With the help of the online PDF tool by FormsPal, you can fill in or edit formato qw 483 right here and now. Our editor is constantly developing to grant the best user experience attainable, and that's thanks to our resolve for continual development and listening closely to user comments. With some simple steps, you can begin your PDF journey:

Step 1: Click on the "Get Form" button above on this page to get into our PDF editor.

Step 2: After you access the file editor, you'll see the form made ready to be completed. Besides filling out various fields, you might also do other things with the PDF, including writing custom words, modifying the initial text, inserting illustrations or photos, signing the PDF, and more.

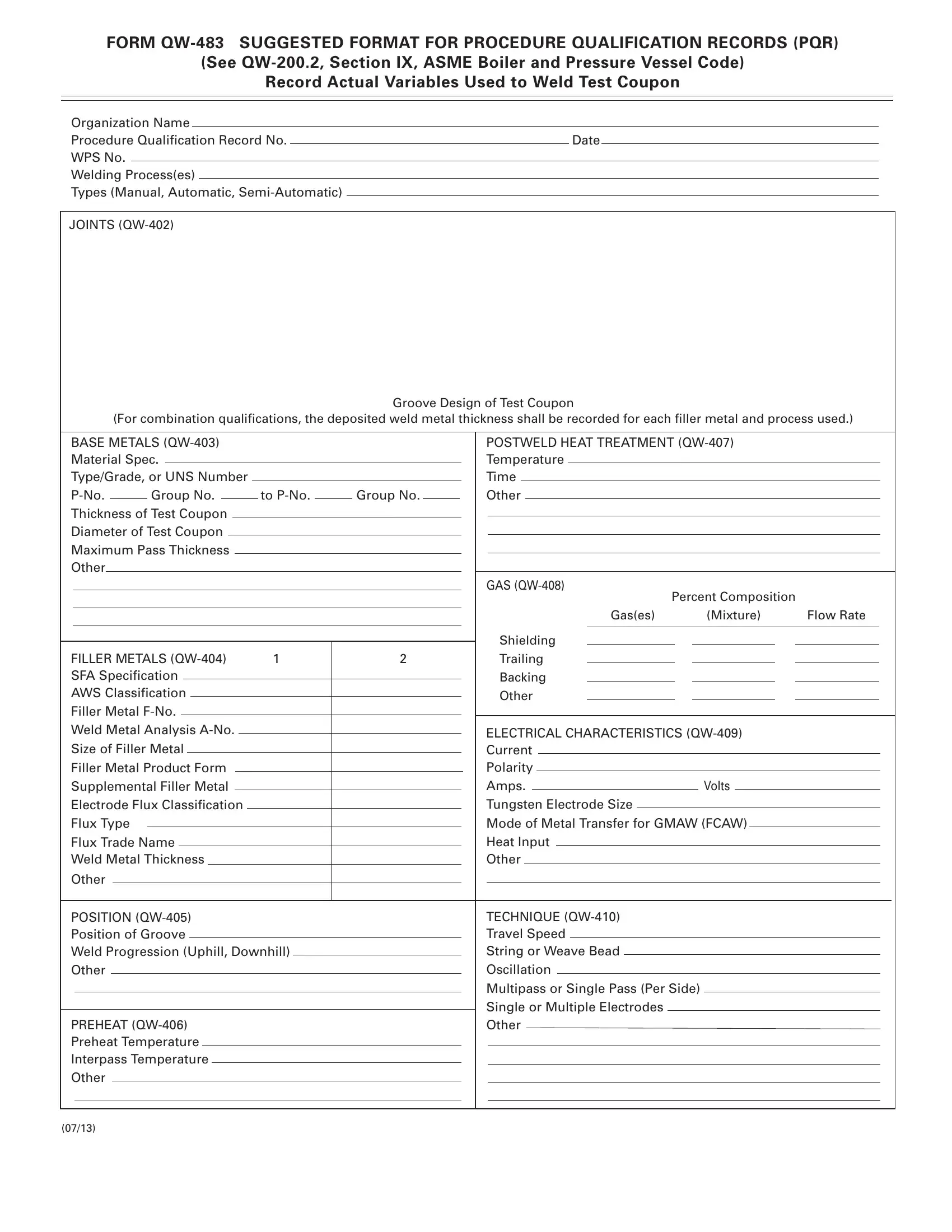

As for the blank fields of this specific document, here is what you should consider:

