DA Form 7485-R can be filled out in no time. Simply make use of FormsPal PDF editing tool to get it done fast. To make our tool better and simpler to use, we continuously develop new features, taking into consideration suggestions coming from our users. To get started on your journey, take these basic steps:

Step 1: Open the PDF doc in our editor by clicking the "Get Form Button" in the top area of this page.

Step 2: After you access the editor, you will notice the document made ready to be filled in. Other than filling in various blank fields, you may as well perform some other actions with the form, that is writing any words, editing the original textual content, adding images, putting your signature on the document, and more.

This document will involve some specific details; to guarantee accuracy and reliability, please make sure to bear in mind the tips below:

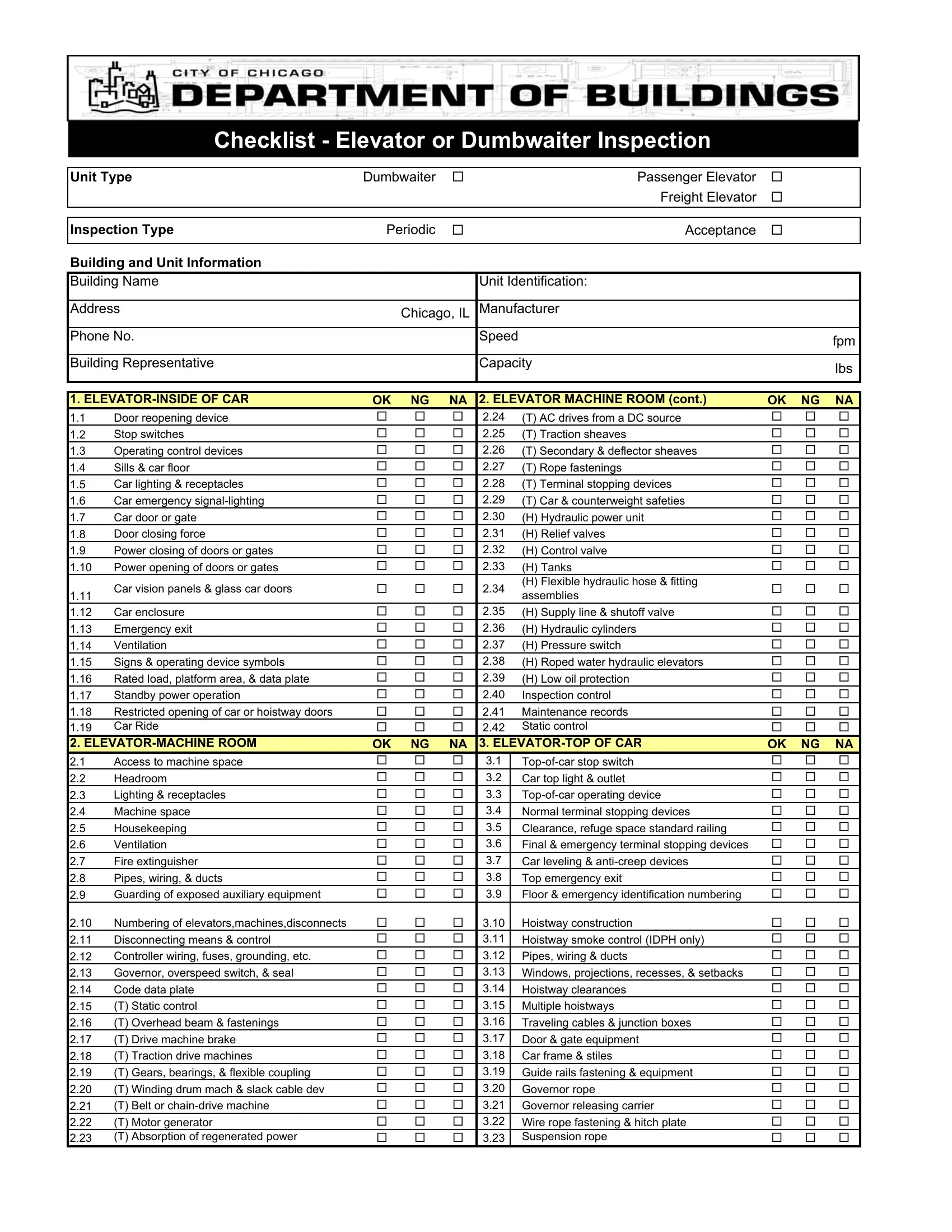

1. To begin with, when completing the DA Form 7485-R, beging with the form section that contains the next blanks:

