In the intricate world of military logistics, precision in the preparation and deployment of supplies is paramount, and the DA Form 1748 plays a critical role in this process. This form, officially titled the Joint Airdrop Inspection Record (Platforms), ensures the thorough inspection and documentation of equipment prior to airdrop operations. It guides the inspection teams through a detailed checklist, which includes identifying the unit being airdropped, the airlift unit, departure airfield, type of aircraft, and specific details about the rigging of the platforms to be dropped. The form is meticulously designed to capture essential data such as the weight, length, width, and height of the load, as well as the configuration of the drogue and cargo parachutes, their connection to the load, and the integrity of the equipment used for the extraction and release of the payload. Furthermore, it goes into granular details regarding the proper packing and securing of parachutes, the condition of the platforms, the safety measures for hazardous materials, and emergency restraint systems. By ensuring that all these elements are inspected and documented, the DA Form 1748 serves as a safeguard to ensure the safety and success of military airdrop missions, reflecting a deep commitment to operational excellence and the well-being of military personnel. Through a comprehensive checklist, this form facilitates a rigorously structured process to examine and validate the readiness of equipment for airdrop, with the aim of minimizing risks and enhancing the effectiveness of airborne operations.

| Question | Answer |

|---|---|

| Form Name | Da Form 1748 |

| Form Length | 2 pages |

| Fillable? | No |

| Fillable fields | 0 |

| Avg. time to fill out | 30 sec |

| Other names | M-3, da form 1954, 1997, IAW |

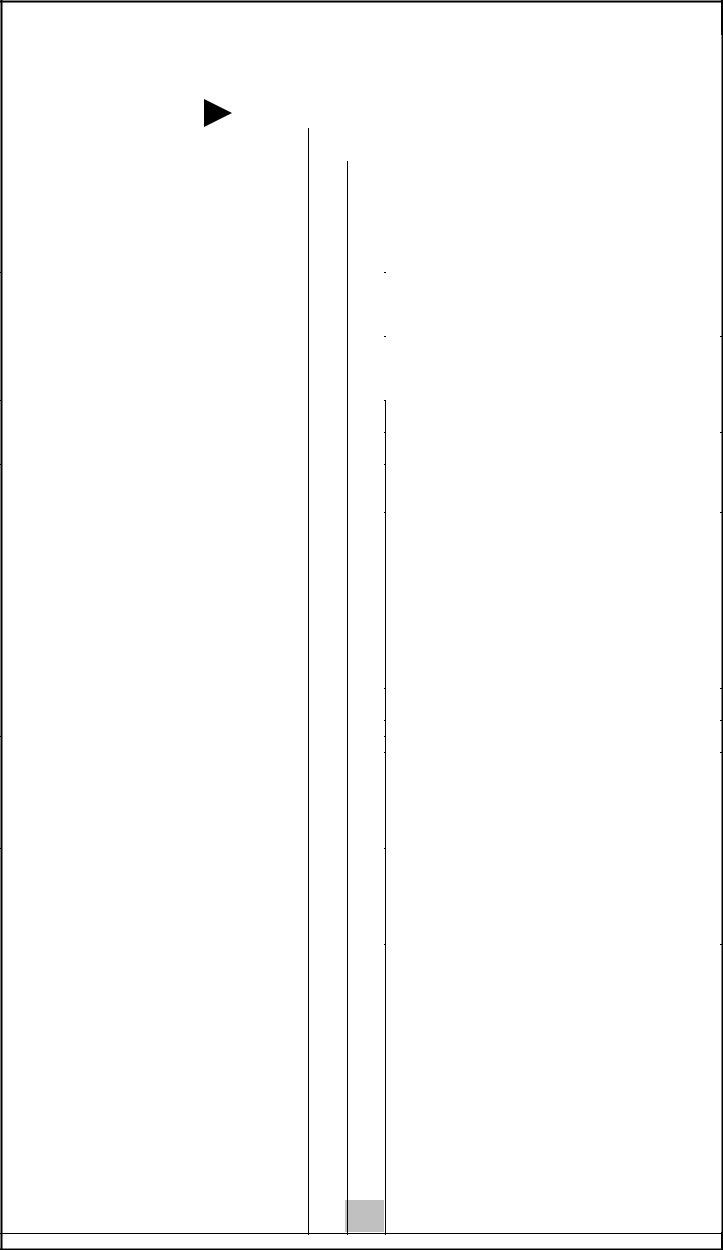

JOINT AIRDROP INSPECTION RECORD (PLATFORMS)

