Once you open the online PDF tool by FormsPal, you can easily complete or modify PVB here. FormsPal team is devoted to giving you the perfect experience with our tool by regularly releasing new capabilities and enhancements. Our editor is now much more useful thanks to the newest updates! Now, filling out PDF files is easier and faster than ever before. It just takes several easy steps:

Step 1: Press the "Get Form" button in the top area of this page to get into our PDF editor.

Step 2: As soon as you start the tool, there'll be the document made ready to be completed. Besides filling in various blank fields, it's also possible to do other things with the form, that is adding any text, editing the original text, inserting illustrations or photos, putting your signature on the form, and much more.

It is actually an easy task to finish the form with this detailed guide! Here is what you need to do:

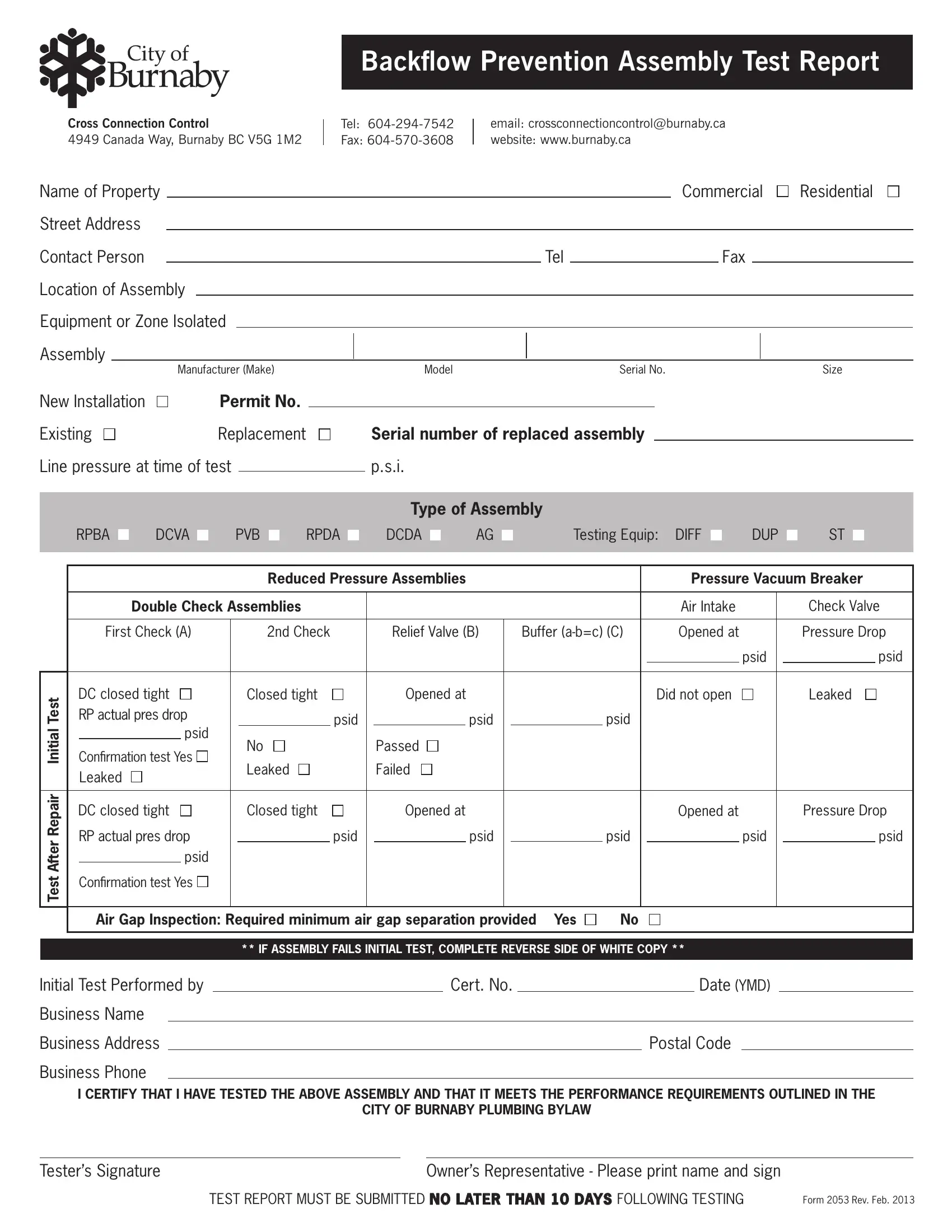