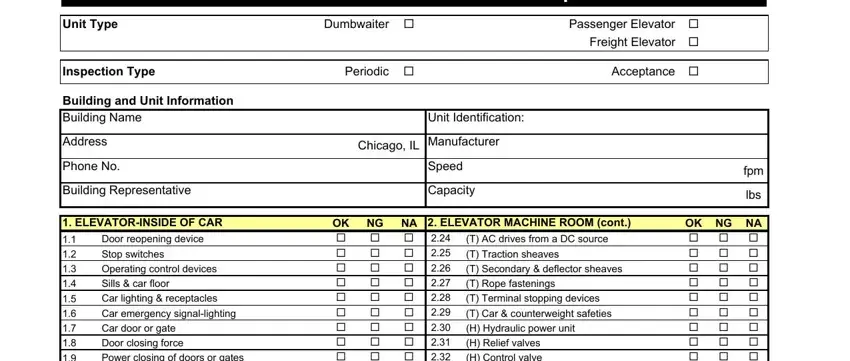

2. Soon after this part is done, proceed to type in the applicable information in all these - NA ELEVATOR MACHINE ROOM cont cid, H Control valve, H Tanks H Flexible hydraulic hose, cid, OK NG NA cid cid cid cid cid cid, cid cid cid cid cid cid cid cid, cid, cid, cid, Power closing of doors or gates, Power opening of doors or gates, Car vision panels glass car doors, Car enclosure, Emergency exit, and Ventilation.

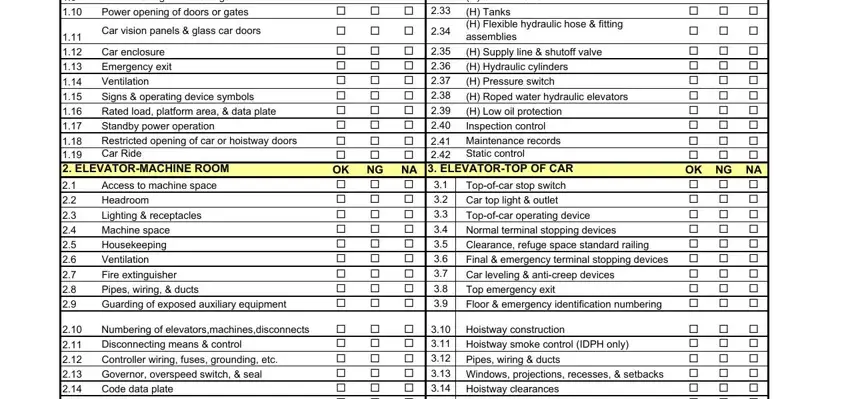

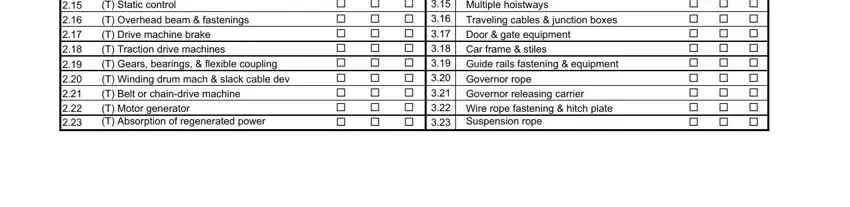

3. Through this part, take a look at T Static control, T Overhead beam fastenings, T Drive machine brake, T Traction drive machines, T Gears bearings flexible coupling, T Winding drum mach slack cable, T Belt or chaindrive machine, T Motor generator T Absorption of, cid cid cid cid cid cid cid cid, cid cid cid cid cid cid cid cid, cid Hoistway construction cid, Traveling cables junction boxes, Door gate equipment, Car frame stiles, and Suspension rope. All of these are required to be taken care of with highest accuracy.

