You can prepare web sling inspection checklist pdf effectively with our PDF editor online. The tool is consistently upgraded by our team, getting additional features and growing to be more versatile. All it takes is a few simple steps:

Step 1: Press the orange "Get Form" button above. It'll open our pdf tool so that you could start filling out your form.

Step 2: With our state-of-the-art PDF editing tool, you are able to accomplish more than merely fill out blanks. Express yourself and make your forms look sublime with custom textual content added, or fine-tune the file's original input to excellence - all accompanied by the capability to insert almost any pictures and sign the PDF off.

Be mindful while completing this pdf. Make sure all required areas are filled in properly.

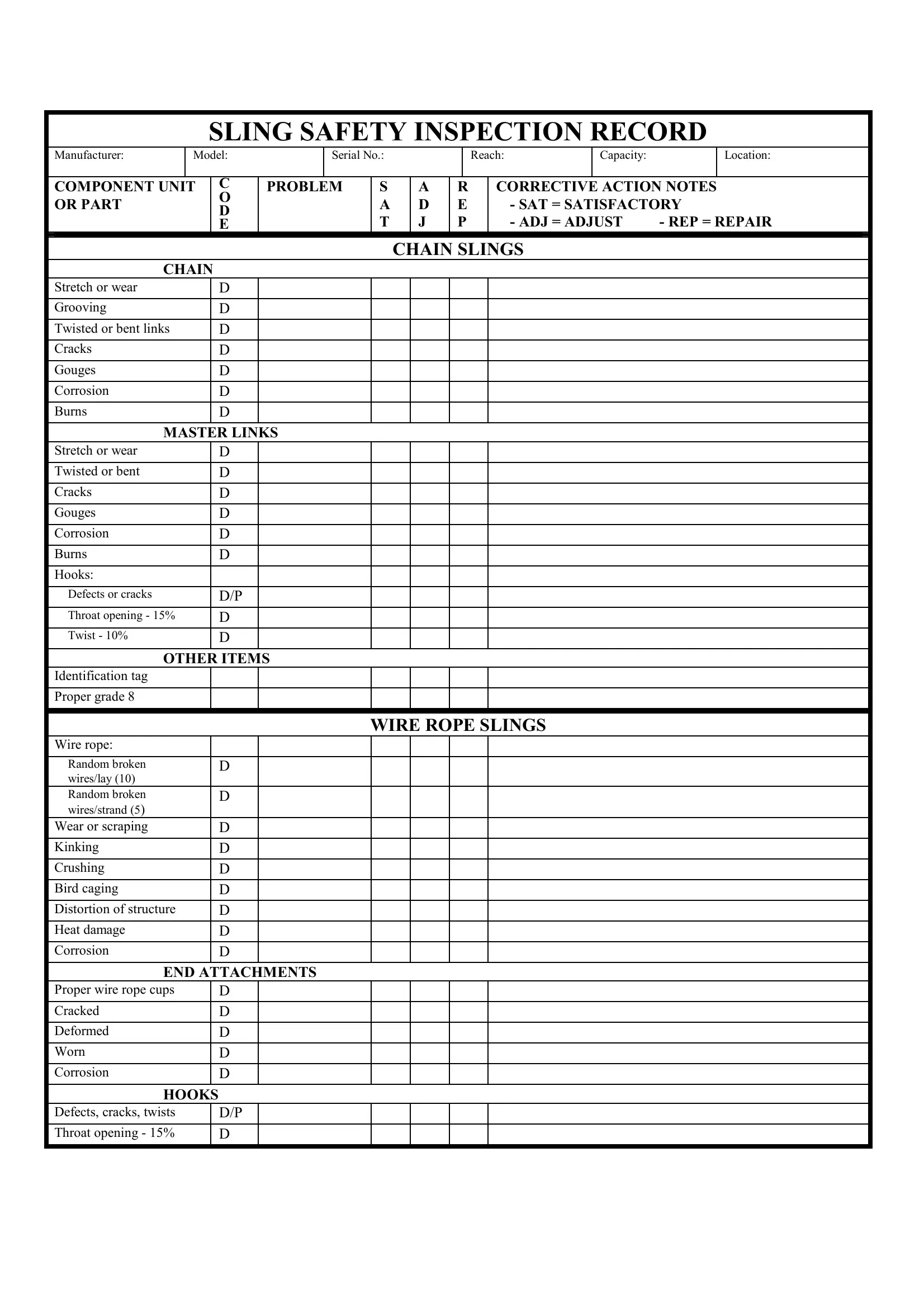

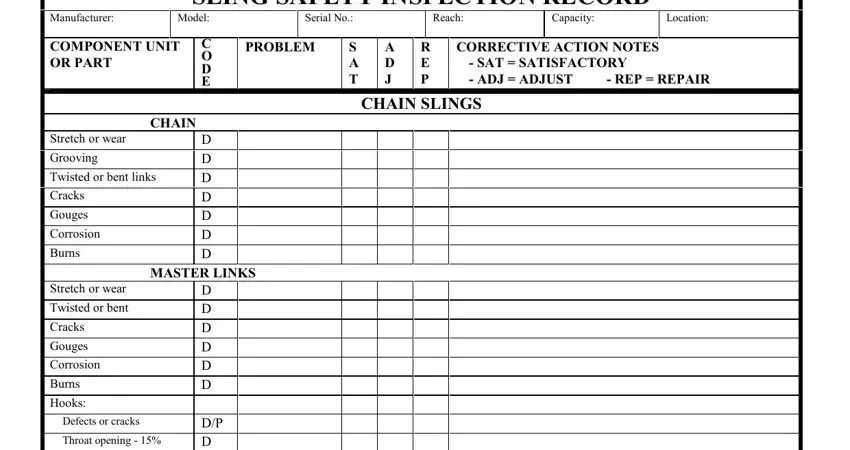

1. While filling in the web sling inspection checklist pdf, be sure to incorporate all necessary blanks in the associated form section. It will help speed up the process, making it possible for your information to be handled without delay and appropriately.