(See reverse for instructions)

1. UNIT BEING AIRDROPPED |

|

|

|

|

2. AIRLIFT UNIT (*) |

|

|

3. DEPARTURE AIRFIELD (ONLOAD) |

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

4. TYPE AIRCRAFT |

|

5. AIRCRAFT SERIAL NO. (*) |

|

6. ITEM DESCRIPTION |

|

|

7. RIGGED IAW FM/TO NO |

8. LOAD POSITION (*) |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LOAD DATA TAG INFORMATION |

|

|

|

9. WEIGHT |

|

|

|

10. LENGTH |

|

11. WIDTH |

|

|

12. HEIGHT |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LOADING |

CHECK ONLY ITEMS APPLICABLE TO YOUR SPECIFIC |

|

LOADING |

||||||||||

|

CHECK ONLY ITEMS APPLICABLE TO YOUR SPECIFIC LOAD |

|

INSPECTION |

|

INSPECTION |

|||||||||||||||||

|

|

LOAD |

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BEFORE AFTER |

|

|

|

|

|

|

|

|

BEFORE |

AFTER |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

13. EXTRACTION/DROGUE PARACHUTE AND RIGGING |

|

|

|

|

19. |

CARGO PARACHUTE SYSTEM |

|

|

|

|

||||||||||||

A. CORRECT SIZE, BAG CLOSING TIES CORRECT |

|

|

|

|

|

A. CORRECT NUMBER OF PARACHUTES |

|

|

|

|||||||||||||

B. SAFETY LOOP/PENDULUM LINE ATTACHED |

|

|

|

|

|

B. PARACHUTE SECURED TO LOAD, CONNECTED TO RELEASE |

|

|

|

|||||||||||||

C. SAFETY LOOP OVER BENT |

|

|

|

|

|

WITH |

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

D. |

|

|

|

|

|

C. RELEASE STRAPS ATTACHED TO CLEVIS AT PARACHUTE |

|

|

|

|||||||||||||

E. PENDULUM LINE PROPERLY SECURED (IAW |

|

|

|

|

D. RESTRAINT STRAP PROPERLY SECURING PARACHUTE(S) |

|

|

|

||||||||||||||

|

|

|

|

|

|

AND ROUTED THROUGH RELEASE KNIFE(S) |

|

|

|

|

||||||||||||

14. |

EXTRACTION (ELB)/DROGUE LINE BAG (DLB) |

|

|

|

|

|

|

|

|

|||||||||||||

A. EXTRACTION/DROGUE LINE CORRECT LENGTH, LOOP, & TYPE |

|

|

|

|

E. RELEASE KNIFE SHARP, PROPERLY SAFETIED |

|

|

|

|

|||||||||||||

B. DROGUE/EXTRACTION LINE INSERTED INTO CLIPS AND/OR TIED TO |

|

|

|

|

F. RISER EXTENSIONS CORRECT LENGTH, ATTACHED TO |

|

|

|

||||||||||||||

PROPER RECESS |

|

|

|

|

|

|

|

|

|

PARACHUTE(S) AND RELEASE(S) |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

C. ELB/DLB PROPERLY PACKED, BAG CLOSING TIES CORRECT |

|

|

|

|

20. |

|

|

|

||||||||||||||

D. EXTRACTION/DROGUE LINE PROPERLY PLACED AND SECURED |

|

|

|

|

A. RELEASE POSITIONED CORRECTLY AND SECURED TO LOAD |

|

|

|

||||||||||||||

E. DROGUE LINE CONNECTED TO TOWPLATE JETTISON LINK |

|

|

|

|

B. PARACHUTE CONNECTOR(S) SEATED IN RETAINER CLAMP |

|

|

|

||||||||||||||

F. EXTRACTION LINE CONNECTED TO EXTRACTION SYSTEM |

|

|

|

|

|

C. RELEASE TIMER KEYS EXTENDED, ARMING LANYARD WIRE |

|

|

|

|||||||||||||

15. |

TOWPLATE EXTRACTION LINK |

|

|

|

|

|

SEATED, LANYARD SAFETIED AND SECURED TO PARACHUTE |

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|||||||||||||||

A. DROGUE JETTISON LINK SAFETIED TO DROGUE EXTRACTION LINE |

|

|

|

|

ONLY) |

|

|

|

|

|

|

|

|

|

|

|||||||

B. EXTRACTION LINK INSTALLED IN TOWPLATE |

|

|

|

|

|

21. |

SUSPENSION SLINGS |

|

|

|

|

|||||||||||

C. ENSURE LINK LATCH CAM FOLLOWERS LOCK OVER EXTRACTION LINK |

|

|

|

|

A. ATTACHED TO COUPLER/CLEVIS/LINKS |

|

|

|

|

|||||||||||||

16. |

DROGUE EXTRACTION SYSTEM |

|

|

|

|

|

B. CORRECT LENGTH, LOOP, AND NUMBER |

|

|

|

|

|||||||||||

A. ELB BRIDLE ATTACHED TO EXTRACTION LINK |

|

|

|

|

|

C. ATTACHED TO LOAD OR PLATFORM |

|

|

|

|

|

|

||||||||||

B. CENTERLINE ATTACHED TO EXTRACTION LINK AND CONNECTOR LINK |

|

|

|

|

D. PROPERLY PADDED, ROUTED AND SECURED |

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C. ELB BRIDLE SECURELY ATTACHED TO ELB (6 PLACED) AND PARACHUTE |

|

|

|

|

22. |

GENERAL ITEMS |

|

|

|

|

|

|

||||||||||

DEPLOYMENT BAG BRIDLE(S) |

|

|

|

|

|

A. LASHINGS UNIFORM TENSION AND BINDERS SAFETIED |

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

D. PARACHUTE(S) CLUSTERED AND TIED TO ELB |

|

|

|

|

|

B. ACCOMPANYING LOAD SECURED |

|

|

|

|

|

|

||||||||||

E. PARACHUTE(S) BAG CLOSING TIES AND MINIATURE KNIFE(S) INSTALLED |

|

|

|

|

C. HONEYCOMB FLUSH AGAINST LOAD, GOOD CONDITION, |

|

|

|

||||||||||||||

AND SAFETIED |

|

|

|

|

|

|

|

|

|

PROPERLY ARRANGED |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

F. KNIFE LANYARD(S) EQUAL EFFECTIVE LENGTH AND ATTACHED TO |

|

|

|

|

D. PLATFORM NOT DAMAGED OR BOWED, BOTTOM CHECKED |

|

|

|

||||||||||||||

CONNECTOR LINK |

|

|

|

|

|

|

|

|

|

FOR CONDITION (CHECKED BEFORE OR DURING LOADING) |

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

G. PARACHUTE(S) ADAPTER WEB(S) ATTACHED TO CONNECTOR LINK |

|

|

|

|

E. HAZARDOUS MATERIAL CERTIFIED IAW TM |

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

H. MAIN EXTRACTION LINE CONNECTED TO CONNECTOR LINK, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

CONNECTOR LINK SAFETIED TO PARACHUTE(S) |

|

|

|

|

|

F. EMERGENCY RESTRAINT PROVISIONS ON THE |

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

I. EXTRACTION LINE CORRECT LENGTH, LOOP, TYPE AND PROPERLY |

|

|

|

|

PLATFORM/LOAD |

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

PACKED, BAG CLOSING TIES CORRECT |

|

|

|

|

|

23. OTHERS |

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

J. PARACHUTE(S) AND ELB POSITIONED AND SECURED |

|

|

|

|

|

(REF: |

|

|

|

|

|

|

|

|

|

|

||||||

K. CONNECTED TO EXTRACTION SYSTEM |

|

|

|

|

|

24. ADS LOCKS |

A. NUMBER |

|

|

B. SETTING |

|

|||||||||||

17. SEQUENTIAL LOAD EXTRACTION PARACHUTE(S) AND ELB |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

A. CORRECT SIZE, BAG CLOSING TIES CORRECT |

|

|

|

|

|

25. BEFORE LOADING INSPECTION |

DATE/TIME COMPLETE |

|

|

|||||||||||||

B. PROPERLY PLACED, ATTACHED TO LOAD |

|

|

|

|

|

CERTIFICATION |

|

|

|

|

/ |

|

||||||||||

C. PENDULUM LINE/SAFETY LOOP PROPERLY ROUTED AND SECURED |

|

|

|

|

A. TRANSPORTED FORCE INSPECTOR |

|

|

|

|

|||||||||||||

D. EXTRACTION LINE ATTACHED TO PARACHUTE, SAFETIED TO LOAD |

|

|

|

|

UNIT (PRINT) |

|

|

|

|

LAST NAME (PRINT) |

|

INITIALS |

||||||||||

E. ELB PROPERLY PACKED, POSITIONED/SECURED, AND CONNECTED TO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

EXTRACTION SYSTEM |

|

|

|

|

|

|

|

|

|

SIGNATURE |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

18. |

EXTRACTION FORCE TRANSFER COUPLING (EFTC) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