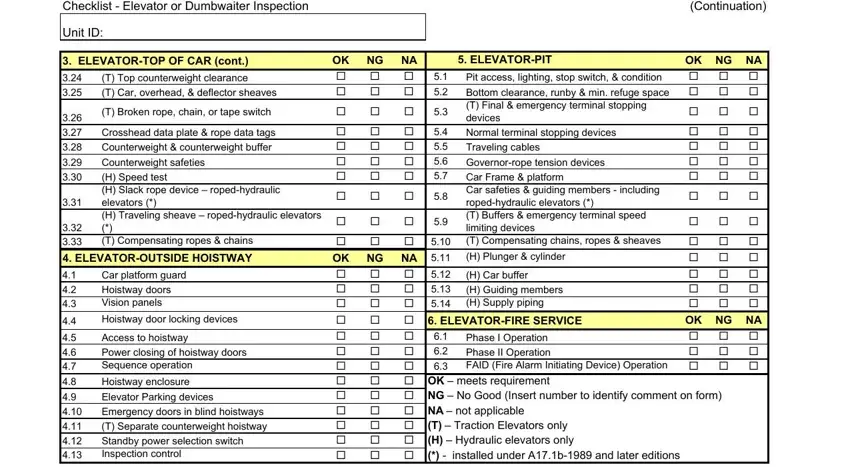

4. The fourth section comes next with these blank fields to fill out: Checklist Elevator or Dumbwaiter, Continuation, Unit ID, ELEVATORPIT, OK NG NA cid cid Pit access, cid cid, cid, cid, cid, Normal terminal stopping devices, Traveling cables, Governorrope tension devices, Car Frame platform Car safeties, cid cid cid cid, and cid.

Be very mindful when filling in OK NG NA cid cid Pit access and Continuation, since this is the section in which a lot of people make mistakes.

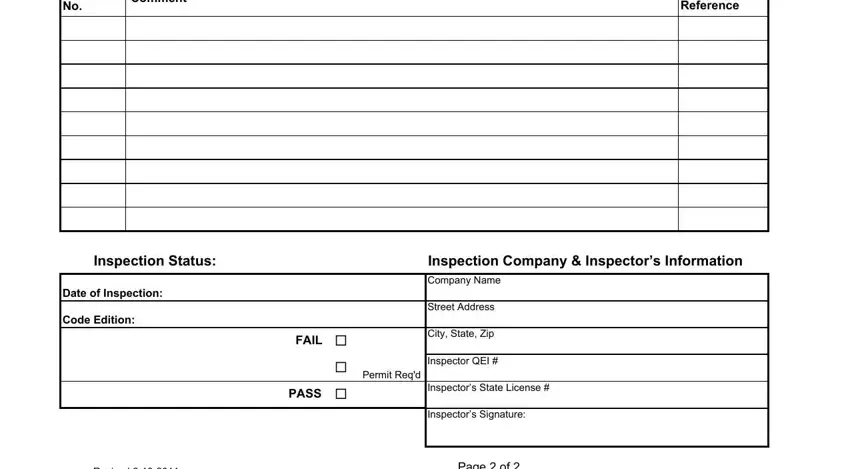

5. The form needs to be wrapped up by filling in this area. Here one can find a full set of form fields that require specific information for your document usage to be complete: Item No, Comment, Code Reference, Inspection Status, Inspection Company Inspectors, Date of Inspection, Code Edition, FAIL cid, cid, Permit Reqd, PASS cid, Company Name, Street Address, City State Zip, and Inspector QEI.

Step 3: Before moving forward, make sure that all blanks were filled out properly. The moment you’re satisfied with it, click “Done." Try a 7-day free trial plan at FormsPal and obtain direct access to DA Form 7485-R - downloadable, emailable, and editable in your FormsPal cabinet. FormsPal guarantees your data confidentiality by using a secure system that never saves or shares any type of sensitive information typed in. You can relax knowing your paperwork are kept safe when you work with our services!