We chose the top-rated web programmers to set-up this PDF editor. This application will assist you to fill out the hot works permit nyc document with no trouble and won't eat up a lot of your energy. This straightforward guide can help you get started.

Step 1: Select the orange button "Get Form Here" on the web page.

Step 2: You can now alter your hot works permit nyc. Our multifunctional toolbar permits you to insert, delete, transform, and highlight content or perhaps carry out several other commands.

The next parts are within the PDF form you'll be creating.

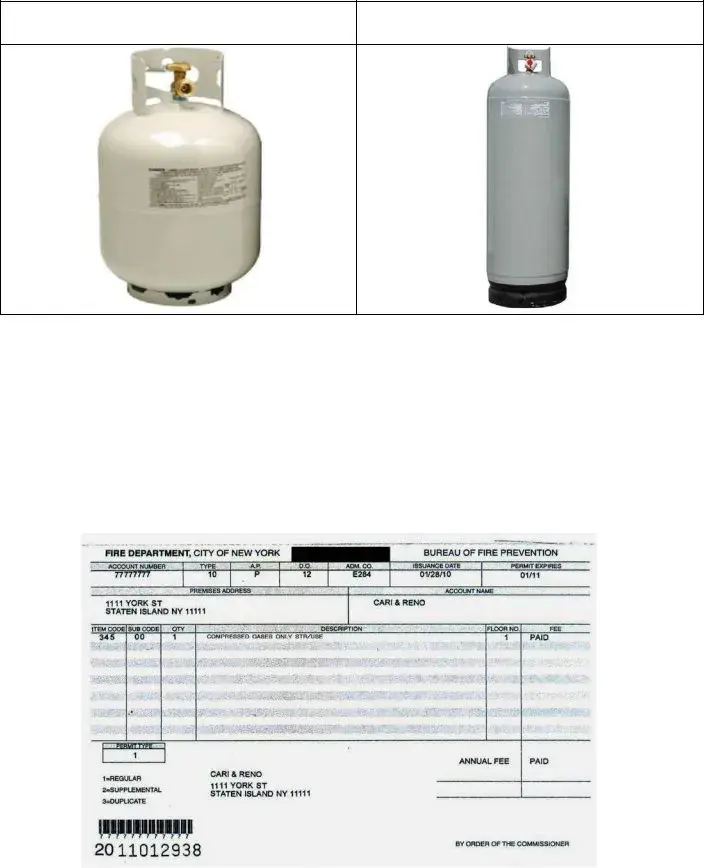

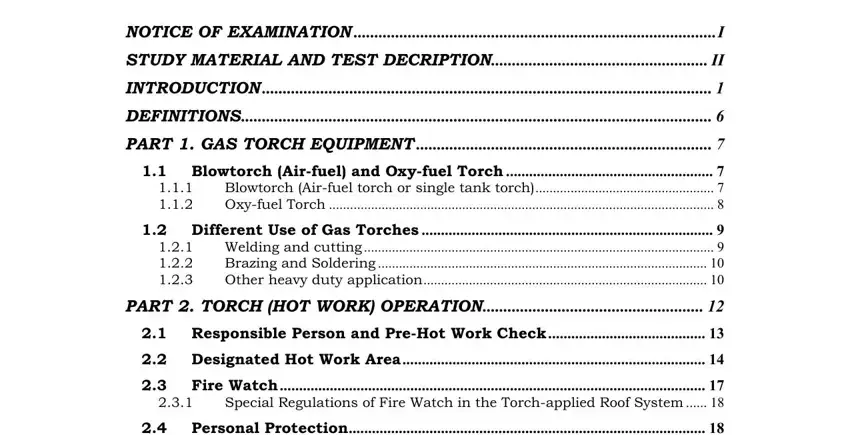

You have to complete the Personal Protection, Gas Torch Operation Precautions, Guidelines for Using an Oxygenfuel, Set Up an OxyFuel Torch Turn On an, General Guidelines for Using a, Set Up a Blowtorch Turn On a, Common Problems Occur With Torch, Backfire Flashback Check for Leaks, PART COMPRESSED GAS CONTAINER, Handling Use and Storage of, General Guidance Related Equipment, and Handling and Use of Acetylene Gas area with the expected data.

Write down any details you need inside the space PART PORTABLE FIRE EXTINGUISHERS, Operation Instructions for a Fire, Fire Extinguishers, Typical Fire Extinguishers, and Fire Extinguisher Inspections.

You will need to define the rights and responsibilities of each party in field If the torch operation is to be, Turn off the gas torch valves, side first to prevent soot from, Close both the oxygen and fuel, Disconnect the regulators from, regulators, Special Precautions for Using, Avoid oil or grease, and Containers valves regulators hose.

Step 3: Select the "Done" button. So now, you can transfer the PDF file - upload it to your device or send it by using electronic mail.

Step 4: In order to avoid potential forthcoming difficulties, it is important to get at least a couple of duplicates of each separate file.