TECHNICAL DATA INSTRUCTION

NUMBER 523

06 Jan 2011

INSTRUCTIONS FOR THE PREPARATION OF

AN ENGINEERING CHANGE PROPOSAL UTILIZING RDMR FORM 523

1. GENERAL

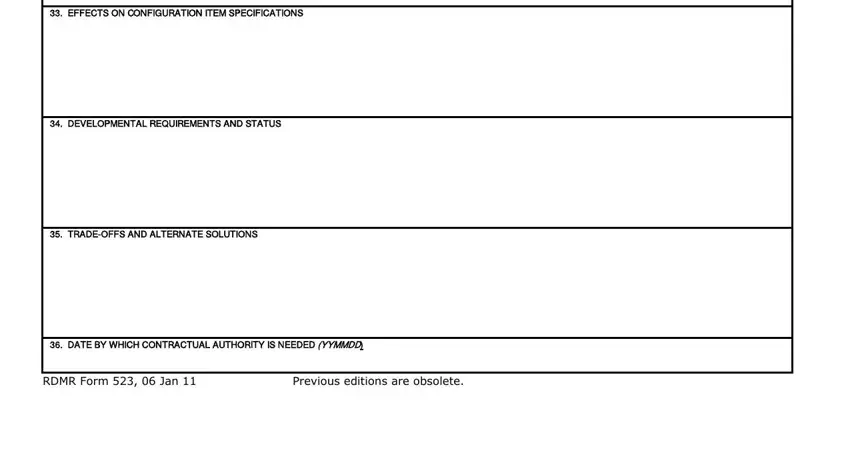

1.1SCOPE. This Technical Data Instruction (TDI) establishes uniform requirements for the preparation of the RDMR Form 523, “Engineering Change Proposal (ECP),” Pages 1-7. A copy of RDMR Form 523 is included in this TDI as Appendix A. The information contained herein is intended to assist in completing the RDMR Form 523.

1.2Application. The provisions of this TDI apply to all ECP preparing activities and to proposed engineering changes for systems, configuration items (CIs), hardware configuration items (HWCIs), and computer software configuration items (CSCIs).

2. APPLICABLE DOCUMENTS

EIA-649 – National Consensus Standard for Configuration Management

MIL-HNBK-61 – Military Handbook: Configuration Management Guidance

3. DEFINITIONS

3.1Definitions. For purposes of this TDI, the definitions contained in EIA-649 and

MIL-HDBK-61 shall apply unless in conflict with this TDI, in which case this TDI shall govern.

4. GENERAL REQUIREMENTS

4.1Use of the ECP forms. RDMR Form 523 (Pages 1-7) shall be used for the submission and processing of all Class I engineering changes. When ECP Short Form procedures are specified, only require Page 1 of the ECP form. Supplemental page(s) may be used with the ECP forms as necessary.

4.2Supporting data. In addition to the information required by this TDI, the ECP package shall include adequate supporting technical data required for proper evaluation.

4.3Local reproduction. Local reproduction of RDMR Form 523 (Pages 1-7) is authorized.

4.4Distribution statement. The appropriate distribution markings shall be affixed to the ECP package in accordance with the requirements of the contract.

5.DETAILING REQUIREMENTS. Detailed instructions for completion of the RDMR Form

523(Pages 1-7).

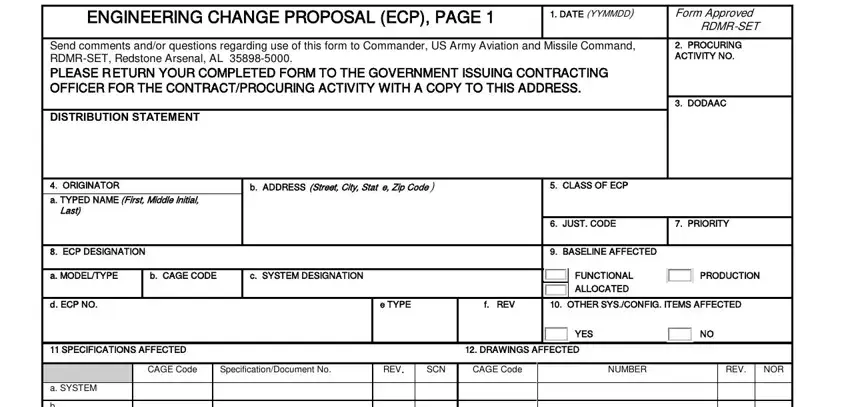

5.1RDMR Form 523 (Page 1), “Engineering Change Proposal.”

5.1.1Block 1. Date. Enter the submittal date of the ECP. If the submittal is a Revision (Block 8f), then the date will be the date of submittal for the Revision.

5.1.2Block 2. Procuring activity number. To be used by Government for entry of internal processing number if desired.

5.1.3Block 3. DODAAC. Department of Defense Activity Address Code (DODAAC). The DODAAC is in the Logistics Integration Data Base and is managed by the Army Central Service Point. Enter the DODAAC of the procuring activity.

