fusible can be filled out online with ease. Simply use FormsPal PDF editing tool to complete the job in a timely fashion. The editor is consistently improved by our team, acquiring awesome features and turning out to be much more versatile. It merely requires a few simple steps:

Step 1: Just hit the "Get Form Button" at the top of this site to start up our pdf file editing tool. There you'll find everything that is required to fill out your document.

Step 2: After you access the online editor, you'll see the document all set to be filled out. Other than filling out different blank fields, you may as well do some other actions with the form, that is adding custom text, modifying the original textual content, adding graphics, putting your signature on the document, and a lot more.

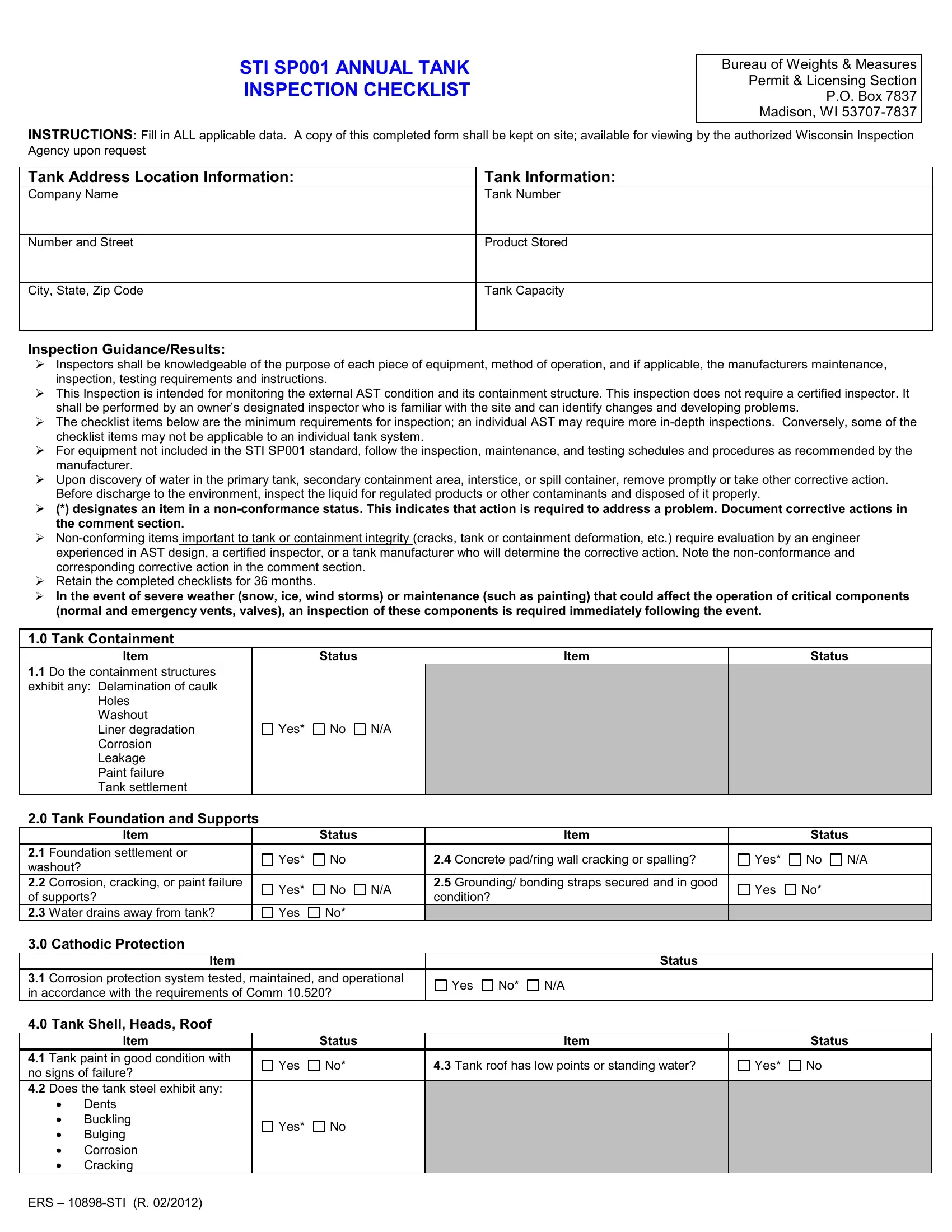

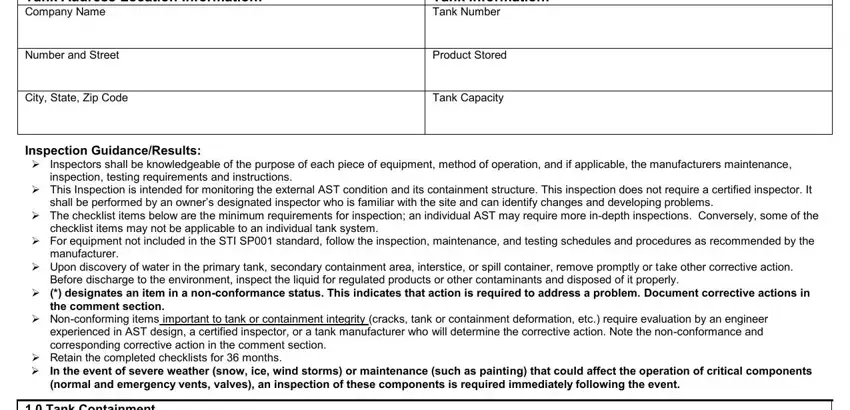

To be able to complete this PDF document, be sure to type in the necessary information in every single field:

1. Complete the fusible with a selection of essential blank fields. Get all the necessary information and make certain nothing is left out!