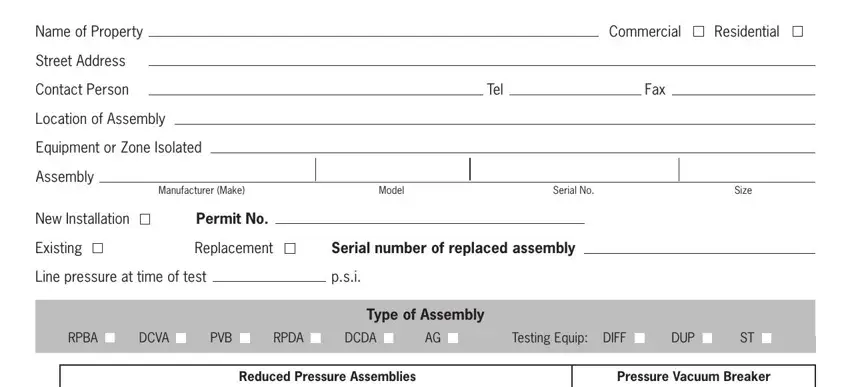

1. When submitting the PVB, make certain to incorporate all of the essential blanks within its associated section. This will help to expedite the process, enabling your details to be processed efficiently and accurately.

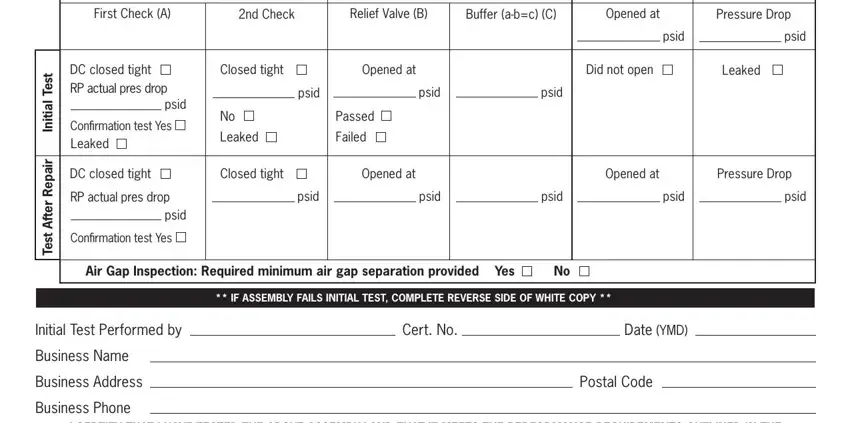

2. Soon after performing the last part, go on to the subsequent stage and complete the necessary particulars in these fields - First Check A, nd Check, Relief Valve B, Buffer abc C, Opened at, Pressure Drop, psid, psid, DC closed tight, Closed tight, Opened at, Did not open, Leaked, RP actual pres drop, and psid.

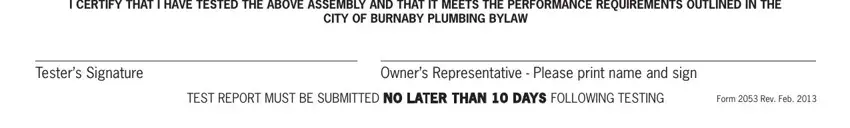

3. This next stage is usually straightforward - complete all of the form fields in I CERTIFY THAT I HAVE TESTED THE, CITY OF BURNABY PLUMBING BYLAW, Testers Signature Owners, TEST REPORT MUST BE SUBMITTED NO, and Form Rev Feb to complete this part.

