It is possible to fill out the haccp plan example form with this PDF editor. These actions will assist you to immediately create your document.

Step 1: To start out, hit the orange button "Get Form Now".

Step 2: Now you are going to be on the file edit page. You can add, update, highlight, check, cross, include or erase areas or words.

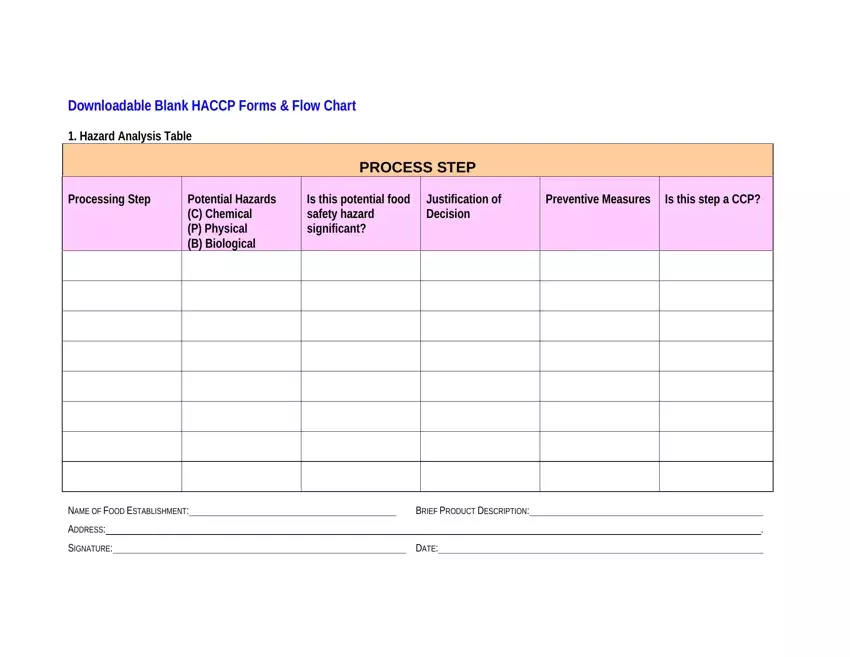

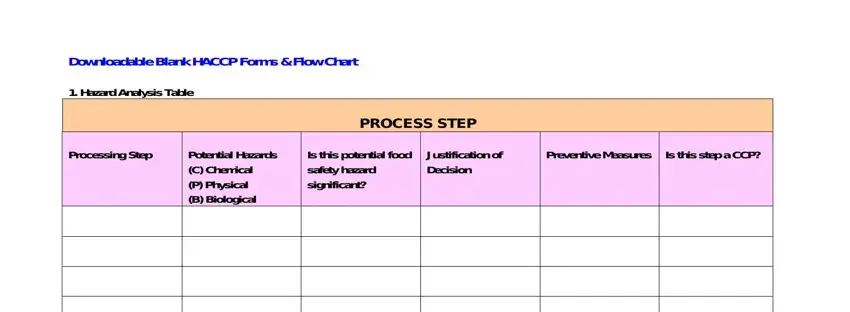

To prepare the haccp plan example PDF, enter the details for each of the sections:

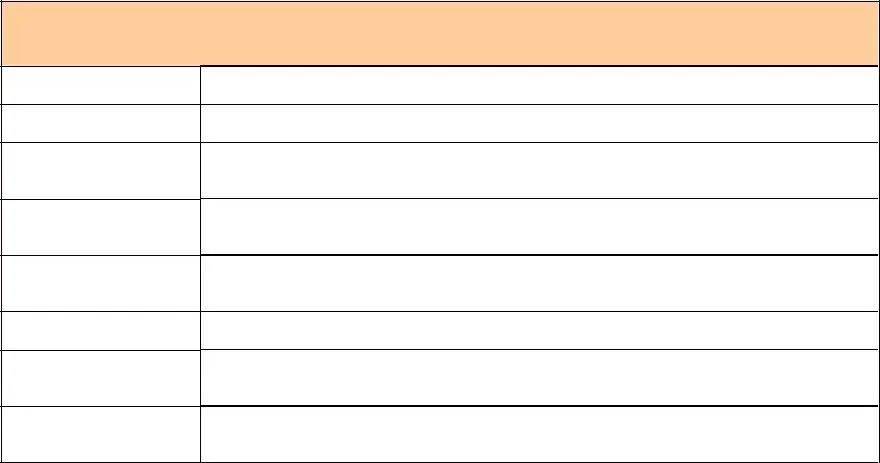

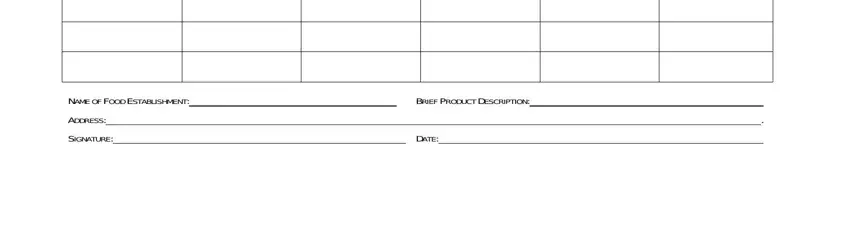

Make sure you enter your information in the part NAME OF FOOD ESTABLISHMENT, BRIEF PRODUCT DESCRIPTION, ADDRESS, SIGNATURE, and DATE.

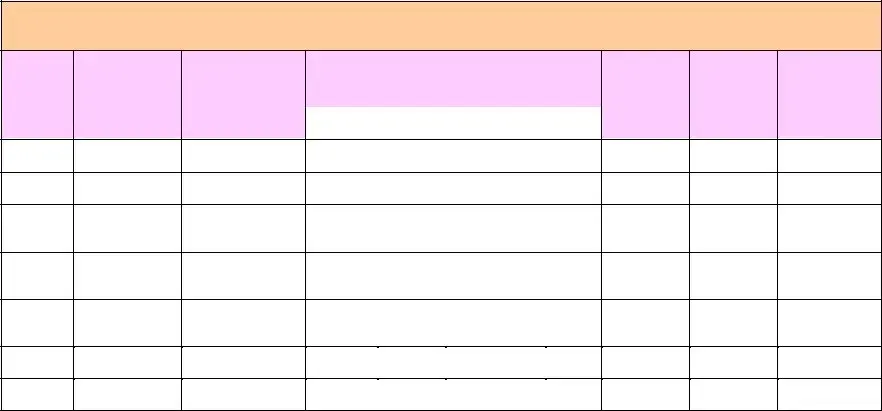

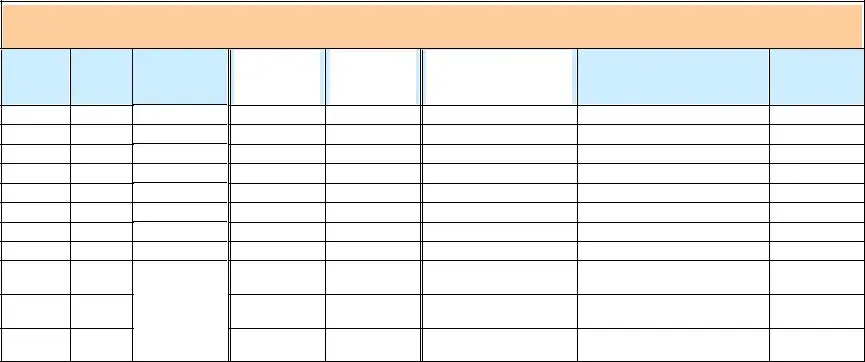

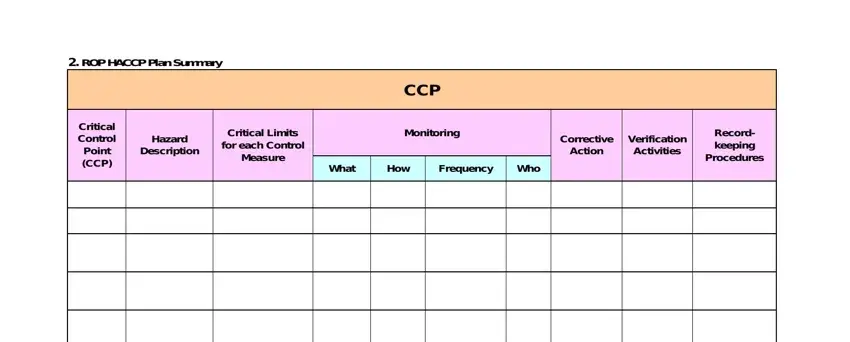

It is vital to write down particular data within the area ROP HACCP Plan Summary, Critical Control Point CCP, Hazard Description, Critical Limits for each Control, CCP, Monitoring, What, How, Frequency, Who, Corrective Action, Verification Activities, and Record keeping Procedures.

