Ensuring the safety and efficiency of cranes and hoisting equipment is critical, particularly in industries where the lifting and moving of heavy materials are daily tasks. The Hoist Inspection Checklist form, as outlined by the USACE Galveston District Safety and Health Requirements Manual (EM 385-1-1 15/sep/2008), serves as a comprehensive tool designed to guide thorough inspections of such equipment. It encompasses a wide array of checkpoints, including inspector qualifications, availability of operator manuals, condition of wire ropes, and the presence of all necessary safety devices. Moreover, the form demands the verification of operator qualifications, the condition of critical components such as brakes, clutches, and controls, and the inclusion of safety features like rollover protective structures and warning devices. Documentation, such as the report of crane test outcomes which must align with the manufacturer's recommendations and not exceed the specified load ratings, plays a key role in affirming the equipment's readiness and safety. Additionally, it records attachments that are essential for operation, including plans for electrical clearance and communications systems, further underscoring the emphasis on preemptive safety measures. The checklist culminates in a section detailing the observed condition of various components, ranging from load charts to specific parts like hooks, blocks, and drums, alongside a segment for noting any deficiencies and corrective actions taken. This meticulous approach ensures that cranes and hoisting equipment are not only compliant with mandated safety regulations but are also in optimal working condition, thereby safeguarding the well-being of all individuals on-site.

| Question | Answer |

|---|---|

| Form Name | Hoist Inspection Checklist Form |

| Form Length | 3 pages |

| Fillable? | No |

| Fillable fields | 0 |

| Avg. time to fill out | 45 sec |

| Other names | Hoist Safety Inspection Form, Pre-Use and Monthly Inspection Checklist Form for Overhead Cranes and Hoists |

SAFETY INSPECTION FOR CRANES AND HOISTING EQUIPMENT

USACE, Galveston District

Safety and Health Requirements Manual (EM

Contract No. |

|

|

|

Date of Inspection: |

|

|

|

||||||

Prime contractor Name: |

|

|

|

|

|

|

|

|

|||||

Inspector Name/signature: |

|

|

|

|

|

|

|

|

|||||

Make: |

|

Name of competent person: |

|

|

|

||||||||

|

|

|

|

|

|

|

|

||||||

Model: |

|

|

Signature of CP/QP: |

|

|

|

|||||||

Serial no. |

|

|

|

|

|

|

|

|

|||||

|

|

|

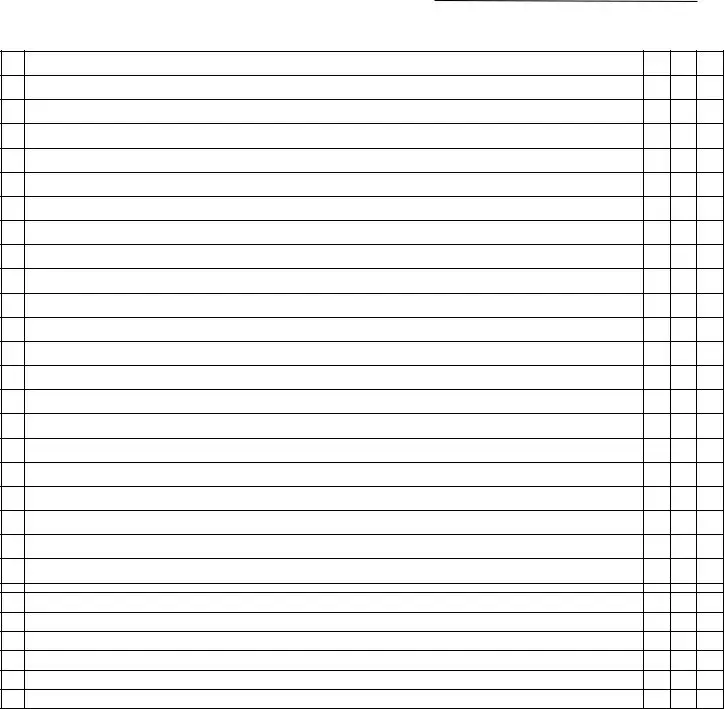

CRANE INSPECTION CHECKLIST |

yesn no n/a |

|||||||||

1Inspector Qualification and Certification - 16.D.02

2 Operator manual available in the cab - 16.A.03

3 Documents of certified mechanic inspection

4 Does equipment have and in working condition: 16.A.08 A- Fuel gage

B- Auditable warning devise (horn) C- Adequate rearview mirrors

D-

E- Power operator starting device F- A seat for the operator

G- At minimum two head lights and two taillights H- Windshield, windows and door

I- A fire extinguisher

J- A Back or motion alarm

K- Rollover protective

5 Operator manual for hydraulic equipment and attachment- 16.A.10 6 Are all guarding and safety devices in place- 16.A.11