You can easily make an error while filling out the I CERTIFY THAT I HAVE TESTED THE, thus make sure you look again before you decide to send it in.

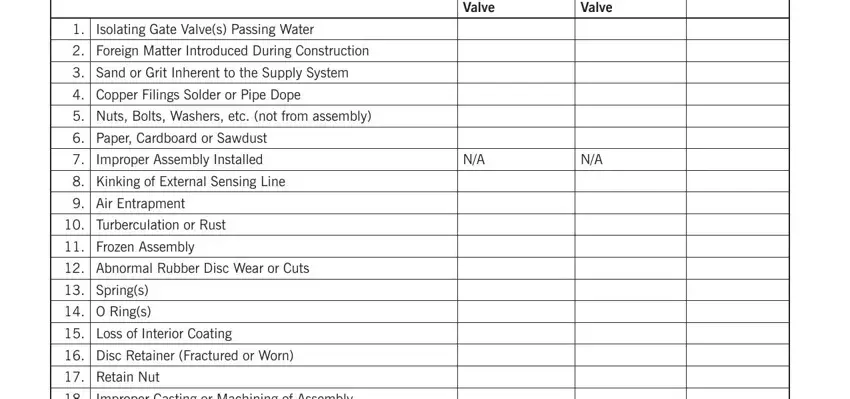

4. Filling in No Check Valve, No Check Valve, Isolating Gate Valves Passing Water, Foreign Matter Introduced During, Sand or Grit Inherent to the, Copper Filings Solder or Pipe Dope, Nuts Bolts Washers etc not from, Paper Cardboard or Sawdust, Improper Assembly Installed, Kinking of External Sensing Line, Air Entrapment, Turberculation or Rust, Frozen Assembly, Abnormal Rubber Disc Wear or Cuts, and Springs is vital in this fourth part - ensure to invest some time and be attentive with each blank area!

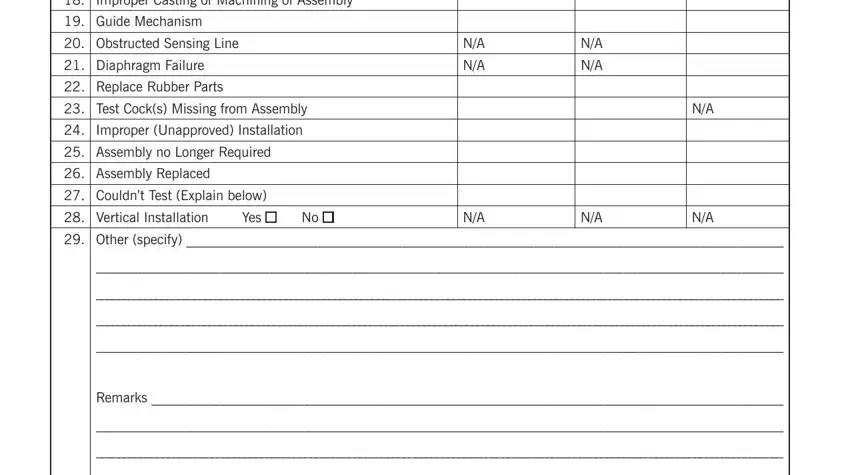

5. While you approach the final sections of the form, you'll find a few more points to undertake. Particularly, Improper Casting or Machining of, Guide Mechanism, Obstructed Sensing Line, Diaphragm Failure, Replace Rubber Parts, Test Cocks Missing from Assembly, Improper Unapproved Installation, Assembly no Longer Required, Assembly Replaced, Couldnt Test Explain below, Vertical Installation Yes, Other specify, and Remarks must be done.

Step 3: Prior to finishing this form, ensure that blanks were filled out the proper way. The moment you confirm that it is good, press “Done." Grab the PVB as soon as you join for a 7-day free trial. Readily access the document within your FormsPal account, along with any edits and adjustments conveniently synced! FormsPal is dedicated to the confidentiality of our users; we ensure that all information used in our tool is protected.