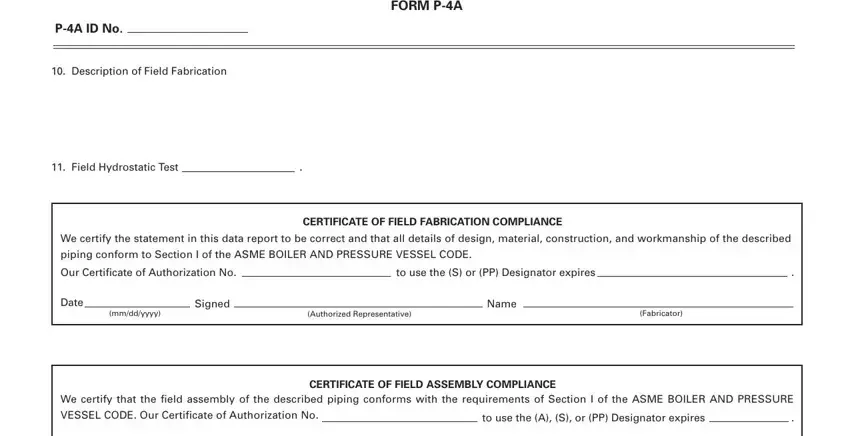

3. This next step is mostly about PA ID No, Description of Field Fabrication, FORM PA, Field Hydrostatic Test, We certify the statement in this, piping conform to Section I of the, Our Certificate of Authorization No, to use the S or PP Designator, CERTIFICATE OF FIELD FABRICATION, Date, Signed, Name, mmddyyyy, Authorized Representative, and Fabricator - fill out all these empty form fields.

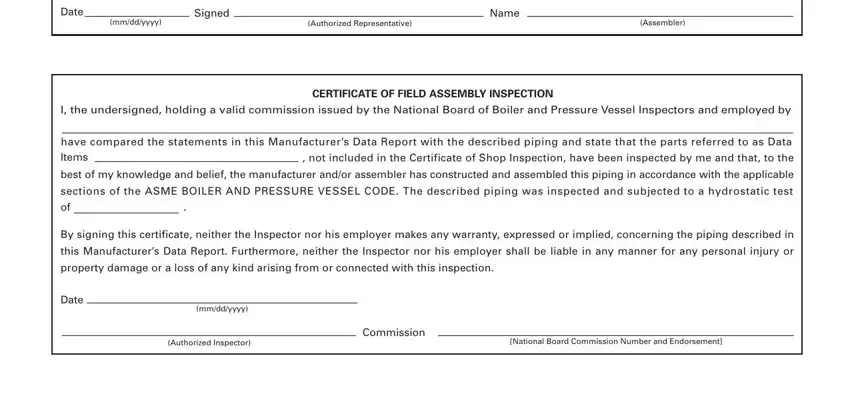

4. Completing Date, mmddyyyy, Signed, Authorized Representative, Assembler, Name, I the undersigned holding a valid, CERTIFICATE OF FIELD ASSEMBLY, have compared the statements in, Items, not included in the Certificate, best of my knowledge and belief, sections of the ASME BOILER AND, By signing this certificate, and this Manufacturers Data Report is crucial in the fourth stage - make sure to take your time and fill in every field!

Regarding Signed and Date, make certain you take a second look here. Both of these are the most important fields in this file.

Step 3: After double-checking the fields you have filled out, press "Done" and you're good to go! Get your undersigned after you sign up for a free trial. Readily get access to the pdf document in your personal account, along with any edits and changes being conveniently kept! Here at FormsPal, we aim to guarantee that all your information is kept secure.