weld procedure s can be filled out online effortlessly. Simply make use of FormsPal PDF editor to do the job quickly. To keep our editor on the cutting edge of convenience, we aim to integrate user-oriented features and improvements on a regular basis. We are always looking for feedback - play a vital role in remolding how we work with PDF docs. Here's what you'd need to do to get going:

Step 1: Simply press the "Get Form Button" above on this page to start up our pdf file editing tool. Here you'll find all that is required to work with your file.

Step 2: Using this online PDF file editor, you could accomplish more than simply fill in blanks. Edit away and make your documents seem sublime with customized text put in, or optimize the file's original content to perfection - all that backed up by the capability to add just about any images and sign it off.

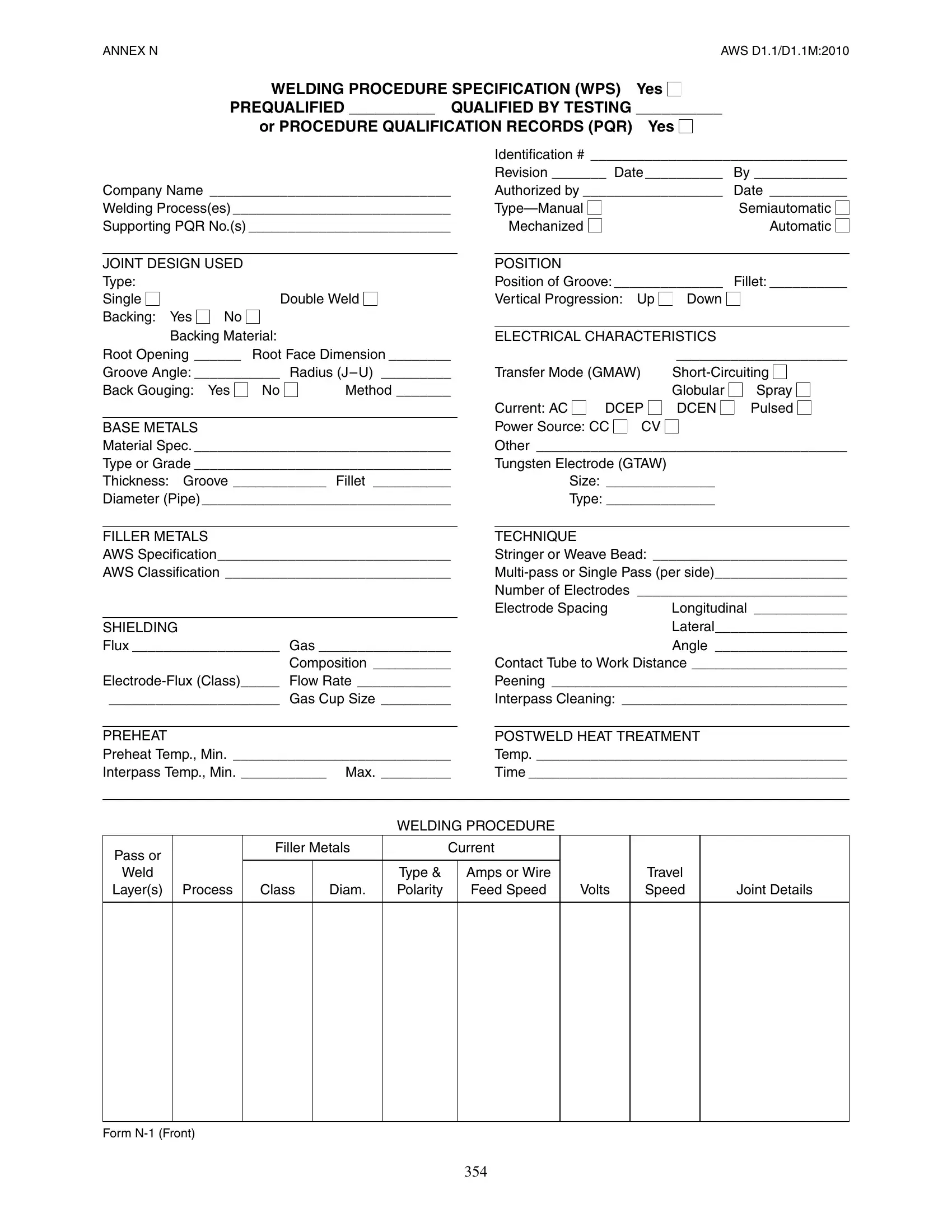

For you to complete this PDF form, be sure to type in the required information in every single area:

1. It's essential to fill out the weld procedure s properly, so be mindful while filling out the segments containing all of these blanks:

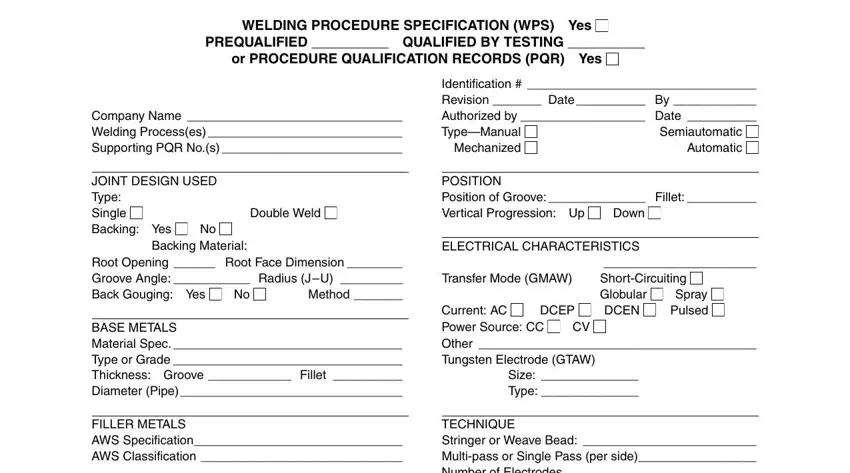

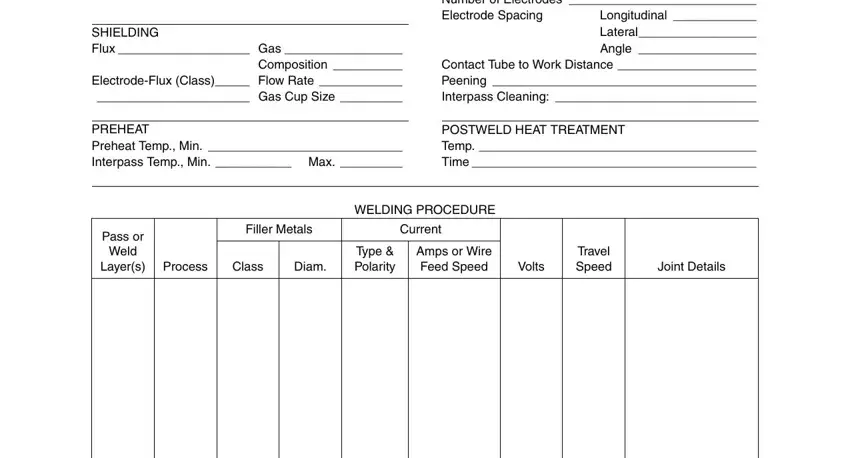

2. After filling out the previous part, go to the subsequent part and fill in the necessary details in these fields - SHIELDING Flux Gas Composition , TECHNIQUE Stringer or Weave Bead , PREHEAT Preheat Temp Min , POSTWELD HEAT TREATMENT Temp Time , WELDING PROCEDURE, Filler Metals, Current, Process, Class, Diam, Type Polarity, Amps or Wire Feed Speed, Volts, Travel Speed, and Joint Details.

