INSTRUCTION FOR COMPLETION OF

“Report on Test and Maintenance of Containment Backflow Prevention Assembly”

(FORM GEN215B)

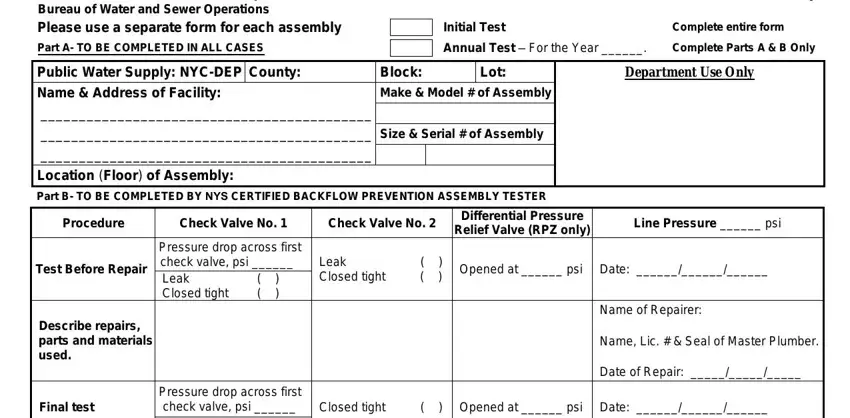

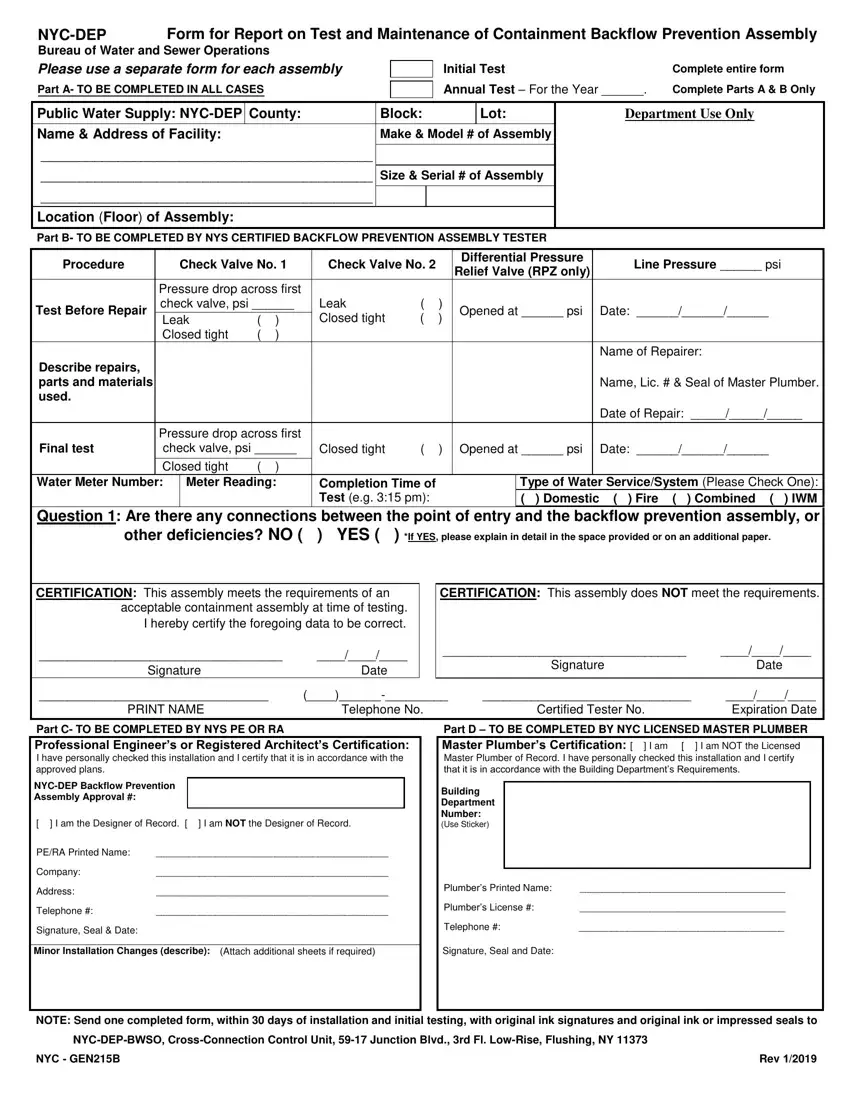

Use a separate form for each particular assembly

Indicate Initial Test or Annual Test by checking the appropriate choice.

Initial Test and Certification: Complete all 4 parts.

Annual Test/Re-Certification: Complete parts A and B only

Please follow these tips to have the form completed:

Part A: To be completed in ALL cases for the current address, block and lot #s, the tested BFP assembly (make, model # in full, size and serial #) and actual location of the tested assembly (floor/level, vault, hot box) along with a specific location (meter/boiler/pump room, store, garage, etc.), if any.

