nfpa 13 underground form can be completed online without any problem. Simply open FormsPal PDF tool to get the job done quickly. In order to make our tool better and simpler to utilize, we continuously implement new features, taking into account suggestions from our users. To start your journey, go through these basic steps:

Step 1: Open the PDF file in our tool by hitting the "Get Form Button" above on this page.

Step 2: The editor grants the ability to modify PDF files in various ways. Enhance it by writing any text, correct existing content, and put in a signature - all manageable within a few minutes!

With regards to the blank fields of this specific form, this is what you should do:

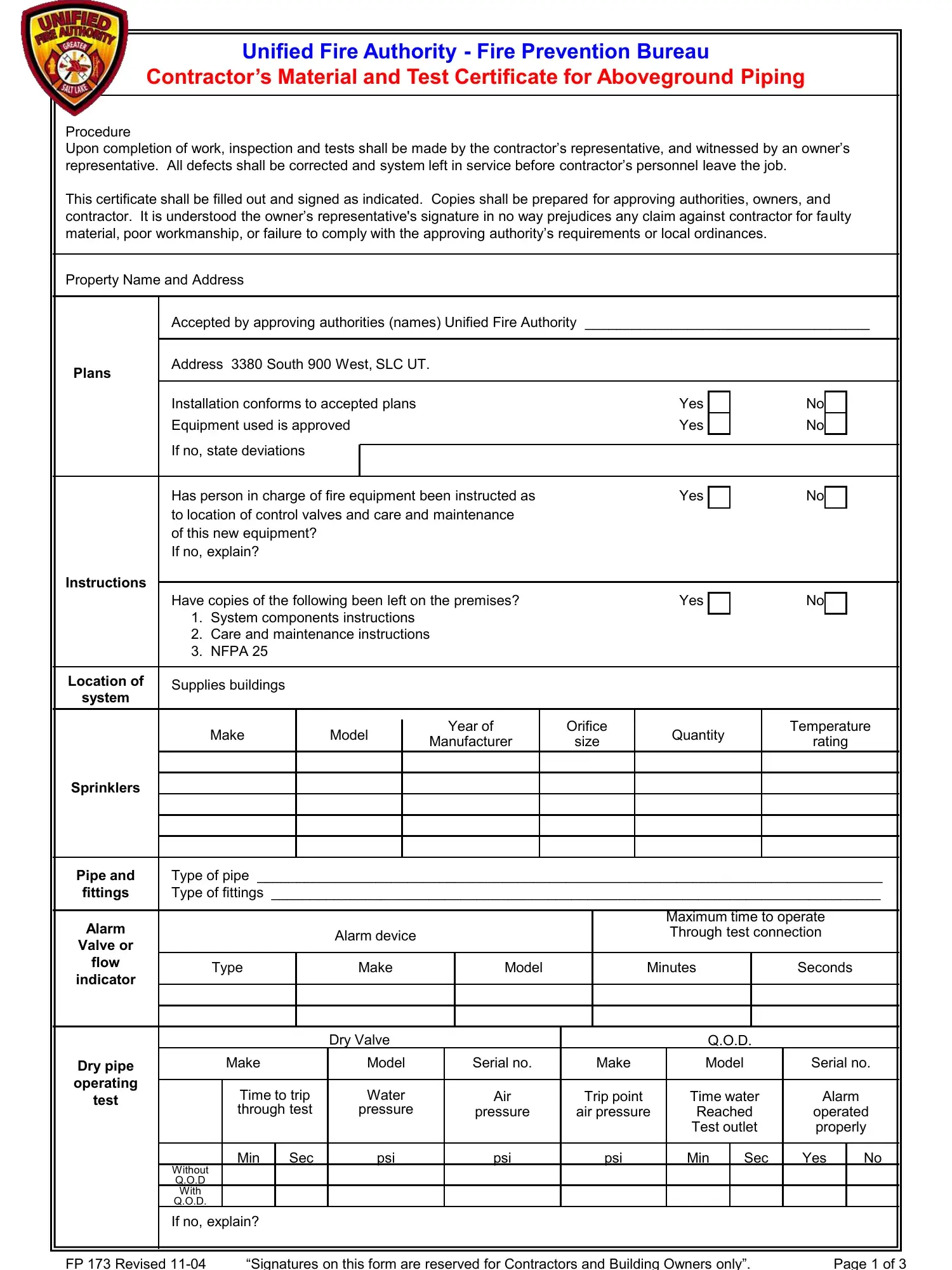

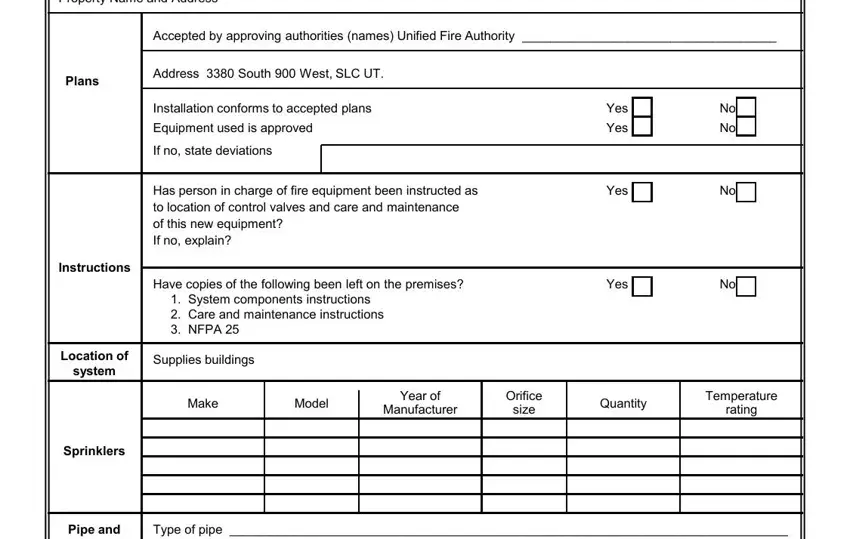

1. Before anything else, once filling out the nfpa 13 underground form, start out with the form section that has the next blanks:

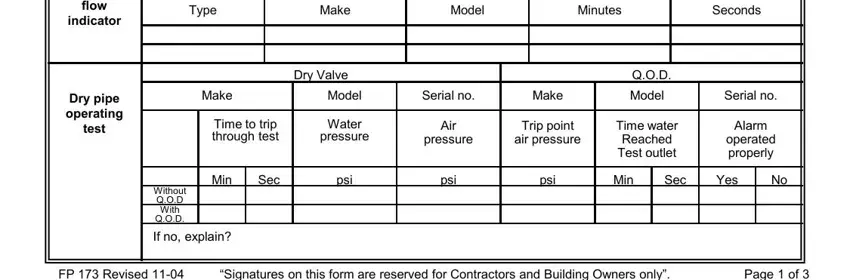

2. Right after filling out this step, head on to the subsequent stage and complete the essential details in these blanks - Type, Make, Model, Minutes, Seconds, Dry Valve, Make, Model, Serial no, Make, Time to trip through test, Water, pressure, Air, and pressure.

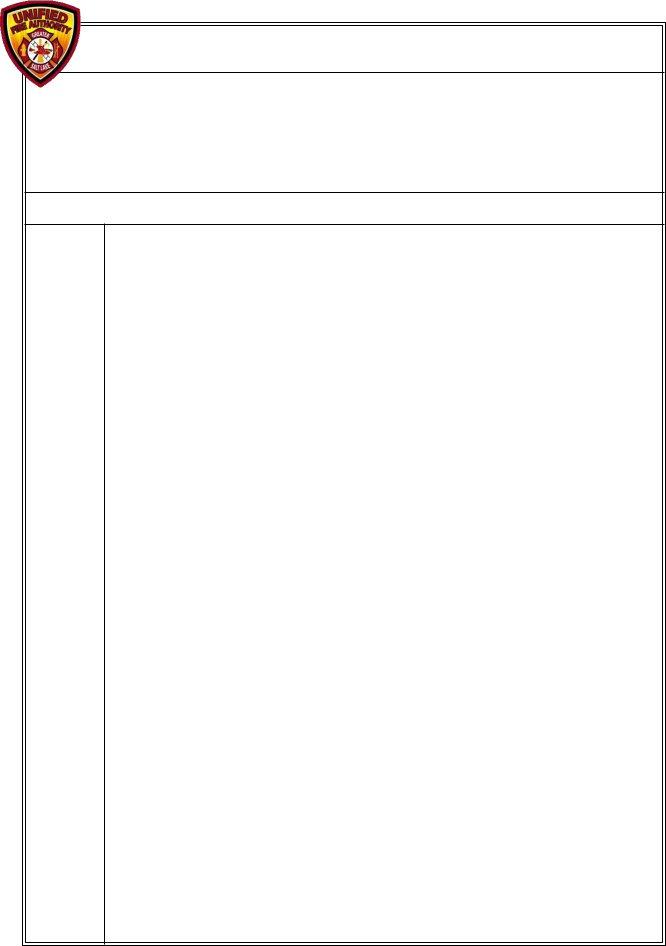

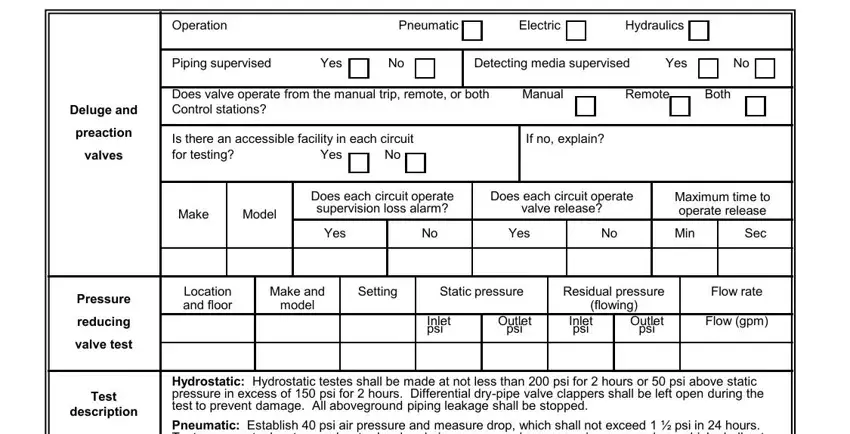

3. The following part is all about Deluge and, preaction, valves, Pressure, reducing, valve test, Test, description, Operation, Pneumatic, Electric, Hydraulics, Piping supervised, Yes No, and Detecting media supervised Yes No - type in every one of these blank fields.

