Navigating the complexities of factory inspections, the CIG 023 form stands as a cornerstone document for ensuring compliance and maintaining standards within manufacturing environments. Designed as a PERMANENT DOCUMENT by the revered Underwriters Laboratories Inc., this factory inspection report is instrumental only when deployed by ECS members and their authorized agents. With a clear caveat, the document underlines its authenticity and exclusivity, cautioning against unauthorized use. The content warns users about the limitations regarding endorsements, errors, or inaccuracies, stressing that UL abstains from assuming responsibility in these realms. Not merely a form, but a comprehensive guide, it encompasses a thorough inspection framework spanning across various sections inclusive of a detailed report form, inspector evaluations, and test data sheets, alongside precise identification criteria for selected samples. Furthermore, it underscores important procedural guidelines, urging inspectors to evaluate production processes even in their absence and stipulate detailed findings and rationale for any deviation from the norm. Indeed, the form exemplifies a meticulous approach towards maintaining quality and safety in manufacturing practices, ensuring that entities adhere to the expected standards, whilst clearly delineating the accountability lines. However, it's crucial to comprehend the structured methodology it advocates—right from verifying purchased components to maintaining robust incoming inspection records—all underscored by a steadfast commitment to accuracy and integrity in the inspection process.

| Question | Answer |

|---|---|

| Form Name | Cig 023 Form |

| Form Length | 25 pages |

| Fillable? | No |

| Fillable fields | 0 |

| Avg. time to fill out | 6 min 15 sec |

| Other names | cig023, ies, cig023 blank report, cig 023 factory inspection report |

CIG 023

Factory Inspection

Report

PERMANENT DOCUMENT

CIG 023

Factory Inspection Report

WARNING:

THIS DOCUMENT IS ONLY VALID IF USED BY ECS MEMBERS

AND THEIR AUTHORISED AGENTS

UL does not endorse any vendors or products referenced herein.

UNDERWRITERS LABORATORIES INC. ASSUMES NO RESPONSIBILITY FOR ANY OMISSIONS OR ERRORS OR INACCURACIES WITH RESPECT TO THIS INFORMATION. UL MAKES NO REPRESENTATION OR WARRANTY OF ANY KIND WHATSOEVER, WHETHER EXPRESS OR IMPLIED, WITH RESPECT TO THE ACCURACY, CONDITION, QUALITY, DESCRIPTION, OR SUITABILITY OF THIS INFORMATION, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE AND EXPRESSLY DISCLAIMS THE SAME.

Copyright Underwriters Laboratories Inc. All rights reserved. May not be reproduced without permission. This document is controlled and has been released electronically. The version on the UL intranet is the

Page 1 of 25 |

CIG 023

Factory Inspection

Report

PD CIG 023 reports shall not contain any unauthorised modifications which change the

original meaning or the requirements.

Any additions created to any document in the series shall be shown in an Appendix.

This document contains:

∙two cover pages

∙a report form of 14 pages

∙Inspector’s Evaluation – Findings

∙Inspector’s Evaluation - Informative

∙TEST DATA SHEET- Product Verification Test

∙TEST DATA SHEET Routine Tests

∙IDENTIFICATION OF SELECTED SAMPLE

Page 2 of 25 |

CIG 023

Factory Inspection

Report

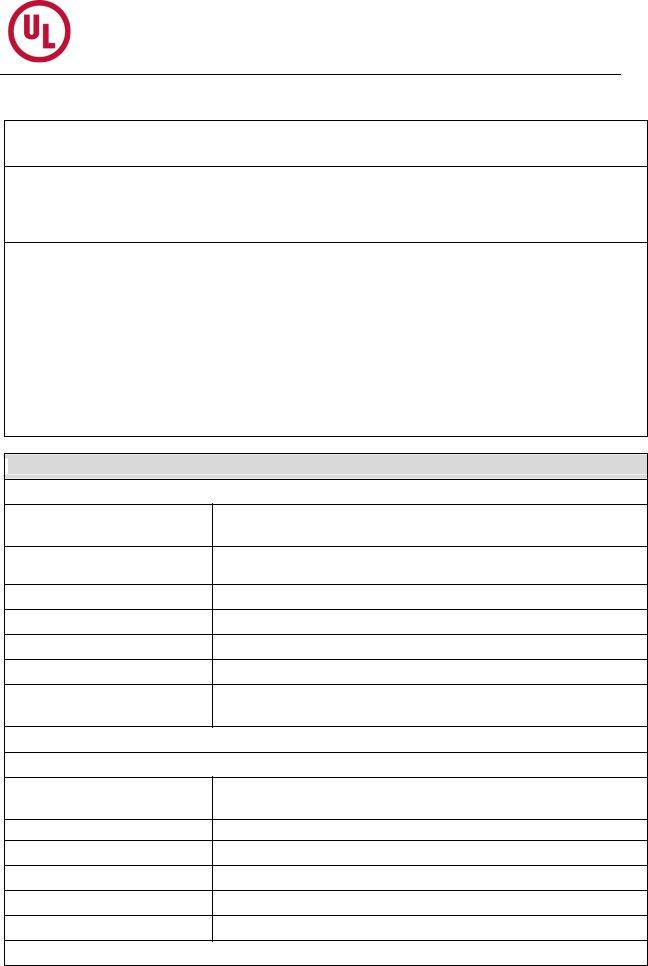

Reference number of the body carrying out the inspection:

FACTORY INSPECTION REPORT

Inspection carried out by (Name of Inspection Body):

Reference number of the Body carrying out the inspection:

–For page control, please write this number in the header of each page (including the attachments)

GENERAL GUIDANCE

–The questions of this factory inspection report are based on the requirements given in Permanent Document CIG 021.

–Guidance for the inspector is given in Permanent Document CIG 024.

