Navigating through the complexities of construction compliance and ensuring that every aspect of building design meets state-specific codes can be a daunting task. This is where the Installation Certificate CF-6R-ENV-01 plays a pivotal role, especially in the context of California's residential projects. A comprehensive document, it spans three pages, each detail-oriented to cover various mandatory measures ranging from insulation specifics in roofing to fenestration. At its core, the certificate functions as a binding attestation by contractors or builders, confirming that all installation work, whether it be thermal insulation or the application of roofing products, aligns with the stringent requirements set forth by local enforcement agencies. It meticulously catalogs the type, brand, thickness, and thermal resistance of materials used across different parts of a building's envelope, ensuring that everything from raised floors to attic insulation meets or exceeds recommended R-values. Not only does it touch on material specifics, but it also delves into the realm of roofing products, highlighting their solar reflectance, thermal emittance, and even the precise weight per square foot. Fenestration details, too, are not overlooked, with a clear emphasis on achieving lower U-factors and SHGC (Solar Heat Gain Coefficient) values in compliance with energy efficiency standards. This certificate serves a dual purpose: as a declaration of accurate and code-compliant installation work, and as a crucial document for building inspectors, indicating adherence to approved plans and specifications. It culminates in a declaration statement—a legal assertion regarding the truthfulness and compliance of the information provided, underscoring the accountability held by those responsible for construction. The CF-6R-ENV-01 is not just a form; it's a testament to a project's commitment to energy efficiency, quality construction practices, and the overarching goal of sustainable development.

| Question | Answer |

|---|---|

| Form Name | Cf 6R Env 01 Form |

| Form Length | 3 pages |

| Fillable? | No |

| Fillable fields | 0 |

| Avg. time to fill out | 45 sec |

| Other names | cf 6r env 01 installation certificate, how can i No Download Needed a copy of cf 6r env 01 paper, cf 6r env 01, cf 2r env 01 |

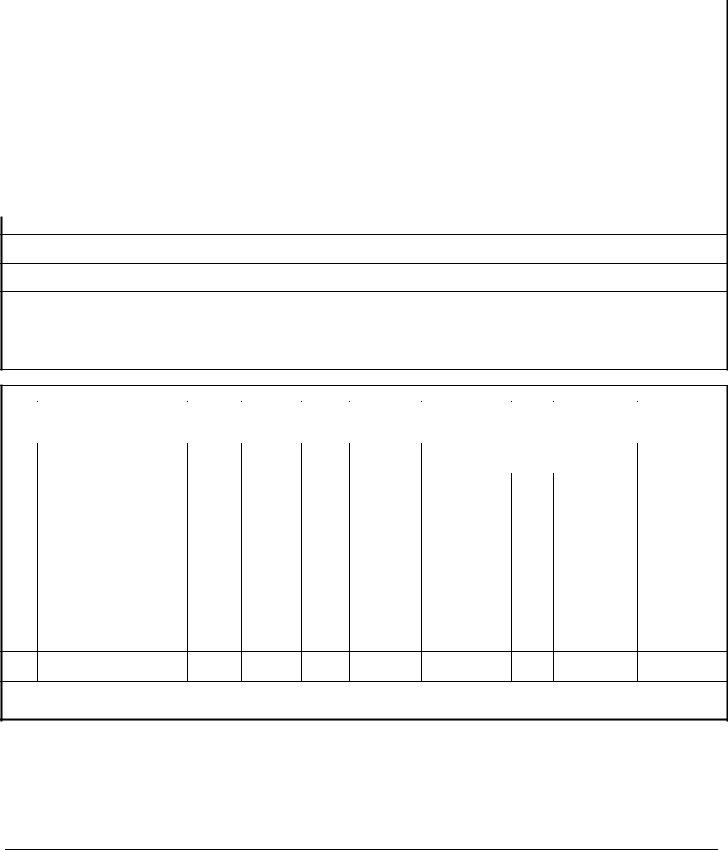

INSTALLATION CERTIFICATE |

|

|

Envelope – Insulation; Roofing; Fenestration |

|

(Page 1 of 3) |

Site Address: |

Enforcement Agency: |

Permit Number: |

|

|

|

If more than one person has responsibility for installation of the items on this certificate, each person shall prepare and sign a certificate applicable to the portion of construction for which they are responsible; alternatively, the person with chief responsibility for construction shall prepare and sign this certificate for the entire construction. All applicable Mandatory Measures with check boxes require to be checked to ensure the mandatory measures have been met.

