We've used the efforts of our best programmers to design the PDF editor you are going to begin using. The software will help you create the building safety checklist document without trouble and don’t waste precious time. All you have to do is adhere to these particular easy-to-follow instructions.

Step 1: Choose the button "Get Form Here" on the following webpage and click it.

Step 2: So, you are on the file editing page. You can add text, edit present data, highlight particular words or phrases, place crosses or checks, insert images, sign the file, erase needless fields, etc.

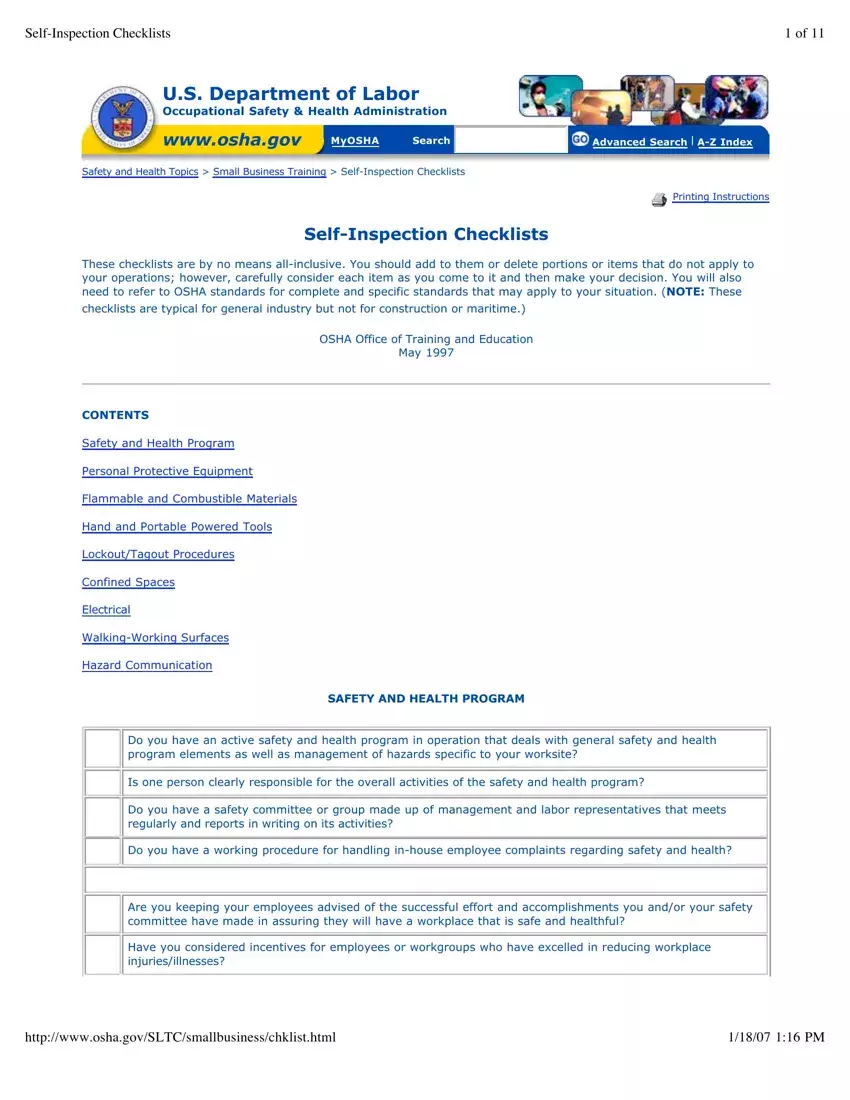

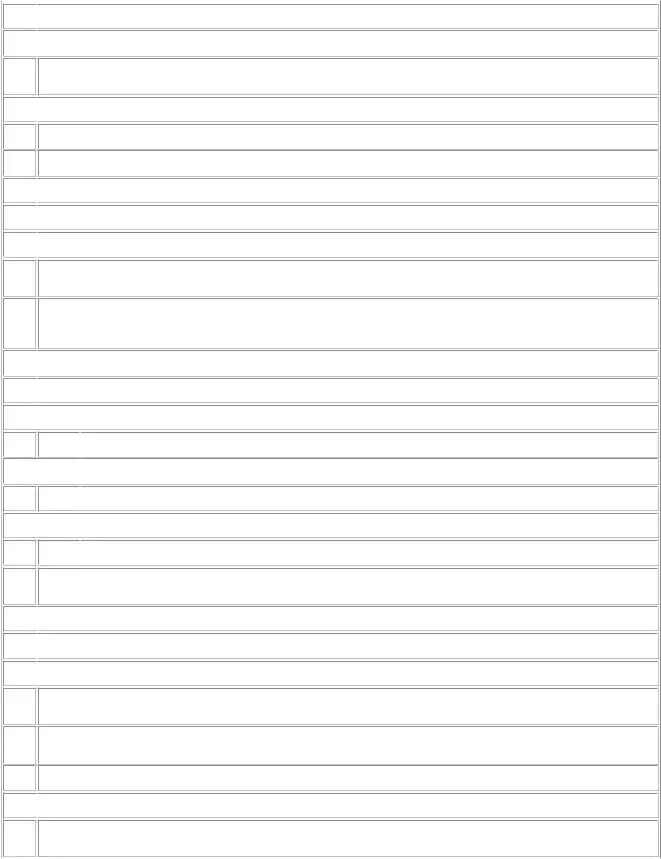

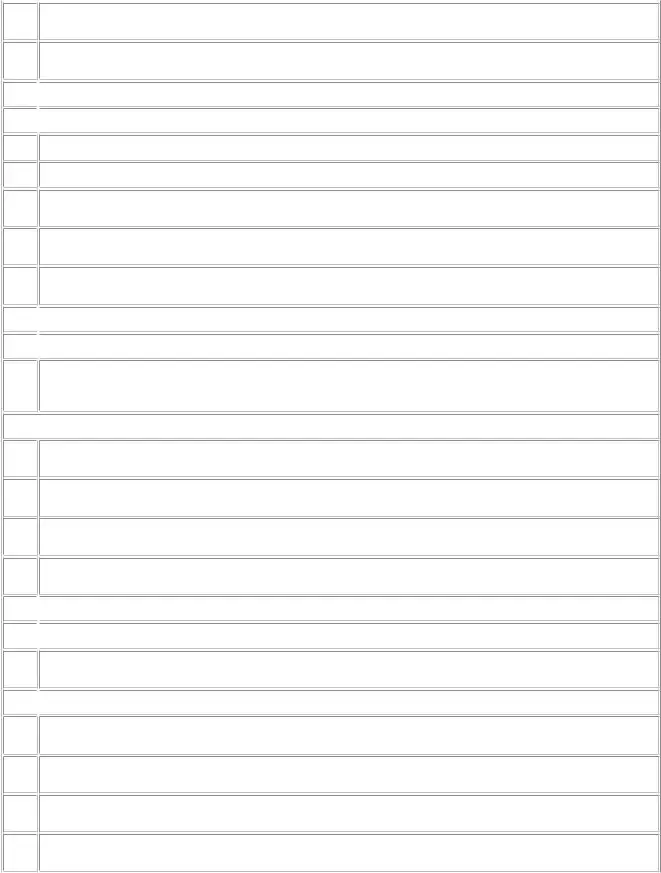

You'll need to type in the next information so that you fill out the template:

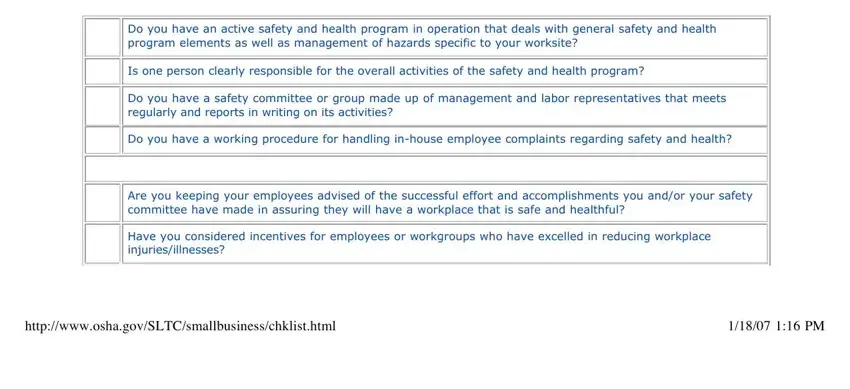

The system will expect you to submit the Do you have an active safety and, Is one person clearly responsible, Do you have a safety committee or, Do you have a working procedure, Are you keeping your employees, and Have you considered incentives for box.

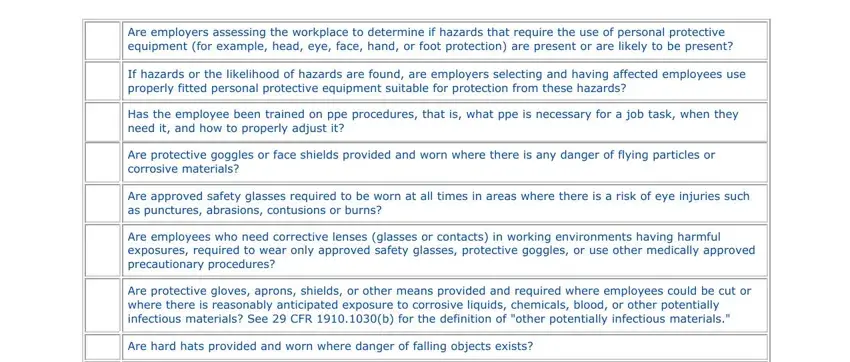

In the segment referring to Are employers assessing the, If hazards or the likelihood of, Has the employee been trained on, Are protective goggles or face, Are approved safety glasses, Are employees who need corrective, Are protective gloves aprons, and Are hard hats provided and worn, you have got to note down some vital details.

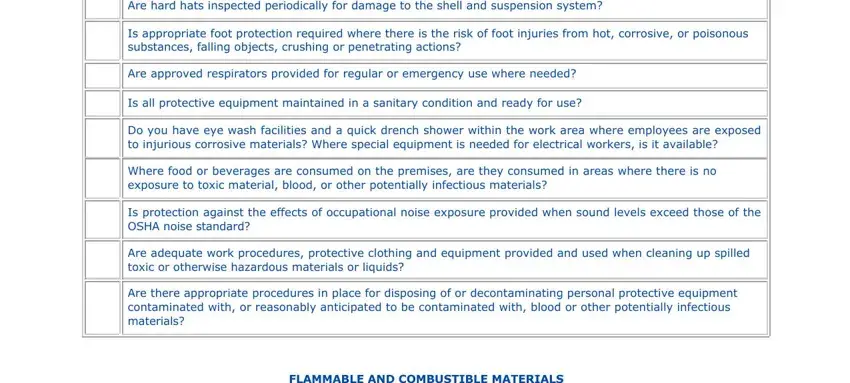

Identify the rights and responsibilities of the sides in the field Are hard hats inspected, Is appropriate foot protection, Are approved respirators provided, Is all protective equipment, Do you have eye wash facilities, Where food or beverages are, Is protection against the effects, Are adequate work procedures, Are there appropriate procedures, and FLAMMABLE AND COMBUSTIBLE MATERIALS.

Finish the template by analyzing these particular areas: Are combustible scrap debris and, and Is proper storage practiced to.

Step 3: Hit the "Done" button. At that moment, you can export the PDF document - save it to your electronic device or send it by using email.

Step 4: To protect yourself from probable future concerns, make sure to possess more than a couple of copies of any file.

MyOSHA

MyOSHA

Advanced Search

Advanced Search  Printing Instructions

Printing Instructions

Is one person clearly responsible for the overall activities of the safety and health program?

Is one person clearly responsible for the overall activities of the safety and health program?

Are hard hats provided and worn where danger of falling objects exists?

