Are you looking for a reliable and secure way to store and share important documents? Sec Electronics Slovenia has developed an innovative PDF Form that meets the needs of both individuals and businesses. This blog post will explain how this form works, its key features, as well as how it can help make document sharing easier, faster and more secure than ever before. By the end of this post, you should have a better understanding of the benefits of using Sec Electronics Slovenia's PDF Form for your document management needs.

| Question | Answer |

|---|---|

| Form Name | Sec Electronics Slovenia Pdf Form |

| Form Length | 93 pages |

| Fillable? | No |

| Fillable fields | 0 |

| Avg. time to fill out | 23 min 15 sec |

| Other names | sec electronics e type emergency, sec electronics e type 14 fault, sec electronics manoeuvre e type, sec electronics e type board fault 14 |

E – TYPE

lift control system

SPECIFICATION AND INSTALLATION MANUAL

Manual ver. 2.0

Program ver. 2.06

SEC ELECTRONI CS |

Neverke 30 6256 Košana, SLOVENI A |

tel: + + 386 5 753 2006 |

email: sec.electronics@siol.net |

fax: + + 386 5 753 2007 |

web: http: / / www.secelectro.com |

ISO 9001

The information held in this manual may be modified without notice and SEC electronics will not be responsible for changes that may occur in the future.

No part of this manual can be reproduced, for any reason, in any form or by any means ( including recording and photocopying) without the written consent of SEC electronics.

Before the control panel installation, wiring, commissioning and inspection, read this instruction manual carefully.

Keep the manual in a safe place and available to engineering and installation personnel during the control panel functioning period.

SEC electronics is not responsible for those mistakes that may be found in this manual and for the damages that they may cause.

All rights reserved.

2 |

291 842 003 |

CONTENTS

|

SAFETY SIMBOL LEGEND |

5 |

0. |

SAFETY PRECAUTIONS |

6 |

1. |

PRODUCT LIABILITY AND WARRANTY |

9 |

1.1 |

TERMS OF WARRANTY |

9 |

2. |

INSPECTION PROCEDURE |

10 |

2.1. |

UPON DELIVERY INSPECTION PROCEDURE |

10 |

2.2. |

CONTROL PANEL TYPE DESIGNATION |

10 |

2.3. |

NAMEPLATE |

11 |

2.4. |

STANDARD SPECIFICATIONS |

12 |

2.5. |

DISPOSAL OF THE DEVICE |

12 |

3. |

INSTALLATION GUIDELINES |

13 |

3.1. |

MECHANICAL SPECIFICATION |

13 |

3.2. |

INSTALLATION MOUNTING CLEARANCE |

14 |

4. |

WIRING PROCEDURE |

15 |

4.1. |

AC INPUT CONNECTION |

15 |

4.2. |

MAIN MOTOR CONNECTION |

16 |

5. |

CONNECTION TO PC OR PDA |

17 |

5.1. |

CONNECTION TO PC |

17 |

5.2. |

CONNECTION TO PDA |

17 |

6. |

PROGRAMMING |

19 |

6.1. |

MAIN MENU |

19 |

6.2. |

SUBMENU ORGANISATION |

20 |

6.3. |

1L FLOW CONTROL |

20 |

6.4. |

2E SHOW ERROR HISTORY |

22 |

6.5. |

3C STATISTICS |

27 |

6.6. |

4F FUNDAMENTAL SETTINGS |

28 |

6.7. |

5V DOOR SETTINGS |

29 |

6.8. |

6P PARAMETERS |

32 |

6.9. |

7D SPECIAL DRIVES |

37 |

6.10. |

8S ENCODER SETTINGS |

38 |

6.11. |

9I INPUT / OUTPUT SETTINGS |

39 |

6.12. |

0W SAVE SETTINGS TO EEPROM |

40 |

6.13. |

PRESETING AND FACTORY RESET |

40 |

7. |

ABBREVIATIONS |

42 |

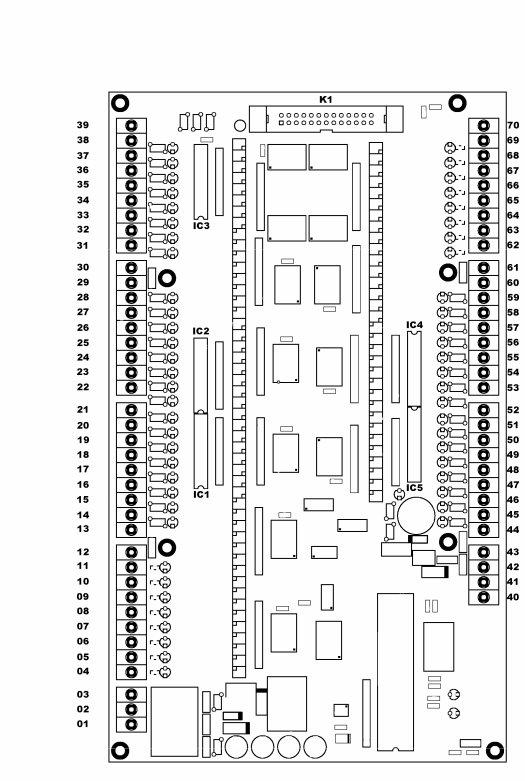

7.1. |

TERMINALS ON CONTROL PANEL |

42 |

7.2. |

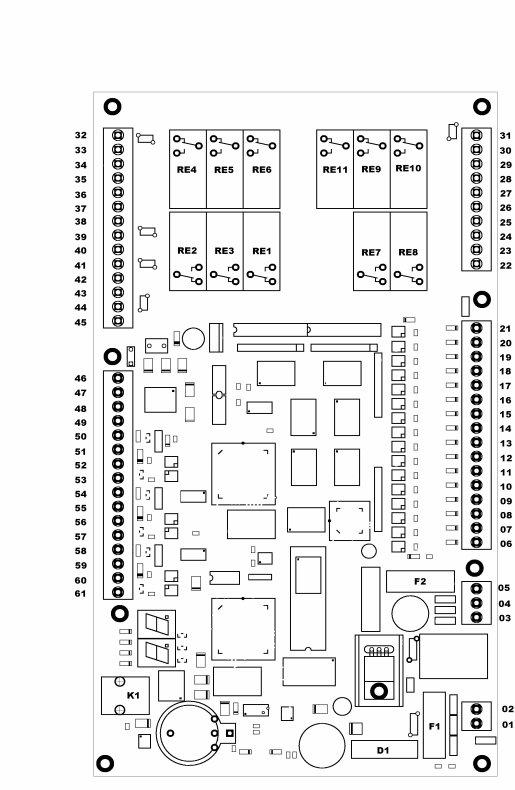

ELEMENTS ON CONTROL PANEL |

44 |

3 |

291 842 003 |

8. |

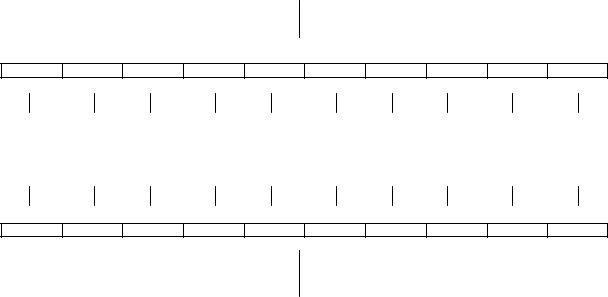

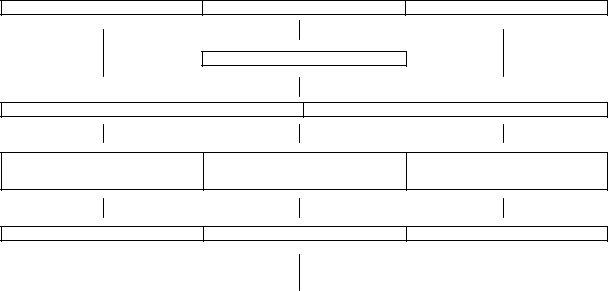

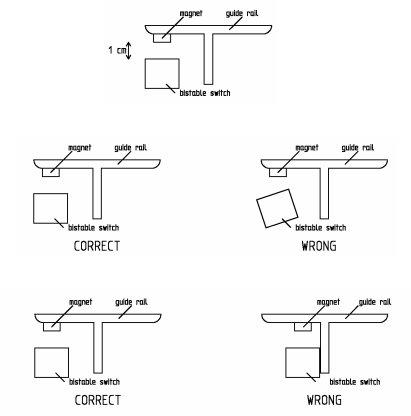

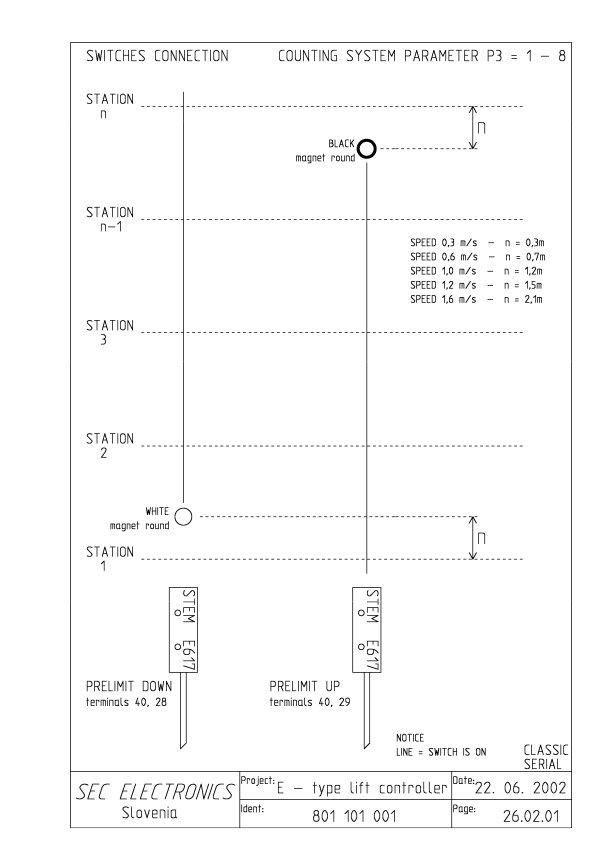

COUNTING SENSORS CONNECTION AND POSITION |

46 |

8.1. |

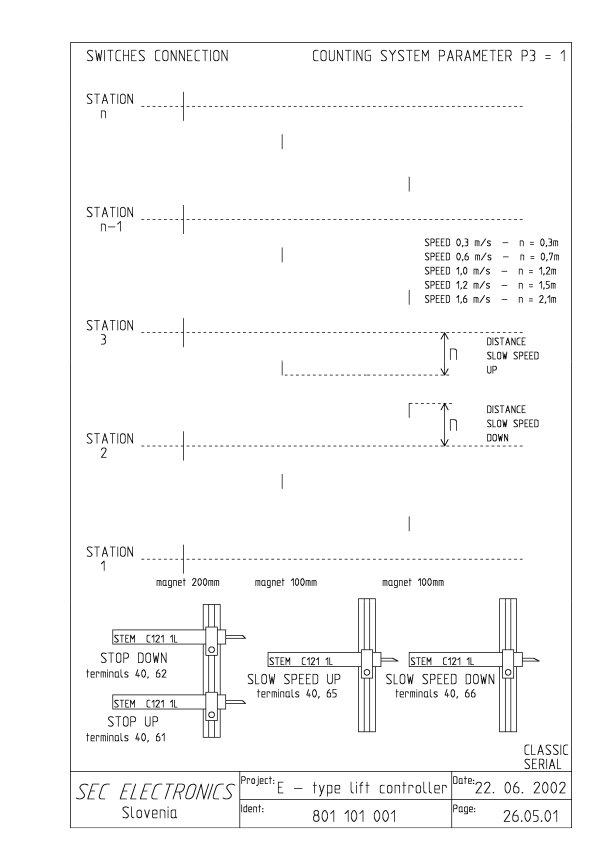

COUNTING SYSTEM PARAMETER P3 = 1- 8 |

47 |

8.2. |

COUNTING SYSTEM PARAMETER P3 = 1 |

48 |

8.3. |

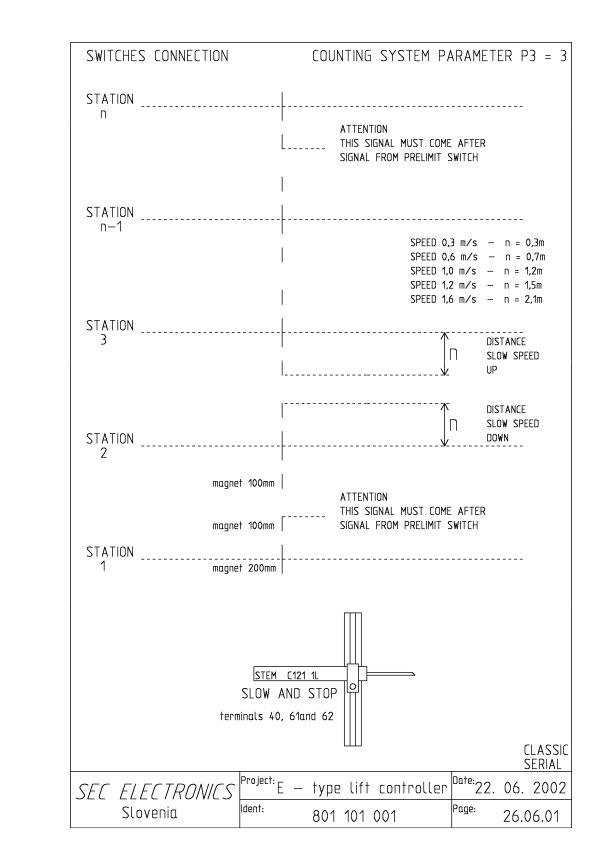

COUNTING SYSTEM PARAMETER P3 = 3 |

49 |

8.4. |

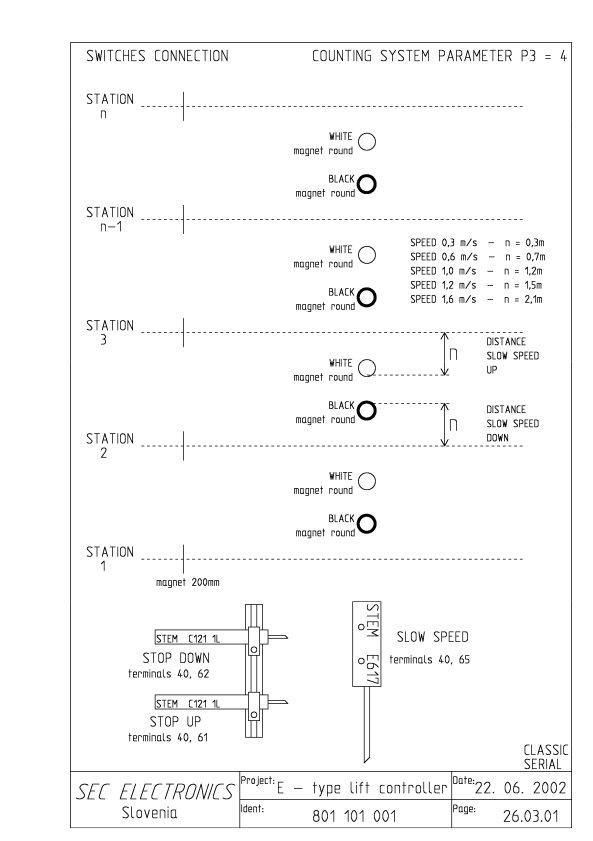

COUNTING SYSTEM PARAMETER P3 = 4 |

50 |

8.5. |

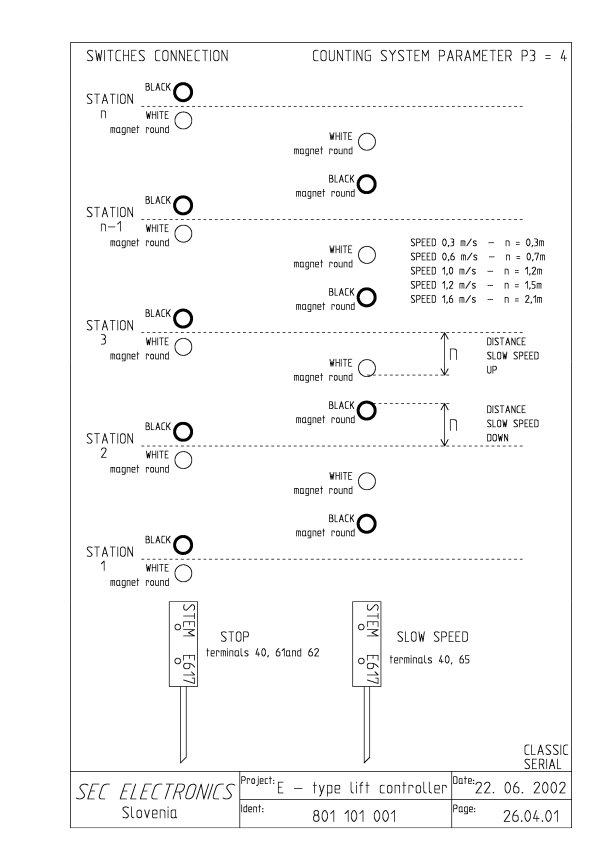

COUNTING SYSTEM PARAMETER P3 = 4 WITH SEPARATED MAGNETS |

51 |

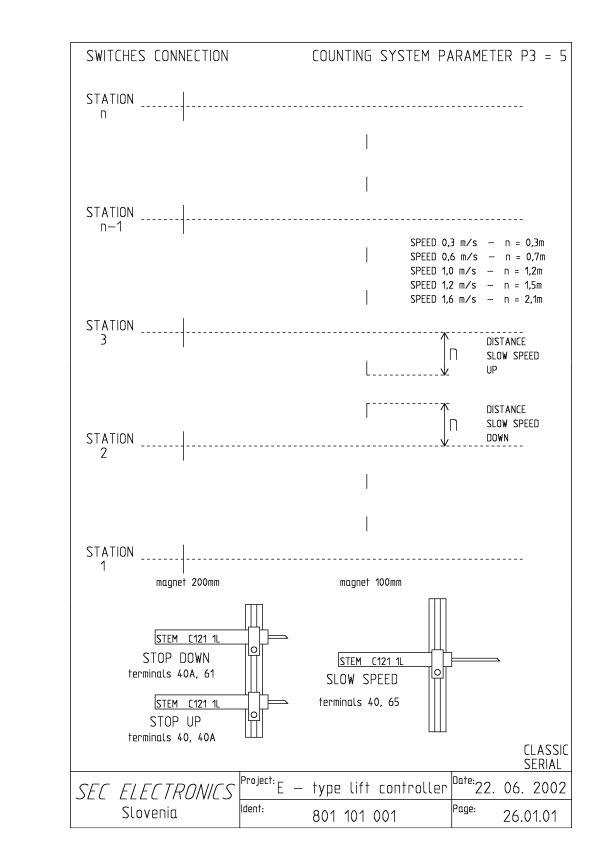

8.6 |

COUNTING SYSTEM PARAMETER P3 = 5 |

52 |

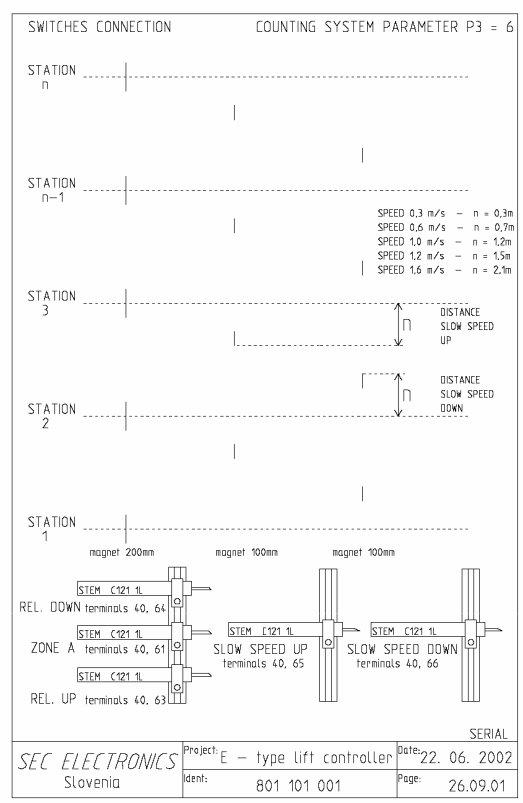

8.7 |

COUNTING SYSTEM PARAMETER P3 = 6 |

53 |

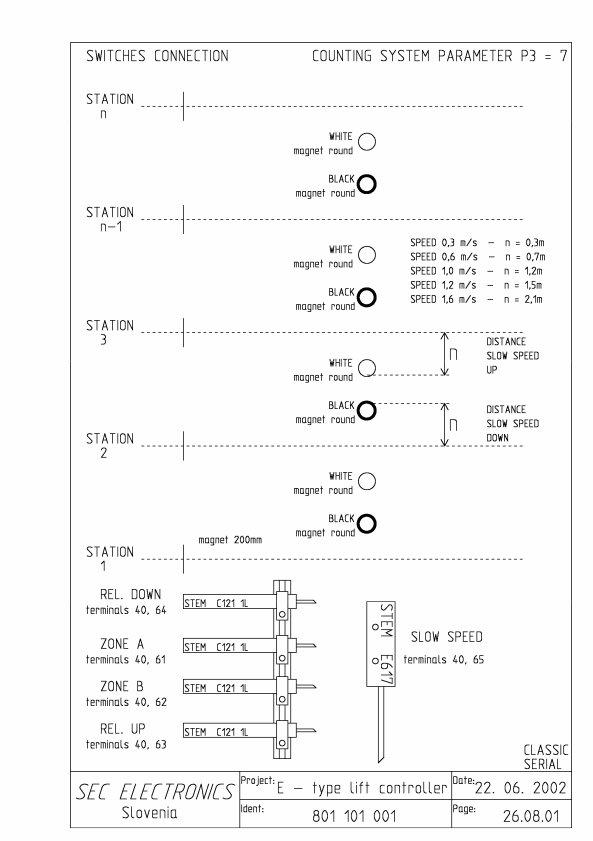

8.8 |

COUNTING SYSTEM PARAMETER P3 = 7 |

54 |

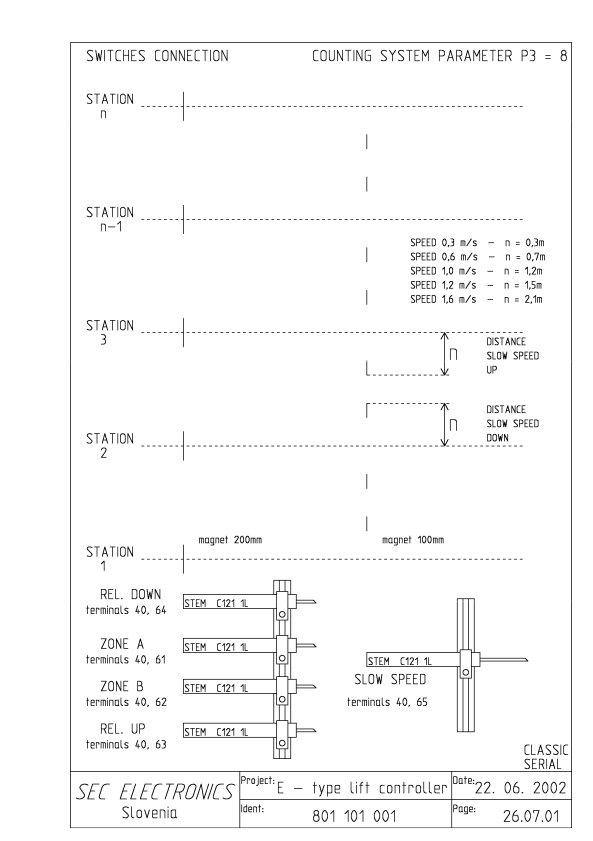

8.8. |

COUNTING SYSTEM PARAMETER P3 = 8 |

55 |

9. |

CONNECTION DURING INSTALLATION PHASE |

56 |

9.1. |

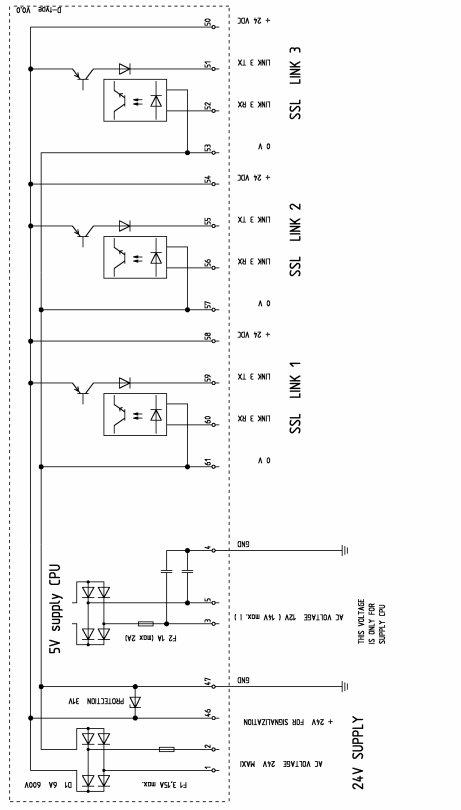

POWER SUPPLY |

56 |

9.2. |

MOTOR CONNECTION |

56 |

9.3. |

MAINTENANCE AND SAFETY CONNECTION |

57 |

10. |

START UP |

58 |

10.1. |

PRE POWER CHECK |

58 |

10.2. |

VOLTAGE AND CONTROL ELEMENTS CHECK |

58 |

10.3. |

MAINTENANCE MODE |

59 |

10.4. |

NORMAL MODE |

59 |

10.5. |

TROUBLESHOOTING |

60 |

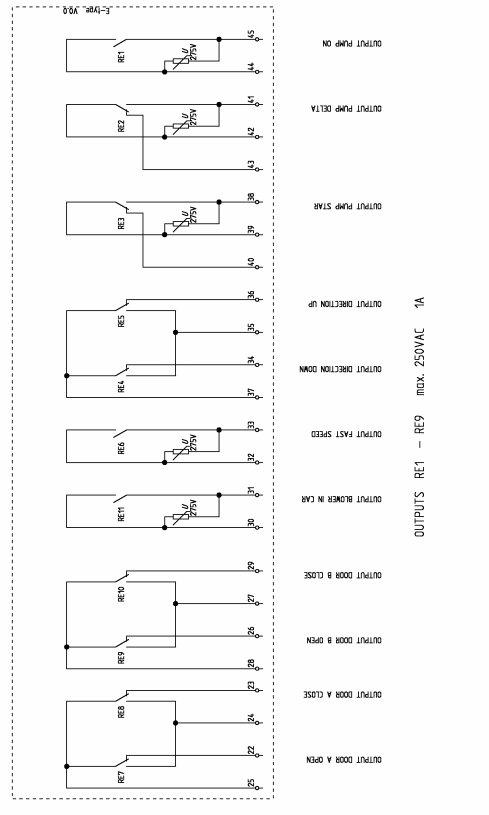

11. |

63 |

|

11.1 |

TECHNICAL CHARACTERISTICS |

63 |

11.2. |

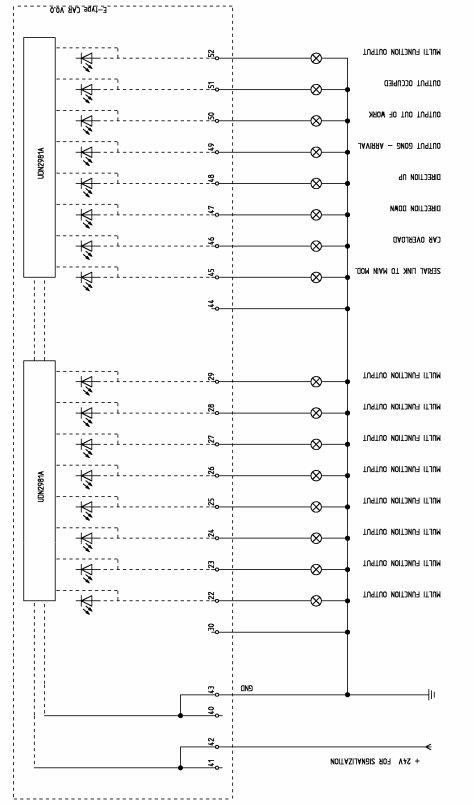

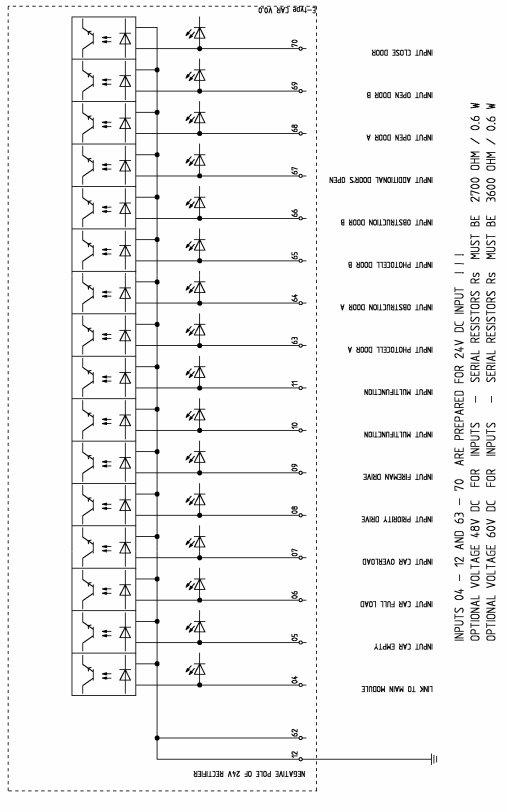

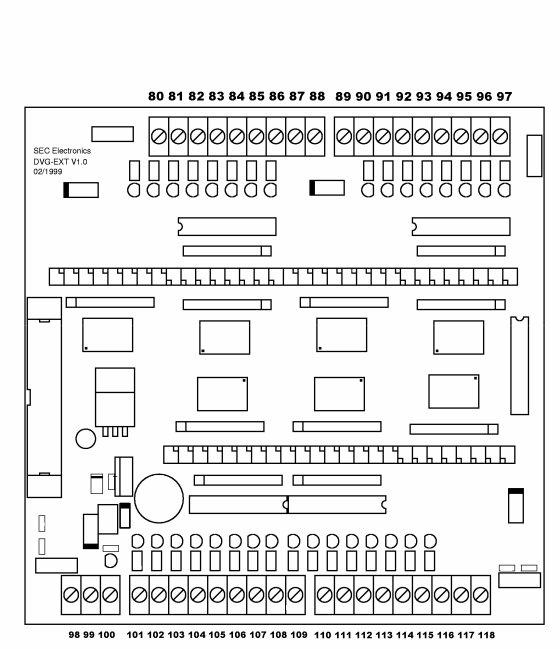

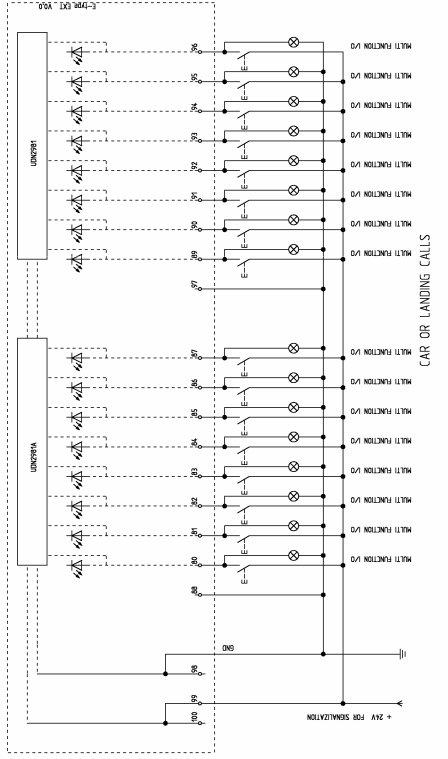

65 |

|

11.3. |

71 |

|

11.4. |

78 |

|

11.5. |

82 |

|

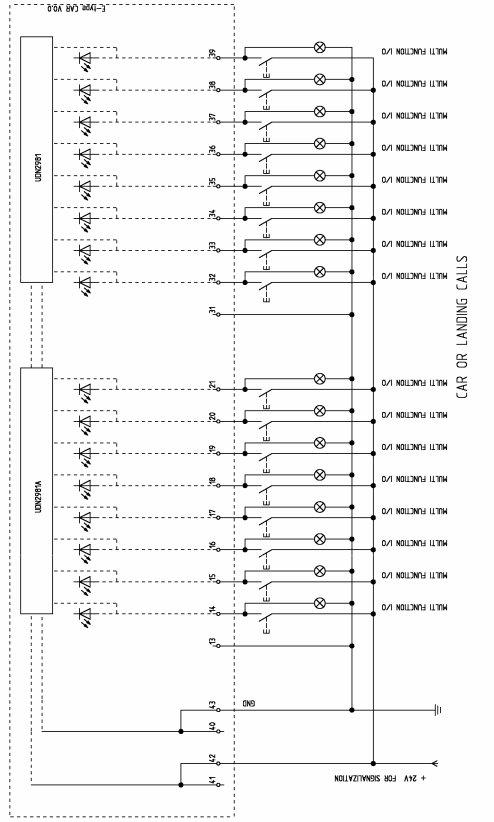

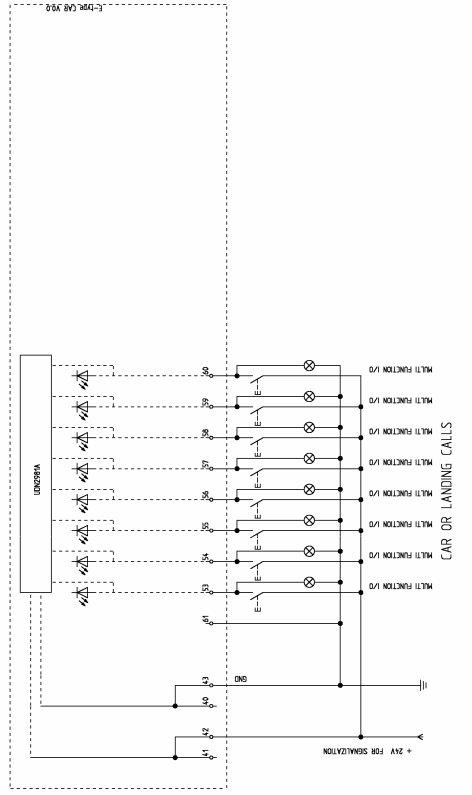

11.6. |

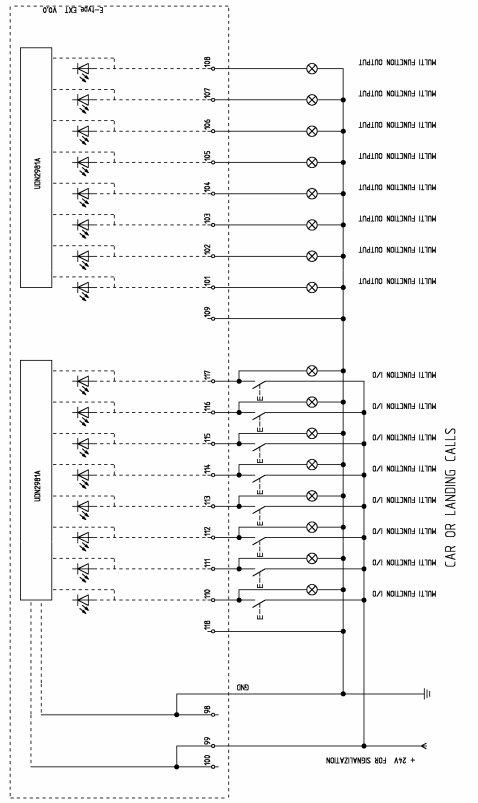

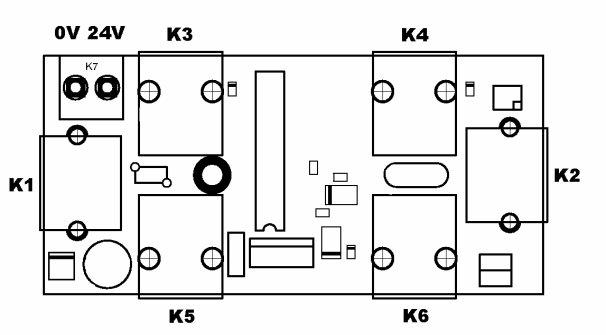

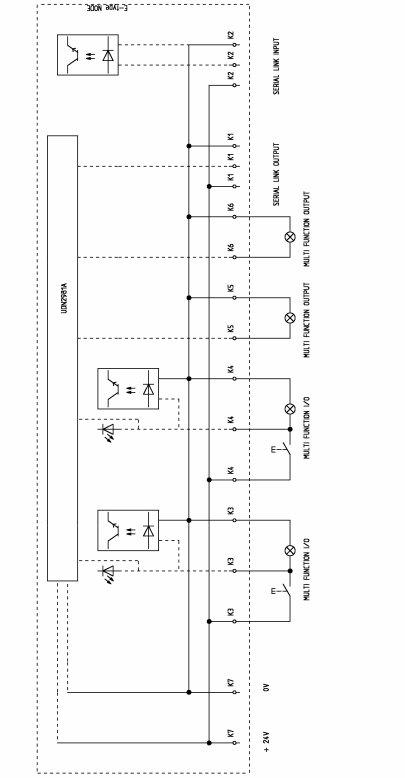

MULTIFUNCTION INPUTS / OUTPUTS |

84 |

12. |

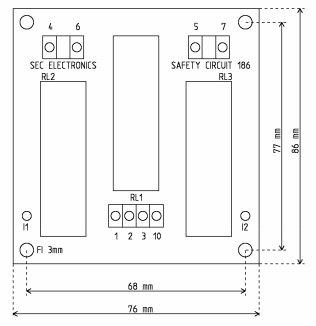

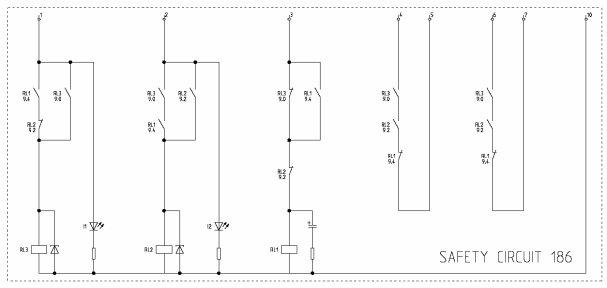

SAFETY CIRCUIT 186 |

89 |

12.1. |

GENERAL FEATURES |

89 |

12.2. |

DETAILS AND CONNECTIONS |

90 |

12.3. |

REQUIREMENTS FOR INSTALLATION |

90 |

13. |

GUIDE TO ELECTROMAGNETIC COMPATIBILITY |

91 |

13.1. |

THE EMC DIRECTIVE AND APPLICABLE STANDARD |

91 |

13.2. |

EMC COMPLIANT ELECTRICAL CABINET WIRING RULES |

92 |

DECLARATION OF CONFORMITY |

93 |

|

ADDENDUMS FOR NEWER PROGRAM VERSIONS |

|

|

PRESET PARAMETERS |

|

|

4 |

291 842 003 |

SAFETY SYMBOL LEGEND

WARNING: Commands attention to an operating procedure, practice, condition, or statement, which, if not strictly observed, could result in personal injury or death.

CAUTION: Commands attention to an operation procedure, practice, condition, or statement, which, if not strictly observed, could result in damage or destruction of equipment .

NOTE: Commands attention to an operating procedure, practice, condition, or statement that must be highlighted.

5 |

291 842 003 |

0.SAFETY PRECAUTIONS

WARNING – ATTENTION

Drive systems cause mechanical motion. I t is the responsibility of the user to ensure that any such motion does not result in an unsafe condition. Factory provided interlocks and operating limits should not be bypassed or modified.

WARNING – ELECTRICAL SHOCK AND BURN HAZARD

When using instruments such as oscilloscopes to work on live equipment, the oscilloscope’s chassis should be grounded and a differential amplifier input should be used. Care should be used in the selection of probes and leads and in the adjustment of the oscilloscope so that accurate readings may be made. See instrument manufacturer’s instruction book for proper operation and adjustment to the instrument .

WARNING – FIRE AND EXPLOSION HAZARD

Fires or explosions might result from mounting control panels in hazardous areas such as locations where flammable or combustible vapors or dusts are present . Control panels should be installed away from hazardous areas, even if used with motors suitable for use in these locations.

WARNING – STRAIN HAZARD

I mproper lifting practices can cause serious or fatal injury. Lift only with adequate equipment and trained personnel. When carrying equipment without packaging the boards or metal panels can cause damage to the equipment and injury to you.

WARNING – CRUSHING HAZARD

Risk of crushing and dama ge to the control panel if it does not have a firm stand. Be sure to place the control panel on a flat surface witch can support it’s weight before installation! Do not stand the control panel on end as it could fall over.

WARNING – HIGH TEMPERATURE

After prolonged use, the parts in control panel will reach a maximum temperature of 90 oC. Touching them with bare hands can be painful. Allow the unit to cool before you get near the hot parts. When braking resistors are used (they are normally installed at the top or in the side of the box) this resistors can reach a maximum temperature of 200 oC. Touching them with bare hands can cause serious or fatal injury.

ATTENTION – ELECTRIC SHOCK

Control panel, motors and all other equipment must be ground connected according to the NEC ( Code Electrique National).

WARNING / ATTENTION

Replace all covers before applying power to the control panel. Failure to do so may result in death or serious injury.

WARNING / ATTENTION

Control panels are electrical apparatus for use in industrial installations. Parts of the control panels are energized during operation. The electrical installation and the opening of the device should therefore only be carried out by qualified personnel. I mproper installation of motors, control panel or other equipment may therefore cause the failure of the device as well as serious injury to persons or material damage. Control panels are not equipped with motor overspeed protection logic.

Follow the instructions given in this manual and observe the local and national safety regulations applicable.

6 |

291 842 003 |

CAUTION / PRECAUTION

Do not connect power supply voltage that exceeds the standard specification voltage fluctuation permissible. I f excessive voltage is applied to the control panel, damage to the internal components will result .

CAUTION / PRECAUTION

Do not operate the control panel without the ground wire connected. The motor chassis should be grounded to earth through a ground lead separate from all other equipment ground leads to prevent noise coupli ng.

The grounding wires shall be sized in accordance with the NEC or Canadian Electrical Code. The connection shall be made by a UL listed or CSA certified closed- loop terminal connector sized for the wire gauge involved. The connector is to be fixed using the crimp tool specified by the connector manufacturer.

CAUTION / PRECAUTION

Do not perform a megger test between the control panel terminals or on the control circuit terminals.

CAUTION / PRECAUTION

Because the ambient temperature greatly affects control panel life and reliability, do not install the control panel in any location that exceeds the allowable temperature. Leave the ventilation cover attached for temperatures of 40 oC or below.

CAUTION / PRECAUTION

The control panel must be mounted on a wall that is constructed of heat resistant material. While the control panel is operating, the temperature of the control panel parts can rise to a temperature of 90 oC. I n case when braking resistors are used, the temperature of this resistor can rise up to 200 oC.

7 |

291 842 003 |

NOTE

The terms ‘’controller’’, ‘’lift controller’’ and ‘’control box’’ are sometimes used interchangeably throughout the industry. We will use the term ‘’control panel’’ in this document

1Never remove the covers while the AC I nput power supply is switched on. Minimum time to wait before working on the terminals or inside the device is 1 minute after disconnecting for control panels without electronic regulators for motors and 5 minutes for control panels with electronic regulators

( VVVF, ACVV, soft start)

2Do not touch or damage any components when handling the device. The changing of the isolation gaps or the removing of the isolation and covers is not permissible. I f the doors have to be removed (or opened) because the room temperature is higher than 40 degrees, the user has to ensure that no occasional contact with live parts may occur.

3Protect the control panel from impermissible environmental conditions (temperature, humidity, shock etc.)

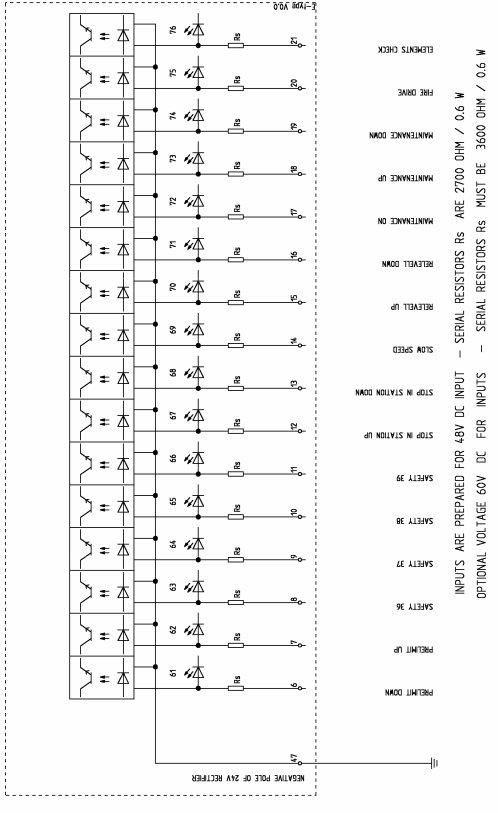

4No voltage should be connected to the output terminals for the motors, magnets, valves, lights

and switches (terminals 5, 6, 7, 8, 9, 10, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 25, 25a, 26, 26a, 27, 31, 40, 45, 46, 47, 48, 56, 57, 58, 59, 121, 122, 123, 130, 131,132, 222, 351, 352, 358, 360, 371, 372)

5A capacitative load ( e.g. Var compensation capacitors) should not be connected to the outputs for the motors (terminals 5, 6, 7, 8, 9, 10, 12, 13, 14, 15, 16, 17, 18, 19, 20)

6Always connect the control panel to the protective ground ( PE ) via the marked connection terminals ( 0 or GND ) and the housing ( 0 or GND ) . Control panels have ground discharge currents greater than 3,5 mA. EN 50178 specifies that with discharge currents greater than 3,5 mA the protective conductor ground connection ( 0 or GND ) must be fixed type and doubled for redundancy.

7The electrical commissioning should only be carried out by qualified personnel, who are also responsible for the provision of a suitable ground connection and a protected power supply feeder in accordance with the local and national regulations.

8No dielectric tests should be carried out on parts of the control panel. A suitable measuring

instrument (internal resistance of at least 10 kohm/ V ) should be used for measuring the signal voltages.

9I f the control panel has been stored for longer than three years, the operation of the capacitors may be impaired. Before commissioning devices that have been stored for long periods, connect them to a power supply for two hours with no load connected in order to regenerate the capacitors, ( the input

voltage has to be applied without enabling the functionality) .

10The control panel may start accidentally in the event of a failure, even if it is disabled, unless it has been disconnected from the AC input feeder.

8 |

291 842 003 |

1. PRODUCT LIABILITY AND WARRANTY

We guarantee the faultless condition of our product as described in our advertising, the product documentation we have published, and this manual. Product characteristics over and above this are not guaranteed.

Claims for damages are generally excluded, except in the case of proven premeditation, gross negligence by SEC electronics, or the absence of any promised features. I n particular we do not accept any liability if the control panels are used with other systems, encoders, switches, power supply systems and drive motors for which the control panels are unsuitable as stated in this manual or which fail to conform with the customary state of technology by virtue of their individual design.

We also disclaim responsibility for any damage to lift facilities and building facilities due to malfunction of the product or due to errors in this manual.

We are not responsible for violation of the patents and other rights of thir d parties.

We shall not be liable for any damage resulting from improper handling as defined in this manual. We expressly exclude liability for lost profit and especially for consequential damage due to the non- observance of safety regulations and warnings and/ or resulting from accessories not supplied by SEC electronics.

SEC electronics products are designed for a long service life. They confirm with the current state of science and technology and were individually tested in all their promised functions pr ior to shipment . SEC electronics is continuously engaged in product and market analysis in the interest of further development and constant improvement . However, if any malfunctions or breakdowns occur in spite of all the preventive measures, you should no tify the customer service department in Neverke, Slovenia. We assure you that suitable action to rectify the damage will be taken without delay.

1.1. TERMS OF WARRANTY

We guarantee the product’s proper working order as defined in this operating ma nual for a period of 24 months after shipment as per delivery note.

Repairs will only be carried out free of charge if this manual was observed for storage, transportation, installation, commissioning and operation.

I nterventions in a unit by the customer or third parties are only allowed after special consultation with SEC electronics. I f this condition is not observed, SEC electronics will accept no responsibility for any damage to the unit, injury to persons or consequential damage; in this case the warr anty shall expire. SEC electronics also disclaims all responsibility for unit faults resulting from damaged or functionally defective equipment in the control panel’s environment or following the use of accessories which were not supplied by SEC electronics.

The General Terms of Business of SEC electronics shall apply.

9 |

291 842 003 |

2. INSPECTION PROCEDURE

2.1. UPON DELIVERY INSPECTION PROCEDURES

A high degree of care is taken in packing our control panels and preparing them for delivery. They should only be transported with suitable transport equipment (see weight data) . Observe the instructions printed on the packaging. This also applies when the device is unpacked and installed.

Upon delivery, check the following:

-the packaging f or any external damage

-whether the delivery note matches your order

Open the packaging with suitable tools. Check whether:

-any parts were damaged during transport

-the device type corresponds to your order

In the event of any damage or of an incomplete or incorrect delivery please notify the responsible sales offices immediately.

The devices should only be stored in dry rooms within the specified temperature ranges.

NOTE:A certain degree of moisture condensation is permissible if this arises from changes in temperature ( see ‘’Permissible Environmental Conditions’’ ) . This does not however, apply when the devices are in operation. Always ensure that there is no moisture condensation in devices t hat are connected to the power supply

2.2 CONTROL PANEL TYPE DESIGNATION

The technical specification of the control panel is stated in the type code. Example

E 078/ 01

where letter E corresponds to E- type lift control panel

This code is also the same as is the code in the confirmation of order and other related papers. A Label with the type code is located at the bottom right corner of the control panel.

10 |

291 842 003 |

2.3. NAMEPLATE

Check that all the data stated in the nameplate enclosed wit h the control panel corresponds to what has been ordered.

SEC ELECTRONICS

Type |

________________ |

S/N ___________________ |

Input voltage ______________ |

Input frequency _________ |

|

Rated current ____________ |

Brake __________________ |

|

Retiring cam ______________ |

Valves _________________ |

|

Dimensions __________________________________________

Type |

- control panel model |

S/ N |

- serial number ( type code) |

I nput voltage |

- power supply voltage |

I nput frequency |

- power supply frequency |

Rated current |

- output rated current |

Brake |

- rated voltage of brake ( in electric lift) |

Retiring cam |

- rated voltage of retiring cam |

Valves |

- rated voltage of valves ( in hydraulic lift) |

Dimensions |

- dimensions of control panel H x W x D |

Nameplate is located in the left side of the box door.

11 |

291 842 003 |

2.4. STANDARD SPECIFICATIONS

|

Ta Ambient temperature |

0 … +40oC; 40 … +50oC with current derated to 0.8 rated output current |

||

|

|

|

||

|

Installation location |

Pollution degree 2 or better ( free from direct sunlight, vibration, dust, corrosive or |

||

|

|

inflammable gases, fog, vapor oil and dripped water, avoid saline environment) |

||

|

Degree of protection |

IP 44 |

|

|

|

|

|

||

|

Installation altitude |

Up to 1000 m above the sea level; for higher altitudes a current reduction of 1,2% |

||

ENVIRONMENT |

|

for every 100 m of additional height applies |

||

Temperature |

5% to 85% |

|

||

Air humidity |

|

|||

|

operation |

0… +50oC |

|

|

|

storage |

|

||

|

transport |

|

||

|

operation |

1 g/m3 to 25 g/m3 without moisture condensation or icing Class 3K3 as per |

||

|

|

5% to 95% |

|

|

|

storage |

1 g/m3 to 29 g/m3 |

Class 1K3 as per |

|

|

|

95% 60 g/m3 |

|

|

|

transport |

greatest absolute air humidity if the device is brought suddenly from 70 to 15oC |

||

|

|

A light condensation of moisture may occur for a short time occasionally if the |

||

|

|

device is not in operation ( Class 2K3 as per EN50178) |

||

|

|

|

|

|

STANDARD |

Climatic conditions |

IEC |

|

|

|

|

|

||

EMC compatibility |

EN12015 and EN12016 |

(see chapter ‘’EMC Guidelines ‘’) |

||

|

||||

|

|

|

|

|

|

Approvals |

CE |

|

|

|

|

|

|

|

2.5. DISPOSAL OF THE DEVICE

SEC electronics will take back old units free of charge provided they are delivered carriage paid to the SEC electronic factory in Neverke, Slovenia

Applicable local waste treatment and disposal regulations must be observed if you dispose of a unit yourself or replace any components. SEC electronics shall accept no liability for any parts and components that are not disposed of properly!

The following details are useful for disposal purposes:

the control panel box is made of steel, usually painted

the back panel is made of steel or aluminum, usually without lacquering or surface treatment

regulations on the disposal of electronic parts and components apply for disposal of p.c. boards, LCD units and other electric parts

backup battery is Lithium battery wich must be disposed properly

12 |

291 842 003 |

3.INSTALLATION GUIDELINES

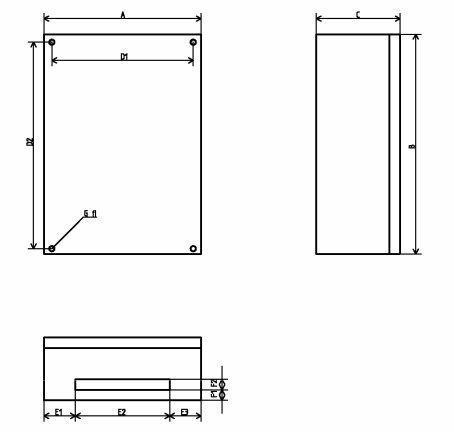

3.1.MECHANICAL SPECIFICATION

Control panel dimensions and fixing holes dimensions

Doors can be left or right side opening.

|

|

|

CONTROL PANEL DIMENSIONS |

( information on nameplate) |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

700 x |

|

700 x |

800 x |

800 x |

800 x |

1000 x |

1000 x |

1000 x |

900 x |

|||

|

|

500 x |

|

500 x |

600 x |

600 x |

600 x |

600 |

x |

600 |

x |

600 |

x |

800 x |

|

|

200 |

|

250 |

200 |

250 |

300 |

250 |

|

300 |

|

350 |

|

350 |

A |

mm |

500 |

|

500 |

600 |

600 |

600 |

600 |

|

600 |

|

600 |

|

800 |

B |

mm |

700 |

|

700 |

800 |

800 |

800 |

1000 |

|

1000 |

|

1000 |

|

900 |

C |

mm |

200 |

|

250 |

200 |

250 |

300 |

250 |

|

300 |

|

350 |

|

350 |

D1 |

mm |

450 |

|

450 |

550 |

550 |

550 |

550 |

|

550 |

|

550 |

|

700 |

D2 |

mm |

650 |

|

650 |

750 |

750 |

750 |

950 |

|

950 |

|

950 |

|

870 |

E1 |

mm |

107,5 |

|

107,5 |

157,5 |

157,5 |

157,5 |

157,5 |

157,5 |

157,5 |

150 |

|||

E2 |

mm |

285 |

|

285 |

285 |

285 |

285 |

285 |

|

285 |

|

285 |

|

500 |

E3 |

mm |

107,5 |

|

107,5 |

157,5 |

157,5 |

157,5 |

157,5 |

157,5 |

157,5 |

150 |

|||

F1 |

mm |

40 |

|

40 |

40 |

40 |

40 |

40 |

|

40 |

|

40 |

|

40 |

F2 |

mm |

30 |

|

30 |

30 |

30 |

30 |

30 |

|

30 |

|

30 |

|

40 |

G fi |

mm |

10 |

|

10 |

10 |

10 |

10 |

10 |

|

10 |

|

10 |

|

8 |

NOTE: I n case when VVVF control panel is used, the braking resistor is mounted on the control panel. Dimensions of braking resistor depends on model, power and manufacturer. Braking resistor can be fixed at the side or at the top of the box.

13 |

291 842 003 |

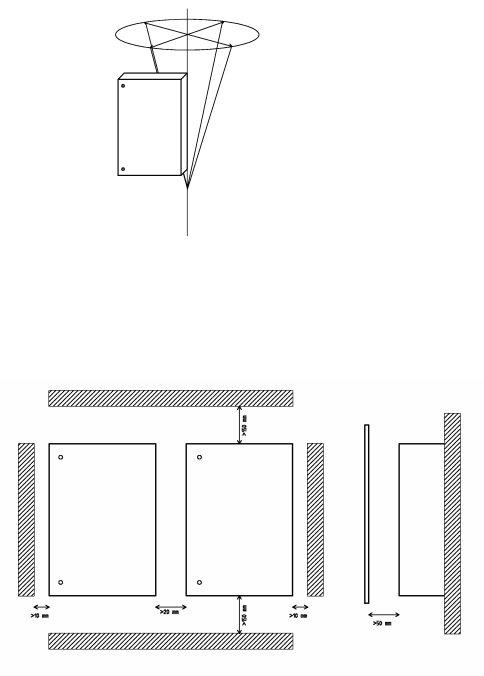

3.2. INSTALLATION MOUNTING CLEARANCE

NOTE: The dimensions specified in this manual and weights should be taken into consideration when the device is mounted. The technical equipment required ( carriage or crane for large weights) should be used. I m proper handling and the use of unsuitable tools may cause damage.

NOTE: The maximum angle of inclination is 30o

NOTE: The control panels must be mounted in such a way that the free flow of air is ensured. The clearance to the device must be at least 150 mm. A space of at lease 50 mm must be ensured at the front . Devices that generate a large amount of heat must not be mounted in the direct vicinity of the control panel.

14 |

291 842 003 |

4. WIRING PROCEDURE

4.1. AC INPUT CONNECTION

The device must be connected to a protective grounding which will be the first to be connected and the last one to be disconnected. Flexible copper cables, class 5, type O5V- K must be used for mains connection of the device. These copper cables must be short circuit protected with external fuses. Thermomagnetic differential switches for protection can be used.

NOTE: Residual – current ( FI- type)

Cable diameters and dimensions of protective switches must be consistent with table 4.4.4 for input voltage 400 V AC (415 V AC) or table 4.4.5 for in put voltage 230 V AC (240 V AC) .

INPUT VOLTAGE 400 VAC

P |

kW |

3 |

4 |

5,5 |

7,5 |

10 |

11 |

15 |

18,5 |

22 |

25 |

30 |

37 |

45 |

I n |

A |

8,6 |

10,5 |

13,5 |

17,5 |

20,5 |

24 |

32 |

39 |

46 |

54 |

62 |

72 |

87 |

Ci |

mm2 |

2,5 |

2,5 |

4 |

6 |

6 |

10 |

16 |

16 |

25 |

25 |

35 |

50 |

50 |

Cl |

mm2 |

2,5 |

2,5 |

2,5 |

2,5 |

2,5 |

2,5 |

2,5 |

2,5 |

2,5 |

2,5 |

2,5 |

2,5 |

2,5 |

S1 |

A |

16 |

16 |

20 |

25 |

32 |

32 |

40 |

50 |

63 |

80 |

80 |

100 |

125 |

S2 |

A |

25 |

25 |

25 |

40 |

40 |

40 |

63 |

63 |

80 |

100 |

100 |

125 |

160 |

S3 |

A |

16 |

16 |

16 |

16 |

16 |

16 |

16 |

16 |

16 |

16 |

16 |

16 |

16 |

S4 |

A |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

INPUT VOLTAGE 230 VAC

P |

kW |

3 |

4 |

5,5 |

7,5 |

10 |

11 |

15 |

18,5 |

22 |

25 |

I n |

A |

13,5 |

16,5 |

22 |

29 |

37 |

41 |

54 |

66 |

77 |

87 |

Ci |

mm2 |

4 |

4 |

6 |

10 |

16 |

25 |

25 |

35 |

50 |

50 |

Cl |

mm2 |

2,5 |

2,5 |

2,5 |

2,5 |

2,5 |

2,5 |

2,5 |

2,5 |

2,5 |

2,5 |

S1 |

A |

20 |

20 |

32 |

40 |

63 |

63 |

80 |

100 |

100 |

125 |

S2 |

A |

25 |

25 |

40 |

63 |

63 |

80 |

100 |

125 |

125 |

160 |

S3 |

A |

16 |

16 |

16 |

16 |

16 |

16 |

16 |

16 |

16 |

16 |

S4 |

A |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

P- rated power

In |

- rated current |

Ci |

- diameter of wires for main supply (mm2) |

Cl |

- diameter of wires for lighting connection (mm2) |

S1 |

- thermomagnetic main switch – curve type C (value is equivalent to short circuit current) |

S2 |

- differential main switch – sensitivity 300 mA |

S3 |

- thermomagnetic switch – lighting – curve C |

S4 |

- differential switch – lighting – sensitivity 30 mA |

15 |

291 842 003 |

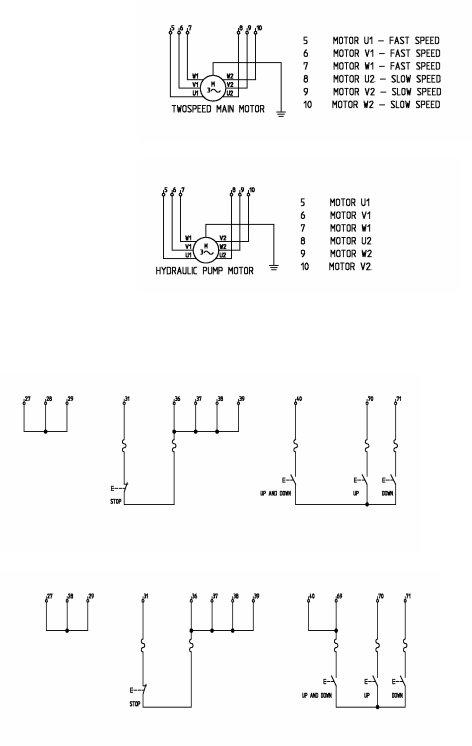

4.2. MAIN MOTOR CONNECTION

Cable diameters must be consistent with table below for input voltage 400 V AC (415 V AC) or table below for input voltage 230 V AC (240 V AC) .

INPUT VOLTAGE 400 VAC

P |

kW |

3 |

4 |

5,5 |

7,5 |

10 |

11 |

15 |

18,5 |

22 |

25 |

30 |

37 |

45 |

I n |

A |

8,6 |

10,5 |

13,5 |

17,5 |

20,5 |

24 |

32 |

39 |

46 |

54 |

62 |

72 |

87 |

Isd |

A |

|

|

|

10 |

12 |

14 |

19 |

23 |

27 |

31 |

36 |

42 |

50 |

Cm |

mm2 |

2,5 |

2,5 |

4 |

4 |

6 |

6 |

10 |

16 |

25 |

25 |

35 |

35 |

50 |

Csd |

mm2 |

|

|

|

2,5 |

2,5 |

4 |

6 |

10 |

10 |

16 |

16 |

25 |

25 |

INPUT VOLTAGE 230 VAC

P |

kW |

3 |

4 |

5,5 |

7,5 |

10 |

11 |

15 |

18,5 |

22 |

25 |

I n |

A |

13,5 |

16,5 |

22 |

29 |

37 |

41 |

54 |

66 |

77 |

87 |

I sd |

A |

7,8 |

10 |

13 |

17 |

22 |

24 |

28 |

33 |

45 |

50 |

Cm |

mm2 |

4 |

4 |

6 |

10 |

16 |

16 |

25 |

35 |

50 |

50 |

Csd |

mm2 |

2,5 |

2,5 |

4 |

4 |

6 |

10 |

16 |

16 |

25 |

25 |

P- rated power

In |

- rated current |

I sd |

- star / delta current |

Cm |

- diameter of wires for motor (mm2) |

Csd |

- diameter of wires for star delta connection (mm2) |

16 |

291 842 003 |

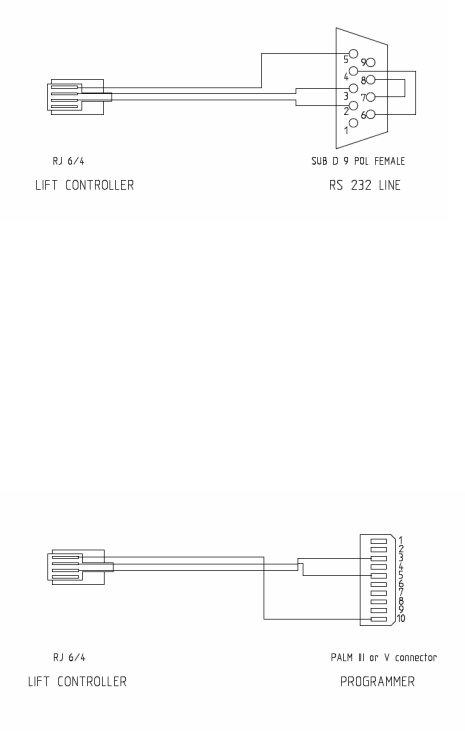

5.CONNECTION TO PC OR PDA

5.1. CONNECTION TO PC

Programming with PC is possible through RS 232 line. The drawing of cable is: Necessary program for programming is one of VT100 emulators. Suitable is program

Hyper Terminal wich is part of Windows operational system. Settings of Hyper Terminal

for using it for programming is next: |

|

|

|

|

- emulation |

ANSI |

|

|

|

- baud rate |

9600 |

8 |

N |

1 |

5.2. CONNECTION TO PDA

Programming with PDA is possible through RS232 line. The drawing of connection cable for PALM device series I I I or V is:

17 |

291 842 003 |

Necessary program for programming is one of VT100 emulators. Suitable is program PTELNET. Settings of Ptelnet program for using it for programming is next:

- Serial |

Port |

RS232 |

|

Baud |

9600 |

|

Parity |

N |

|

Word |

8 |

|

StopBits |

1 |

|

Xon/ Xoff |

0 |

|

RTS/ CTS |

0 |

- Terminal |

Mode |

Serial |

|

Return |

CR |

|

Font |

large |

|

Width |

32 |

|

Charset |

I SO- Latin 1 |

|

Lochal echo |

1 |

- the connection icon in the main window must be ON

WARNING:

Do not connect fourth wire from lift controller connector RJ 6/ 4.

This wire is internal + 5 VDC for special programmers only.

NOTE:

Windows |

is Microsoft trademark |

Hyper Terminal |

is Hilgraeve I nc. trademark |

Palm |

is 3com t radmark |

18 |

291 842 003 |

6.PROGRAMMING

6.1.MAIN MENU

After connection is establish between programmer or E- Type console and controller, main menu appear in the display. I f not press ENTER or # two or three times.

The numbers in front of word for entering in menus are present in eprom version E1.10 or higher. They are made for programming with console where # is ENTER and * is ESCAPE.

SEC Electronics E - Type Lift

Controller V0.0

1L |

Flow control |

2 E |

Show error hist ory |

3C |

Statistics |

4 F |

Fundamental settings |

5V |

Door settings |

6P |

Parameters |

7 D |

Sprecial drives |

8S |

Encoder settings |

9 I |

I nput / Output settings |

0W |

Save settings to EEPROM |

To select submenu press or write first letter of submenu. T he submenu must appear.

MAIN MENU

1L

2E

3C

4F

5V

6P

7D

8S

9I

0W

Flow |

Error |

Statistics |

Fund. |

Door |

Parameter |

Special |

Encoder |

I / O |

Save |

control |

history |

|

settings |

settings |

|

drives |

settings |

settings |

all |

Escape

Enter

Enter

Enter

Enter

Enter

Enter

Enter

Enter

Enter

MAIN MENU

19 |

291 842 003 |

6.2.SUBMENU ORGANISATION

The submenus F- Fundamental settings, V- Doors settings, P- Parameters, D- Special drives,

1L = list, 2E = edit, 3C = change

1L

2E

3C

Parameter number 00 - 99

Parameter value 00 - 99

Parameter value 00 – 99

Listing of all parameters

in submenu

Edit single parameter

Change parameters staring from first

Enter

Escape

Escape

1L = list, 2E = edit, 3C = change

Enter

MAIN MENU

6.3.1L FLOW CONTROL

Display show actual informations, activities, problems or errors of controll panel Sample of one display with explanations is next:

Flow control |

|

21 / 01 / 03 |

13: 45: 06 |

Station: 03 |

Status: 61 |

Maintenace drive on |

|

Press Esc for main menue...

20 |

291 842 003 |

Explanation: |

|

|

|

First row: |

Date (21 / 01 / 03) |

Hour (13: 45: 06) |

|

Second row: |

Position of lift |

(Station: 03) |

Message number as in seven segment |

|

lowest floor is 01 |

|

display in the main board (Status: 61) |

Third row: |

Message definition (Maintenance drive on) |

||

Message numbers 0 0 - 49 are ERRORS, numbers 50 - 99 are EVENTS.

List of messages:

|

EVENTS |

|

ERRORS |

50 |

Doors open |

1 |

Second slip correction |

51 |

Doors preopen |

2 |

First slip correction |

52 |

Doors close |

3 |

Error counting |

53 |

Doors lock |

4 |

Error preopening |

54 |

Error on doors closing |

5 |

Error car door A |

55 |

Fast speed up |

6 |

Error car door B |

56 |

Slow speed up |

7 |

Error door lock A |

57 |

Stabilisation time |

8 |

Error door lock B |

58 |

Fast speed down |

9 |

Error switch stop up |

59 |

Slow speed down |

10 |

Error switch slow up |

60 |

Fire alarm drive |

11 |

Error switch stop down |

61 |

Maintenance drive on |

12 |

Error switch slow down |

62 |

Parking drive |

13 |

Error battery low |

63 |

Waiting for call |

14 |

Error elements check |

65 |

Safety line 36 |

15 |

Error limit timer fast speed |

66 |

Doors are not lock |

16 |

Error limit timer slow speed |

68 |

Obstruction door A |

17 |

Error limit timer maintenance speed |

69 |

Obstruction door B |

18 |

Error communication CPU B |

70 |

Cabin oveload |

19 |

Error in parameters |

72 |

Relevelling up |

20 |

Error prelimit switches |

73 |

Relevelling down |

21 |

Error communication CAR module |

75 |

Lift in hold after maintenance function |

22 |

Error relevelling |

76 |

Priority drive |

23 |

Error photocell door A |

77 |

Photocell door A |

24 |

Error photocell door B |

78 |

Photocell door B |

25 |

Error first drive |

79 |

Maintenance drive down |

26 |

Error group |

80 |

Maintenance drive up |

27 |

Error SSL 2 |

81 |

Pump star sequence |

28 |

Error SSL 3 |

82 |

Error doors |

29 |

Error security 36 |

83 |

Corrigation up |

30 |

Start on |

84 |

Corrigation down |

31 |

|

85 |

Firefighters drive |

32 |

Learn floor positions first! |

86 |

Cabin doors are not close |

|

|

87 |

Landing doors are not close |

|

|

21 |

291 842 003 |

6.4.2E SHOW ERROR HISTORY

Display show errors in the error table. Up to 200 errors can be stored in the memory. When

memory is full, errors are not stored in the memory any more. The errors are displayed as first error first . The memory for errors is supplied by lithium battery in case of power down. I f battery is not in the system or battery voltage is low, error table will be destroyed when controller will be switched off . Sample of one display with explanations is next:

Er ror limit switches |

|

21 / 01 / 03 |

13: 45: 06 |

St at ion: 03 |

|

C cleans hist ory |

|

others main menue |

|

Explanation: |

|

|

First row: |

Error message (Error limit switches) |

|

Second row: |

Date of error (21 / 01 / 03) |

Hour of error (13: 45: 06) |

Third row: |

Position of lift when in error |

(Station: 03) |

|

lowest floor is 01 |

|

By pressing any key, errors are displayed. At the end message ( C cleans history others main menue) appear. For clean the error table press C, for leave the error table press any other key.

ERROR EXPLANATIONS

01 Second slip correction

Lift has tried to correct slip from floor after stopping two times unsuccessfully

-error in mechanical brake in electric lift

-brake in electric lift or valves in hydraulic switched off too late

-zone for stop magnet in station is t oo short

-slow speed is too fast (hydraulic or VVVF)

-error on elements for slow speed (lift attempts to stop in fast speed)

02 First slip correction

Lift has tried to correct slip from floor after stopping. First correction fails, second one passes

-error in mechanical brake in electric lift

-brake in electric lift or valves in hydraulic switched off too late

-zone for switch stop in station is too short

-slow speed is too fast (hydraulic or VVVF)

-error on elements for slow speed (lift attempts t o stop in fast speed)

22 |

291 842 003 |

03 Error in counting

Lift approaches bottom or top floor with wrong position number

-error in limit switch for fast speed at bottom (input 6) switch must be off when in zone for slow speed at bottom floor

-error in limit switch for fast speed at top (input 7) switch must be off when in zone for slow speed at top floor

-error on supply voltage for limit switches for fast speed

-magnet to activate bi- stable limit switch for fast speed is too close to switch or wrong polarity (this can cause two pulses)

-number of floors defined in parameter P 04 is not correct .

04 Error on

Error in Lift pre- opening cycle

-one of three conditional inputs failed during pre- opening- or opening in drive up inputs: 16 releve lling down, 12 zone A, 13 zone B in drive down inputs: 15 relevelling up, 12 zone A, 13 zone B

-wrong position of switches or magnets

-error on safety circuit 185 for pre- opening- opening and relevelling with open door

-error on elements for slow speed - pre- opening- opening in fast speed

05 Error on car door A

Error while closing car door

-error on car door contact - when door is closed input 9 and 10 must be activated

-error on motor or elements for drive motor for car door

-time in parameter V02 (closing door time) is too short timer comes to zero before door is closed

-error in power supply for car door contact

06 Error on car door B

Error while closing car door

- error on car door contact - when door is closed input 9 and 10 must be activate d

-error on motor or elements for drive motor for car door

-time in parameter V02 (closing door time) is too short timer comes to zero before door is closed

-error in power supply for car door contact

07 Error on door locks A

Error while locking landing doors (after closing car door)

-error in switches on landing doors when doors are locked inputs 9, 10, and 11 must be activated

-time in parameter F01 (security lock time) is too short timer comes to zero before doors are locked

-error in power supply for locks switches

08 Error on door locks B

Error while locking landing doors (after closing car door)

-error in switches on landing doors when doors are locked inputs 9, 10, and 11 must be activated

-time in parameter F01 (security lock time) is too short timer comes to zero before doors are locked

-error in power supply for locks switches

09 Error on switch for stop up

Error on input 12 - st op up

-error on switch or on magnet

-error on other switches for stop or slow speed

-when using bi- st able magnetic switch - magnet is too close to switch ( two pulses)

-error on power supply for switches

23 |

291 842 003 |

10 Error on switch for slow speed up

Error on input 14 - slow speed

-error on switch or on magnet

-error on other switches for stop or slow speed

-when using bi- stable magnetic switch - magnet is too close to switch ( two pulses)

-error on power supply for switches

11 Error on switch for stop down

Error on input 13 - st op dow n

-error on switch or on magnet

-error on other switches for stop or slow speed

-when using bi- stable magnetic switch - magnet is too close to switch ( two pulses)

-error on power supply for switches.

12 Error on switch for slow speed down

Error on input 14 - slow speed

-error on switch or on magnet

-error on other switches for stop or slow speed

-when using bi- stable magnetic switch - magnet is too close to switch (two pulses)

-error on power supply for switches

13 Error battery low

Battery BT1 in main board is low . This battery keep only statistics and errors information and real time clock during power down periods. All other parameters and values are stored in nonvolatiole memory. I n case of low battery also LED LD4 in main board is lit .

For replacement use same battery type CR 2032 lithium 3V

NOTE: Dispose old batteries properly

14 Error on input 21 - elements check

I nput 21 was off more than 5 seconds when lift was waiting at floor

-one of contractor or relays was not released after end of drive K1, K2, K3, K4, K6, K7, K9, K31, K32, K33, R11, R12, R13, R17

-error on security circuit 185 when elevator stopped at floor

-error on external element for temperature check connected to inputs 381, 382

-motor overheating - controller for thermistors TH1 detected overheat

-error on controller for thermistors TH1 or phase sequence controller

-error on control voltage on controller

15 Error travel timer fast speed

Error on security timer for fast speed

-timer reaches zero before lift changes speed or stops at floor

-error with ropes or oil pressure

-error on elements for drive ( contractor, relays, valves )

-timer setting is to short

16 Error travel timer slow speed

Error on security timer for slow speed

-timer reaches zero before lift changes speed or stops at floor

-error with ropes or oil pressure

-error on elements for drive ( contractor, relays, valves )

-timer setting is to short

24 |

291 842 003 |

17 Error travel timer maintenance speed

Error with security timer for maintenance speed

-timer reaches zero before lift changes speed or stops at floor

-error with ropes or oil pressure

-error on elements for drive ( contractor, relays, valves )

-timer setting is to short

18 Error communication CPU B

I nternal error in main board. There is no communication between microprocesor A and B

-error in microprocesor B

-error in main board

19 Error in parameters

Error in parameters in memory circuit on PCB

-error because parameters in memory circuit changed incorrectly check all parameters

-value in one or more parameters is not within the limits

-error with memory circuit on PCB.

NOTE |

I n this case all fundamental settings, door settings, parameters, encoder settings and |

|

input/ output settings must be read , check if they are good, and write to the control |

|

panel again. Aft er t his swit ch t he power of cont rol panel off and on again |

20 Error on limit switches for fast speed

Limit switches for fast speed both off at the same time

-error on bottom limit switch for fast speed (input 6) switch must be off when in zone for slow speed at bot t om floor

-error on top limit switch for fast speed (input 7) switch must be off when in zone of slow speed for top floor

-error with power supply for limit switches

21 Error communication car module

There is no communication between main and car board

-error in connection between boards

-error in main board

-error in car board

22 Error while relevelling

-while relevelling one of the inputs 12 or 13 (zone A o r zone B) goes off

-error on switches or magnets

-error on elements for drive (contractor, relays, valves)

-elevator has relevelled more than 10 times in a period of 2 minutes

-error on safety circuit 185 for relevelling and

23 Error on door photocell input A

I nput 63 car module door photocell was activated more than 1 minute

Lift runs on without checking input 63 door photocell

-error on photocell connected to input 63

-error on definition of input (NO / NC) with parameter V08

-error on power supply for photocell connected to input 63

25 |

291 842 003 |

24 Error on door photocell input B

I nput 65 car module door photocell was activated more than 1 minute Lift runs on without checking input 65 door photocell

-error on photocell connected to input 65

-error on definition of input (NO / NC) with parameter V10

-error on power supply for photocell connected to input 65

25 Error first drive

Lift was unable to made first drive after power on sequence.

-error on prelimit switches

-error on stop switches

-error on power supply

26 Error group

Lift is parametrized to work in group but no serial line of group is detected

-error in serial cable between group

-error in other lifts parameters

27 Error SSL2

There is an error in serial line link 2

-error in serial cable between nodes from 1 to 24

-error in other lifts parameters

28 Error SSL3

There is an error in serial line link 3

-error in serial cable between nodes from 25 to 48

-error in other lifts parameters

29 Error security 36

Continuous errors (more than 5 in one minute) on security 36 (terminal 303)

-bad connection or interrupted safety line

-continuous disconnections of high pressure safety on hydraulic

30 Start on

Elevator stopped and started again on pre - limit switch out of station.

This can happen due to safety line break (inputs safety line 36- 39) or some other reason. Lift goes to first drive after this error.

31

Elevator moved out of allowed area during

32 Learn floor positions first!

Counting system 2 requires learning of floor positions before normal operation. See explanation of parameter P3 setting 2.

26 |

291 842 003 |

6.5.3C STATISTICS

Statistics menu is menu with some statistical information regarding elevator drives. I n this menue the counters for drives to all floors and for every 30 minutes display how many drives was made.

Sample of display is next:

C0 Number of drives |

12 |

C1 Total drives |

123 |

C2- 50 Number of drives in period

00:00 - 00: 30 : 1

00:30 - 01: 00 : 2

01:00 - 01: 30 : 2

01:30 - 02: 00 : 4

Press any key to continue

Last display is:

C51- 99 Number of drives to floors

floor 01: 6

floor 02: 3

floor 03: 3

C clears counters,

others main menue

At the end message ( C clears counters others main menue) appear. For clear the counters press C, for leave the values in the counters and just go out from menue press any other key.

Explanation of the counters is next:

C1 COUNTER OF DRIVES - resetable

This counter, goes to zero when error table is reset .

C2 COUNTER OF DRIVES - life counter

Counter can not be reset .

C3 – C50 COUNTER OF DRIVES FROM STATION 1 TO STATION 48 - resetable

This counter, goes to zero when error table is reset .

C51 – C98 COUNTER OF DRIVES IN HALF HOUR TIME PERIOD - resetable

This counter, goes to zero when error table is reset .

27 |

291 842 003 |

6.6.4F FUNDAMENTAL SETTINGS

List of parameters in fundamental settings menue is next:

F1 DOORS LOCK TIMER |

1 - 20 sec. |

Time in which locks must be made after closing doors. I nput 11 - main must be active. I f the input is not active when the timer comes to zero, the doors will open again. After three attempts without a result the timer V5 (door error) will activate, and after this time there will be one attempt to close and lock the doors. Also the error will be logged in the error table.

F2 |

PARKING TIMER |

1 - 1250 s. |

Time after which the lift will go to the parking floor if there is no landing or car calls. Parking floor is defined in parameter P13. Value on terminal is multiplied by 5 (if the number is 10 then the value is 50s)

F3 PARKING TIMER FILLING AND EMPTYING |

1 - 1250 s. |

Time after which the lift will go to the parking floor if theere is no landing or car calls in filling or emptying sequece. Parking floors are defined in parameters P14 and P15. Value on terminal is multiplied by 5 (if the number is 10 then the value is 50s)

F4 |

DIRECTION HOLD TIMER |

1 - 20 sec. |

Time in which the output for the direction is still present after arrival at the floor. |

|

|

(outputs 47 and 48 - car) . Also the lift will continue to travel in this direction if a call is active in the same direction when time comes to zero..

F5 CALL DELAY TIMER |

1 - 20 sec. |

I n case using up and down selective system when one input will be accepted another will be refused in period on duration of this timer. Unit of setting is second. We can program from 1 to 20 seconds

F6 |

START FILLING |

hour |

0 - 23 |

|

Setting of hour for start filling |

|

|

|

|

F7 |

START FILLING |

minute |

0 - 59 |

|

Setting of minute for start filling |

|

|

||

F8 |

END FILLING hour |

|

0 - 23 |

|

Setting of hour for end filling |

|

|

|

|

F9 |

END FILLING minute |

0 - 59 |

||

Setting of minute for end filling |

|

|

|

|

F10 |

START EMPTYING |

hour |

0 - 23 |

|

Setting of hour for start emptying |

|

|

||

F11 |

START EMPTYING |

minute |

0 - 59 |

|

Setting of minute for start emptying |

|

|||

F12 |

END EMPTYING |

hour |

0 - 23 |

|

Setting of hour for end emptying |

|

|

||

F13 |

END EMPTYING |

minute |

0 - 59 |

|

Setting of minute for end emptying |

|

|||

28 |

291 842 003 |

F14 GROUP TIMER |

1 - 99 |

Timer is valid in group operaton (multi elevator) . I f first elevator not execute the |

command in this time, |

second one will also start to this command. Unit of setting |

is second. We can program from 1 to 99 |

seconds |

|

F15 ARRIVAL GONG TIMER |

1 - 20 sec. |

Timer for output arrival at floor - gong ( output 49 - car )

F16 CAR EXTRACTION FAN TIME |

1 - 90 sec. |

Timer to define how long the output for the car extraction fan (relay RE11 outputs 30, 31 - main) and (output 52 car) remains on after the end of travel.

F17 BUTTON BACKLIGHT |

0 - 50% |

I nactive call button backlight setting. Call buttons are illuminated all the time so we can see them in the darkness.

0 – button backlight is off

F18 BEEP TIME |

0.0 – 0.7s |

Beep time when some call pushbutton is pressed. |

|

Beeper output on car module is terminal 51 »occupied / beeper«. Combined display / floor modules have beeper already on board.

F18 = 0 – no beep, function of car module terminal 51 is occupied

F18 = 0.1 … 0.7 – beep, function of car module terminal 51 is beeper

NOTE: Function works only with system types P0= 5 and 6 with combined display / node (floor) modules.

F19 GONG DELAY TIME |

1 - 20s |

Gong delay after switching to slow speed or coming to the station (depends on parameter P5) .

6.7.5V DOOR SETTINGS

List of parameters in door settings menue is next:

V1 |

OPEN DOOR TIMER |

1 - 60 sec. |

Time in which doors will remain open at a floor |

|

|

V2 |

CLOSING DOOR TIMER |

1 - 60 sec. |

Time in which the doors must close - input 10- main must be active. I f input is not active when timer comes to zero, t he doors will open again. After three attempts without a result the timer V5 (door error) will activate, then after this time there will be one attempt to close the doors. Also the error will be logged in t he error t able

V3 HOLD DOOR TIMER |

1 - 90 sec. |

Timer is active when we use door type 5 or 8 (parameter V61) . I n this case after the timed period the outputs for doors will cancel as long as the lift stays at the floor. I f timer is set on value 60 then antivandal is not in function.

V4 EXCHANGE CLOSE OPEN TIMER |

0.1 - 9.0 sec. |

Time delay between close relay de- energizing and open relay energizing.

29 |

291 842 003 |

V5 DOOR ERROR TIMER |

1 - 10 min. |

Time which will start after 3 errors in doors closing or locking. Also all commands will be cleared when this is active.

V6 EXTEND OPEN DOOR TIMER |

1 - 60 sec. |

Additional time which will add to open door time (V1) when input Photocell (input 63- car for photocell door A and input 65 - car for photocell door B) is activated

V7 SPECIAL OPEN DOOR TIMER |

1 - 90 sec. |

Special open door timer will add time to open door time (V1) when input (Additional doors open terminal 67- car) is activated

V8 |

INPUT PHOTOCELL DOOR A |

NO / NC |

( 0 |

- 1) |

|

Definition for terminal 63 |

- car module |

|

|

|

|

V9 |

INPUT OBSTRUCTION DOOR A |

NO / NC |

( 0 |

- 1) |

|

Definition for terminal 64 |

- car module |

|

|

|

|

V10 |

INPUT PHOTOCELL DOOR B |

NO / NC |

( 0 |

- 1) |

|

Definition for terminal 65 |

- car module |

|

|

|

|

V11 |

INPUT OBSTRUCTION DOOR B |

NO / NC |

( 0 |

- 1) |

|

Definition for terminal 66 |

- car module |

|

|

|

|

V12 |

|

0 - 3 |

|||

0 - disabled

1 - reserved

2 - when relevelling switches + zone A and zone B are on

when traveling up |

|

input 16 main module |

relevelling down |

input 12 main module |

zone A |

input 13 main module |

zone B |

when traveling down |

|

input 15 main module |

relevelling up |

input 12 main module |

zone A |

input 13 main module |

zone B |

V13 DOOR TYPE |

1 - 8 |

1 - photocell / semiautomatic NOTE: NOT FOR USE I N THE EU

photocell is connected between inputs 9 and 10 main module. Doors locks are connected in series between inputs 10 and 11 main module. The output relay RE7 drives the retiring cam

2 - manual /

30 |

291 842 003 |

3 - folding ( bus ) / semi - automatic

Semi- automatic landing doors are connected between inputs 8 and 9 main module. Car door contact is connected between inputs 9 and 10 main module. Series connected switches of landing doors are connected between inputs 10 and 11 main module. Outputs RE8 and RE7 drives opening and closing of car door. Car door will remain open when the lift is waiting at floors

4 - automatic / semi - automatic

Semi- automatic landing doors are connected between inputs 8 and 9 main module. Car door contact is connected between inputs 9 and 10 main module. Series connected switches of landing doors are connected between inputs 10 and 11 main module. Outputs RE8 and RE7 drive opening and closing of car door. Car door remains open when lift is waiting at a floor

5 - automatic doors without limit switches / semi- automatic

Semi- automatic landing doors are connected between inputs 8 and 9 main module. Car door contact is connected between inputs 9 and 10 main module. Series connected switches of landing doors are connected between inputs 10 and 11 main module. Outputs RE8 and RE7 drive opening and closing of car door. Car door remains open when lift is waiting at floor. When lift is waiting at floor after time defined with parameter V3, output RE8 for open door goes off

6 - automatic / automatic

I nputs 8 and 9 main module are short connected. Car door contact is connected between inputs 9 and 10 main module. Series connected switches of landing doors are connected between inputs 10 and 11 main module. Outputs RE8 and RE7 drives opening and closing of car door. Car door parks closed when lift is waiting at floor..

7 - automatic / automatic - waiting with open door NOTE: NOT FOR USE I N THE EU

I nputs 8 and 9 main module are short connected. Car door contact is connected between inputs 9 and 10 main module. Series connected switches of landing doors are connected between inputs 10 and 11 main module. Outputs RE8 and RE7 drives opening and closing of car door. Car door parks opened when lift is waiting at floor..

8 - automatic doors without limit switches / automatic

I nputs 8 and 9 main module are short connected. Car door contact is connected between inputs 9 and 10 main module. Series connected switches of landing doors are connected between inputs 10 and 11 main module. Outputs RE8 and RE7 drives opening and closing of car door. Car door parks closed when lift is waiting at floor. Park time defined with parameter V3 output RE7 for close door goes off

V14 – V61 OPENING DOORS FLOOR 1 - 48 |

0 - 3 |

||

Possible setting is 0 do 3 |

0 |

car doors are closed |

|

|

1 |

opening of doors A |

|

|

2 |

opening of doors B |

|

|

3 |

opening of doors A and B |

|

31 |

291 842 003 |

6.8. 6P PARAMETERS

P0 SYSTEM TYPE

1E - type classic 8 stops

2 E - type classic 12 stops

3 E - type classic 16 stops

4 E - type classic 24 stops

5 |

E - type serial |

24 |

stops |

6 |

E - type serial |

48 |

stops |

1 - 6

UP and DOWN collective ( main and car modules ) DOWN collective ( main and car modules )

UP and DOWN collective ( main, car and ext modules ) DOWN collective ( main, car and ext modules )

UP and DOWN collective ( main, car modules and nodes )

UP and DOWN collective ( main, car, ext modules and nodes )

P1 ELEVATOR TYPE |

0 - 4 |

0 - electric two speed - or one speed

1 - electric VVVF

2 - hydraulic type 1 - delay of pump on travel UP time of delay is defined in parameter P11 (delay time) 3 - hydraulic type 2 - no delays

4 - hydraulic type 3 - delay of valves on travel UP time of delay is defined in parameter P11 (delay time)

P2 |

OPERATION SYSTEM |

|

1 - 7 |

||

1 |

- up and down collective two buttons |

|

|

||

2 |

– down collective only single button |

|

|

||

3 |

– down collective all floors + |

2 floors up and down, single button |

|

|

|

4 |

– down collective all floors + |

2 and 3 floor up and down |

|

|

|

5 |

– down collective all floors + |

2 + 3 and 4 floor up and down |

|

|

|

6 |

– not in use |

|

|

|

|

7 |

- APB - only 1 call at any one time |

|

|

||

P3 |

COUNTING SYSTEM |

|

1 - 8 |

||

1 |

- 4 switches |

stop up |

input |

12 main module |

|

|

|

|

stop down |

input |

13 main module |

|

|

|

slow speed up |

input |

15 main module |

|

|

|

slow speed down |

input |

16 main module |

2 |

– incremental pulses (in preparation) |

|

|

||

3 |

- 1 switch |

stop and slow speed |

input |

12 and 13 main module |

|

4 |

- 3 switches ( 2 switches ) |

stop up |

input |

12 main module |

|

|

|

|

stop down |

input |

13 main module |

|

|

|

slow speed |

input |

14 main module |

5 |

- 3 switches ( 2 switches ) |

stop up |

input |

12 main module |

|

|

|

|

stop down |

input |

13 main module |

|

|

|

slow speed |

input |

14 main module |

6 |

- 6 switches - tip 1 + zone A and B slow speed up |

input |

12 main module |

||

|

|

|

slow speed down |

input |

13 main module |

|

|

|

zone A and B |

input |

14 main module |

|

|

|

relevelling up |

input |

15 main module |

|

|

|

relevelling down |

input |

16 main module |

32 |

291 842 003 |

7 - 5 switches - tip 4 + zone A and B |

zone A |

input |

12 main mo dule |

|

|

|

zone B |

input |

13 main module |

|

|

relevelling up |

input |

15 main module |

|

|

relevelling down |

input |

16 main module |

|

|

slow speed |

input |

14 main module |

8 - 5 switches - tip 5 + zone A and B |

zone A |

input |

12 main module |

|

|

|

zone B |

input |

13 main module |

|

|

relevelling up |

input |

15 main module |

|

|

relevelling down |

input |

16 main module |

|

|

slow speed |

input |

14 main module |

P4 |

NUMBER OF FLOORS |

|

|

2 - 48 |

Defines the number of floors for the lift . Change of value will be valid only after restart of CPU (power off and on)

P5 ARRIVAL (GONG) OUTPUT TYPE |

1 - 8 |

1 and 5 – starts on change down to slow speed.

Output is activated when the lift changes speed from fast to slow . Length of time is defined in parameter F14.

2 and 6 - starts when lift stops at floor level.

Output is activated when lift has stopped at floor level. Length of time is defined in parameter F14.

3 and 7 - starts in slow speed but only active if floor call present .

Output is activated when lift changes speed from fast to slow but only if the landing call is active at the current floor. Length of time is defined in parameter F14.

4 and 8 - starts when lift has stopped at floor and has active floor call.

Output is activated when lift arrives at floor level but only if the landing call is active at that floor. Length of time is defined with parameter F14.

5, 6, 7 and 8 – two outputs for gong.

When lift is traveling down gong output (49 car), and when is traveling up »out of work« output (50 car) is switched on. Output »out of work« doesn't have its basic function in this case.

P6 DIRECTION INDICATOR OUTPUT TYPE |

1 - 4 |

Setting is valid for direction outputs on CAR module and NODE modules!

1 – when lift running + direction hold time.

Outputs for direction (47 and 48 car) are active during all drive time (fast and slow speed) and during direction hold time (parameter F4) .

2 – when lift running only.

Outputs for direction (47 and 48 car) are active during all drive time (fast and slow speed) .

3 – when lift is in slow speed and waiting at floor.

Outputs for direction (47 and 48 car) are active when lift is in slow speed and when waiting at a floor. When the lift is waiting at a floor without calls both outputs (47 and 48 car) are activated.

4 – when lift is waiting at a floor.

Outputs for direction (47 and 48 car) are active when lift is waiting at a floor. When lift is waiting at a floor without calls both outputs (47 and 48 car) are activated.

33 |

291 842 003 |

P7 |

OUTPUT FROM FIRE ALARM |

0 - 2 |

|

0 |

– Lift works normally after end of fire alarm |

|

|

After input (20 main - fire alarm) goes off the lift resumes work normally |

|

||

1 |

- Power off and on after end of fire alarm |

|

|

After input (20 main - fire alarm) goes off, restart of CPU is necessary for normal working (power off and power on again)

2 - maintenance on and maintenance off after fire alarm

After input (20 main - fire alarm) goes off it is necessary for maintenance input (09 car) to be switched on and off for normal working to be resumed

P8 DOORS IN FIRE ALARM |

0 - 5 |

Definition for doors when fire alarm input (input 20 main) is activated. I nput for fire alarm is defined as on when the remote alarm contact is closed. Conversion to a normally closed contact is not possible. With these parameter we also select European or Australian norm:

0 – doors in fire alarm closed – fire drive in AS 1735.2 norm,

1 - doors in fire alarm opened – fire drive in AS 1735.2 norm, 2 - doors in fire alarm closed - fire drive in EN81- 72 norm,

3 - doors in fire alarm opened - fire drive in EN81- 72 norm,

4 - doors in fire alarm closed - fire drive in EN81- 72 norm, when fire drive is on doors are closing with reduced power regardless to door obstruction,

5 - doors in fire alarm opened - fire drive in EN81- 72 norm, when fire drive is on doors are closing with reduced power regardless to door obstruction.

Doors are opened when lift comes to the fire alarm floor and then closed or not regarding to parameter P8. I t is possible to open doors later with car and landing call buttons or with opening door button.

ATTENTION

When doors are closing and obstruction is present door slow speed must be made with relay logic. (EN81- 72 norm chapter 5.8.6)

P9 CORRECTION AT SLIP |

0 - 1 |

0 - if the lift drops the input for the stop signal after it has stopped at a floor before the time of stabilization (parameter P23) The lift will continue to the next floor in the same direction in fast speed.

1 - if the lift drops the input for the stop signal after it has stopped at a floor before the time of stabilization (parameter P23) The lift is reversed back to previous floor in slow speed in the opposite direction

P10 STAR DELTA TIMER |

0 - 20 sec. |

Timer for the pump change- over in star delta connection. On starting, outputs (relay RE1 terminals 44,45 main) and (relay RE3 terminals 38,39 main) are activated. After the star delta timer output (relay RE3) goes off and output (relay RE2 terminals 41,42 main) goes on.

P11 PUMP OR VALVES DELAY TIME |

0.0 - 9.9 sec. |

Timer defining the delay of outputs for the pump or valves after the end of travel in up direction on hydraulic lifts. Selection between pump or valves is made with parameter P1 (settings 2 or 4 ) .

P12 SPEED AT TEST slow / fast |

1 - 2 |

1 - maintenance ( test ) speed is low speed 2 - maintenance ( test ) speed is high speed

34 |

291 842 003 |

P13 |

PARKING STATION |

0 |

- 48 |

Definition of parking station . I f input value is 0 parking is disabled. |

|

|

|

Time without calls needed before parking is defined with parameter F2. |

|

|

|

I f value is set to 99, the AUTOPARK system is in use. Lift define most usable station for each 30 |

minutes |

||

as parking station. |

|

|

|

P14 |

PARKING STATION FOR FILLING |

0 |

- 48 |

Definition of parking station for filling . I f input value is 0 filling is disabled. |

|

|

|

Time without calls needed bef ore parking is defined with parameter F3. |

|

|

|

Real time for filling function is define with parameters F6, F7, F8 and F9 |

|

|

|

P15 |

PARKING STATION FOR EMPTYING |

0 |

- 48 |

Definition of parking station for emptying . I f input value is 0 emptying is disabled. |

|

|

|

Time without calls needed before parking is defined with parameter F3. |

|

|

|

Real time for emptying function is define with parameters F10, F11, F12 and F13 |

|

|

|

P16 |

FIRE ALARM STATION |

1 |

- 48 |

Defines fire alarm floor. Setting 0 is not possible. