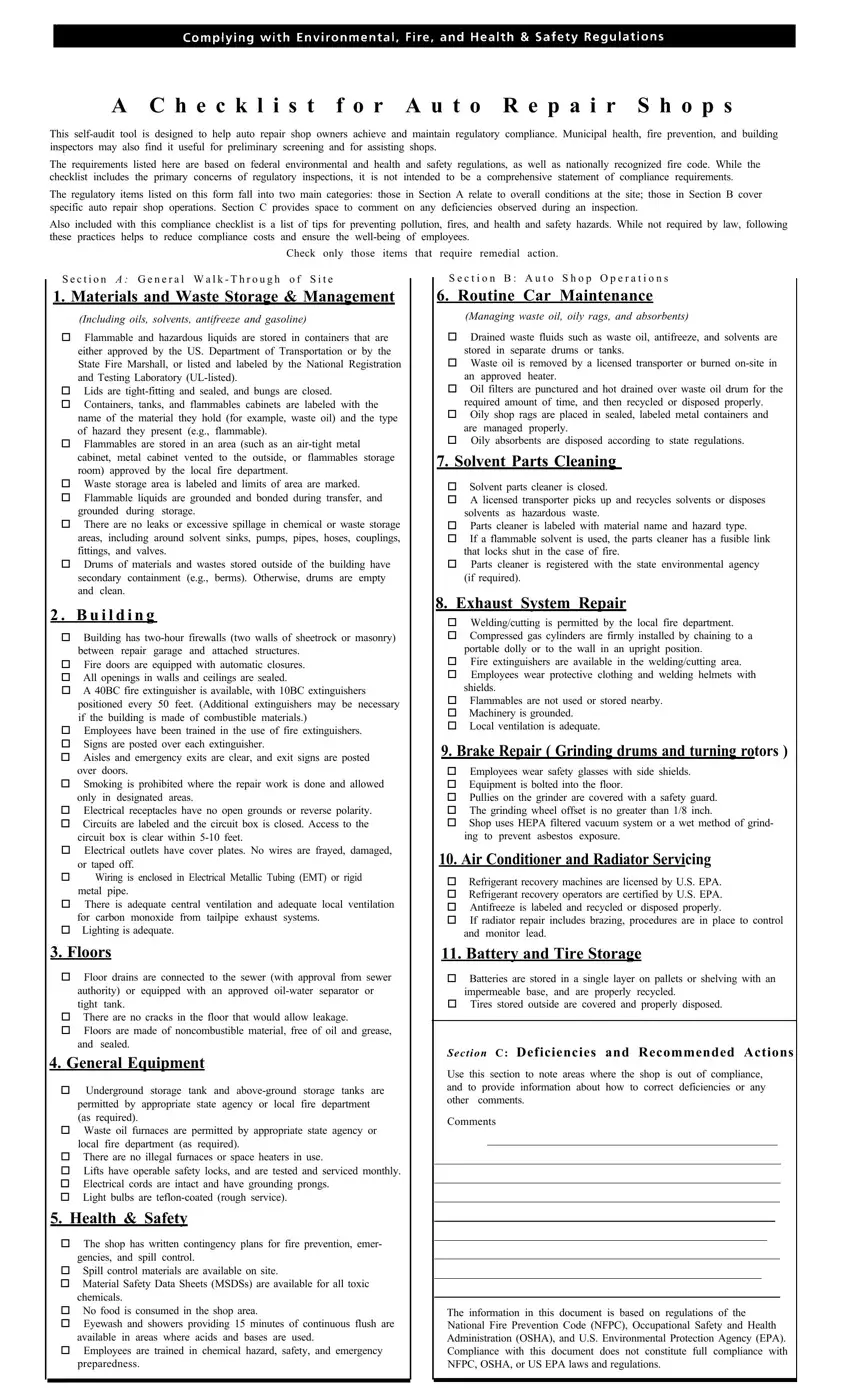

Section A : G e n e r a l W a l k - T h r o u g h o f S i t e

1. Materials and Waste Storage & Management

(Including oils, solvents, antifreeze and gasoline)

oFlammable and hazardous liquids are stored in containers that are either approved by the US. Department of Transportation or by the State Fire Marshall, or listed and labeled by the National Registration and Testing Laboratory (UL-listed).

oLids are tight-fitting and sealed, and bungs are closed.

oContainers, tanks, and flammables cabinets are labeled with the name of the material they hold (for example, waste oil) and the type of hazard they present (e.g., flammable).

oFlammables are stored in an area (such as an air-tight metal

cabinet, metal cabinet vented to the outside, or flammables storage room) approved by the local fire department.

oWaste storage area is labeled and limits of area are marked.

oFlammable liquids are grounded and bonded during transfer, and grounded during storage.

oThere are no leaks or excessive spillage in chemical or waste storage areas, including around solvent sinks, pumps, pipes, hoses, couplings, fittings, and valves.

oDrums of materials and wastes stored outside of the building have secondary containment (e.g., berms). Otherwise, drums are empty and clean.

