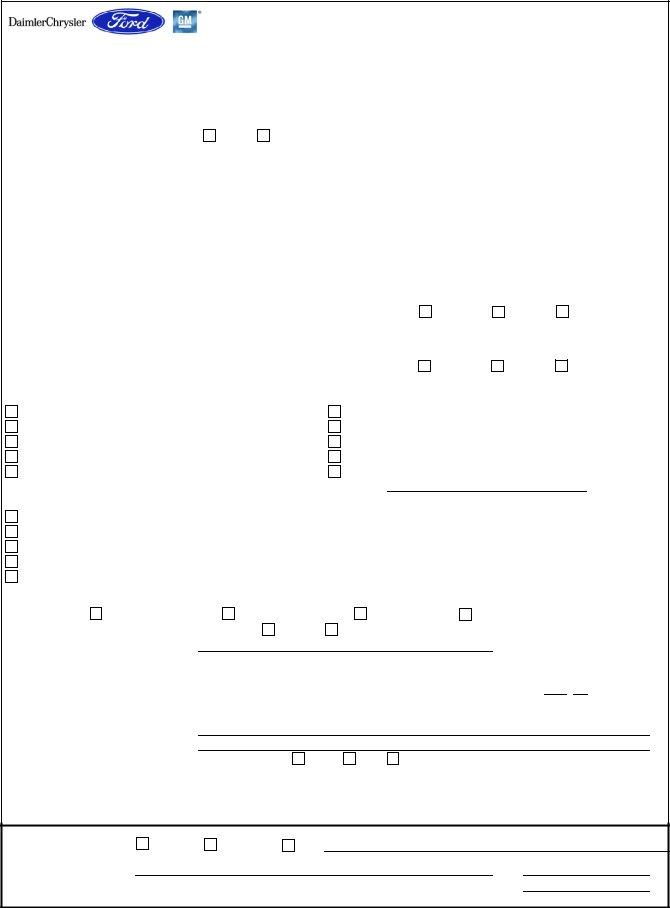

The CFG 1001 form plays a critical role in the manufacture of parts and components, serving as an essential document that communicates vital information between suppliers and buyers. This comprehensive form covers a wide range of details crucial to the approval and quality control processes within the manufacturing sector. It encompasses sections such as the Part Submission Warrant, which includes the part name, customer and organization part numbers, engineering change levels, and any additional engineering changes, addressing both safety and governmental regulation compliance. The form extends to capture organizational manufacturing information and customer submittal information, detailing supplier and customer names, addresses, and codes essential for ensuring the correct parts reach the right location. A significant part of the CFG 1001 form is dedicated to materials reporting, inquiring whether substances of concern information required by the customer has been accurately reported and if polymeric parts are identified with the correct ISO marking codes. The reason for submission section explores various scenarios that would necessitate the form's use, including initial submission, engineering changes, and discrepancies that need correction. Furthermore, the form outlines requested submission levels, providing options that range from basic warranty to comprehensive review at the supplier's manufacturing location, thus ensuring flexibility and specificity in the submission process. Lastly, the form concludes with submission results and a declaration section where the supplier affirms compliance with the Production Part Approval Process Manual requirements, along with space for any deviations or additional comments. For customer use, the form facilitates part warrant disposition, allowing for approval, rejection, or other specified outcomes. In essence, the CFG 1001 form is instrumental in streamlining communication between manufacturers and suppliers, ensuring quality control, and compliance with regulatory standards.

| Question | Answer |

|---|---|

| Form Name | Cfg 1001 Form |

| Form Length | 1 pages |

| Fillable? | No |

| Fillable fields | 0 |

| Avg. time to fill out | 15 sec |

| Other names | part submission warrant pdf, part submission warrant, cfg warrant edit, part submission warrant form |

|

|

|

|

|

|

|

|

|

PART SUBMISSION WARRANT |

|

|

|

|

|

|||||

Part Name |

|

|

|

|

|

|

|

|

|

|

Cust. Part Number |

|

|

|

|

|

|

||

Shown on Drawing No. |

|

|

|

|

|

|

|

Org. Part Number |

|

|

|

|

|

|

|||||

Engineering Change Level |

|

|

|

|

|

|

|

|

Dated |

|

|

|

|

|

|

||||

Additional Engineering Changes |

|

|

|

|

|

|

|

Dated |

|

|

|

|

|

|

|||||

Safety and/or Government Regulation |

Yes |

No |

|

Purchase Order No. |

|

Weight (kg) |

|

|

|||||||||||

Checking Aid No. |

|

|

|

Checking Aid Engineering Change Level |

|

Dated |

|

|

|||||||||||

ORGANIZATION MANUFACTURING INFORMATION |

|

|

CUSTOMER SUBMITTAL INFORMATION |

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||

Supplier Name & Supplier Code |

|

|

|

Customer Name/Division |

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

Buyer/Buyer Code |

|

|

|

|

|

|||||

Street Address |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Application |

|

|

|

|

|

|||||

City |

State |

Zip |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

MATERIALS REPORTING

Has

Are polymeric parts identified with appropriate ISO marking codes?

REASON FOR SUBMISSION

YES |

NO |

n/a |

|

|

|

|

|

|

YES |

NO |

n/a |

Initial Submission

Engineering Change(s)

Tooling: Transfer, Replacement, Refurbishment or additional Correction of Discrepancy

Tooling Inactive > 1 year

REQUESTED SUBMISSION LEVEL (CHECK ONE)

Change to Optional Construction or Material

Part Produced at Additional Location Other - Please specify below

Level 1 - Warrant only (and for designated appearance items, an Appearance Approval Report) submitted to customer. Level 2 - Warrant with product samples and limited supporting data submitted to customer.

Level 3 - Warrant with product samples and complete supporting data submitted to customer. Level 4 - Warrant and other requirements as defined by customer.

Level 5 - Warrant with product samples and complete supporting data reviewed at supplier's manufacturing location.

SUBMISSION RESULTS

The results for

dimensional measurements

material and functional tests

appearance criteria

statistical process package

These results meet all drawing and specification requirements:

Mold / Cavity / Production Process

DECLARATION

YES

NO |

(If "NO" - Explanation Required) |

I hereby affirm that the samples represented by this warrant are representative of our parts, have been made to the applicable

Production Part Approval Process Manual 4th Edition Requirements. I further affirm that these samples were produced at the production rate of / hours. I also certify that documented evidence of such compliance is on file and available for review. I have noted any deviations from this declaration below.

EXPLANATION/COMMENTS:

Is each Customer Tool Properly tagged and numbered? |

YES |

NO |

n/a |

|

|

|

|

||||||

Organization Authorized Signature |

|

|

|

|

|

|

|

Date |

|

||||

Print Name |

|

|

|

|

Phone No. |

|

|

|

Fax No. |

|

|||

Title |

|

|

|

|

|

|

|

|

|

||||

FOR CUSTOMER USE ONLY (IF APPLICABLE)

Part Warrant Disposition: |

Approved |

Rejected |

Customer Signature |

|

|

Other

Date

Print Name |

|

Customer Tracking Number (optional) |

March2006