Are hard hats provided and worn where danger of falling objects exists?

Are hard hats inspected periodically for damage to the shell and suspension system?

Are hard hats inspected periodically for damage to the shell and suspension system?

Are approved respirators provided for regular or emergency use where needed?

Are approved respirators provided for regular or emergency use where needed?

Is all protective equipment maintained in a sanitary condition and ready for use?

Is all protective equipment maintained in a sanitary condition and ready for use?

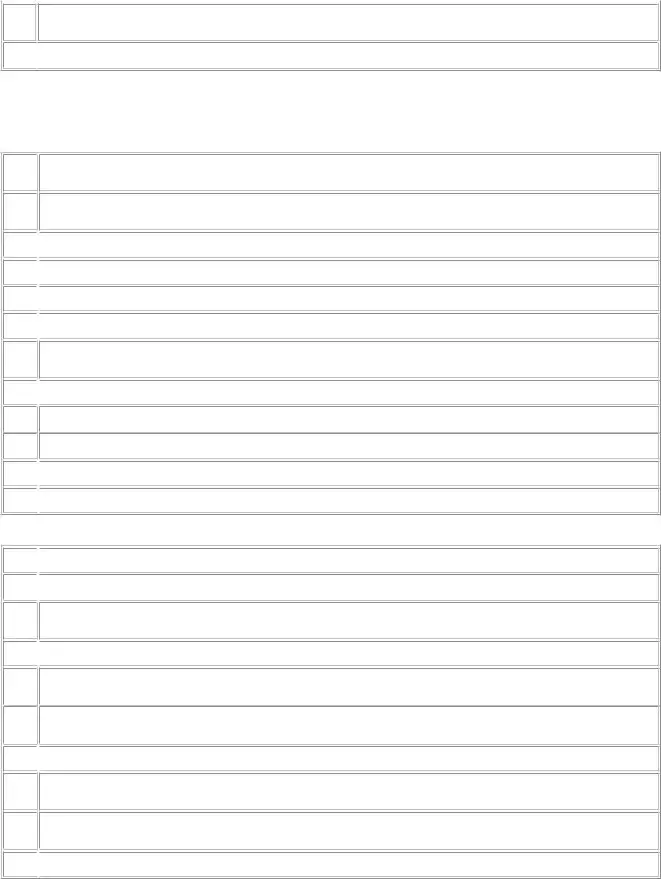

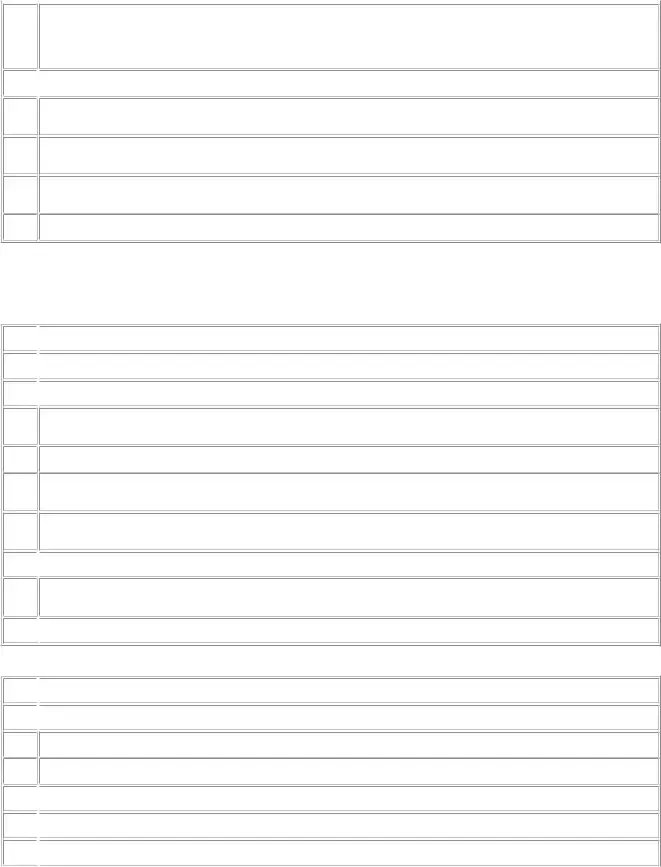

Is proper storage practiced to minimize the risk of fire including spontaneous combustion?