A. RELEASE CABLE ATTACHED TO ACTUATOR AND CABLE CLEVIS PIN |

|

|

|

|

B. AIR FORCE INSPECTOR |

|

|

|

|

|

|

|||||||||||

INSTALLED |

|

|

|

|

|

|

|

|

|

UNIT (PRINT) |

|

|

|

|

LAST NAME (PRINT) |

|

INITIALS |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

B. ACTUATOR MOUNTED, PINS INSTALLED AND SEATED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

C. ACTUATOR ARM SAFETY PIN REMOVED AND STOWED |

|

|

|

|

|

SIGNATURE |

|

|

|

|

|

|

|

|

|

|

||||||

D. LATCH AND ADAPTER SECURED TO THE LOAD, COUPLING LINK FULLY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

SEATED |

|

|

|

|

|

|

|

|

|

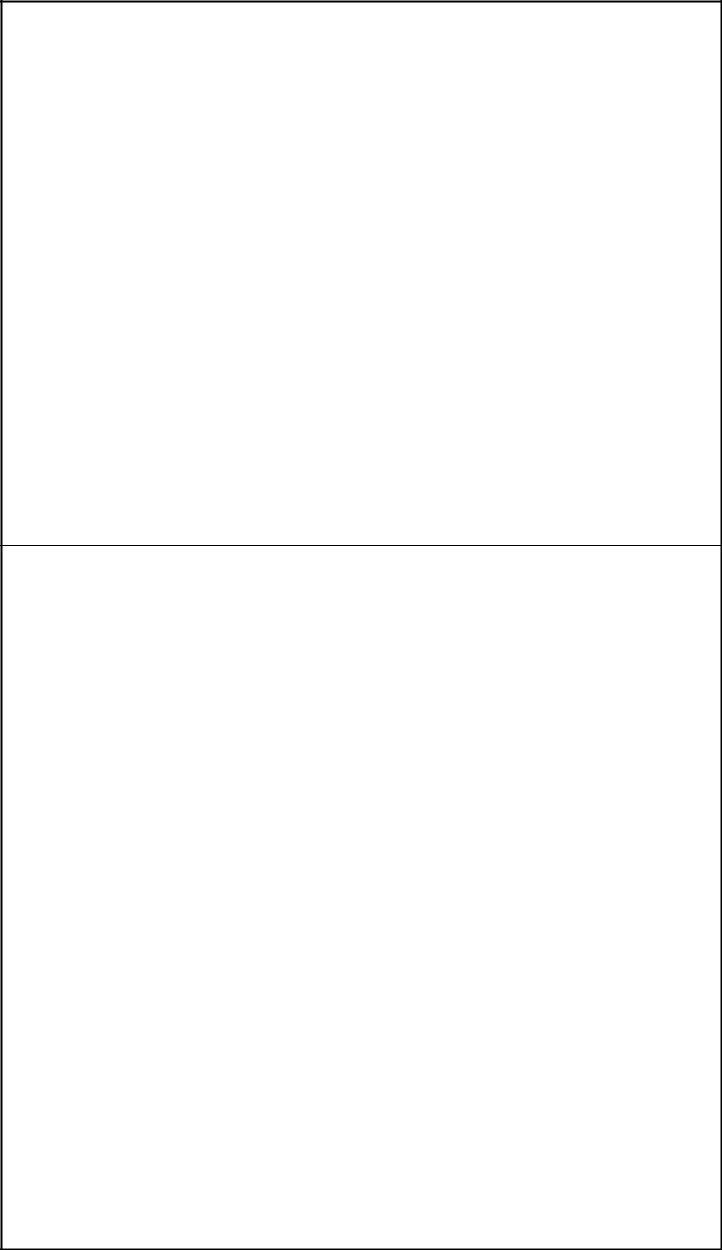

26. AFTER LOADING INSPECTION |

|

DATE/TIME COMPLETE |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

E. LATCH LOCKED, INDICATOR MARKS ALIGNED, RELEASE CABLE |

|

|

|

|

CERTIFICATION |

|

|

|

|

/ |

|

|||||||||||

ATTACHED, CLEVIS PIN INSTALLED |

|

|

|

|

|

A. TRANSPORTED FORCE INSPECTOR |

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

F. MARKED END OF SLOT IN LOCK LINK LINES UP WITH WHITE DIMPLE |

|

|

|

|

UNIT (PRINT) |

|

|

|

|

LAST NAME (PRINT) |

|

INITIALS |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

MARK ON LATCH BODY (60K) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G. PUSH DOWN ON LATCH PUSH ROD (NO RED VISIBLE ABOVE LATCH SIDE |