–Both documents, PD CIG 021 and PD CIG 024 shall be taken into account during inspection.

–Instructions to the Inspector are shown in italics

–The report shall be completed even if there is no production at the time of the visit.

–For all ‘NO’ answers details shall be provided on the INSPECTORS

–For all ‘N/A’ answers rationale shall be provided as to why the item is not applicable

–Details should be given on INSPECTOR’S

1.0 GENERAL INFORMATION

1.1Manufacturer's registered name and factory location

Manufacturer’s registered

name:

Street address of the factory and Number:

Postal code:

City:

County:

Country:

1.2Manufacturer's representative name and contact data

Manufacturer's representative name:

Position:

Position:

Telephone:

Fax:

Page 3 of 25 |

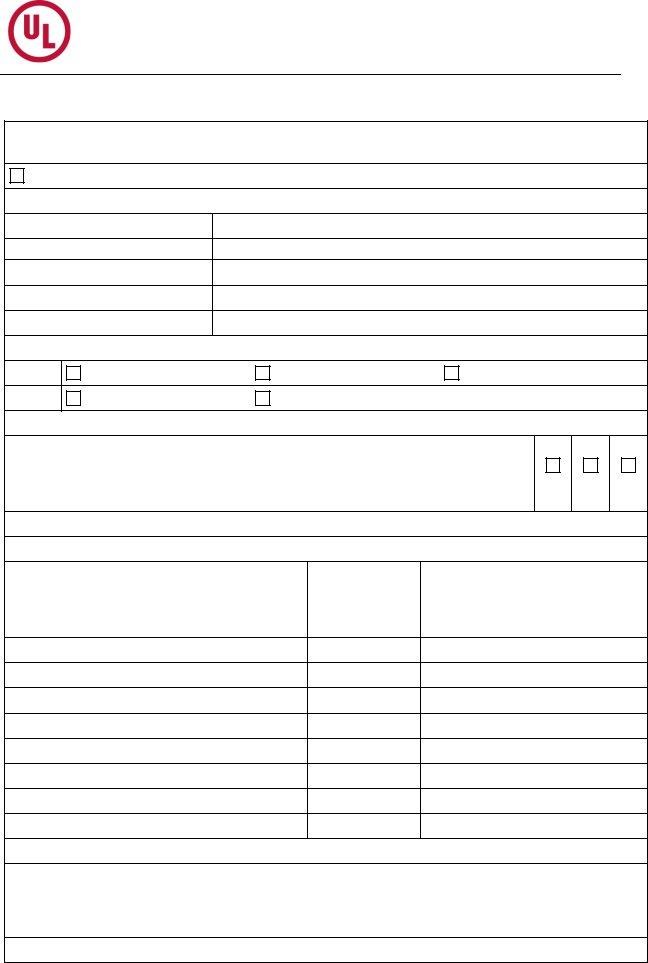

CIG 023

Factory Inspection

Report

Reference number of the body carrying out the inspection:

1.3Record below the names and position held of the main people involved in the inspection

same as mentioned under 1.2

If not the same as mentioned under 1.2 please give details

Name:

Position:

Telephone:

Fax:

1.4

Routine |

ENEC |

|

HAR |

EMC |

Others: |

|

|

|

1.5

If 'no', amend the Questionnaire as appropriate and attach a copy to this report.

YES N/A

NO

1.6Inspection Details:

Certification |

Inspection |

File Reference |

Body |

X of Y |

No. |

requesting |

|

|

inspection |

|

|

|

|

|

Product

Category

Type of Product

1.7

Name of Inspector |

Date of inspection: |

(YYYY – MM – DD )

Page 4 of 25 |

CIG 023

Factory Inspection

Report

Reference number of the body carrying out the inspection:

2Verification of purchased components and materials which have a safety implication on the certified product (Incoming Inspection)

2.1 Are materials, components and |

YES |

N/A |

NO |

manufacturer as complying with appropriate specification? |

|

|

|

|

|

|

|

|

|

|

|

2.2 Does this verification also include the verification of the Certification |

YES |

N/A |

NO |

Marks? |

|

|

|

|

|

|

|

|

|

|

|

Description of procedure (one or more boxes may be ticked) |

|

|

|

Rely on suppliers’ |

|

|

|

Audit conducted at the suppliers’ premises |

|

|

|

Supplier control based on manufacturers’ check list |

|

|

|

Conduct own incoming inspection |

|

|

|

Identification check |

|

|

|

Checked for correct type |

|

|

|

Comparison to a reference |

|

|

|

Rating |

|

|

|

Certification mark |

|

|

|

Certificate of conformity |

|

|

|

Others |

|

|

|

Details given on INSPECTOR’S |

|

|

|

Description of the procedure or ref. of documented procedure & revision or issue date:

Details are given on INSPECTOR’S

2.3 |

If the manufacturer relies on Certificates of Conformity, do they clearly |

YES |

N/A |

NO |

|

identify the product, quantity of items covered, the specification to which |

|

|

|

|

the products conform, the production date and are they properly issued? |

|

|

|

|

|

|

|

|

|

|

|

|

|

2.4 |

Is there a procedure covering the way to handle |

YES |

N/A |

NO |

|

components and materials? |

|

|

|

Description of the procedure or ref. of documented procedure & revision or issue date:

Details are given on INSPECTOR’S

2.5 |

Is the procedure and the way in which it is applied satisfactory? |

YES |

N/A |

NO |

|

(e.g.: components and materials clearly identified and/or segregated to |

|

|

|

|

prevent unauthorised use?) |

|

|

|

|

|

|

|

|

|

|

|

|

|

2.6 |

Are records of the incoming inspection maintained and satisfactory? |

YES |

N/A |

NO |

|

|

|

|

|

Page 5 of 25 |