It's very easy to fill out the aerial lift training card empty blanks. Our software will make it almost effortless to edit any type of PDF file. Down the page are the only four steps you should take:

Step 1: Hit the button "Get form here" to access it.

Step 2: When you get into the aerial lift training card editing page, there'll be lots of the actions you can undertake with regards to your template within the upper menu.

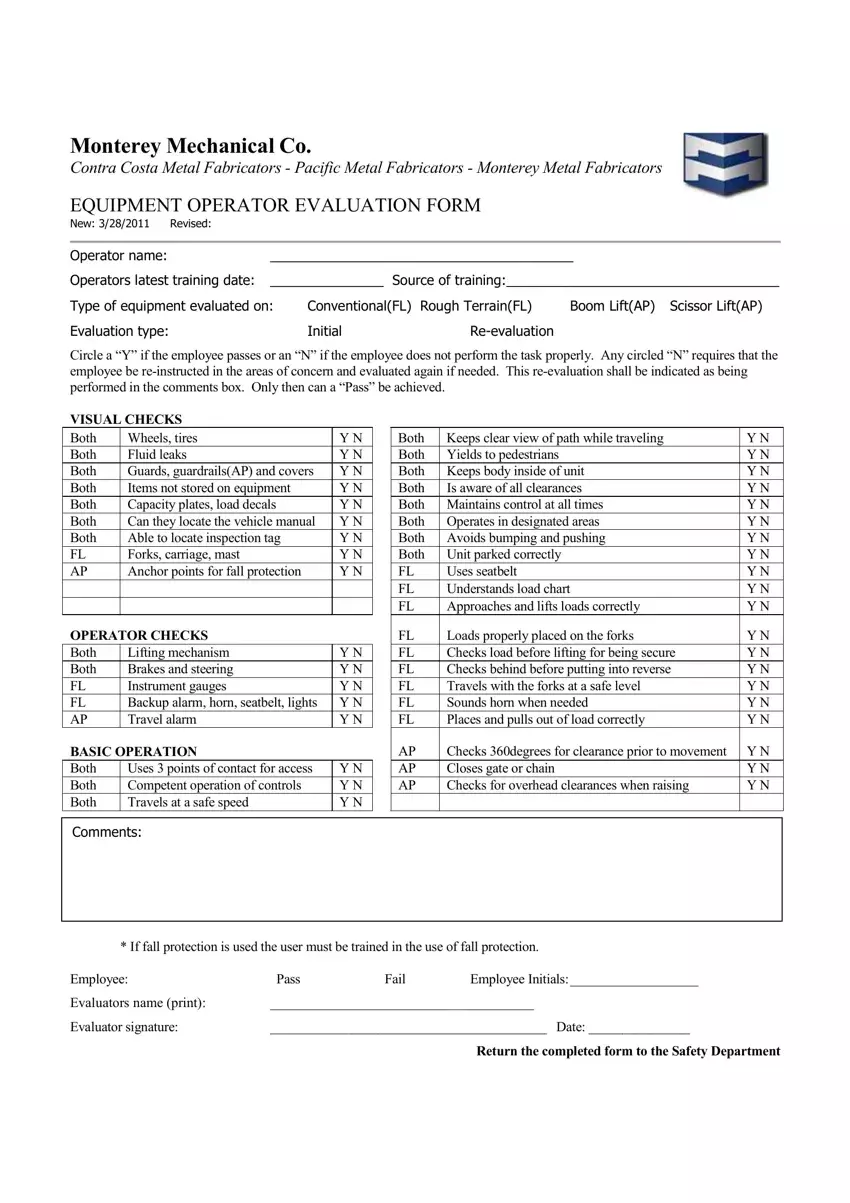

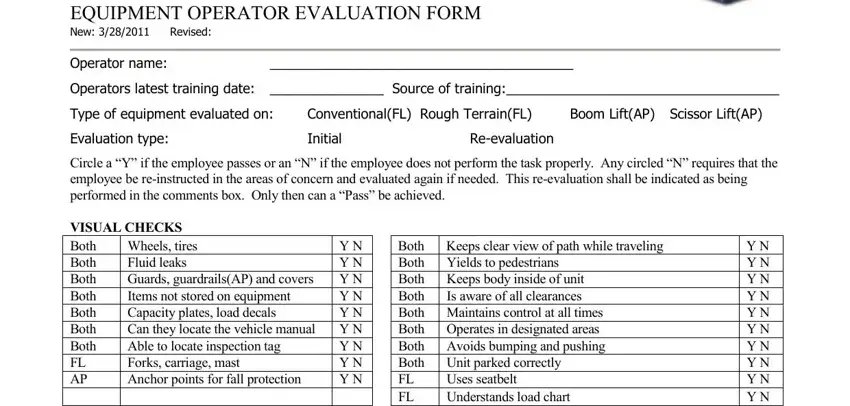

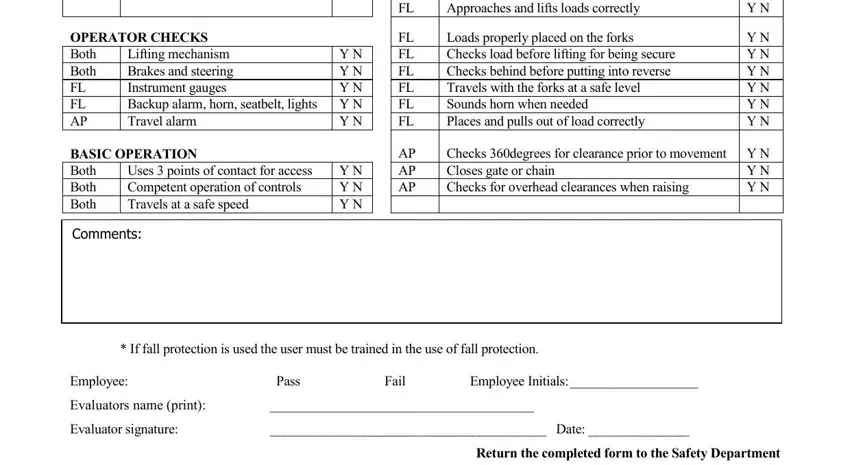

All of the following parts are what you will need to fill out to get your prepared PDF form.

Put the asked data in the OPERATOR CHECKS Both Both FL FL AP, Lifting mechanism Brakes and, BASIC OPERATION Both Both Both, Uses points of contact for access, Comments, Y N Y N Y N Y N Y N, Y N Y N Y N, Both Both Both Both Both Maintains, FL FL FL FL FL FL, AP AP AP, Loads properly placed on the forks, Checks degrees for clearance prior, Y N Y N Y N Y N Y N Y N Y N Y N Y, Y N Y N Y N Y N Y N Y N, and Y N Y N Y N segment.

Step 3: Choose the Done button to save the document. So now it is at your disposal for transfer to your gadget.

Step 4: Create copies of your document - it can help you prevent potential future difficulties. And don't get worried - we cannot disclose or read your data.