Description of Insulation |

|

1. RAISED FLOOR |

|

Material:__________________________________ |

Brand Name:_______________________________ |

Thickness (inches):_________________________ |

Thermal Resistance |

§150(d): Minimum

2. SLAB FLOOR/PERIMETER |

|

Material:__________________________________ |

Brand Name:_______________________________ |

Thickness (inches):_________________________ |

Thermal Resistance |

Perimeter Insulation Depth (inches): ____________ |

|

§150(l): Water absorption rate for the insulation material alone without facings is no greater than 0.3%; water vapor permeance rate is no greater than 2.0 perm/inch and shall be protected from physical damage and UV light deterioration.

3. EXTERIOR WALL

a. Insulation Type (e.x. Batt, Loose Fill, Spray Foam)

________________

b. . Insulation Type (e.x. Batt, Loose Fill, Spray Foam)

________________

Brand: ___________________________________

Spray/Loose fill) Installed Actual Thickness (inches):_____________

Manufacturer’s installed weight per square foot to achieve Thermal Resistance

§150(c): Minimum

Exterior Foam Sheathing (rigid Insulation) |

|

|

Material:________________________________ |

Brand Name:_______________________________ |

|

Thickness (inches) :_______________________ |

Thermal Resistance |

|

4. |

FOUNDATION WALL |

|

Material:________________________________ |

Brand Name:______________________________ |

|

Thickness (inches):_______________________ |

Thermal Resistance |

|

5. |

CEILING |

|

Batt or Blanket Type: _______________________ |

Brand Name: _____________________________ |

|

Loose Fill Type: ___________________________ |

Thermal Resistance |

|

Spray Foam Type: _________________________ |

Brand Name: _____________________________ |

|

Installed Actual Thickness (inches):____________ |

Contractor’s min installed weight/ft² _______lb |

|

Manufacturer’s installed weight per square foot to achieve Thermal Resistance

§150(a): Minimum

6. ATTIC ROOF INSULATION AND/OR ATTIC RADIANT BARRIER

Material: _________________________________ |

Brand Name: ______________________________ |

Material: _________________________________ |

Brand Name: ______________________________ |

Thickness (inches): ________________________ |

Thermal Resistance |

§118(a): Insulation installed meets Standards for Insulating Material.

§150(g): Mandatory Vapor barrier installed in Climate Zones 14 or 16.

2008 Residential Compliance Forms |

August 2009 |

INSTALLATION CERTIFICATE |

|

|

|

|

|

|

|

|

|

|

|||||||

Envelope – Insulation; Roofing; Fenestration |

|

|

|

|

|

|

(Page 2 of 3) |

|

|||||||||

Site Address: |

|

|

|

|

|

|

Enforcement Agency: |

|

Permit Number: |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Description of Roofing Products |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

CRRC Product ID |

Manufacturer |

|

|

Product |

|

Roof |

Roof |

|

Product |

Initial Solar |

Aged Solar |

Thermal |

|

||||

|

Number1 |

Information |

|

Brand/Model |

Type |

|

Area |

Slope |

|

Weight 2 |

Reflectance |

Reflectance4 |

Emittance |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

1. |

The CRRC Product ID Number can be obtained from the Cool Roof Rating Council’s Rated Product Directory at |

|

|

|

|

||||||||||||

|

ww.coolroofs.org/products/search.php |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