Is proper storage practiced to minimize the risk of fire including spontaneous combustion?

Are approved containers and tanks used for the storage and handling of flammable and combustible liquids?

Are approved containers and tanks used for the storage and handling of flammable and combustible liquids?

Are all connections on drums and combustible liquid piping, vapor and liquid tight?

Are all connections on drums and combustible liquid piping, vapor and liquid tight?

Are bulk drums of flammable liquids grounded and bonded to containers during dispensing? Do storage rooms for flammable and combustible liquids have

Are bulk drums of flammable liquids grounded and bonded to containers during dispensing? Do storage rooms for flammable and combustible liquids have

Is liquefied petroleum gas stored, handled, and used in accordance with safe practices and standards?

Is liquefied petroleum gas stored, handled, and used in accordance with safe practices and standards?

Are "NO SMOKING" signs posted on liquefied petroleum gas tanks?

Are "NO SMOKING" signs posted on liquefied petroleum gas tanks?

Are liquefied petroleum storage tanks guarded to prevent damage from vehicles?

Are liquefied petroleum storage tanks guarded to prevent damage from vehicles?

Are fuel gas cylinders and oxygen cylinders separated by distance, and

Are fuel gas cylinders and oxygen cylinders separated by distance, and

Are fire extinguishers selected and provided for the types of materials in areas where they are to be used?

Are fire extinguishers selected and provided for the types of materials in areas where they are to be used?

Class A Ordinary combustible material fires.

Class A Ordinary combustible material fires.

Class B Flammable liquid, gas or grease fires.

Class B Flammable liquid, gas or grease fires.

Class C

Class C

Are extinguishers free from obstructions or blockage?

Are extinguishers free from obstructions or blockage?

Are all extinguishers serviced, maintained and tagged at intervals not to exceed 1 year?

Are all extinguishers serviced, maintained and tagged at intervals not to exceed 1 year?

Are all extinguishers fully charged and in their designated places?

Are all extinguishers fully charged and in their designated places?

Are all spills of flammable or combustible liquids cleaned up promptly?

Are all spills of flammable or combustible liquids cleaned up promptly?

Are "NO SMOKING" rules enforced in areas involving storage and use of hazardous materials?

Are "NO SMOKING" rules enforced in areas involving storage and use of hazardous materials?

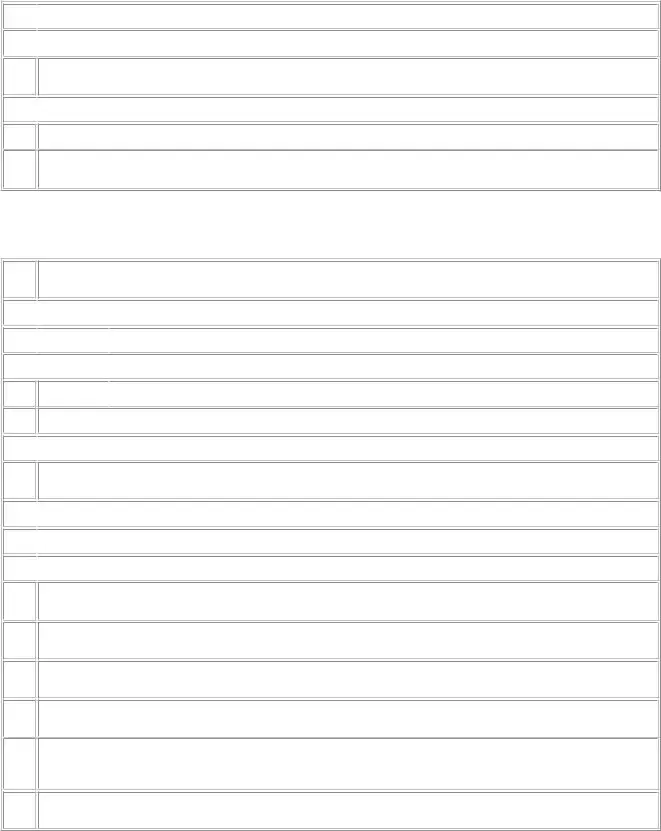

Are broken or fractured handles on hammers, axes and similar equipment replaced promptly?