Part B: NYS Certified Backflow Prevention Assembly Tester shall fill out this portion in ALL cases:

Include the line pressure (taken at number 1 test cock with shutoff valve number 1 closed).

Include the pressure drop across the first check valve (the pressure differential between the second and the third test cocks).

Include the condition of check valves # 1 and 2.

Describe repairs, parts and materials used, replacement of assembly and details of procedures. If any, complete final test.

Indicate the water meter # (8 digits) and reading.

Completion time of test refers to the time of day (e.g. 8:00 am) and test date.

Check actual type of the water service/system (Internal Water Main “IWM”).

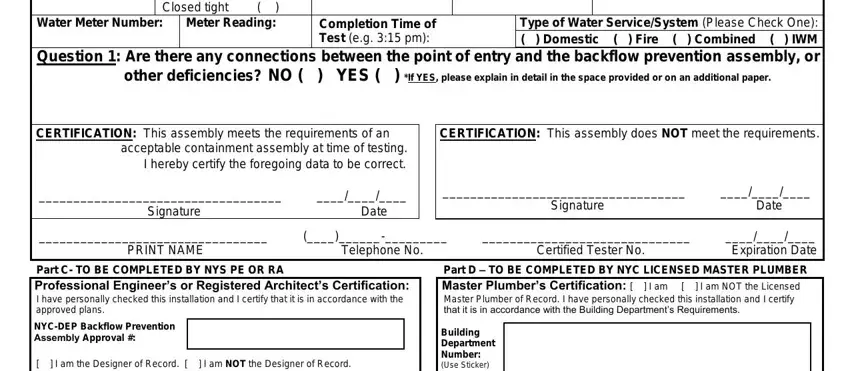

Be sure to answer (check) Question 1. If the answer is “YES”, explain in the space provided. A connection for a properly installed and certified parallel assembly should not be construed as a connection. Hose cocks and spigots shall be considered as connections. Tees/ells shall be removed completely and hard pipe. Cross-connections upstream of the assemblies are prohibited except otherwise allowed and approved for the parallel assemblies’ installations.

Then, clearlyprint, type or rubber stamp: Date, Name, Phone #, Certified Tester # and Certified Tester Expiration Date.

Part C: Complete for Initial Test Report only!

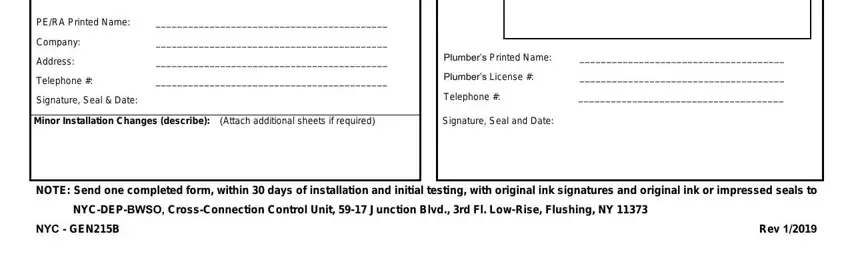

The NYS Licensed Professional Engineer or Registered Architect (PE/RA) shall complete Part C. Be sure to fill in the following:

The “NYC-DEP Backflow Prevention Assembly Approval #”.

Indicate whether being the designer of record or not.

Indicate minor changes, if any. Use back or additional pages as required. Indicate “See Back” or “See Additional Pages” as appropriate. If an equivalent make and model # of assembly is used, the PE or RA shall certify that the submission is acceptable and will not cause any adverse hydraulic effects on the water system. Also satisfy the submersion calculations (for RPZ/RPD assemblies only, if installed below grade level).

If the installation changes meet DEP requirements while deviating from the approved plans, the job shall be resubmitted for re-approval or an as-built plans shall be submitted to legalize the on-site condition/discrepancy.

When the installation deviates from the approved plans and minimum requirements are not satisfied, the job should NOT be certified.

Part D: NYC Licensed Master Plumber shall complete Part D. Be sure to fill in the following:

Indicate whether being the Licensed Master Plumber of record or not

The Department of Buildings Number (ARA #, ALT #, NB #, LAA #, etc.). Use of sticker is preferred.

Licensed Master Plumber’s Name.

Licensed Master Plumber’s License #.

Licensed Master Plumber’s Telephone Number.

Original Ink Signature, raised impression Seal of Licensed Master Plumber & Date.

Notes: The PE/ RA, Licensed Master Plumber & Certified Tester shall sign the same form for each particular assembly. For each completed form, USE ORIGINAL INK SIGNATURES & ORIGINAL INK OR RAISED IMPRESSION SEALS. Mail one completed form to: NYC- DEP-BWSO

Cross-Connection Control Unit

59-17 Junction Boulevard, 3rd Fl. Low-Rise, Flushing, NY 11373-5108

Refer to “NEW YORK CITY CROSS-CONNECTION CONTROL PROGRAM HANDBOOK”, latest version on DEP web site.