1. To start off, when filling out the formato qw 483, start out with the section with the subsequent fields:

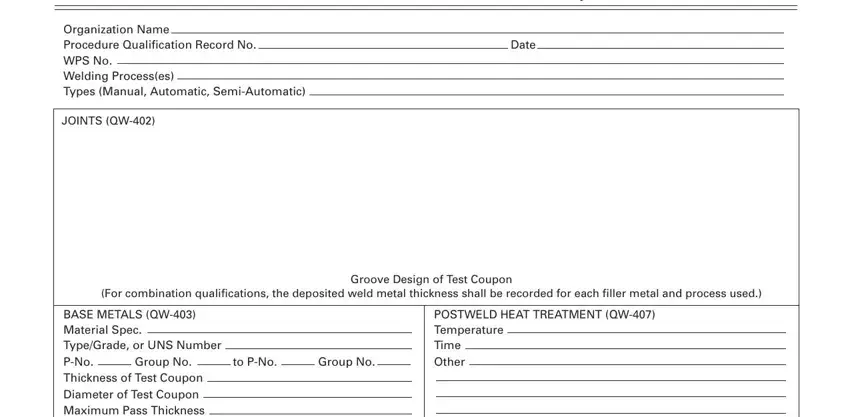

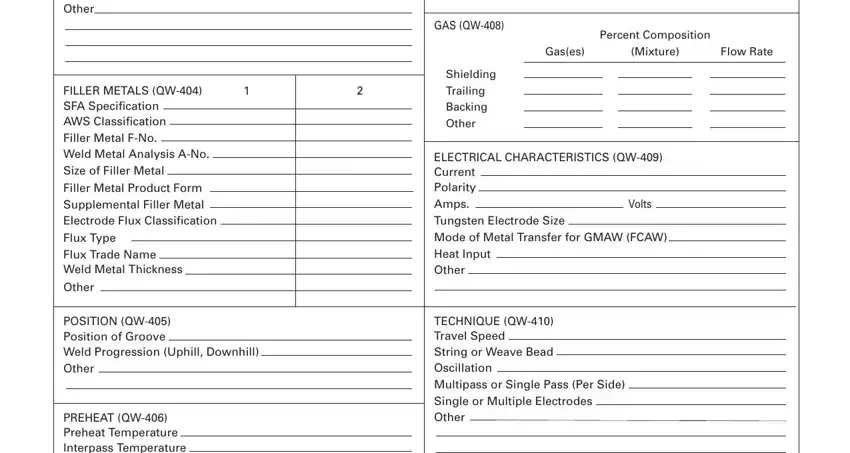

2. Once this part is complete, it is time to insert the required specifics in Maximum Pass Thickness Other, FILLER METALS QW SFA, Percent Composition, Gases, Mixture, Flow Rate, GAS QW, Shielding, Trailing, Backing, Other, Filler Metal FNo, Weld Metal Analysis ANo, Size of Filler Metal, and Filler Metal Product Form so that you can proceed further.

3. The next section is quite straightforward, PREHEAT QW Preheat Temperature, and Other - each one of these form fields needs to be filled out here.

