Any time you intend to fill out test certificate piping, you won't have to install any applications - simply try our online tool. The editor is constantly upgraded by our team, acquiring awesome features and becoming better. Here's what you'd need to do to start:

Step 1: Firstly, open the pdf tool by pressing the "Get Form Button" in the top section of this site.

Step 2: The tool helps you work with your PDF form in a variety of ways. Modify it by including customized text, adjust what's originally in the PDF, and include a signature - all at your convenience!

It really is easy to finish the document with our helpful guide! This is what you have to do:

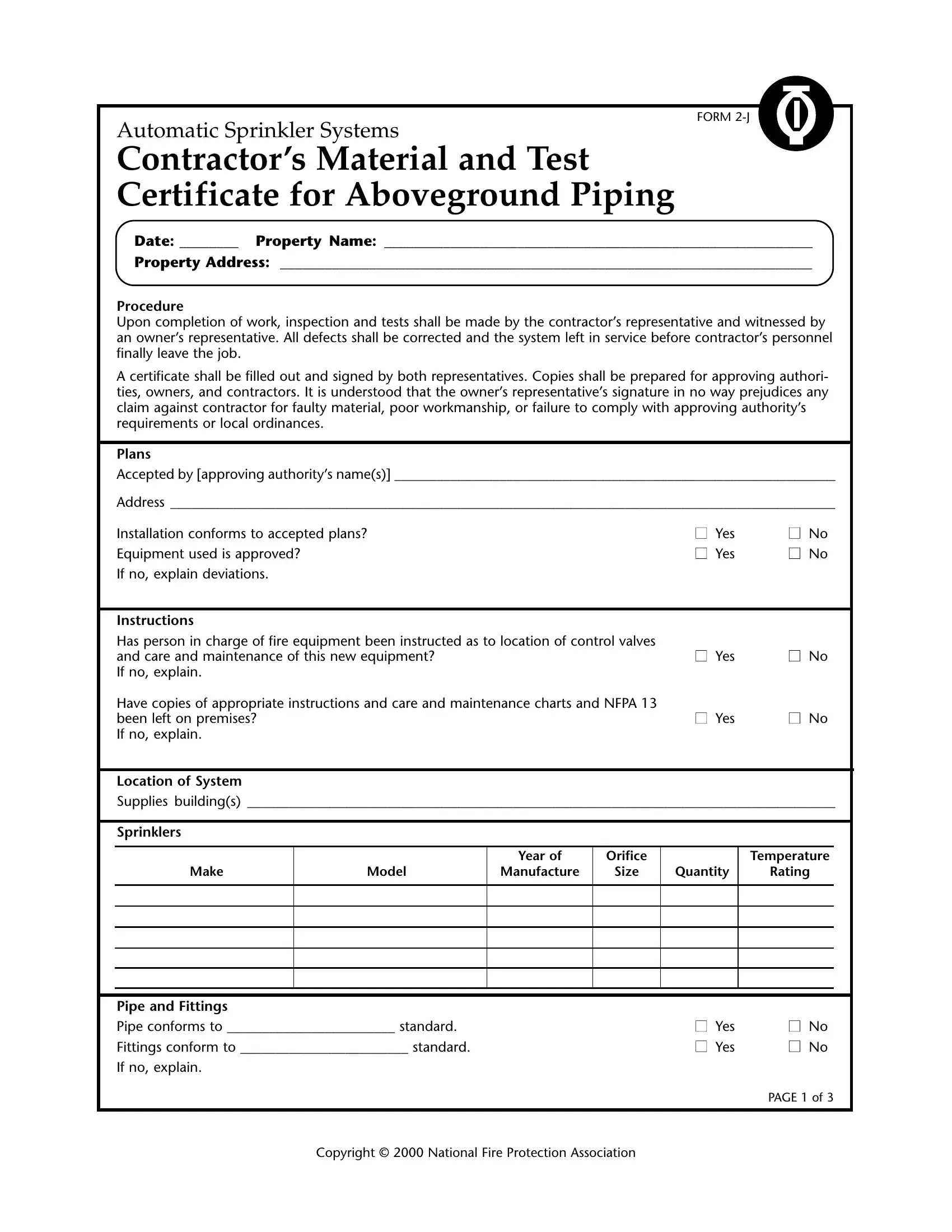

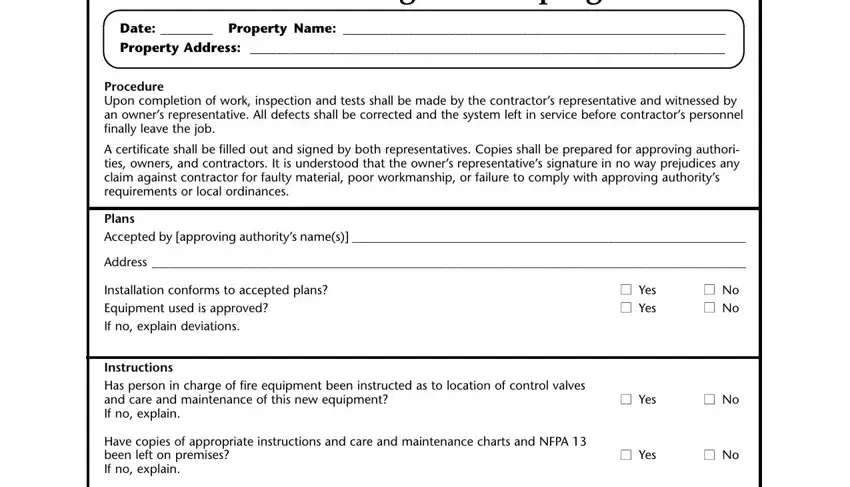

1. For starters, once filling out the test certificate piping, start out with the page that contains the following blank fields:

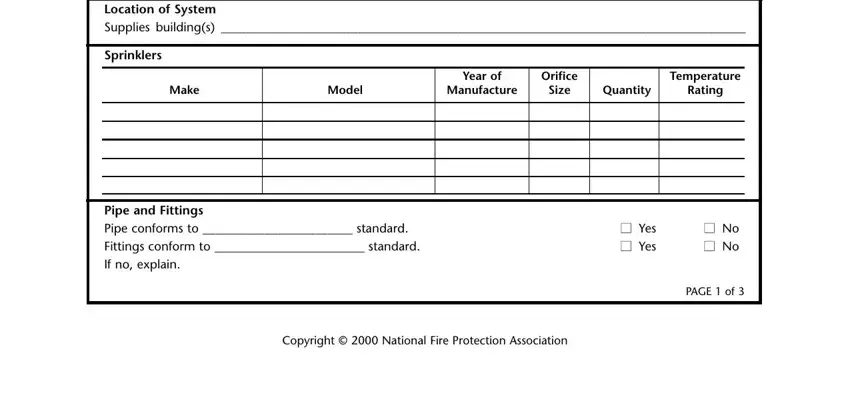

2. The third stage is to fill in the following blank fields: Location of System Supplies, Sprinklers, Make, Model, Year of, Manufacture, Orifice, Size, Temperature, Quantity, Rating, Pipe and Fittings Pipe conforms to, Yes Yes, No No, and PAGE of.