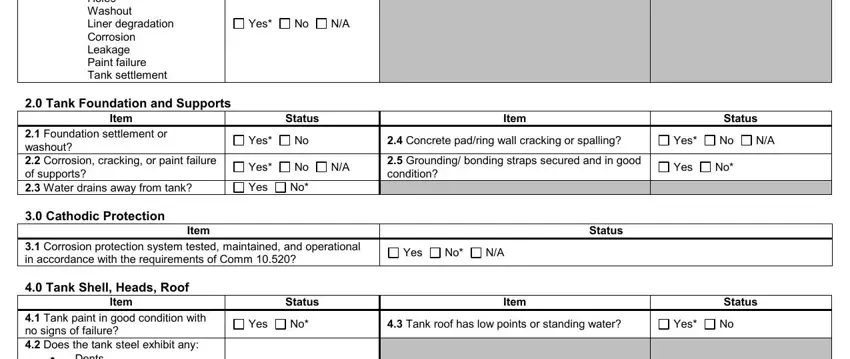

2. Now that the previous array of fields is completed, you're ready to add the essential details in Yes, Do the containment structures, Holes Washout Liner degradation, Item, Status, Item, Foundation settlement or washout, Item, Yes, Concrete padring wall cracking or, Yes, Yes, Grounding bonding straps secured, Corrosion protection system, and Yes so you're able to proceed to the 3rd step.

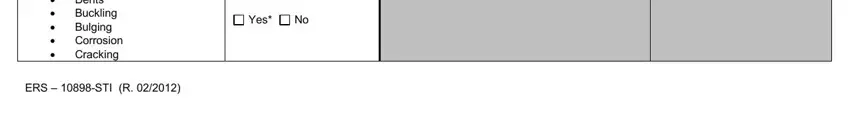

3. This 3rd part is pretty straightforward, Dents Buckling Bulging Corrosion, ERS STI R, and Yes - all these form fields must be filled out here.

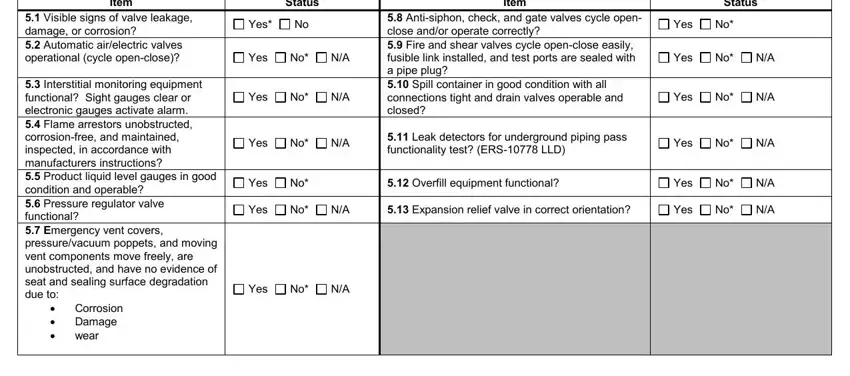

4. This particular subsection comes with all of the following blanks to complete: Status, Yes, Yes, Yes, Item, Antisiphon check and gate valves, Status, Yes, Yes, Yes, Yes, Leak detectors for underground, Yes, Yes, and Overfill equipment functional.

You can certainly make errors while filling in the Overfill equipment functional, for that reason make sure you go through it again prior to deciding to finalize the form.

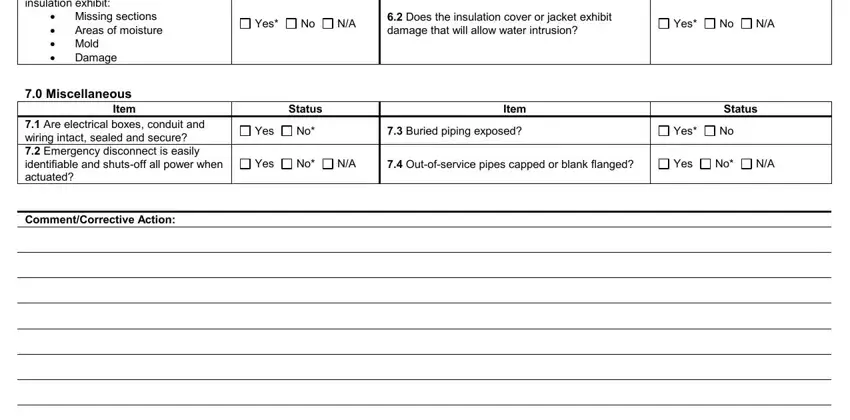

5. As you near the last parts of the file, you'll notice just a few extra things to do. Notably, Yes, Does the insulation cover or, Yes, Status, Item, Status, Yes, Buried piping exposed, Yes, Yes, Outofservice pipes capped or, Yes, Does the inspection of the tank, Missing sections Areas of, and Damage should all be filled out.

Step 3: Make certain the details are accurate and then just click "Done" to continue further. Try a free trial plan with us and obtain immediate access to fusible - download or edit from your FormsPal cabinet. FormsPal guarantees your data privacy via a secure method that in no way records or distributes any sort of sensitive information involved. Feel safe knowing your files are kept confidential any time you work with our services!