In case you would like to fill out scissor lift annual inspection form, you won't need to download any software - simply use our PDF editor. FormsPal professional team is ceaselessly endeavoring to enhance the editor and ensure it is much better for users with its cutting-edge features. Uncover an ceaselessly revolutionary experience now - explore and find out new opportunities along the way! With a few basic steps, it is possible to begin your PDF editing:

Step 1: Hit the "Get Form" button above on this webpage to get into our PDF tool.

Step 2: As you launch the PDF editor, you will notice the document all set to be filled in. Apart from filling out different blanks, you can also do other things with the form, that is putting on your own textual content, editing the original text, inserting illustrations or photos, affixing your signature to the form, and a lot more.

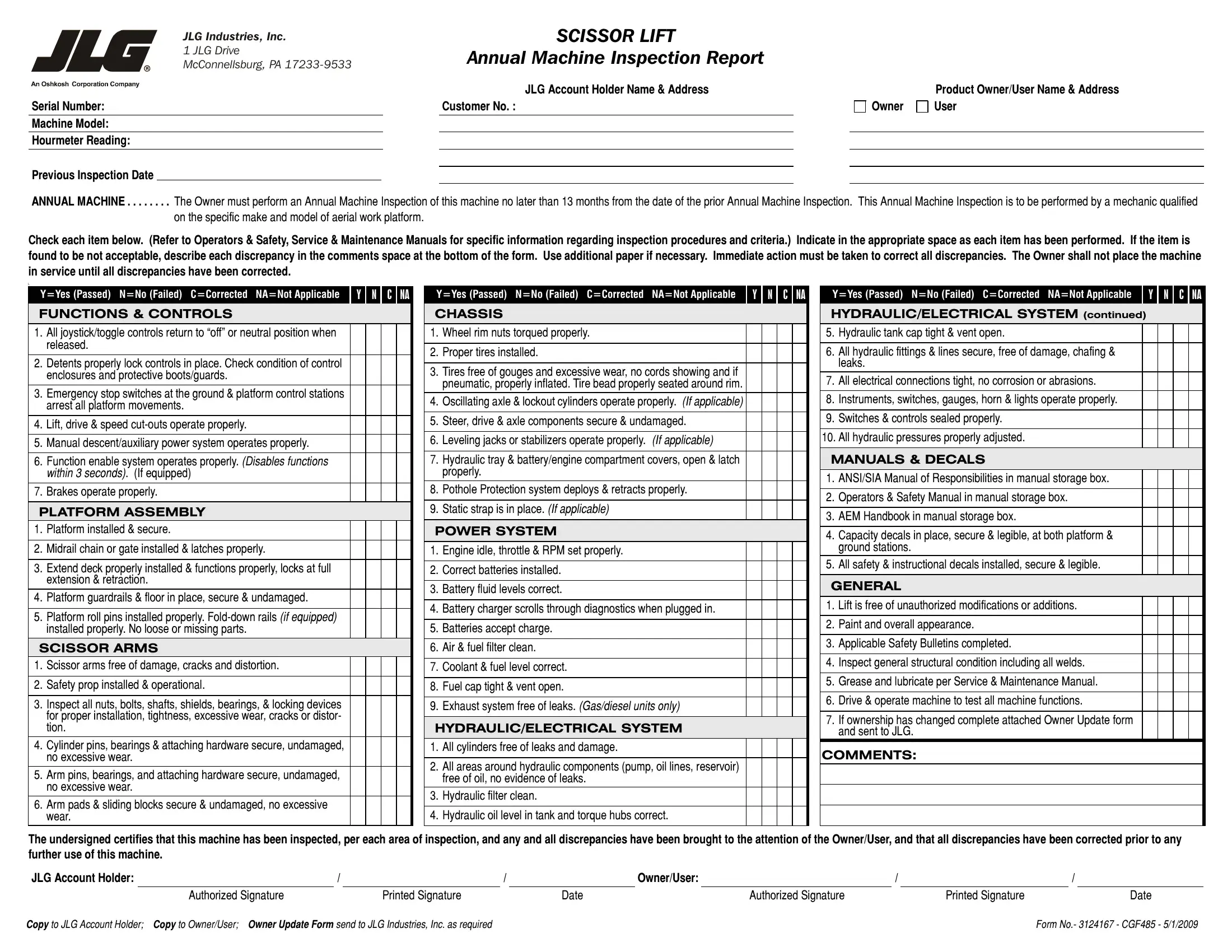

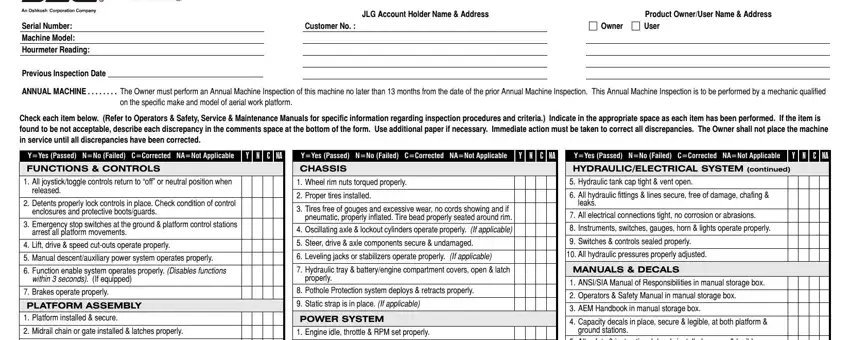

This PDF form will require specific details to be filled in, hence be certain to take whatever time to provide precisely what is asked:

1. The scissor lift annual inspection form will require certain information to be typed in. Be sure that the next fields are filled out:

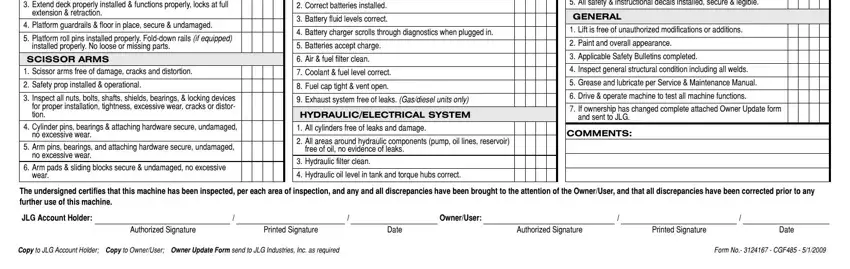

2. Soon after the prior array of blank fields is completed, proceed to type in the applicable details in these: Extend deck properly installed, extension retraction, Platform guardrails floor in, Platform roll pins installed, installed properly No loose or, SCISSOR ARMS Scissor arms free of, Safety prop installed operational, Inspect all nuts bolts shafts, Cylinder pins bearings attaching, no excessive wear, Arm pins bearings and attaching, no excessive wear, Arm pads sliding blocks secure, wear, and Correct batteries installed.

Regarding Arm pads sliding blocks secure and Correct batteries installed, make certain you double-check them here. Those two could be the most important ones in the page.

Step 3: Just after proofreading the entries, press "Done" and you're done and dusted! Try a free trial option at FormsPal and get immediate access to scissor lift annual inspection form - which you'll be able to then begin using as you would like in your personal account. FormsPal guarantees your data confidentiality via a protected system that never records or shares any private information involved. Rest assured knowing your documents are kept protected when you use our services!