You could work with daily job safety briefings form instantly with the help of our online tool for PDF editing. Our tool is constantly evolving to give the very best user experience achievable, and that's because of our commitment to continual improvement and listening closely to customer comments. In case you are looking to start, here is what it requires:

Step 1: Click the "Get Form" button at the top of this page to open our editor.

Step 2: With the help of our advanced PDF editor, it is possible to accomplish more than just fill in blank fields. Edit away and make your documents seem great with custom textual content put in, or optimize the original input to perfection - all comes with the capability to insert almost any photos and sign the document off.

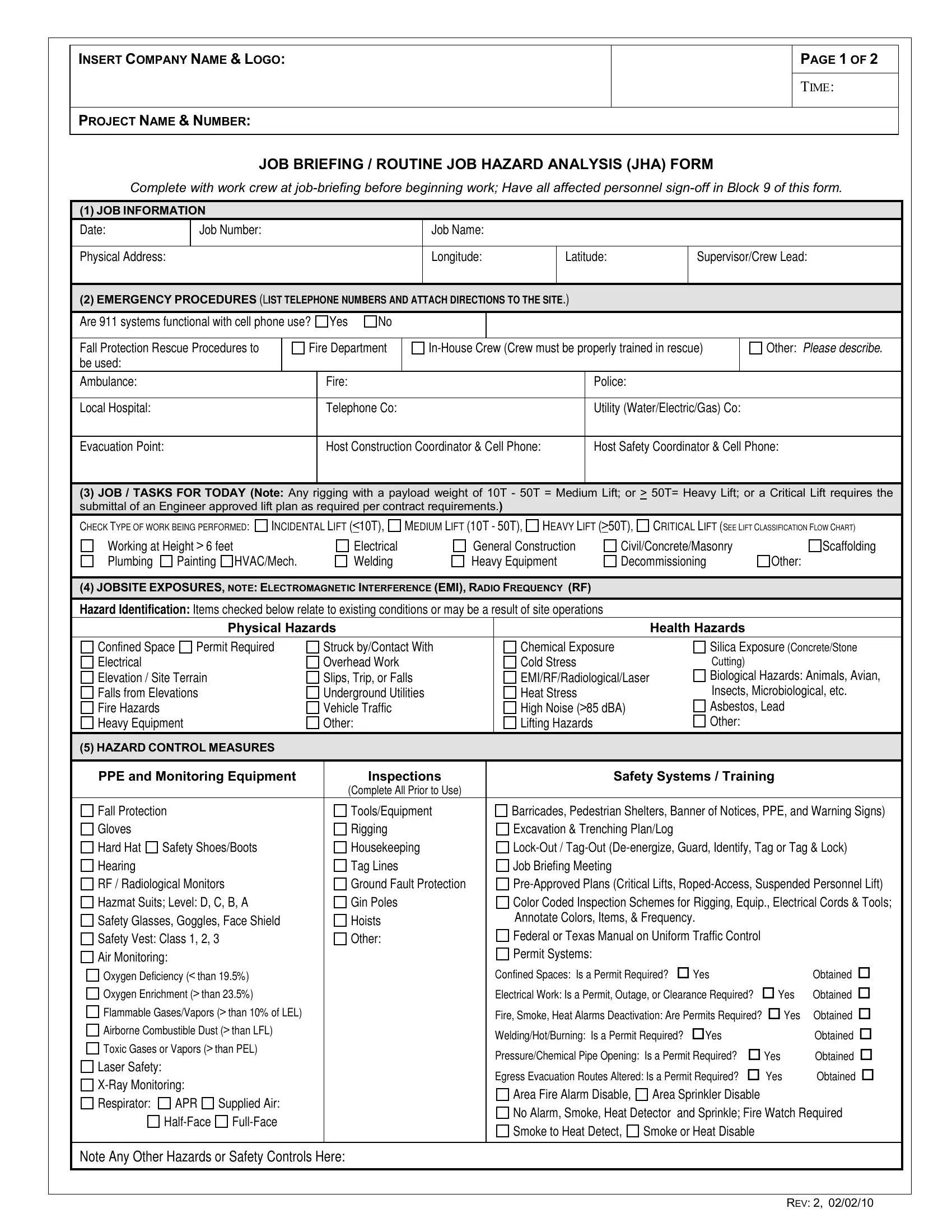

As a way to finalize this form, be sure to type in the required details in every area:

1. When completing the daily job safety briefings form, be certain to complete all of the essential blank fields within the associated section. This will help to speed up the process, which allows your information to be handled fast and accurately.

