It is possible to fill in generator run log sheet instantly with the help of our online editor for PDFs. Our tool is continually evolving to grant the best user experience possible, and that is because of our resolve for continual enhancement and listening closely to customer comments. It just takes a few easy steps:

Step 1: Access the PDF doc in our editor by clicking the "Get Form Button" in the top area of this webpage.

Step 2: This editor will let you modify PDF documents in a range of ways. Modify it by writing your own text, correct what is already in the document, and put in a signature - all close at hand!

It is easy to finish the pdf with this detailed tutorial! Here is what you must do:

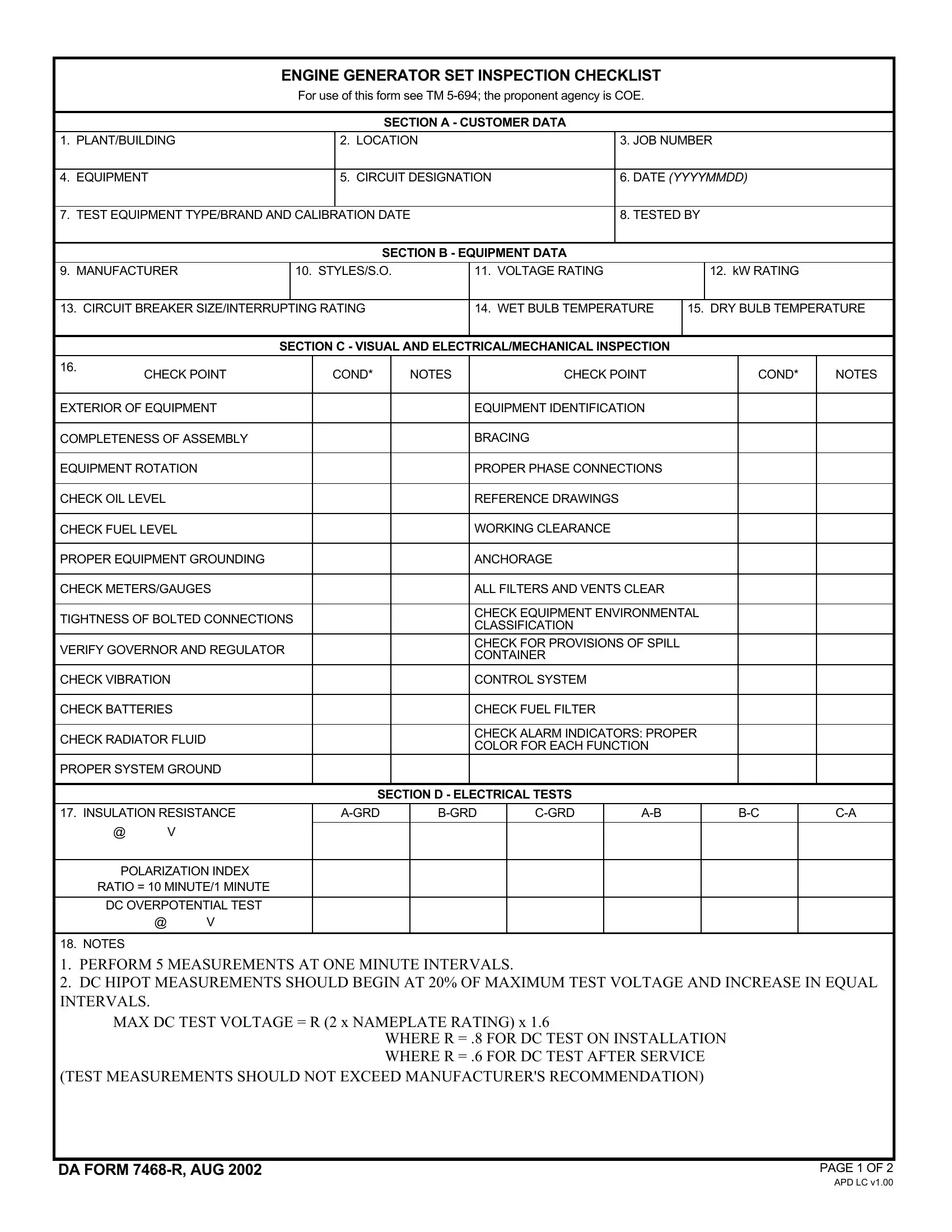

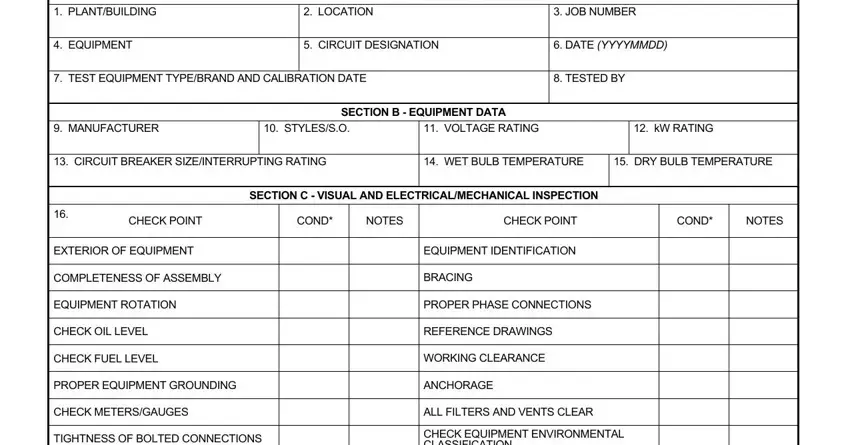

