The BCCC PPE Checklist form is an essential tool designed to ensure the safety and compliance of workers in various environments, focusing on the use of Personal Protective Equipment (PPE). This comprehensive inspection form meticulously categorizes equipment into several categories such as head, foot, hand, body, hearing, eye/face/inhalation, and fall protection, alongside water hazard protection. Each category demands a rigorous inspection to confirm whether PPE is being worn as required by the Job Hazard Analysis (JHA), is inspected by the wearer before use, and does not show signs of excessive wear or damage. It also checks for the proper decontamination or disposal of certain items to prevent contamination. The form is structured to highlight areas marked for specific PPE use, ensuring employees wear the appropriate gear in designated zones. This attention to detail underlines the form's goal of minimizing workplace injuries and promoting an environment of safety and preparedness through the thorough inspection and maintenance of protective gear.

| Question | Answer |

|---|---|

| Form Name | BCCC PPE Checklist Form |

| Form Length | 2 pages |

| Fillable? | No |

| Fillable fields | 0 |

| Avg. time to fill out | 30 sec |

| Other names | Personal Protective Equipment Inspection Checklist Form, Personal Protective Equipment Testing and Inspection Form |

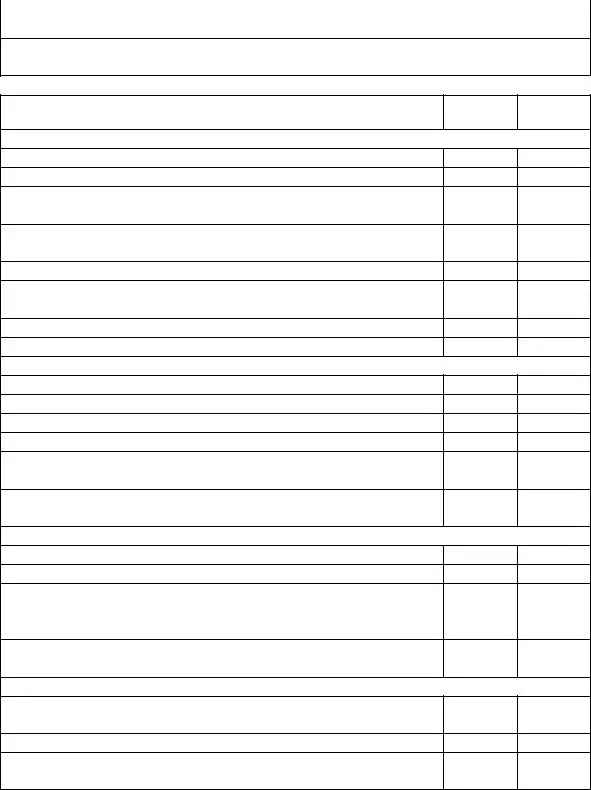

Attachment 5

Personal Protective Equipment Inspection Form

Date: |

Name of Inspector: |

Location:

Specific tasks performed at this location:

PERSONAL PROTECTIVE EQUIPMENT USED

Yes

No

(or N/A)

Head Protection

Head protection is being worn when required by the JHA.

Head protection is inspected by wearer prior to each use.

The brim or shell does not show signs of exposure or excessive wear, loss of surface gloss, chalking, or flaking.

The brim or shell does not have any signs of paint or solvent use.

The brim or shell is not cracked, perforated, or deformed.

The suspension system inside hardhat does not shoe signs of deterioration, including cracking, tearing, or fraying.

Hardhat areas are marked.

Employees wear hard hats in marked areas.

Footwear

Safety footwear is being worn when required by the JHA.

Safety footwear is inspected by wearer prior to each use.

Safety footwear areas are marked.

Employees wear safety footwear in marked areas.

Safety footwear worn by employees does not show signs of excessive wear.

Chemical resistant footwear is decontaminated or disposed prior to leaving the work area.

Hand Protection

Hand protection is being worn when required by the JHA.

Gloves are inspected by wearer prior to each use.

Gloves do not show signs of exposure or excessive wear, cracking, scrapes/cuts, thinning, discoloration, or breakthrough to the skin.

Chemical resistant gloves are decontaminated or disposed prior to leaving the work area.

Body Protection/Protective Clothing

Body protection/protective clothing is being worn when required by the JHA.

Protective clothing is inspected by wearer prior to each use.

Protective clothing does not show signs of exposure or excessive wear, cracking, scrapes/cuts, thinning,

Version 1.0 Effective October 2007

discoloration, or breakthrough to the skin.

Chemical resistant clothing is decontaminated or disposed prior to leaving the work area.

Hearing Protection

Hearing protection is being worn when required by the JHA.

Hearing protection is inspected by wearer prior to each use.

Noise hazardous areas are marked.

Employees wear hearing protection in marked noise hazard areas/ equipment.

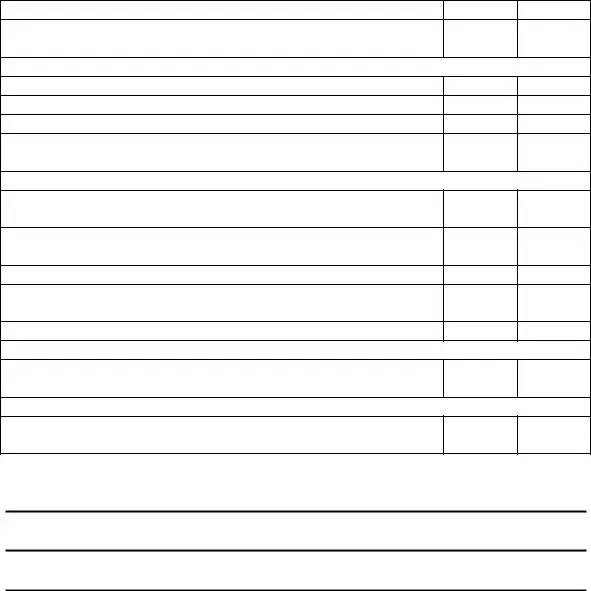

Eye/Face/Inhalation Protection

Eye/Face/Respirator protection is being worn when required by the JHA.

Eye/Face/Respirator protection is inspected by wearer prior to each use.

Eye/Face hazardous areas are marked.

Employees wear eye/face protection in marked eye/face hazard areas/ equipment.

Employees store, clean, maintain respirators properly.

Fall Protection

Equipment & PPE used, maintained according to Chapter 10, Safety Manual

Water Hazard Protection

U.S. Coast Guard approved flotation devices used, maintained.

Remarks:

Version 1.0 Effective October 2007