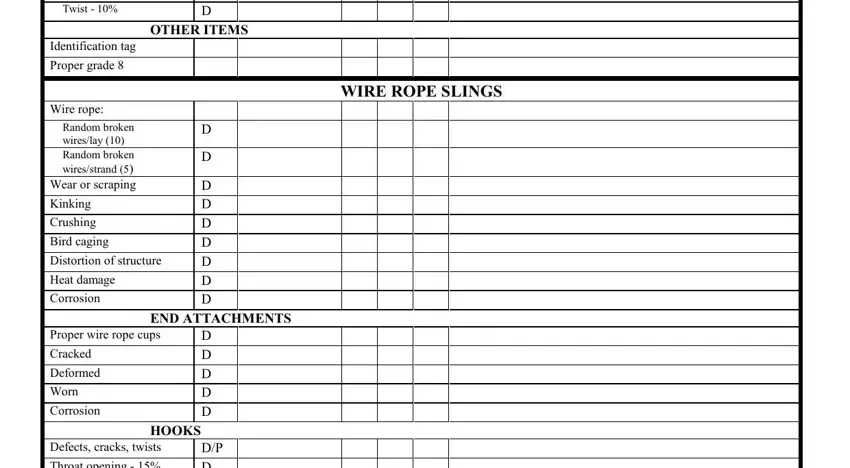

2. Just after finishing the last section, go to the next part and complete the essential particulars in these blank fields - Twist, WIRE ROPE SLINGS, OTHER ITEMS, Identification tag, Proper grade, Wire rope, Random broken wireslay Random, Kinking, Crushing, Bird caging, Distortion of structure, Heat damage, Corrosion, END ATTACHMENTS, and Proper wire rope cups.

Lots of people often make errors when filling in Proper grade in this part. Make sure you reread everything you enter right here.

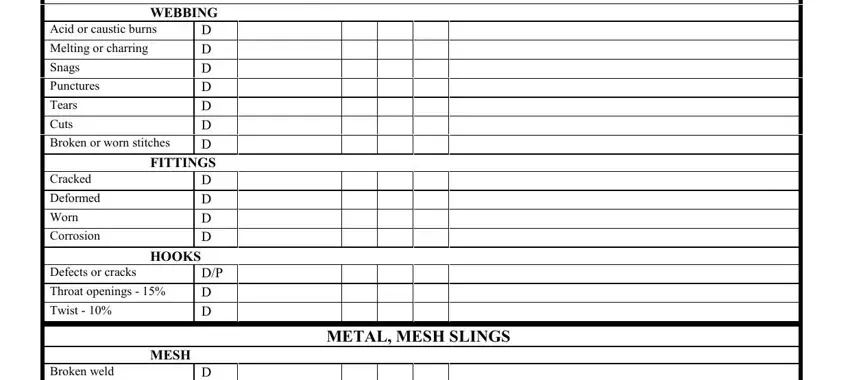

3. This next section should also be quite uncomplicated, SYNTHETIC WEB SLINGS, WEBBING, Acid or caustic burns, Melting or charring, Snags, Punctures, Tears, Cuts, Broken or worn stitches, Cracked, Deformed, Worn, Corrosion, FITTINGS D, and HOOKS - all these blanks will have to be completed here.

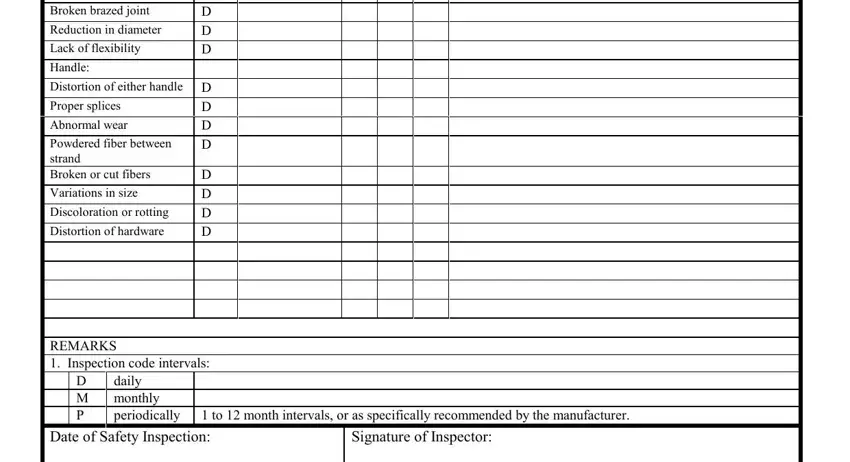

4. This next section requires some additional information. Ensure you complete all the necessary fields - Broken brazed joint, Reduction in diameter, Lack of flexibility, Handle, D D, Distortion of either handle D, Abnormal wear, Powdered fiber between strand, Variations in size, Discoloration or rotting, Distortion of hardware, REMARKS Inspection code intervals, D M P, daily monthly periodically, and to month intervals or as - to proceed further in your process!

Step 3: Before getting to the next stage, it's a good idea to ensure that all blank fields have been filled in as intended. When you think it is all good, press “Done." Make a 7-day free trial option at FormsPal and gain direct access to web sling inspection checklist pdf - which you may then work with as you want from your FormsPal account. At FormsPal.com, we strive to ensure that all of your information is stored secure.