2 . Building

oBuilding has two-hour firewalls (two walls of sheetrock or masonry) between repair garage and attached structures.

oFire doors are equipped with automatic closures.

oAll openings in walls and ceilings are sealed.

oA 40BC fire extinguisher is available, with 10BC extinguishers positioned every 50 feet. (Additional extinguishers may be necessary if the building is made of combustible materials.)

oEmployees have been trained in the use of fire extinguishers.

oSigns are posted over each extinguisher.

oAisles and emergency exits are clear, and exit signs are posted

over doors.

oSmoking is prohibited where the repair work is done and allowed only in designated areas.

oElectrical receptacles have no open grounds or reverse polarity.

oCircuits are labeled and the circuit box is closed. Access to the circuit box is clear within 5-10 feet.

oElectrical outlets have cover plates. No wires are frayed, damaged, or taped off.

oWiring is enclosed in Electrical Metallic Tubing (EMT) or rigid

metal pipe.

oThere is adequate central ventilation and adequate local ventilation for carbon monoxide from tailpipe exhaust systems.

oLighting is adequate.

3.Floors

oFloor drains are connected to the sewer (with approval from sewer authority) or equipped with an approved oil-water separator or tight tank.

oThere are no cracks in the floor that would allow leakage.

oFloors are made of noncombustible material, free of oil and grease, and sealed.

4.General Equipment

oUnderground storage tank and above-ground storage tanks are permitted by appropriate state agency or local fire department (as required).

oWaste oil furnaces are permitted by appropriate state agency or local fire department (as required).

oThere are no illegal furnaces or space heaters in use.

oLifts have operable safety locks, and are tested and serviced monthly.

oElectrical cords are intact and have grounding prongs.

oLight bulbs are teflon-coated (rough service).

5.Health & Safety

oThe shop has written contingency plans for fire prevention, emer- gencies, and spill control.

oSpill control materials are available on site.

oMaterial Safety Data Sheets (MSDSs) are available for all toxic chemicals.

oNo food is consumed in the shop area.

oEyewash and showers providing 15 minutes of continuous flush are available in areas where acids and bases are used.

oEmployees are trained in chemical hazard, safety, and emergency preparedness.

S e c t i o n B : A u t o S h o p O p e r a t i o n s

6. Routine Car Maintenance

(Managing waste oil, oily rags, and absorbents)

oDrained waste fluids such as waste oil, antifreeze, and solvents are stored in separate drums or tanks.

oWaste oil is removed by a licensed transporter or burned on-site in an approved heater.

oOil filters are punctured and hot drained over waste oil drum for the required amount of time, and then recycled or disposed properly.

oOily shop rags are placed in sealed, labeled metal containers and are managed properly.

oOily absorbents are disposed according to state regulations.

7.Solvent Parts Cleaning

oSolvent parts cleaner is closed.

oA licensed transporter picks up and recycles solvents or disposes solvents as hazardous waste.

oParts cleaner is labeled with material name and hazard type.

oIf a flammable solvent is used, the parts cleaner has a fusible link that locks shut in the case of fire.

oParts cleaner is registered with the state environmental agency

(if required).

8. Exhaust System Repair

oWelding/cutting is permitted by the local fire department.

oCompressed gas cylinders are firmly installed by chaining to a portable dolly or to the wall in an upright position.

oFire extinguishers are available in the welding/cutting area.

oEmployees wear protective clothing and welding helmets with shields.

oFlammables are not used or stored nearby.

oMachinery is grounded.

oLocal ventilation is adequate.

9.Brake Repair ( Grinding drums and turning rotors )

oEmployees wear safety glasses with side shields.

oEquipment is bolted into the floor.

oPullies on the grinder are covered with a safety guard.

oThe grinding wheel offset is no greater than 1/8 inch.

oShop uses HEPA filtered vacuum system or a wet method of grind- ing to prevent asbestos exposure.

10. Air Conditioner and Radiator Servicing

oRefrigerant recovery machines are licensed by U.S. EPA.

oRefrigerant recovery operators are certified by U.S. EPA.

oAntifreeze is labeled and recycled or disposed properly.

oIf radiator repair includes brazing, procedures are in place to control and monitor lead.

11. Battery and Tire Storage

oBatteries are stored in a single layer on pallets or shelving with an impermeable base, and are properly recycled.

oTires stored outside are covered and properly disposed.

SECTION C: Deficiencies and Recommended Actions

Use this section to note areas where the shop is out of compliance, and to provide information about how to correct deficiencies or any other comments.

Comments

The information in this document is based on regulations of the National Fire Prevention Code (NFPC), Occupational Safety and Health Administration (OSHA), and U.S. Environmental Protection Agency (EPA). Compliance with this document does not constitute full compliance with NFPC, OSHA, or US EPA laws and regulations.