It is simple to get forms applying our PDF editor. Improving the asme csd1 file is easy for those who adhere to the next actions:

Step 1: This page has an orange button saying "Get Form Now". Click it.

Step 2: At the time you access our asme csd1 editing page, you will find all the actions you can undertake regarding your document within the top menu.

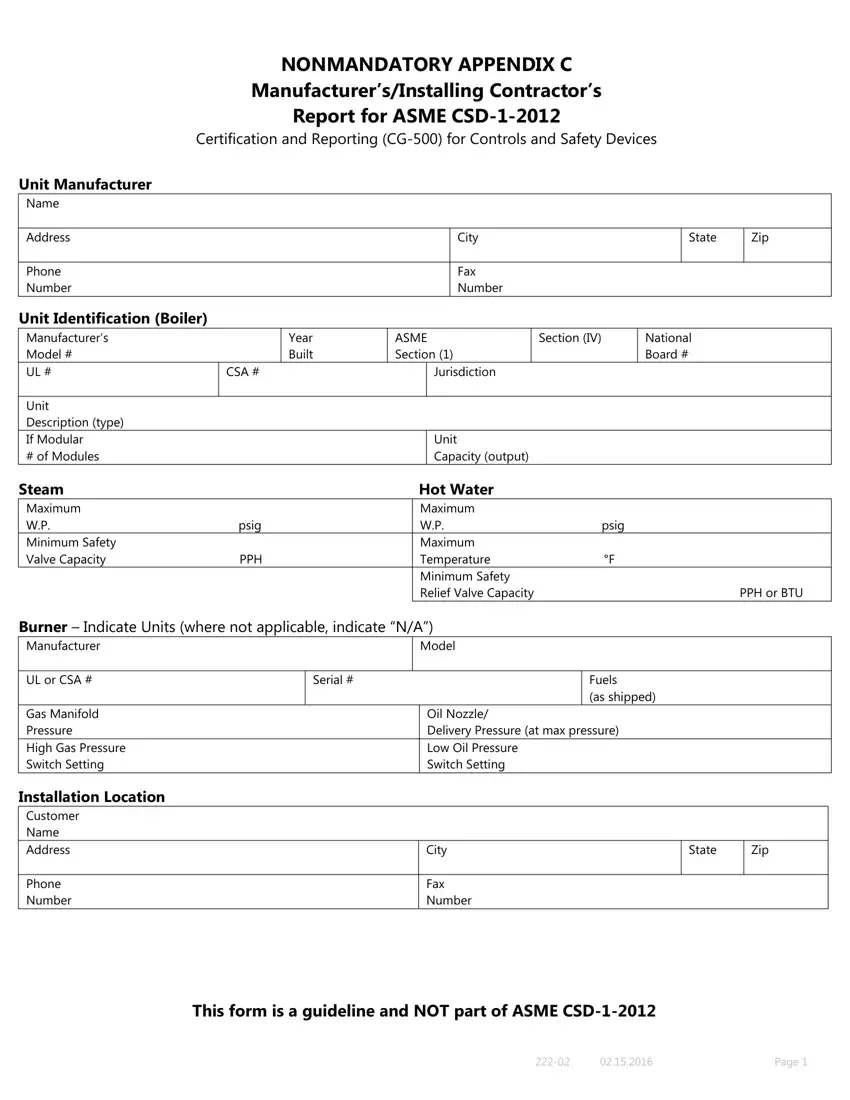

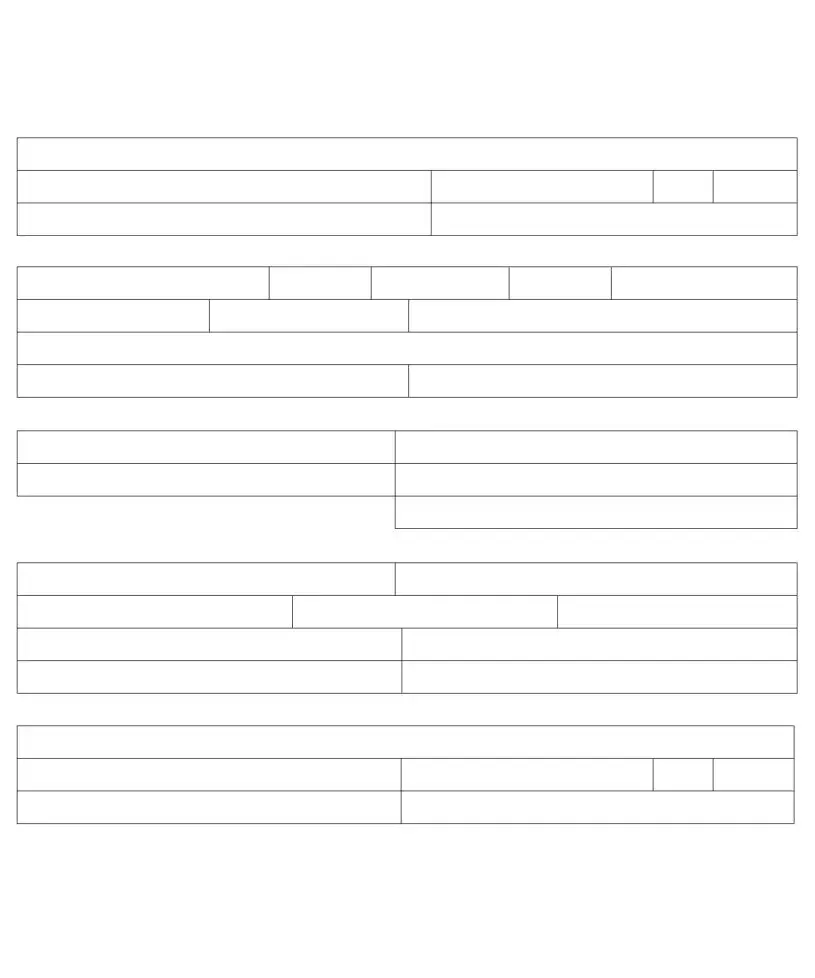

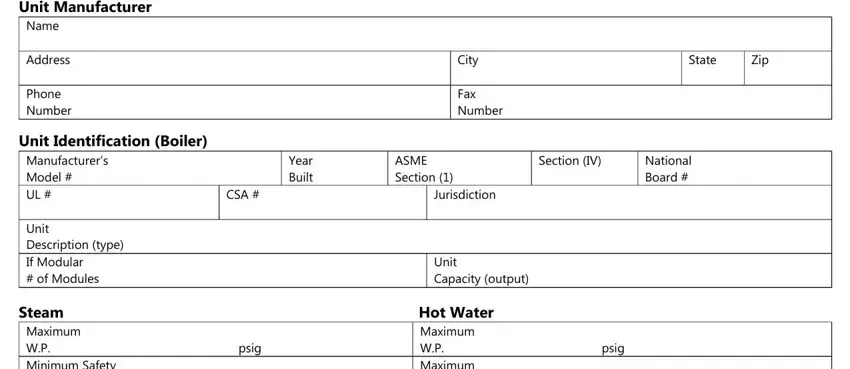