Are broken or fractured handles on hammers, axes and similar equipment replaced promptly?

Are worn or bent wrenches replaced regularly?

Are worn or bent wrenches replaced regularly?

Are appropriate handles used on files and similar tools?

Are appropriate handles used on files and similar tools?

Are employees made aware of the hazards caused by faulty or improperly used hand tools?

Are employees made aware of the hazards caused by faulty or improperly used hand tools?

Are jacks checked periodically to ensure they are in good operating condition?

Are jacks checked periodically to ensure they are in good operating condition?

Are tools stored in dry, secure locations where they won't be tampered with?

Are tools stored in dry, secure locations where they won't be tampered with?

Is eye and face protection used when driving hardened or tempered spuds or nails?

Is eye and face protection used when driving hardened or tempered spuds or nails?

Are grinders, saws and similar equipment provided with appropriate safety guards?

Are grinders, saws and similar equipment provided with appropriate safety guards?

Are power tools used with the correct shield, guard, or attachment, recommended by the manufacturer?

Are power tools used with the correct shield, guard, or attachment, recommended by the manufacturer?

Are rotating or moving parts of equipment guarded to prevent physical contact?

Are rotating or moving parts of equipment guarded to prevent physical contact?

Are portable fans provided with full guards or screens having openings ½ inch or less?

Are portable fans provided with full guards or screens having openings ½ inch or less?

Are pneumatic and hydraulic hoses on power operated tools checked regularly for deterioration or damage?

Are pneumatic and hydraulic hoses on power operated tools checked regularly for deterioration or damage?

Are employees who operate

Are employees who operate

Is each

Is each

Are

Are

Where the power disconnecting means for equipment does not also disconnect the electrical control circuit:

Where the power disconnecting means for equipment does not also disconnect the electrical control circuit:

Are the appropriate electrical enclosures identified?

Are the appropriate electrical enclosures identified?

Is means provided to assure the control circuit can also be disconnected and

Is means provided to assure the control circuit can also be disconnected and

Are all equipment control valve handles provided with a means for

Are all equipment control valve handles provided with a means for

Are appropriate employees provided with individually keyed personal safety locks?

Are appropriate employees provided with individually keyed personal safety locks?

Are employees required to keep personal control of their key(s) while they have safety locks in use?

Are employees required to keep personal control of their key(s) while they have safety locks in use?

Is it required that only the employee exposed to the hazard, place or remove the safety lock?

Is it required that only the employee exposed to the hazard, place or remove the safety lock?

Is adequate illumination provided for the work to be performed in the confined space?

Is adequate illumination provided for the work to be performed in the confined space?

Is the standby employee appropriately trained and equipped to handle an emergency?

Is the standby employee appropriately trained and equipped to handle an emergency?

Is each confined space checked for decaying vegetation or animal matter which may produce methane?

Is each confined space checked for decaying vegetation or animal matter which may produce methane?

Is the confined space checked for possible industrial waste which could contain toxic properties?

Is the confined space checked for possible industrial waste which could contain toxic properties?