5.1.4Block 4. Originator name, phone number, and address. In 4a, enter the person's name and phone number. In 4b, enter the Company name and address of the contractor or the Government activity submitting the ECP.

5.1.5Block 5. Class of ECP. Enter I or II for the applicable ECP as defined in the contract or as defined below if not addressed in the contract. If addressed in the contract, the contract governs.

5.15.1Class I ECPs should be limited to those that are necessary or offer significant benefit to the Government. Class I ECPs are those that affect the performance, reliability, maintainability, survivability, weight, balance, moment of inertia, interface characteristics, electromagnetic characteristics, or other technical requirements in the specifications and drawings. Class I ECPs also include those changes that affect Government Furnished Equipment, safety, compatibility, retrofit, operation and maintenance manuals, interchangeability, substitutability, replaceability, source control specifications and drawings, costs, guarantees or warranties, deliveries, or schedules. Class II ECPs are those that do not affect form, fit, function, cost, or schedule or the system Configuration Item and do not meet the other criteria described above for Class I ECPs.

5.1.6Block 6. Justification code. Enter the justification code from the codes provided below which best describes to the proposed Class I engineering change.

CODES

C- Correct documentation design problem or deficiency

O- Operational or logistics support

P- Production stoppage

R- Cost Reduction

V- Value engineering

5.1.6.1Value engineering ECP. When the contract contains a value-engineering clause, each value engineering ECP shall be identified both by the “V” in block 6 and by the all capital letters entry of the following notation as the first line in Block 19 (Description of Change) on Page 1 of the ECP form: "VALUE ENGINEERING CHANGE PURSUANT TO CONTRACT CLAUSE."

5.1.7Block 7. Priority. The contractor shall recommend a priority to the Government and enter an "E," "U," or "R" (Emergency, Urgent, or Routine). Emergency priorities will be assigned to those ECPs for which approval are needed within 48 hours. Urgent priorities are assigned to those ECPs for which approvals are needed within 30 days. Routine priorities are assigned for those ECPs for which approvals can wait for up to 90 days.

5.1.8Block 8. ECP designation.

5.1.8.1Block 8a. Model/Type. Enter model or type designation of the CI for which this proposal is being filled out. For CSCIs, enter the CSCI identification number.

5.1.8.2Block 8b. CAGE code. Enter the Commercial and Government Entity (CAGE) code as shown in Defense Logistic Agency (DLA) Cataloging Handbook H4/H8 for the activity originating the ECP.

5.1.8.3Block 8c. System designation. The system or top-level CI designation or nomenclature assigned by the Government shall be entered, if known.

5.1.8.4Block 8d. ECP number. Once an ECP number is assigned to the first submission of a change proposal, that number shall be retained for all subsequent submissions of that change proposal. The number of characters is limited to 15. Use of Government assigned numbers assures the numbers are unique. Otherwise, one of the following methods of assigning ECP numbers may be used unless otherwise stated in the contract:

a.A very descriptive method for composing the ECP number for a commercial company is to begin the number with the two to six letter company abbreviation followed by a dash, then the last four digit of the contract number, followed by another dash, and finally followed by the sequential number of the ECP written under that contract.

b.When an ECP is split into a basic ECP and related ECPs, the basic ECP shall be identified with the number prescribed above and each related ECP shall be identified by the basic number plus a separate dash number. The number of characters in the ECP number, dash number, type, and revision identification shall not exceed 15.

c.Other systems may be used provided the ECP number is unique for any CAGE code identified activity, and the IS-character limitation is not exceeded.

5.1.8.5Block 8e. Type. Enter either a "P" for preliminary or "F" for formal. Formal (type F) changes contain all the documentation required to make the proposed change to the technical data. Type P or preliminary ECPs will be clearly identified as preliminary in Blocks 19 and 20.

5.1.8.6Block 8f. Revision. If an ECP is being revised, enter the proper identification of the

revision, i.e., R 1 for the first revision. The letter R will precede the numbers for subsequent revisions. (The date submitted shall be the date of the revised ECP.)

5.1.9Block 9. Baseline affected. Place an "X" in the box(es) according to the baseline(s) affected.

5.1.10Block 10. Other systems/configuration items affected. Enter an "X" in the "yes" or "no" box, as applicable, to indicate whether there is an effect on other systems or CIs, which will require the submittal of related Class I ECPs. Supply details in Blocks 28 and 30.

5.1.11Block 11. Specification affected. If specifications cited in the contract are affected by the ECP, their identity by the CAGE code of the design activity, document number, revision letter, and number of the SCN (or NOR) being submitted with the ECP, shall be entered.

5.1.12Block 12. Drawings affected. Enter the indicated information for all drawings affected by the ECP. The CAGE code to be entered is that of the design activity whose number is assigned to the listed drawings. If more than three drawings are affected, enter the information required in the first line for the top-level drawing affected by the ECP and make direct reference on the second line to the enclosure and paragraph containing the list of all the affected drawings.

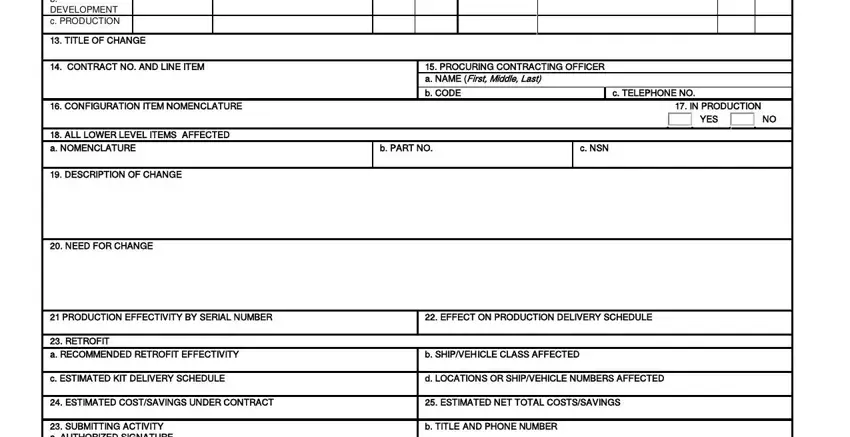

5.1.13Block 13. Title of change. Enter a brief title to identify the component or system affected

by the ECP. Do not include the purpose or description which are to be entered in Block 16. For example: F18 Aircraft Air Turbine Start Connector Backshell Replacement; AN/AYK-14(v) CP- 1502/CP-1503. Reconfiguration to CP-1799; (CSCI name) Block Update.

5.1.14Block 14. Contract number(s) and line item(s). Enter the number(s) of all currently active contract(s), and the affected contract line item number(s), at the originating CAGE-coded activity that are affected by the engineering change. If more contracts are affected than can be fit in the block, make reference to the enclosure and paragraph where this information is provided. In the case of a Government-prepared change, the task number under which the ECP will be funded and implemented shall be provided in this block.

5.1.15Block 15. Procuring contracting officer. Enter the procuring contracting officer's name, code, and telephone number applicable to the CI shown in Block 16.

5.1.16Block 16. Configuration item nomenclature. Enter the Government assigned name and type designation, CSCI name and number if applicable, or authorized name and number of the CI(s) affected by the ECP.

5.1.17Block 17. In production. The "yes" box shall be marked if deliveries have not been completed on the contract(s). The "no" box shall be marked if the deliveries have been completed. This block is not always applicable to software. If not applicable, so indicate.

5.1.18Block 18. All lower level items affected.

a.For hardware, an appropriate, complete descriptive name of the part(s) shall be given here without resorting to such terms as "Numerous bits and pieces." The number(s) of the part(s) shall also be entered. Additionally, applicable National Stock Numbers (NSNs) shall be entered. An attached list may be used when necessary.

b.For CSCI's, enter the name and identifier of each lower level CI and computer software unit affected.

5.1.19Block 19. Description of change. The description of the proposed change shall include the purpose and shall be given in sufficient detail to adequately describe what is to be accomplished. IT shall be phrased in definitive language such that, if it is repeated in the contractual document authorizing the change, it will provide the authorization desired. A description as to which part of the item or system is being changed shall be provided. Supplemental drawings and sketches shall be provided to the extent necessary to clearly portray the proposed change. If the proposed change is an interim solution, it shall be so stated. If additional space is needed, use continuation pages for details but provide an overview in this block. Information should be included as to whether the revision is a resubmitta1, replacing the existing ECP in its entirety, or provides change pages to the existing ECP.

5.1.20Block 20. Need for change. Enter an explanation of the need for the change to include specifically identifying the benefit of the change to the Government. The nature of the defect, failure, incident, malfunction, etc. substantiating the need for the change shall be described in detail. Full utilization shall be made of available failure data. If a new capability is to be provided, improvements in range, speed, performance, endurance, striking power, defensive or offensive capabilities, etc. shall be described in quantitative terms. Correspondence establishing requirements for the change and any testing accomplished prior to the submission shall be identified and summarized. If the ECP is needed to correct maintenance/logistics problems, that fact will be included with sufficient detail to identify the issues. If the ECP is being submitted as a response to a request for ECP or Government direction, cite that authority herein. Additional pages may be added as required.

5.1.21Block 21. Production effectivity by serial number.

a.For hardware, enter the contractor's estimated production effectivity point for the production items including serial number, or other item identification (e.g., block or lot number) as approved by the Government. In determining the effectivity point for the proposed change, the contractor shall consider, in addition to the time factors, the availability of all support elements affected and the most economical point of introduction consistent with all the salient factors involved. The earliest production incorporation is not necessarily the singular or most important factor in the establishment of a proposed change effectivity point. The effectivity point will be based on concurrent availability of all logistics support elements and materials affected by the change to the item.

b.For CSCI's, identify the CSCI version number into which the change will be incorporated. Where applicable, the effectivity of the end item CI and vehicle (aircraft, tank, ship, etc.) into which the capability represented by the new version of the software is proposed to be incorporated, shall also be provided. If the impact of the ECP merits the release of a new