In the realm of workplace safety, the implementation and adherence to a Hot Work Permit form stands as a cornerstone precaution for operations involving heat and sparks that could ignite hazardous materials. This form acts as a formal checklist and authorization tool that ensures all safety measures and protocols are rigorously evaluated and followed before any hot work—such as welding, cutting, and other fire-invoking activities—commences. Key aspects covered in the form include specifying the type of work, the validity period of the permit (typically restricted to one shift or a specified time limit), and a detailed description of the work to be performed. Furthermore, it mandates systematic safety checks, including but not limited to the removal or protection of combustible materials within a 35-foot radius, ventilation of the work area, the arrangement of fire watches, and the availability of fire extinguishers and personal protective equipment for the operator. Additionally, special precautions are outlined to mitigate risks associated with specific hazards like pressurized systems, containers of hazardous chemicals, or areas containing potentially radioactive materials. The completion and signing of the Hot Work Permit by relevant supervisors from the operating and safety departments culminate in a formal acknowledgment that all conditions have been inspected and deemed safe for hot work to proceed, thereby minimizing risk and ensuring a safe work environment.

| Question | Answer |

|---|---|

| Form Name | Hot Work Permit Form |

| Form Length | 1 pages |

| Fillable? | Yes |

| Fillable fields | 32 |

| Avg. time to fill out | 6 min 43 sec |

| Other names | work permit blanked sample, format ww blanked sample, format ww blanked template, work format blanked printable |

HOT WORK PERMIT

After this is filled out and signed, send to _________________________ _____________________

for recordkeeping in the____________________________________ file.

Type of work:

Permit is good for one shift only, or not to exceed the time limit. |

TIME LIMIT: |

|

a.m. |

||||

|

p.m. |

||||||

Area: |

|

Date: |

|

|

|||

|

|

|

|||||

Describe work to be done: |

|

|

|

|

|

|

|

Note: Check Yes or No. If question does not apply, indicate it with N/A (not apply).

1.Can this equipment be removed from the building?

2.Have all process materials been removed from equipment?

3.Have all connections been blanked off and switches been locked open?

4.Has equipment been ventilated?

5.Can sparks ignite material in vicinity lower level?

6.Is the work area clear of all explosive, flammable, and hazardous material

7.Is all combustible material removed from the work area or protected

8.Has a fire watch been assessed?

9.Is an operational fire extinguisher readily available?

10.Has the nearest fire alarm pull station been located?

11.Does the operator have the correct personal protective equipment (e.g., eye protection, gloves, face shield)?

12.Is the area where the work will occur adequately ventilated?

13.Have the dangers associated with the following been eliminated or specifically addressed?

a)Penetrating a pressurized system?

b)Penetrating a container of hazardous chemicals?

c)Affecting an item that is potentially radioactive

d)Damaging property?

14.SPECIAL PRECAUTIONS TO BE OBSERVED:

YES NO

I have personally inspected and approve conditions for above.

Signed: |

|

|

|

Department: |

|

|

|

|

|

|

(Operating Supervisor) |

|

|

|

|||

and/or Signed: |

|

|

Time: |

|

|

Date: |

|

|

|

|

(Safety Department) |

|

|

|

|||

HW.P/ELE5000(12/97)

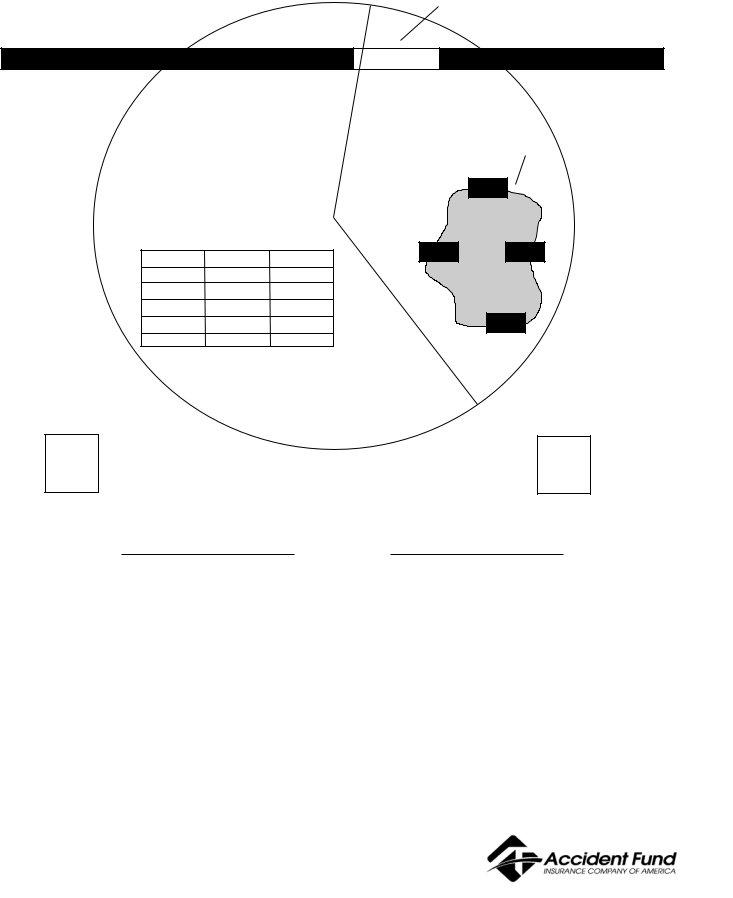

Example of the Hot Work

Fire

Door

Fire Wall |

Fire Wall |

35 ft. (11m)

Rack

Heavy

Storage

Work

Area

Storage

Cart of |

35 ft. (11m) |

|

|

|

|

Canned |

|

Palletized |

|

||

Paint |

|

Storage |

70 ft. (21m)

•Remove or shield from sparks all potential fuels within 35 ft. (11m) of the work area. In this case, the paint cart and palletized storage.

•Empty racks on which the work is to be done of all storage.

•Close fire doors and seal floor openings such as the area surrounding process piping with noncombustible caulking.

•Cover heavy combustible storage that is impractical to move with a