You are able to fill out procedure qualification pqr online without difficulty with the help of our PDFinity® editor. Our team is committed to providing you with the ideal experience with our editor by regularly releasing new capabilities and enhancements. With all of these updates, using our tool becomes better than ever! All it requires is just a few simple steps:

Step 1: Hit the "Get Form" button above. It is going to open our pdf tool so you can begin filling out your form.

Step 2: When you launch the file editor, you will notice the document all set to be completed. Aside from filling out various blank fields, you may as well do many other actions with the PDF, such as putting on your own words, modifying the initial textual content, inserting images, placing your signature to the form, and more.

This PDF form requires specific details; in order to ensure correctness, make sure you adhere to the suggestions listed below:

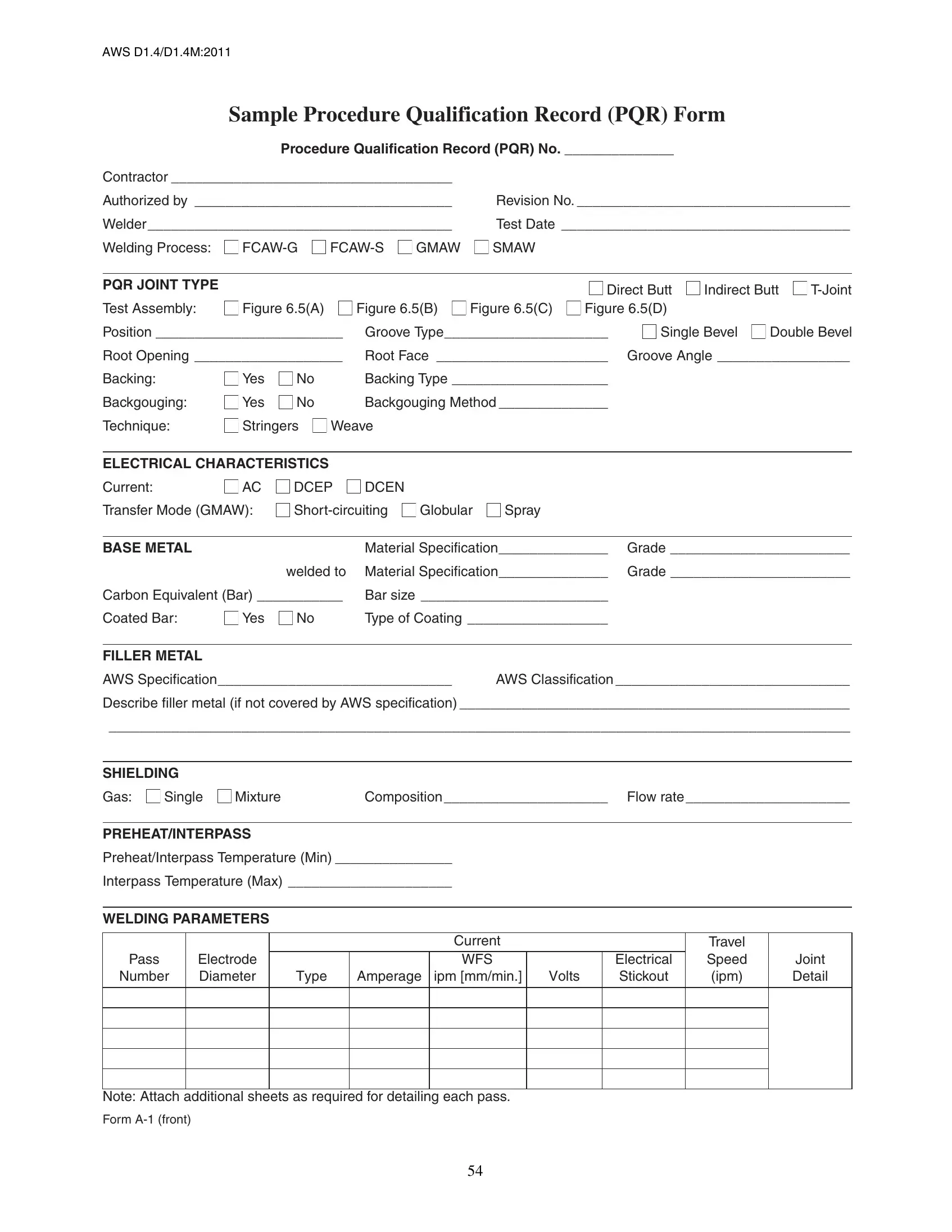

1. The procedure qualification pqr online usually requires specific information to be entered. Ensure that the subsequent blanks are filled out:

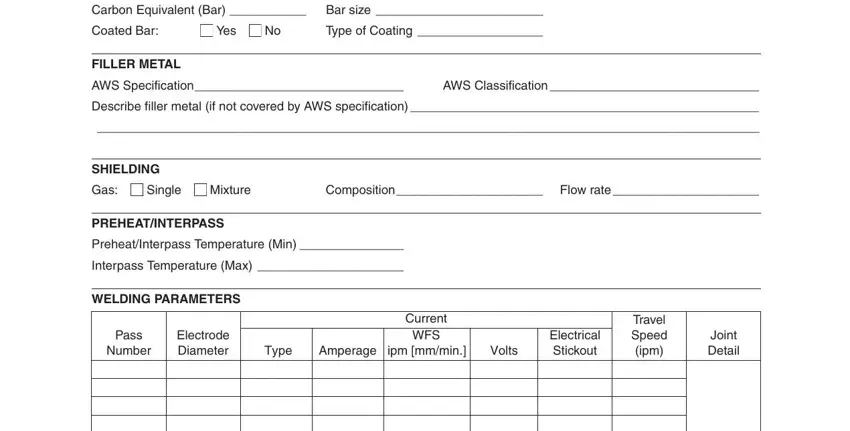

2. When the last section is complete, it is time to insert the essential specifics in Carbon Equivalent Bar, Bar size, Coated Bar, Yes, Type of Coating, FILLER METAL, AWS Specification, AWS Classification, Describe filler metal if not, SHIELDING, Gas, Single, Mixture, Composition, and Flow rate allowing you to move forward to the third step.