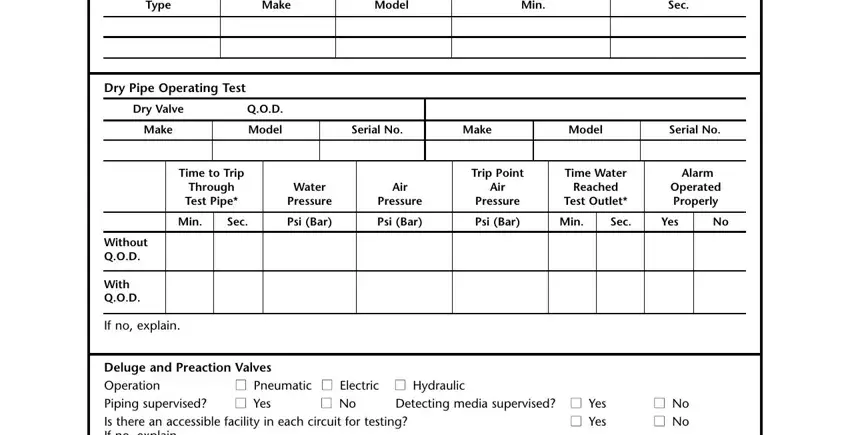

3. Completing Type, Make, Model, Min, Sec, Dry Pipe Operating Test, Dry Valve, Make, QOD, Model, Serial No, Make, Model, Serial No, and Time to Trip is essential for the next step, make sure to fill them out in their entirety. Don't miss any details!

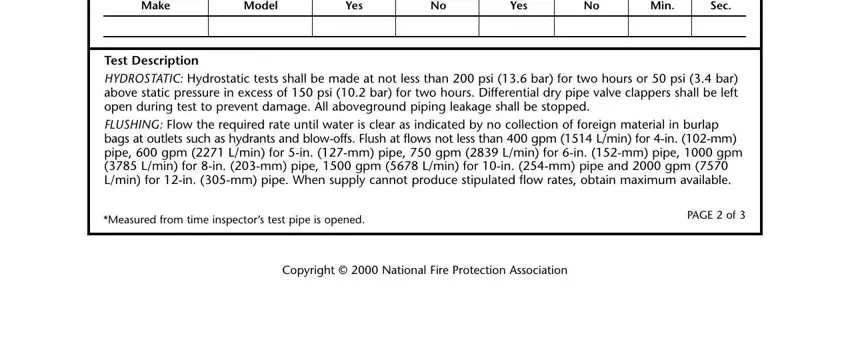

4. To move forward, your next section requires completing a couple of blanks. These comprise of Make, Model, Yes, Yes, Min, Sec, Test Description HYDROSTATIC, Measured from time inspectors test, PAGE of, and Copyright National Fire, which are crucial to going forward with this particular process.

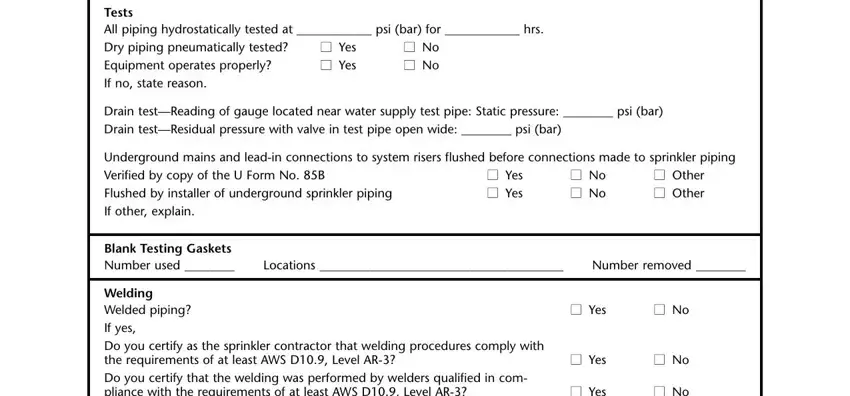

5. Lastly, the following last subsection is what you'll want to finish before using the form. The fields in this instance are the next: Tests All piping hydrostatically, Yes Yes, No No, Drain testReading of gauge located, Underground mains and leadin, Other Other, Yes Yes, No No, Blank Testing Gaskets Number used, Locations, Number removed, Welding Welded piping If yes Do, Yes, Yes, and Yes.

Regarding Tests All piping hydrostatically and Underground mains and leadin, ensure that you take a second look here. Both of these are viewed as the most significant fields in the PDF.

Step 3: Immediately after taking another look at the fields and details, hit "Done" and you are done and dusted! Join FormsPal right now and instantly use test certificate piping, all set for downloading. Every last change you make is conveniently kept , which enables you to customize the pdf later on as needed. FormsPal guarantees protected document completion without personal data recording or sharing. Be assured that your data is secure here!