2. |

The weight in lbs per square feet of the roofing product being installed. |

|

|

|

|

|

|

|

|

|

|

|

|||||

3. |

Check box if the Aged Reflectance is a calculated value using the equation below, footnote 4. |

|

|

|

|

|

|

|

|||||||||

4. |

If the aged reflectance is not available in the Cool Roof Rating Council’s Rated Product Directory then use the initial reflectance value from the |

|

|||||||||||||||

|

directory and use the equation (0.2+0.7(ρinitial – 0.2) to obtain a calculated aged value. |

|

|

|

|

|

|

|

|||||||||

CHECK APPLICABLE BOX BELOW IF EXEMPT FROM THE ROOFING PRODUCT “COOL ROOF” REQUIREMENT:

The roof area covered by building integrated photovoltaic panels and building integrated solar thermal panels are exempt from the above Cool Roof criteria.

Roof constructions that have thermal mass over the roof membrane with a weight of at least 25 lb/ft2 is exempted from the above Cool Roof criteria.

To apply Liquid Field Applied Coatings, the coating must be applied with a minimum dry mil thickness of 20 mils across the entire roof surface and meet minimum performance requirements listed in §118(i)3 and Table

|

|

Other ___________________________ |

|

|

|

(Note if no

FENESTRATION/GLAZING

|

|

Product |

|

# |

|

Total Quantity |

|

Add. Exterior |

Comments/ |

|

|

U- |

Product |

of |

NFRC |

of Like Product |

Area |

Shading Dev. |

|

|

Manufacturer/Brand Name |

Location/ Special |

|||||||

Item |

(GROUP LIKE RODUCTS) |

factor1 |

SHGC1 |

Panes |

Certified1, 2 |

(Optional) |

ft2 |

or Overhang |

Features |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7. |

|

|

|

|

|

|

|

|

|

8.

1.Use values from a fenestration product’s NFRC Certified Label. For fenestration products without an NFRC label, use the default values from Section 116, Table

2.NFRC Label Certificates shall not be removed until the building inspector has verified the efficiency. Enter Yes or No.

§116(a)1: Doors and windows between conditioned and unconditioned spaces designed to limit air leakage.

§116(a)2 and 3: Actual fenestration products installed are equivalent to or have a lower

§116(a)4: Fenestration products (except

§117: Exterior doors and windows

2008 Residential Compliance Forms |

August 2009 |

INSTALLATION CERTIFICATE |

|

|

Envelope – Insulation; Roofing; Fenestration |

|

(Page 3 of 3) |

Site Address: |

Enforcement Agency: |

Permit Number: |

|

|

|

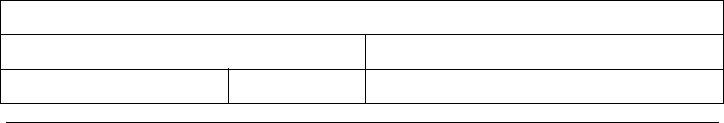

DECLARATION STATEMENT

•I certify under penalty of perjury, under the laws of the State of California, the information provided on this form is true and correct.

•I am eligible under Division 3 of the Business and Professions Code to accept responsibility for construction, or an authorized representative of the person responsible for construction (responsible person).

•I certify that the installed features, materials, components, or manufactured devices identified on this certificate (the installation) conforms to all applicable codes and regulations, and the installation is consistent with the plans and specifications approved by the enforcement agency.

•I reviewed a copy of the Certificate of Compliance

•I will ensure that a completed, signed copy of this Installation Certificate shall be posted, or made available with the building permit(s) issued for the building, and made available to the enforcement agency for all applicable inspections. I understand that a signed copy of this Installation Certificate is required to be included with the documentation the builder provides to the building owner at occupancy.

Company Name: (Installing Subcontractor or General Contractor or Builder/Owner)

Responsible Person's Name:

Responsible Person's Signature:

CSLB License:

Date Signed:

Position With Company (Title):

2008 Residential Compliance Forms |

August 2009 |