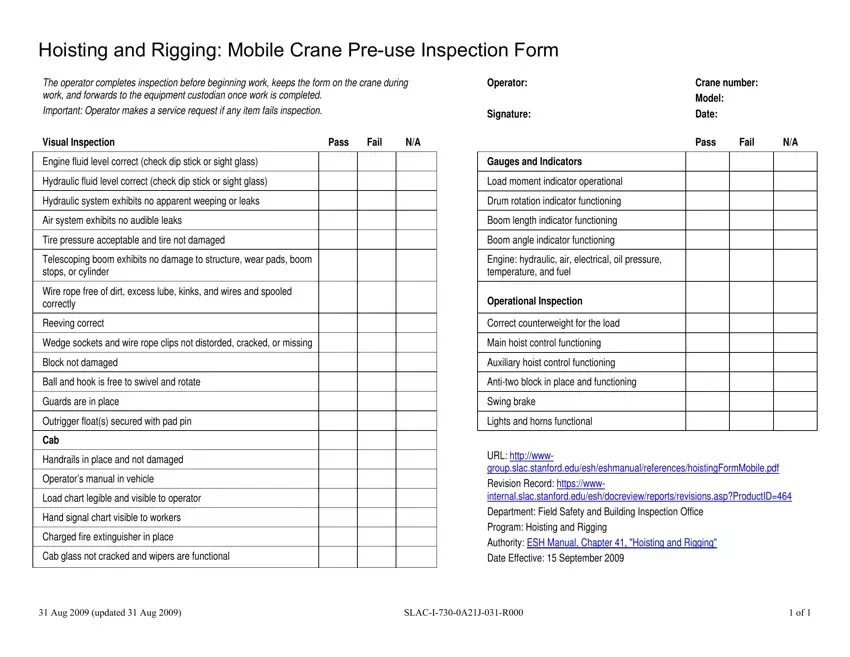

The filling in the crane lift pre inspection form word document is very straightforward. Our experts made certain our PDF tool is easy to utilize and can help complete just about any document within minutes. Listed below are some of the steps you'll want to follow:

Step 1: Click on the "Get Form Here" button.

Step 2: So you will be on your file edit page. You can include, enhance, highlight, check, cross, add or erase fields or text.

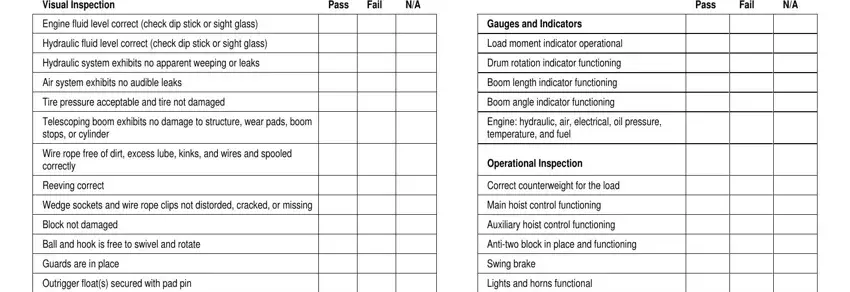

For every single segment, create the information requested by the program.

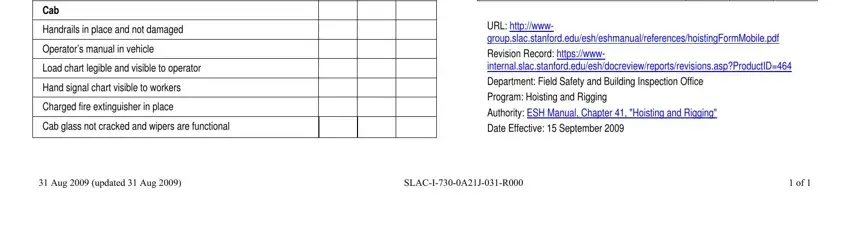

Write the information in Cab, Handrails in place and not damaged, Operators manual in vehicle, Load chart legible and visible to, Hand signal chart visible to, Charged fire extinguisher in place, Cab glass not cracked and wipers, URL httpwww, Aug updated Aug, and SLACIAJR.

Step 3: Choose the "Done" button. Now you may export your PDF file to your gadget. Besides, you may deliver it by email.

Step 4: Generate copies of your form. This may prevent forthcoming complications. We don't read or display your information, thus be certain it's going to be safe.