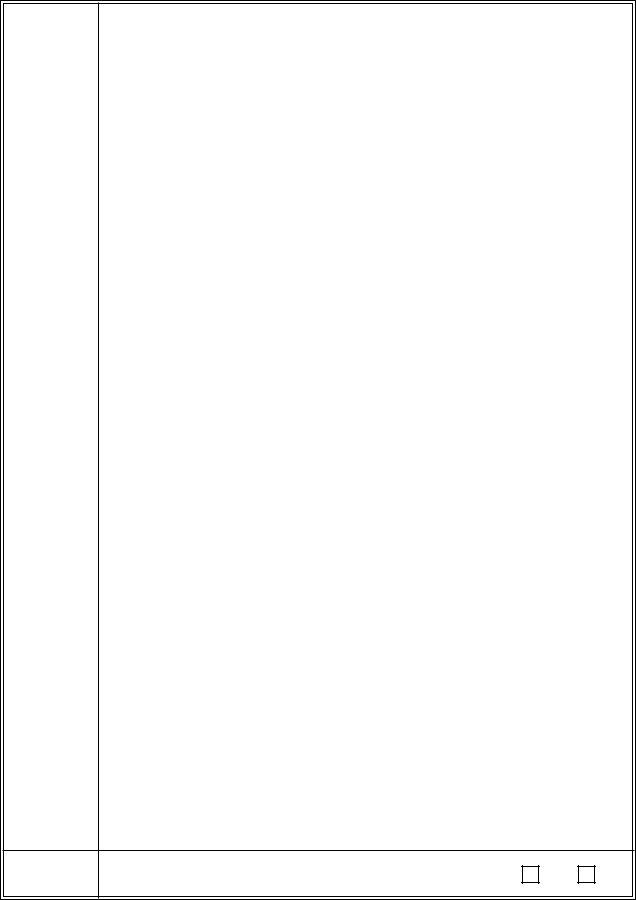

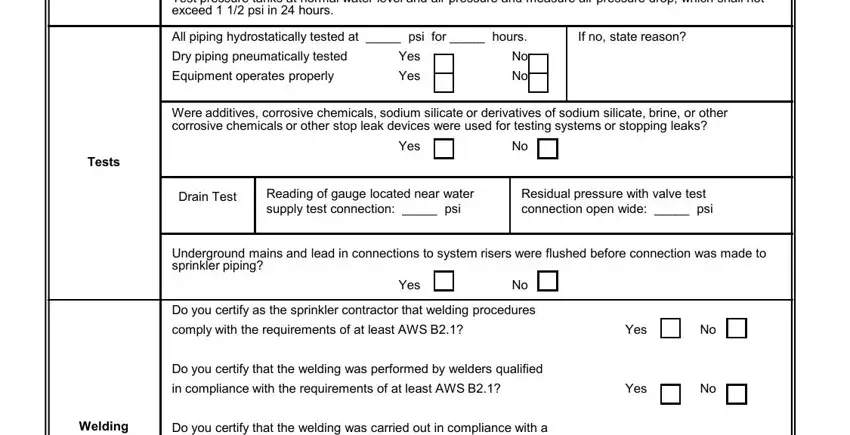

4. This particular paragraph arrives with all of the following fields to enter your particulars in: Tests, Pneumatic Establish psi air, All piping hydrostatically tested, If no state reason, Dry piping pneumatically tested, Equipment operates properly, Yes, Yes, Were additives corrosive chemicals, Yes, Drain Test, Reading of gauge located near, Residual pressure with valve test, Underground mains and lead in, and Yes.

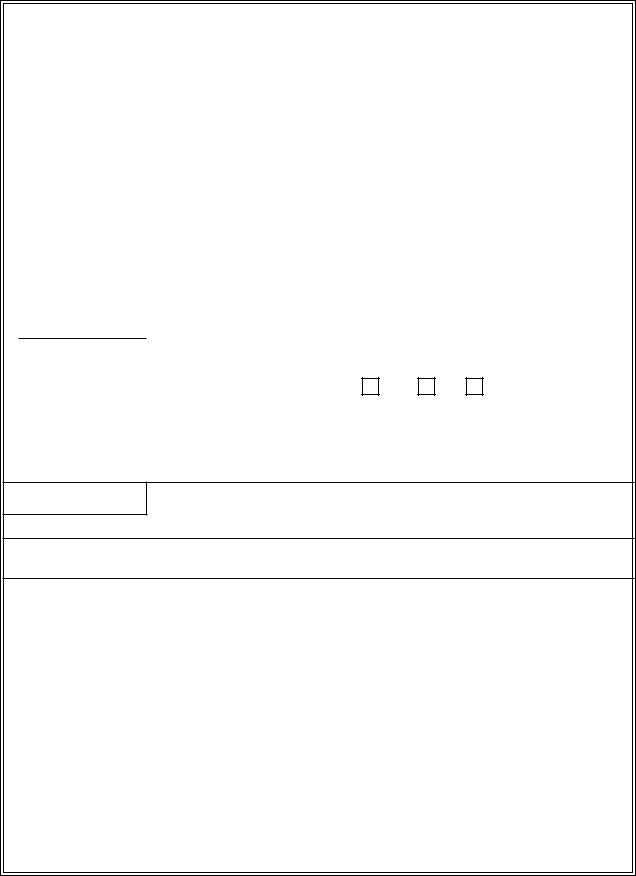

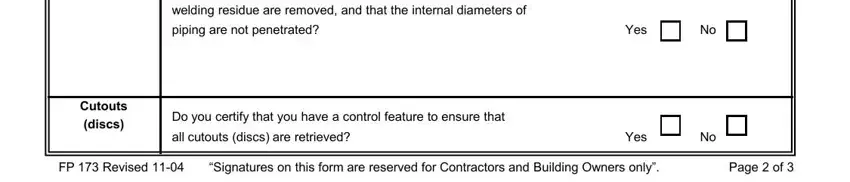

5. This document must be finished by filling in this part. Below you will see a comprehensive list of blank fields that require accurate details for your document submission to be accomplished: welding residue are removed and, piping are not penetrated, Yes No, Cutouts, discs, Do you certify that you have a, all cutouts discs are retrieved, Yes No, FP Revised Signatures on this, and Page of.

Always be extremely attentive while filling out Yes No and piping are not penetrated, as this is where a lot of people make mistakes.

Step 3: Before moving forward, you should make sure that form fields have been filled in correctly. As soon as you verify that it's fine, click “Done." Join FormsPal today and immediately get nfpa 13 underground form, set for downloading. All adjustments you make are saved , allowing you to customize the pdf at a later stage if necessary. We don't sell or share any details you type in when working with forms at our website.