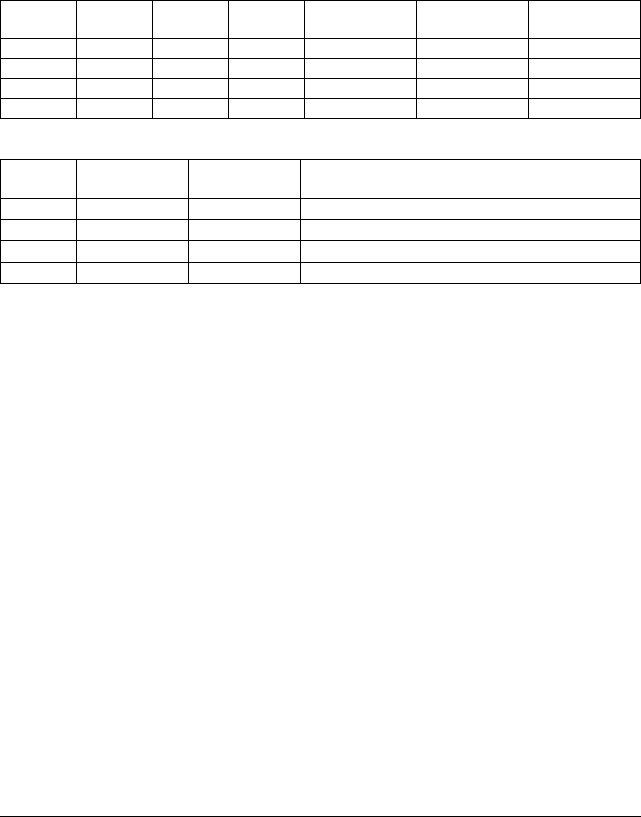

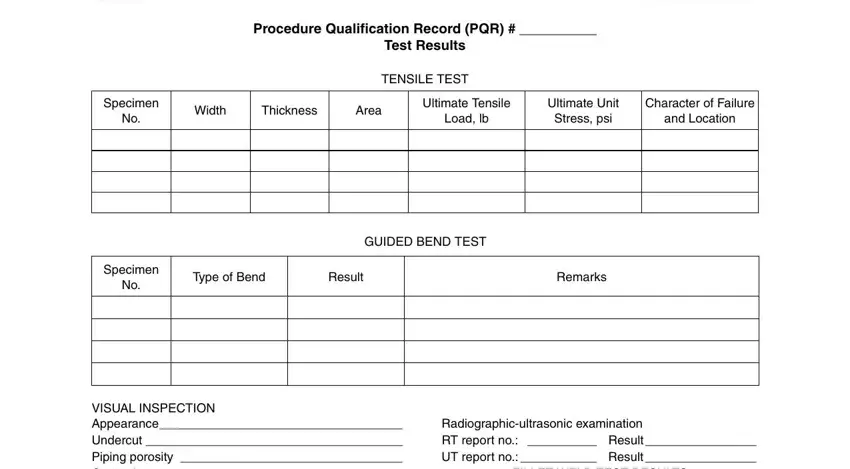

3. Throughout this stage, look at ANNEX N, AWS DDM, Procedure Qualification Record PQR, Test Results, TENSILE TEST, Specimen, Width, Thickness, Area, Ultimate Tensile, Ultimate Unit, Character of Failure, Load lb, Stress psi, and and Location. Each of these will need to be filled out with utmost precision.

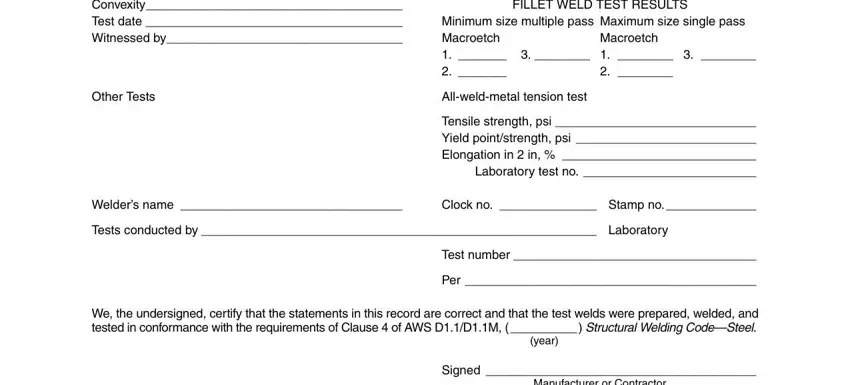

4. The subsequent paragraph will require your input in the following areas: VISUAL INSPECTION Appearance, FILLET WELD TEST RESULTS, Minimum size multiple pass Maximum, Macroetch, Other Tests, Allweldmetal tension test, Tensile strength psi Yield, Welders name , Clock no Stamp no , Tests conducted by Laboratory, Test number , Per , We the undersigned certify that, year, and Signed . Remember to provide all needed information to go forward.

It's easy to make errors while completing your Macroetch, hence be sure you reread it prior to deciding to finalize the form.

5. Since you near the completion of the document, there are a few extra points to undertake. Notably, Manufacturer or Contractor, By , Title , Date , and Form N Back must be done.

Step 3: Before moving on, check that blank fields were filled in correctly. Once you determine that it's fine, click on “Done." Download the weld procedure s the instant you sign up at FormsPal for a 7-day free trial. Readily view the pdf form within your personal account, along with any edits and changes being automatically saved! FormsPal ensures your information privacy via a protected method that never records or shares any sort of sensitive information provided. Feel safe knowing your docs are kept confidential when you use our editor!