1. Complete the generator run log sheet with a group of essential blanks. Gather all the necessary information and make sure there's nothing left out!

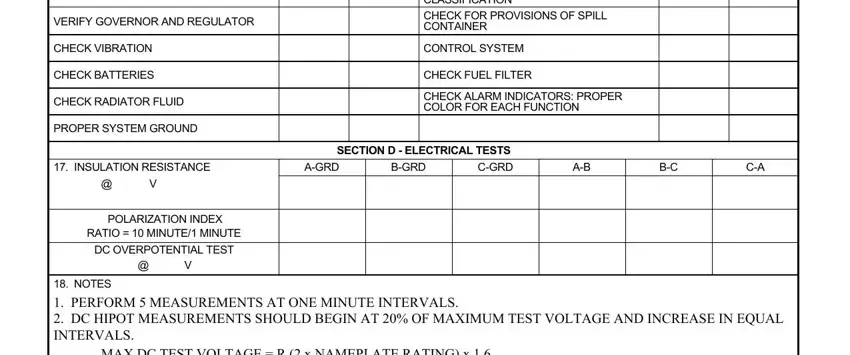

2. The third stage would be to submit the next few blanks: TIGHTNESS OF BOLTED CONNECTIONS, VERIFY GOVERNOR AND REGULATOR, CHECK VIBRATION, CHECK BATTERIES, CHECK RADIATOR FLUID, PROPER SYSTEM GROUND, CHECK EQUIPMENT ENVIRONMENTAL, CHECK FOR PROVISIONS OF SPILL, CONTROL SYSTEM, CHECK FUEL FILTER, CHECK ALARM INDICATORS PROPER, INSULATION RESISTANCE, AGRD, BGRD, and CGRD.

As for CGRD and CHECK EQUIPMENT ENVIRONMENTAL, ensure that you do everything right in this section. Those two are certainly the most significant fields in this page.

3. In this specific step, look at WHERE R FOR DC TEST ON, DA FORM R AUG, and PAGE OF APD LC v. Each of these will have to be taken care of with greatest accuracy.