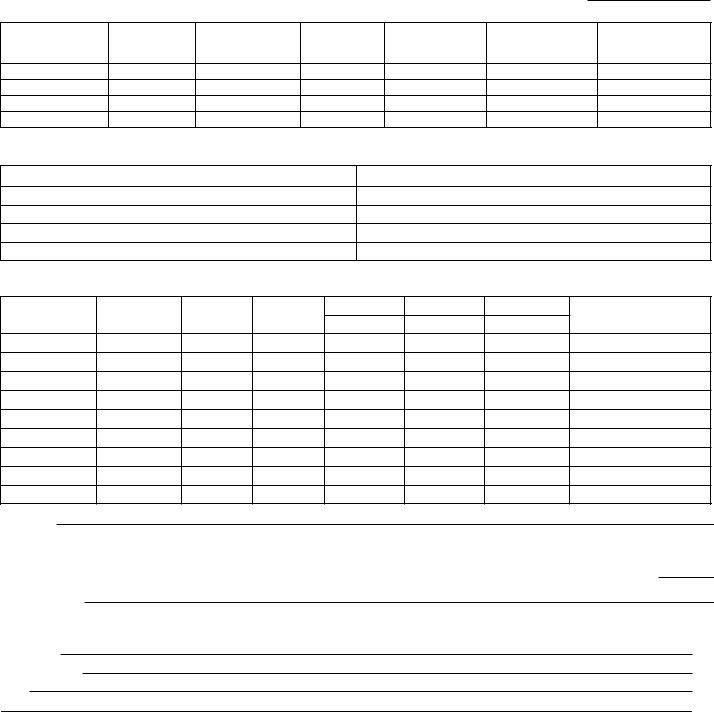

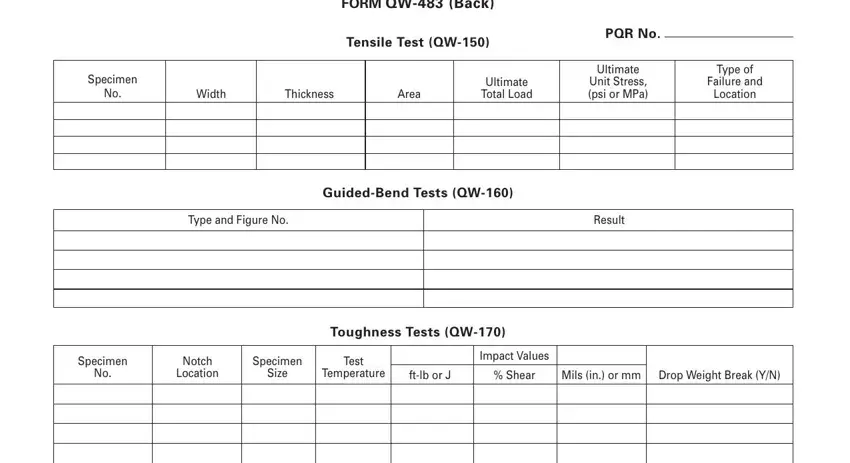

4. Completing FORM QW Back, Tensile Test QW, PQR No, Specimen, Width, Thickness, Area, Ultimate Total Load, Ultimate, Unit Stress psi or MPa, Type of, Failure and, Location, GuidedBend Tests QW, and Type and Figure No is essential in this next form section - you'll want to don't rush and be mindful with every single blank!

It's simple to make a mistake when filling in your Failure and, so be sure you take a second look prior to deciding to send it in.

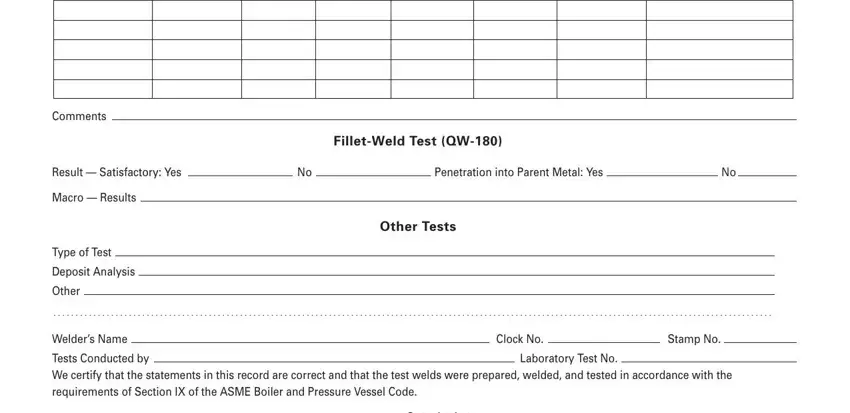

5. This pdf should be finished with this particular segment. Further you have a comprehensive listing of blank fields that have to be filled out with accurate details to allow your document submission to be accomplished: Comments, FilletWeld Test QW, Result Satisfactory Yes, Penetration into Parent Metal Yes, Macro Results, Type of Test, Deposit Analysis, Other, Welders Name, Other Tests, Clock No, Stamp No, Tests Conducted by We certify that, and Laboratory Test No.

Step 3: You should make sure your information is accurate and click on "Done" to continue further. After getting a7-day free trial account here, it will be possible to download formato qw 483 or email it without delay. The document will also be readily accessible from your personal account menu with all your adjustments. FormsPal offers secure document tools devoid of personal information record-keeping or any kind of sharing. Rest assured that your details are in good hands with us!