The SBD 9927 form serves as a critical document within the scope of Wisconsin's public health and safety measures, specifically under the auspices of the Wisconsin Department of Safety and Professional Services. This form is integral to the Cross-Connection Control Performance Test, ensuring that backflow preventers installed within the state's water systems function correctly to safeguard the potable water supply from contamination through backflow. It is a detailed register that captures a comprehensive spectrum of information, including owner details, facility specifics, and the technical data of the backflow prevention assembly being tested. Notably, the form emphasizes the necessity for the device to undergo testing upon installation, following any repairs, and annually thereafter, to be conducted by a department-registered Cross Connection Control Device Tester. Covering various assembly types like Reduced Pressure Principle (RP), Pressure Vacuum Breaker (PVB), and Spill Resistant Vacuum Breaker (SVB), among others, the form outlines the precise requirements for a passing test, such as the closure tightness of checks and the operational metrics of relief valves. The document highlights the shift towards digital submissions for reduced fees, indicating a move by the department to streamline processes and encourage compliance. Moreover, it underscores the legal obligations of device owners and enshrines the principle of protecting water quality through meticulous backflow prevention device testing and maintenance.

| Question | Answer |

|---|---|

| Form Name | Sbd 9927 Form |

| Form Length | 2 pages |

| Fillable? | No |

| Fillable fields | 0 |

| Avg. time to fill out | 30 sec |

| Other names | apps2, fillable 10754, gpm, rp |

|

Phone: |

|

Wisconsin Department of Safety and Professional Services |

Web: http://dsps.wi.gov |

|

Email: dsps@wisconsin.gov |

||

Division of Industry Services |

||

|

||

1400 East Washington Avenue |

Scott Walker, Governor |

|

PO Box 7302 |

||

Madison WI |

Laura Gutierrez, Secretary |

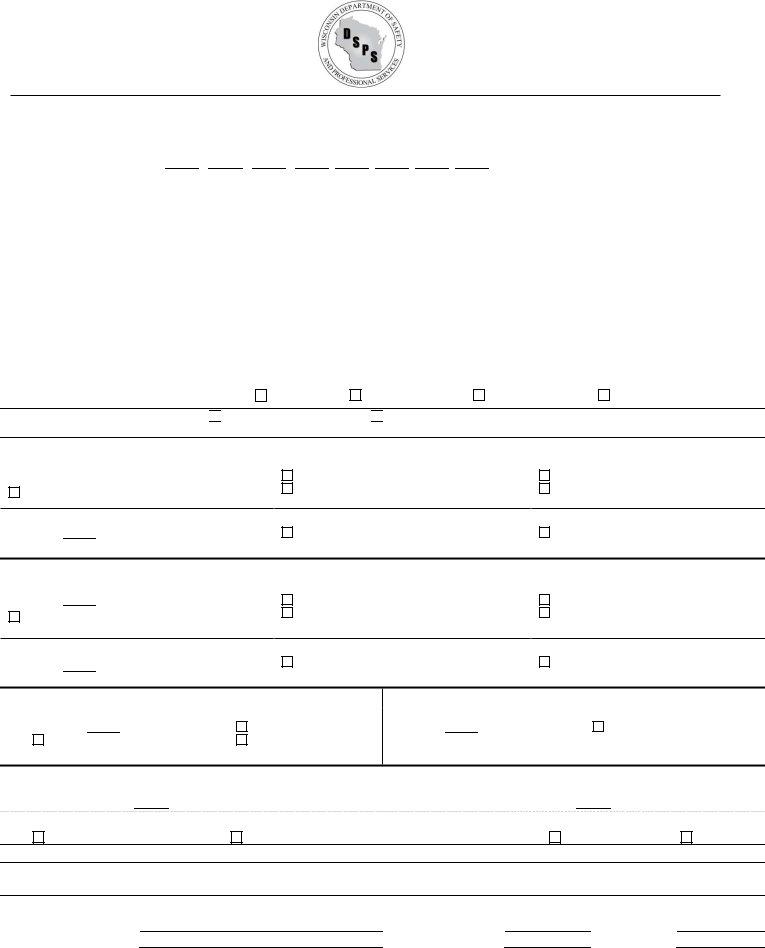

Cross Connection Control Performance Test

NOTE: Registrations for all assemblies (except those located in health care facilities) along with all test reports can be done online for reduced fees at

http://apps2.commerce.wi.gov/SBTestRegister/app/rstRegObjectSearch .

Regulated Object Number:

Personal information you provide may be used for secondary purposes [Privacy Law, s.1504 (1)(m)].