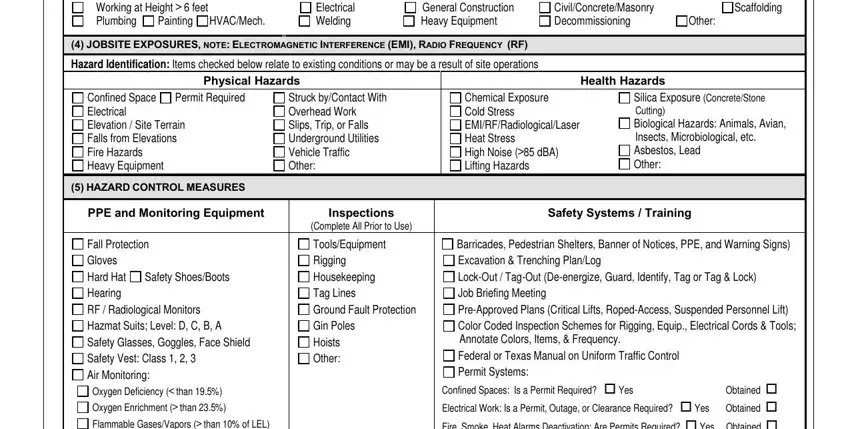

2. The third step would be to fill in these particular blanks: Working at Height feet Plumbing, Painting HVACMech, Electrical Welding, General Construction Heavy, CivilConcreteMasonry, Other, Scaffolding, JOBSITE EXPOSURES NOTE, Hazard Identification Items, Physical Hazards, Health Hazards, Permit Required, Confined Space Electrical, Struck byContact With Overhead, and Chemical Exposure Cold Stress.

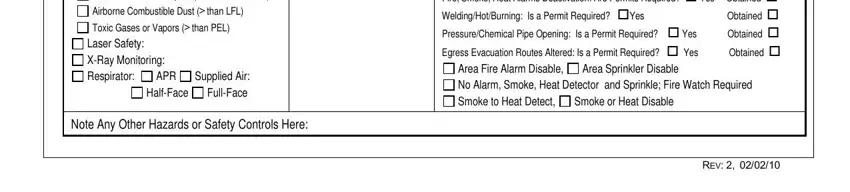

3. This next step will be focused on Fall Protection Gloves Hard Hat, HalfFace, APR, Supplied Air FullFace, Confined Spaces Is a Permit, Area Fire Alarm Disable No Alarm, Smoke or Heat Disable, Area Sprinkler Disable, Note Any Other Hazards or Safety, and REV - type in all of these empty form fields.