7 Operator qualification and certificated available- 16.B.01

8 Is wire rope in good condition in accordance with- 16.D.12 9 Are all documents available in the cab- 16.G.01

10Is load test in accordance with- 16.F.03.b

11Is a

Attachments:

AHA for crane

Communications system

Electrical clearance plan

Critical lift plan

SWG form |

Previous Edition Obsolete |

19/Aug/2010 |

|

Report of Crane Test: |

|

|

|

|

|

|

|

Government Owned: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Contractor Owned/Rented: |

|

If Rented who Owned: |

|

|

|

|

|

|

|

|

|

|

|

|

|

Length of boom: |

|

|

|

|

|

|

|

Manufacture Rate Capacity: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Max Work Load Anticipated: |

Tons : |

Radius Ft: |

|

|

|

|

|

Position # 1 |

Load: |

|

Radius: |

|

|

|

|

|

|

|

|

|

|

|

|

Position # 2 |

Load: |

|

Radius: |

|

|

|

|

|

|

|

|

|

|

|

|

Position # 3 |

Load: |

|

Radius: |

|

|

|

|

Position # 4 |

Load: |

|

Radius: |

|

|

|

|

|

|

|

|

|

|

|

|

Results of Performance Test: |

|

|

|

|

|

|

|

|

|

|

|

|||

|

Note: Performance load test shall be conducted in accordance with the manufacturer's |

|

|

|

|||

|

recommendations. Loads test shall not exceed 100% of the manufacturer's load rating capacity |

|

|

|

|||

|

|

|

|

|

|

||

|

chart at the configuration of the test. |

|

|

|

|

||

|

|

|

|

|

|||

|

The test shall consist of lifting, lowering, swinging and braking the test load through all |

|

|

|

|||

|

positions and operations normally performed to demonstrated the equipment's ability to safety |

|

|

|

|||

|

|

|

|

|

|

|

|

|

maneuver the load. |

|

|

|

|

|

|

|

Written reports of the rated load test, showing test procedures and confirming the adequacy |

|

|

|

|||

|

|

|

|

|

|||

|

of repairs or alterations, shall be maintains with the crane, derrick or at the |

|

|

|

|||

|

|

|

|

|

|

||

|

|

|

|

|

|

||

|

Condition of following: |

S= serviceable U= unserviceable N/A= |

S |

U |

N/A |

||

|

|

|

|

|

|

|

|

|

Load Chart |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Boom hoist kick out |

|

|

|

|

|

|

|

Interior clean and oil free |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hearing protection available |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Operable warning device |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

load indicating device |

|

|

|

|

|

|

|

Bulkhead lifting device |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Boom angle indicator |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Drum rotation sensor |

|

|

|

|

|

|

|

Engine throttle and controls |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Swing controls, clutches and brakes |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Swing lock |

|

|

|

|

|

|

|

Boom hoist controls, clutches and brakes |

|

|

|

|

||

|

|

|

|

|

|

||

|

Main drum controls, clutches and brakes |

|

|

|

|

||

|

|

|

|

|

|

||

|

Aux. drum controls, clutches and brakes |

|

|

|

|

||

|

Travel controls, clutches and brakes |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Master clutch |

|

|

|

|

|

|

|

Hoist lines- main, aux. and boom |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hooks, blocks |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Drums |

|

|

|

|

|

|

|

Rope anchor on drum |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Shavers, rollers, equalizers |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Crawler chain, tracks, sprockets, rollers |

|

|

|

|

||

|

Rotating parts guarded |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mast jib and live mast |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SWG form |

Previous Edition Obsolete |

19/Aug/2010 |

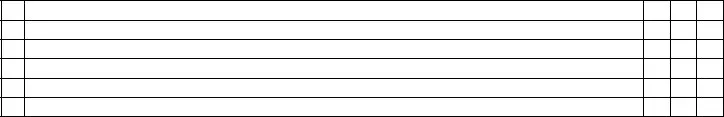

Condition of following: (Continuing)

Boom and jib:

Cords, lacings, pins and cotter

Welds, foot and hinge pins

Ware pads and blackstrap

Boom stop

Remarks:

All dents, scratches or damage that do not interfere with the safe operation of the equipment

1- ___________________________________________________________________________________

2- ___________________________________________________________________________________

3- ___________________________________________________________________________________

4- ___________________________________________________________________________________

5- ___________________________________________________________________________________

Corrections of Deficiencies and date corrected:

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

Note: Crane shall not be utilized until all deficiencies have been corrected. If at anytime the crane or derrick is removed from and subsequently returned to the project it shall be

Name and Signatures: |

|

|

|

Prime Contractor Superintendent: ____________________ |

____________________________ |

||

Prime Contractor Quality Control Rep: ___________________ |

__________________________ |

||

Subcontractor Forman: ___________________ |

_____________________________ |

||

Crane Operator: _____________________ |

|

______________________________ |

|

QA/PE : _______________________ |

_________________________________ |

||

SWG form |

Previous Edition Obsolete |

19/Aug/2010 |