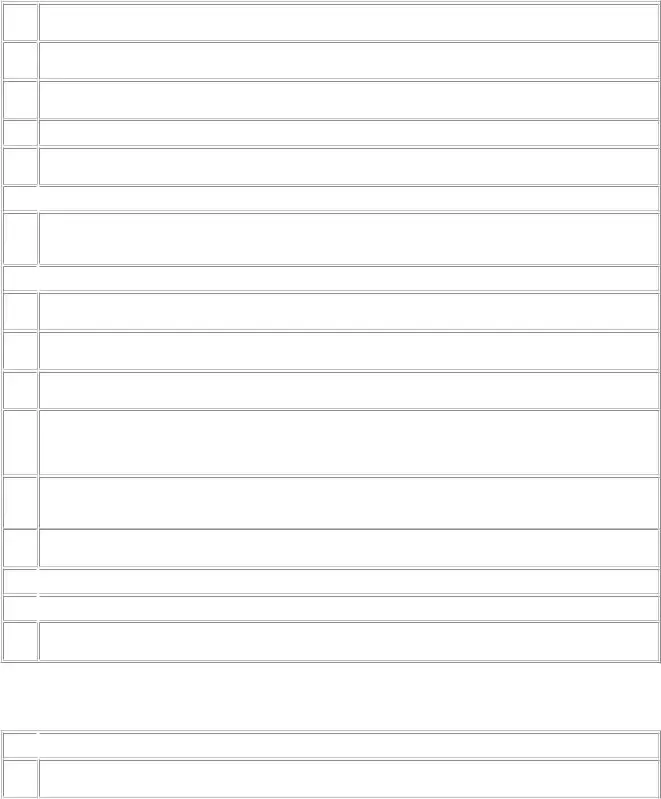

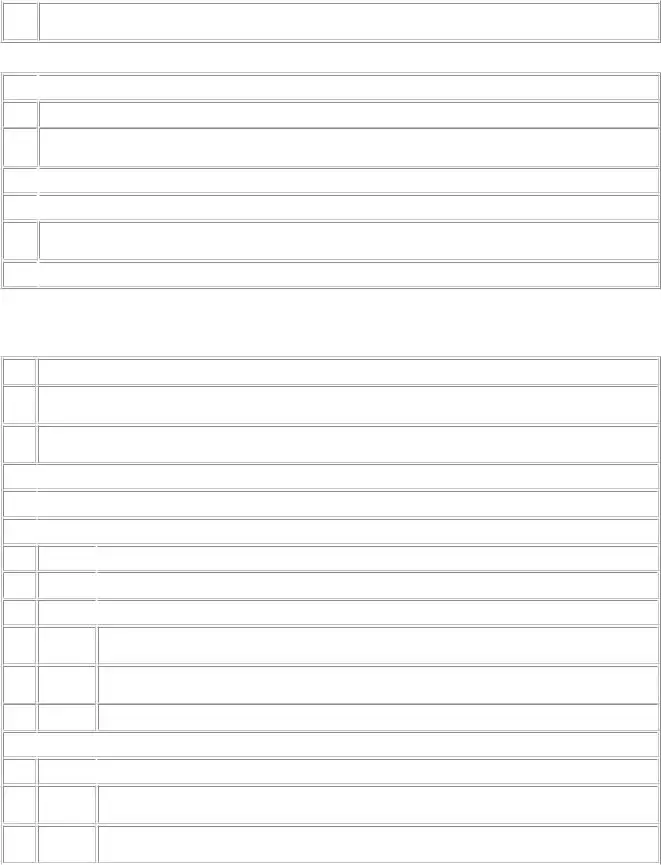

Do you specify compliance with OSHA for all contract electrical work?

Do you specify compliance with OSHA for all contract electrical work?

Are portable electrical tools and equipment grounded or of the double insulated type?

Are portable electrical tools and equipment grounded or of the double insulated type?

Are electrical appliances such as vacuum cleaners, polishers, and vending machines grounded?

Are electrical appliances such as vacuum cleaners, polishers, and vending machines grounded?

Is exposed wiring and cords with frayed or deteriorated insulation repaired or replaced promptly?

Is exposed wiring and cords with frayed or deteriorated insulation repaired or replaced promptly?

Are flexible cords and cables free of splices or taps?

Are flexible cords and cables free of splices or taps?

Are all disconnecting switches and circuit breakers labeled to indicate their use or equipment served?

Are all disconnecting switches and circuit breakers labeled to indicate their use or equipment served?

Are disconnecting means always opened before fuses are replaced?