|

|

|

|

SIGNATURE |

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

PLATE) (60K) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

H. CHECK ROLLER SHAFT DIMPLE CENTERED IN LATCH IN 1/4 INCH |

|

|

|

|

B. AIR FORCE INSPECTOR |

|

|

|

|

|

|

|||||||||||

PEEPHOLE (60K) |

|

|

|

|

|

|

|

|

|

UNIT (PRINT) |

|

|

|

|

LAST NAME (PRINT) |

|

INITIALS |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

I. CHECK LATCH LOCK FOR NO MOVEMENT BEYOND ALIGNMENT OF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

MARKED END OF SLOT WITH WHITE DIMPLE ON LATCH BODY (60K) |

|

|

|

|

SIGNATURE |

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

J. DEPLOYMENT LINE CORRECT LENGTH AND LOOP, ATTACHED TO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

COUPLING LINK AND PARACHUTE(S), PROPERLY ROUTED AND SAFETIED |

|

|

|

|

C. AIRCREW LOADMASTER |

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

K. RELEASE CABLE CORRECT LENGTH, PROPERLY ROUTED AND SAFETIED |

|

|

|

|

UNIT (PRINT) |

|

|

|

|

LAST NAME (PRINT) |

|

INITIALS |

||||||||||

L. ACTUATOR BRACKET PROPERLY MOUNTED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

M. ACTUATOR COCKED AND ARM SAFETY PIN INSTALLED |

|

|

|

|

|

SIGNATURE |

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N.ACTUATOR REMOVED FROM MOUNTING BRACKET AND PLACED INBOARD FOR LOADING