3. Your next step is going to be easy - complete all the blanks in Note Attach additional sheets as, and Form A front to conclude the current step.

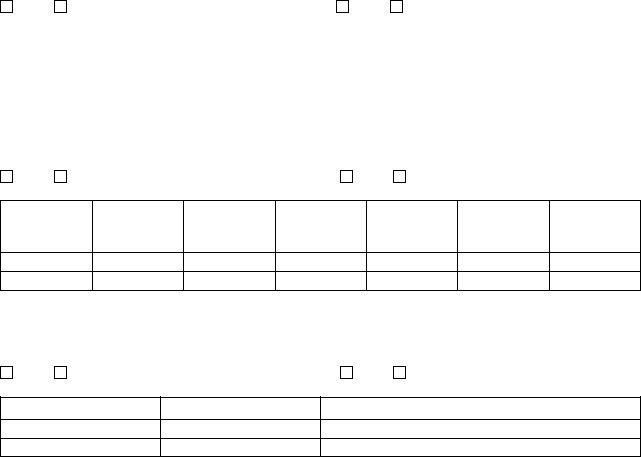

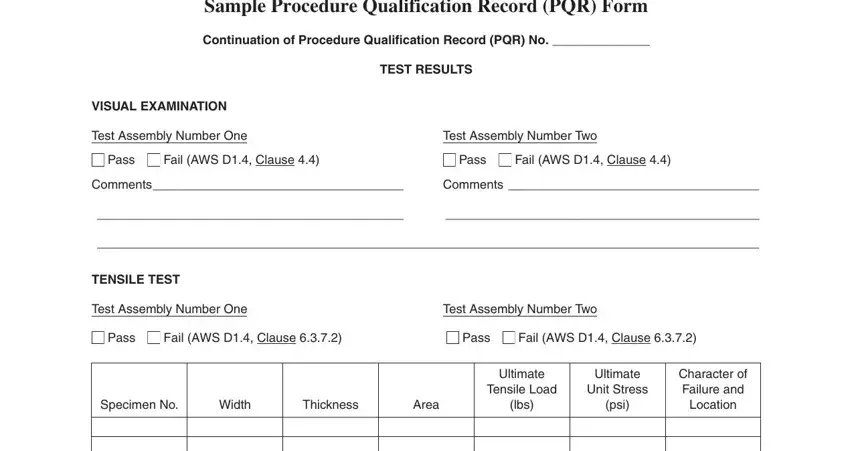

4. Your next part will require your input in the following parts: Sample Procedure Qualification, Continuation of Procedure, TEST RESULTS, VISUAL EXAMINATION, Test Assembly Number One, Test Assembly Number Two, Pass, Fail AWS D Clause, Pass, Fail AWS D Clause, Comments, Comments, TENSILE TEST, Test Assembly Number One, and Test Assembly Number Two. Always fill in all needed info to move forward.

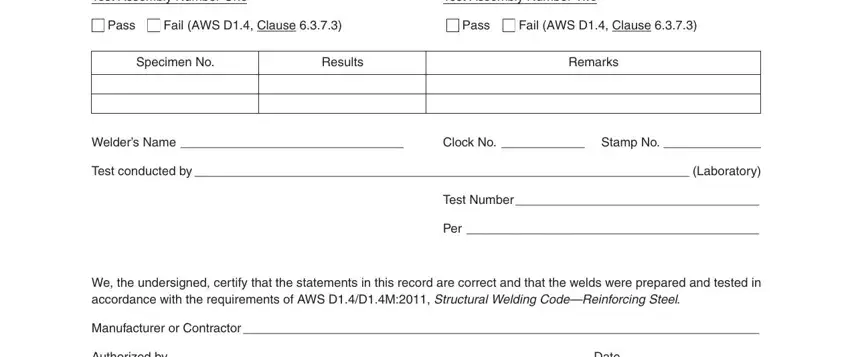

5. This document has to be concluded by going through this part. Here there can be found a detailed set of fields that need to be filled in with correct information to allow your form submission to be faultless: Test Assembly Number One, Test Assembly Number Two, Pass, Fail AWS D Clause, Pass, Fail AWS D Clause, oN nemicepS, stluseR, skrameR, Welders Name, Clock No Stamp No, Test conducted by Laboratory, Test Number, Per, and We the undersigned certify that.

As to stluseR and Test conducted by Laboratory, ensure that you double-check them here. These two could be the key fields in the page.

Step 3: After you've reread the information in the file's blanks, click "Done" to finalize your document creation. After registering afree trial account at FormsPal, you will be able to download procedure qualification pqr online or send it through email right away. The form will also be readily accessible via your personal cabinet with your each change. When you work with FormsPal, you can fill out forms without being concerned about personal data leaks or entries being distributed. Our protected platform ensures that your personal information is maintained safely.