Owner Information

Owner Name |

|

|

Street Address |

|

|

|

|

|

|

City |

State |

Zip Code |

Owner's Contact Person |

Telephone Number |

|

|

|

|

|

Facility Information |

|

|

|

|

Facility Name |

|

|

Street Address |

|

|

|

|

|

|

City |

|

Zip Code |

County |

|

|

|

|

|

|

Assembly Location |

|

|

Assembly is Serving |

|

|

|

|

|

|

Manufacturer |

|

|

Model |

Serial Number |

|

|

|

|

|

Size |

|

Assembly Type |

RP

RP Detector

PVB

SRVB

Water Supply Source: Check One Municipal Water System Other than municipal,

Initial Test

RP relief valve |

|

|

|

1ST check |

|

|

|

|

2nd check |

|

|

|

|

|

||||

Opened at |

|

PSID |

|

|

Closed tight |

|

|

|

Closed tight |

|

||||||||

Did not open |

|

|

|

Leaked |

|

|

|

|

Leaked |

|

|

|

|

|

||||

|

|

|

Static |

PSID |

|

|

|

Static |

|

PSID |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|||||||||

FINAL TEST |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Opened at |

PSID |

|

|

Closed tight |

|

|

|

Closed tight |

|

|||||||||

|

|

|

|

|

Static |

PSID |

|

|

|

Static |

|

PSID |

|

|||||

DETECTOR BYPASS ASSEMBLY INITIAL TEST |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

RP relief valve |

|

|

|

1ST check |

|

|

|

|

2nd check |

|

|

|

|

|

||||

Opened at |

PSID |

|

|

Closed tight |

|

|

|

Closed tight |

|

|||||||||

Did not open |

|

|

|

Leaked |

|

|

|

|

Leaked |

|

|

|

|

|

||||

|

|

|

Static |

PSID |

|

|

|

Static |

|

PSID |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|||||||||

DETECTOR BYPASS ASSEMBLY FINAL TEST |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Opened at |

PSID |

|

|

Closed tight |

|

|

|

Closed tight |

|

|||||||||

|

|

Static |

PSID |

|

|

|

Static |

|

PSID |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|||||||||

PVB/SRVB INITIAL TEST |

|

|

|

|

|

|

PVB/SRVB FINAL TEST |

|

|

|

|

|

|

|

||||

Air inlet valve |

|

Check valve |

|

Air inlet valve |

|

|

|

Check Valve |

|

|||||||||

Opened at |

PSID |

|

Closed tight |

|

Opened at |

PSID |

|

|

|

Closed tight |

||||||||

Did not open |

|

Leaked |

|

|

|

|

|

|

Static |

PSID |

||||||||

|

|

|

|

Static |

|

PSID |

|

|

|

|

|

|

|

|

|

|

|

|

Assemblies in Fire Protection Systems |

|

|

|

|

|

Note: Include hose stream demand where applicable |

||||||||||||

Forward Flow Test |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Designed flow rate |

GPM |

|

|

|

|

|

|

|

Actual flow rate |

|

GPM |

|

||||||

Indicating Control Valves |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

No. one control valve open |

No. two control valves open |

Valve supervision: |

Tamper switch |

Locked |

||||||||||||||

Part (s) Replaced/Comments |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Make Checks Payable to DSPS |

|

|

|

|

|

Attach Check Here |

|

|

|

|

|

|

|

|||||

Total Amount Due $30 Per Assembly

I Hereby Certify the Test Results Are True and the Test Was Conducted by Me Personally.

Tester Name (print) |

Registration No. |

Time of Day |

Tester Signature |

Phone No. |

Date |

Copies: Department, Testers, Owner, Water Purveyor |

Revenue Code 7657 |

Owner Information

The backflow preventer is a mechanical device designed to protect the potable water supply system from being contaminated. There is a physical connection to equipment or water of either unknown or questionable quality, thereby requiring the installation of the backflow preventer. In order to ensure that this device is working as designed, it must be periodically tested.

A test shall be conducted on each backflow preventer prior to it being put into service, after any repairs, and a minimum of once a year thereafter.

It is the responsibility of the owner to make sure the device is tested. The test shall be performed by a department registered Cross Connection Control Device tester.

Owner’s Contact Person: The owner's contact person is the name of the person responsible for the backflow

preventer maintenance and records. (Note: Please provide full name.)

Old Assembly Replacement Information

If this test is for a replacement valve, please include all information for the replacement valve on this form. The manufacturer, model no., serial no., size, and the assembly type of the "old" valve must included on the comment line of this form. The replacement assembly will be given a new regulated object number.

Minimum Requirements for Passing Test

RP and RP Detector

∙The first check must close tight, and a minimum static PSID of 5 is required.

∙The second check must close tight, and have a minimum static 1 PSID.

∙The relief valve must open at a minimum static 2 PSID.

∙The relief valve must not be leaking upon completion of test.

Pressure Vacuum Breaker/SVB

∙The air inlet valve must open at a minimum static 1 PSID.

∙The check valve must close tight, and have a minimum static 1 PSID.