Are disconnecting means always opened before fuses are replaced?

Are all electrical raceways and enclosures securely fastened in place?

Are all electrical raceways and enclosures securely fastened in place?

Is each motor disconnecting switch or circuit breaker located within sight of the motor control device?

Is each motor disconnecting switch or circuit breaker located within sight of the motor control device?

Is a documented, functioning housekeeping program in place?

Is a documented, functioning housekeeping program in place?

Are all worksites clean, sanitary, and orderly?

Are all worksites clean, sanitary, and orderly?

Are work surfaces kept dry or is appropriate means taken to assure the surfaces are

Are work surfaces kept dry or is appropriate means taken to assure the surfaces are

Is combustible dust cleaned up with a vacuum system to prevent the dust from going into suspension?

Is combustible dust cleaned up with a vacuum system to prevent the dust from going into suspension?

Are covered metal waste cans used for oily and

Are covered metal waste cans used for oily and

Are aisles and passageways kept clear?

Are aisles and passageways kept clear?

Are aisles and walkways marked as appropriate?

Are aisles and walkways marked as appropriate?

Is there safe clearance for walking in aisles where motorized or mechanical handling equipment is operating?

Is there safe clearance for walking in aisles where motorized or mechanical handling equipment is operating?

Are materials or equipment stored in such a way that sharp projectives will not interfere with the walkway?

Are materials or equipment stored in such a way that sharp projectives will not interfere with the walkway?

Are spilled materials cleaned up immediately?

Are spilled materials cleaned up immediately?

Are changes of direction or elevation readily identifiable?

Are changes of direction or elevation readily identifiable?

Is adequate headroom provided for the entire length of any aisle or walkway?

Is adequate headroom provided for the entire length of any aisle or walkway?

Are bridges provided over conveyors and similar hazards?

Are bridges provided over conveyors and similar hazards?

Are skylight screens of such construction and mounting that they will withstand a load of at least 200 pounds?

Are skylight screens of such construction and mounting that they will withstand a load of at least 200 pounds?

Are standard stair rails or handrails on all stairways having four or more risers?

Are standard stair rails or handrails on all stairways having four or more risers?

Are all stairways at least 22 inches wide?

Are all stairways at least 22 inches wide?

Do stairs angle no more than 50 and no less than 30 degrees?

Do stairs angle no more than 50 and no less than 30 degrees?

Are step risers on stairs uniform from top to bottom?

Are step risers on stairs uniform from top to bottom?

Are steps on stairs and stairways designed or provided with a surface that renders them slip resistant?

Are steps on stairs and stairways designed or provided with a surface that renders them slip resistant?

Are stairway handrails located between 30 and 34 inches above the leading edge of stair treads?

Are stairway handrails located between 30 and 34 inches above the leading edge of stair treads?

Are signs posted, when appropriate, showing the elevated surface load capacity?

Are signs posted, when appropriate, showing the elevated surface load capacity?

Is a permanent means of access and egress provided to elevated storage and work surfaces?

Is a permanent means of access and egress provided to elevated storage and work surfaces?

Is required headroom provided where necessary?

Is required headroom provided where necessary?

Are dock boards or bridge plates used when transferring materials between docks and trucks or rail cars?

Are dock boards or bridge plates used when transferring materials between docks and trucks or rail cars?

Is there a Material Safety Data Sheet readily available for each hazardous substance used?

Is there a Material Safety Data Sheet readily available for each hazardous substance used?

Is there an employee training program for hazardous substances?

Is there an employee training program for hazardous substances?

Does this program include:

Does this program include:

An explanation of what an MSDS is and how to use and obtain one?

An explanation of what an MSDS is and how to use and obtain one?

MSDS contents for each hazardous substance or class of substances?

MSDS contents for each hazardous substance or class of substances?

Explanation of "Right to Know?"

Explanation of "Right to Know?"

Are employees trained in the following:

Are employees trained in the following:

How to recognize tasks that might result in occupational exposure?

How to recognize tasks that might result in occupational exposure?