Enter the required content in every area to prepare the PDF asme csd1

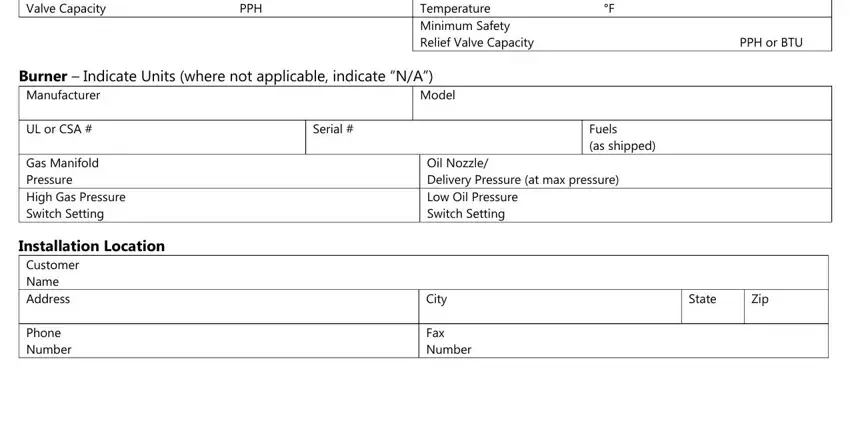

Provide the requested details in the space Hot Water Maximum WP psig Maximum, Steam Maximum WP psig Minimum, Burner Indicate Units where not, Model, UL or CSA, Gas Manifold Pressure High Gas, Installation Location Customer, Phone Number, Serial, Fuels as shipped, Oil Nozzle Delivery Pressure at, City, Fax Number, State, and Zip.

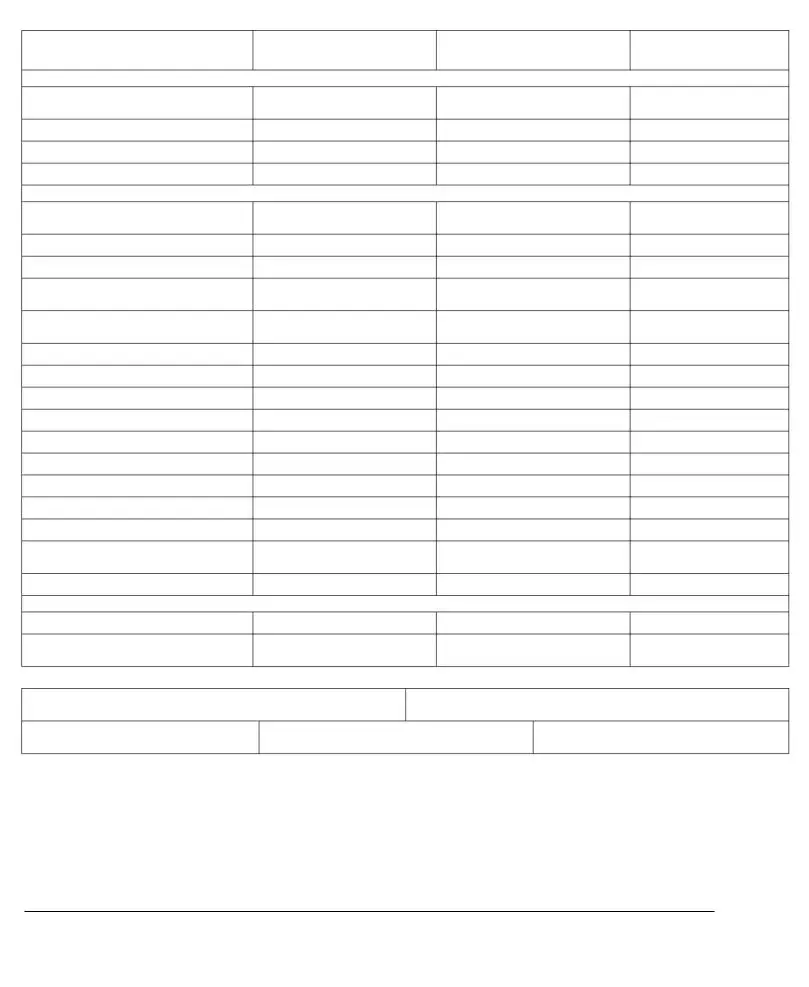

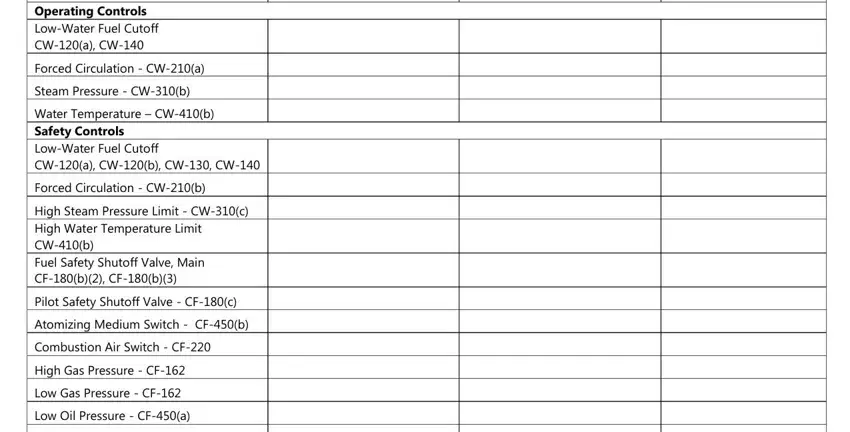

The application will demand for additional information with the intention to instantly complete the area ControlDevice, Operating Controls LowWater Fuel, Forced Circulation CWa, Steam Pressure CWb, Water Temperature CWb Safety, Forced Circulation CWb, High Steam Pressure Limit CWc, Pilot Safety Shutoff Valve CFc, Atomizing Medium Switch CFb, Combustion Air Switch CF, High Gas Pressure CF, Low Gas Pressure CF, Low Oil Pressure CFa, Manufacturer, and Model Number.

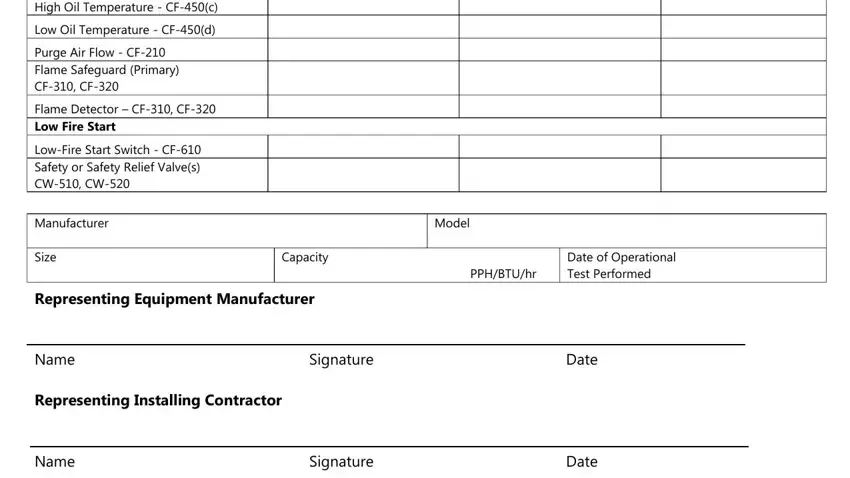

You will have to spell out the rights and obligations of each side in section High Oil Temperature CFc, Low Oil Temperature CFd, Purge Air Flow CF Flame Safeguard, Flame Detector CF CF Low Fire, LowFire Start Switch CF Safety or, Manufacturer, Size, Model, Capacity PPHBTUhr, Date of Operational Test Performed, Representing Equipment Manufacturer, Name Signature Date, Representing Installing Contractor, and Name Signature Date.

Step 3: Press the button "Done". The PDF form can be exported. It is possible to upload it to your computer or send it by email.

Step 4: In avoiding probable upcoming difficulties, be sure to obtain up to two or three copies of each and every file.