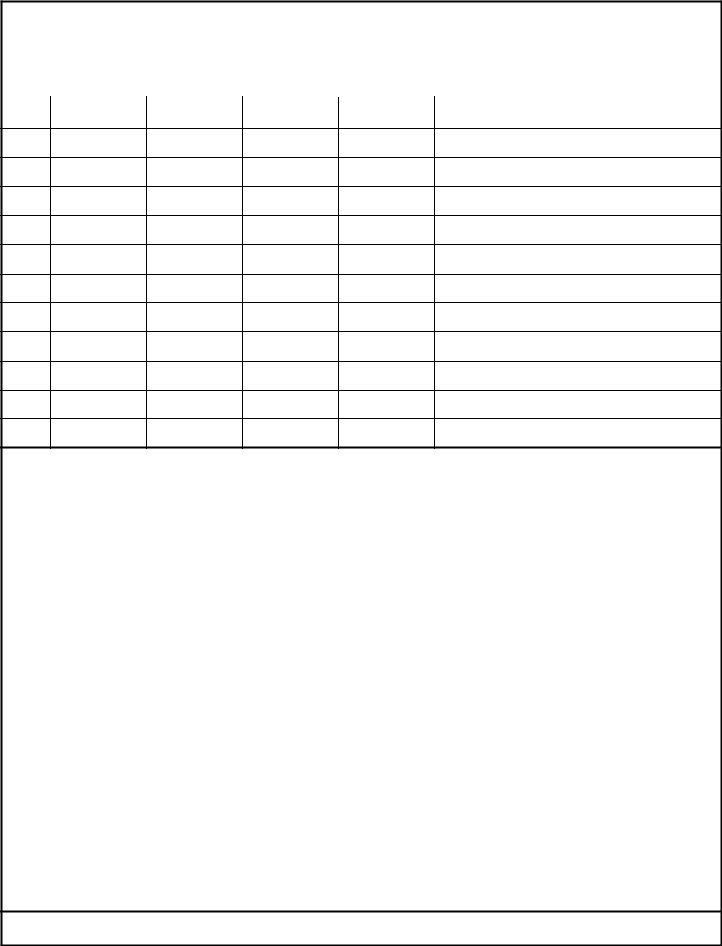

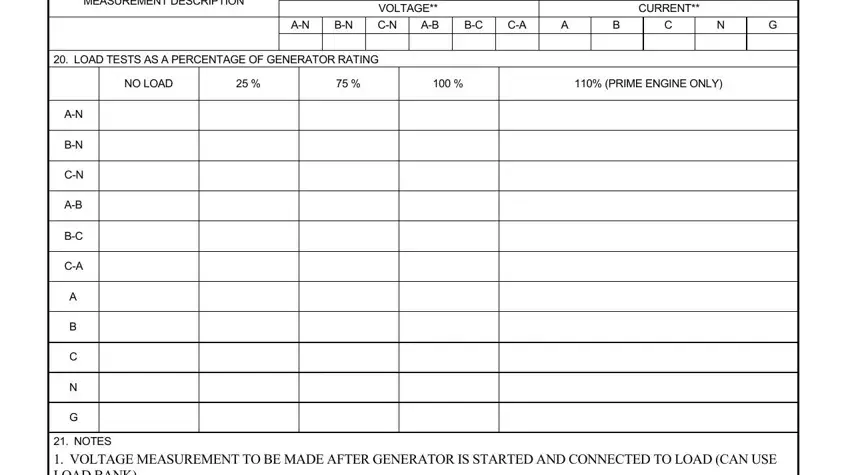

4. This next section requires some additional information. Ensure you complete all the necessary fields - MEASUREMENT DESCRIPTION, VOLTAGE, CURRENT, LOAD TESTS AS A PERCENTAGE OF, NO LOAD, PRIME ENGINE ONLY, NOTES, and VOLTAGE MEASUREMENT TO BE MADE - to proceed further in your process!

5. To finish your document, the particular part features a couple of additional blank fields. Typing in PERFORM AND RECORD ENGINE, CONDITION AACCEPTABLE RNEEDS, DA FORM R AUG, and PAGE OF APD LC v should wrap up everything and you can be done in no time!

Step 3: Check the details you've inserted in the blanks and then hit the "Done" button. Grab the generator run log sheet the instant you register at FormsPal for a 7-day free trial. Easily access the form within your personal account, together with any modifications and changes automatically preserved! FormsPal is focused on the personal privacy of our users; we make certain that all personal data processed by our system is kept secure.