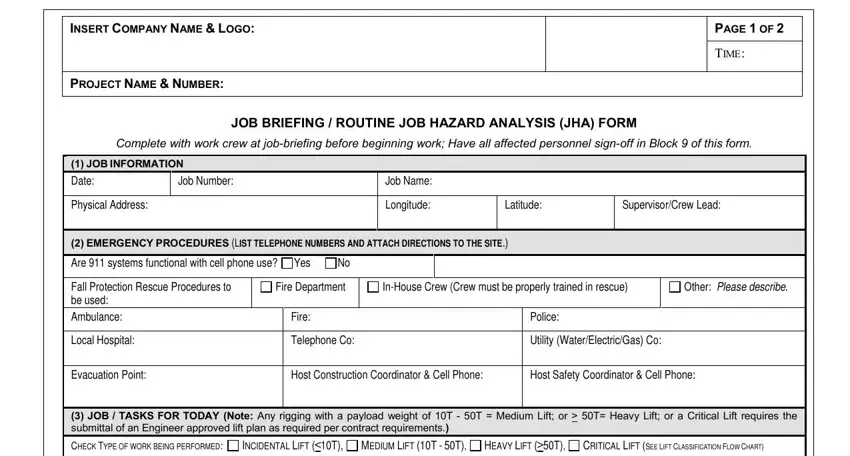

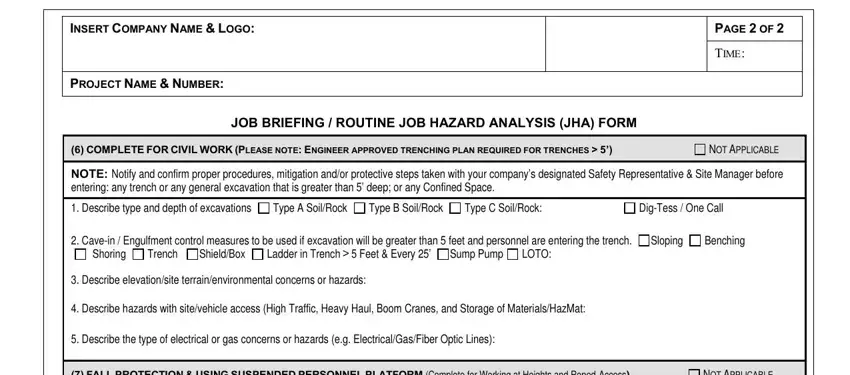

4. To move onward, this fourth stage will require filling in a few blanks. Examples include INSERT COMPANY NAME LOGO, PROJECT NAME NUMBER, PAGE OF, TIME, JOB BRIEFING ROUTINE JOB HAZARD, COMPLETE FOR CIVIL WORK PLEASE, NOT APPLICABLE, NOTE Notify and confirm proper, Describe type and depth of, Type A SoilRock, Type B SoilRock, Type C SoilRock, DigTess One Call, Cavein Engulfment control, and Ladder in Trench Feet Every, which you'll find integral to continuing with this particular process.

As for NOT APPLICABLE and COMPLETE FOR CIVIL WORK PLEASE, make sure that you review things here. The two of these could be the most significant ones in the form.

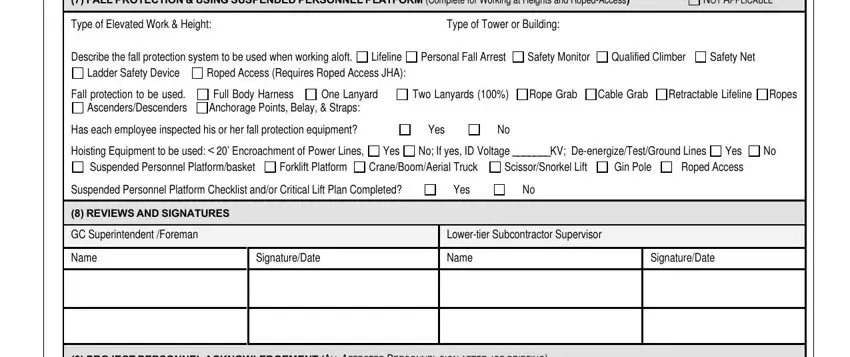

5. This form has to be concluded by filling in this part. Further you can find a full set of form fields that need to be filled in with correct information to allow your form usage to be faultless: FALL PROTECTION USING SUSPENDED, NOT APPLICABLE, Type of Elevated Work Height, Type of Tower or Building, Describe the fall protection, Lifeline, Personal Fall Arrest, Safety Monitor, Qualified Climber, Safety Net, Ladder Safety Device, Roped Access Requires Roped Access, Fall protection to be used, Full Body Harness Anchorage Points, and One Lanyard.

Step 3: When you have glanced through the information entered, simply click "Done" to complete your FormsPal process. Join us now and immediately access daily job safety briefings form, set for download. All modifications you make are kept , which means you can edit the file further when required. At FormsPal, we do everything we can to ensure that all your details are maintained private.