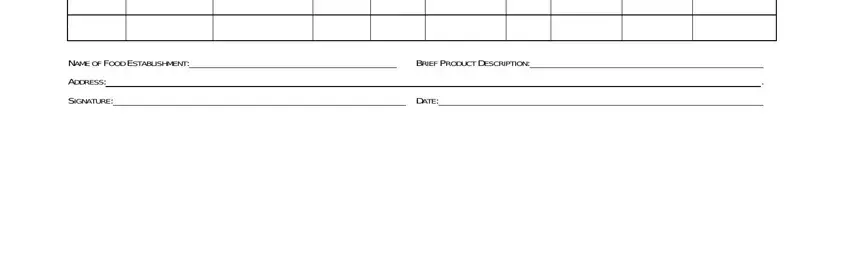

It's essential to identify the rights and responsibilities of every party in section NAME OF FOOD ESTABLISHMENT, BRIEF PRODUCT DESCRIPTION, ADDRESS, SIGNATURE, and DATE.

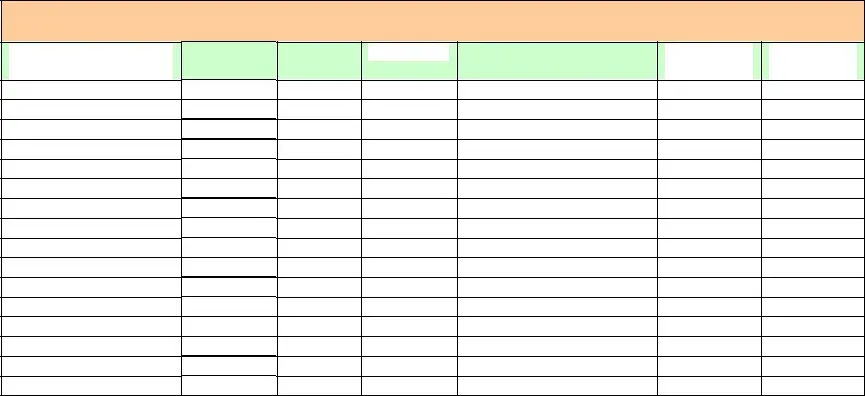

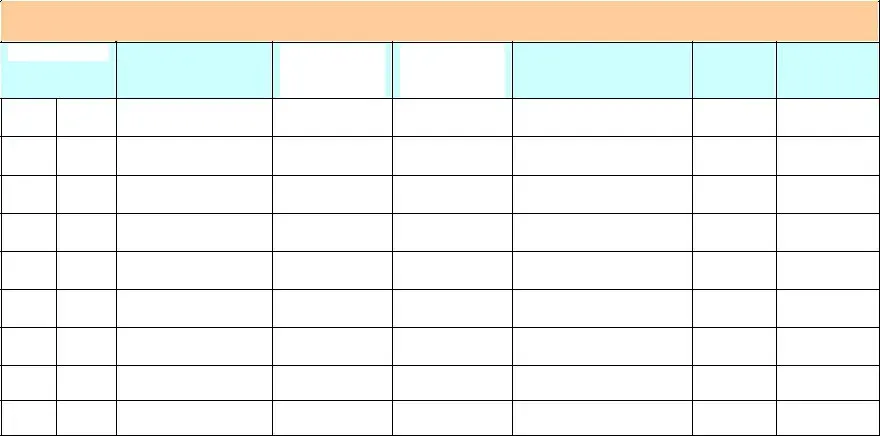

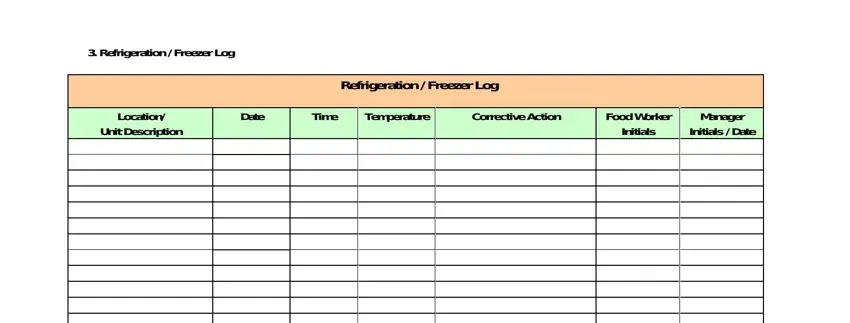

Prepare the document by analyzing these particular sections: Refrigeration Freezer Log, Refrigeration Freezer Log, Location Unit Description, Date, Time, Temperature, Corrective Action, Food Worker Initials, and Manager Initials Date.

Step 3: When you have selected the Done button, your document should be ready for export to every device or email you indicate.

Step 4: Get duplicates of the template. It will prevent future worries. We cannot view or share the information you have, therefore you can be confident it will be safe.