(*) COMPLETE BLOCKS 2, 5 AND 8 DURING AFTER LOADING INSPECTION

DD FORM 1748, NOV 1997 |

PREVIOUS EDITION MAY BE USED. |

ADOBE PROFESSIONAL 8.0 |

|

|

|

INSTRUCTIONS |

|

|

|

||

Complete Joint Airdrop Inspection Record (Platforms) as required by |

|

Item 11. |

Enter the width of the platform or load, whichever is greater. |

|||||

|

||||||||

AFJI |

|

|

|

|

|

|||

detailed below: |

|

|

|

Item 12. |

Enter the height of the platform and load from the bottom of |

|||

|

|

|

|

|

the platform to the highest point on the load. |

|

|

|

Item 1. Enter the designation and geographic location of the military unit |

|

|

|

|

|

|||

responsible for the equipment being tendered for airdrop. |

|

Item 13 through 22. Enter an X for each applicable item. Enter "NA" |

||||||

|

|

|

|

|

for |

|||

*Item 2. |

Enter the unit of aircraft commander (complete during |

|

applicable, it may be crossed out (X). |

|

|

|||

|

|

|

|

|

|

|

||

|

|

|

|

|

Item 23. Use the attachment in appropriate rigging manual and |

|||

Item 3. |

Enter the designation of the locality from which the unit being |

|

attach to inspection form. |

|

|

|||

airlifted is departing. (Example: Bravo LZ, Eglin AFB FL.) |

|

|

|

|

|

|||

|

|

|

|

|

Item 24. Inspect all locks affecting the platform for this pass and |

|||

Item 4. Enter the model and series of aircraft that will airlift the |

|

enter lock number(s) set into the platform and the setting on each |

||||||

equipment to be airdropped. (Example: |

|

|

lock. |

|

|

|

||

*Item 5. |

Enter the complete serial number (tail number) of the aircraft on |

|

Item 25. |

Enter local time and date of inspections. |

All entries, |

|||

which the equipment is loaded. |

(Complete |

during |

|

including |

signatures, must be complete and legible. |

Both |

the |

|

inspections.) |

|

|

|

Transported Force and Air Force inspectors certify completion of the |

||||

|

|

|

|

|

inspection. When the load is delivered to the aircraft, the aircrew |

|||

Item 6. Enter the nomenclature of the equipment tendered for airdrop. If |

|

loadmaster will ensure all items 1 through 12 are entered and correct, |

||||||

additional space is required for mixed pieces of equipment, enter "see |

|

and ensure all checks in the before loading column (items 13 through |

||||||

remarks" and describe the entire load in item 27. |

(Example: HMMWV, |

|

22) are entered. Ensure items 25A and B are completed. |

|

|

|||

ammunition, petroleum) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Item 26. Enter local time and date of inspections. All entries |

|||

Item 7. |

Enter the FM/TO number |

utilized in rigging the equipment |

|

including signatures, must be complete and legible. Both inspectors |

||||

tendered for airdrop. |

|

|

|

must certify completion. NOTE: After all inspections are completed, |

||||

|

|

|

|

|

the aircrew loadmaster ensures that all applicable columns have |

|||

*Item 8. |

Enter the sequential position of each platform in the aircraft. |

|

been checked and affixes his signature certifying completion of all |

|||||

For a |

|

inspection requirements. |

|

|

||||

platform loaded is Load #1. (Complete during |

|

|

|

|

|

|||

|

|

|

|

|

Item 27. Enter any comments pertaining to the load, loading |

|||

Item 9. Enter the total rigged weight of the platform, air items, and |

|

difficulties encountered, or reason for rejection of the |

load. |

Also |

||||

accompanying load as they appear on the load data tag. |

|

include any other pertinent facts concerning the load or delays. |

||||||

|

|

|

|

|

When inflight rigging is required, those items to be completed inflight |

|||

Item 10. |

Enter the length of the platform or load, whichever is greater. |

|

will be annotated. |

|

|

|||

|

|

|

|

|

|

|

|

|

27. REMARKS

DD FORM 1748, NOV 1997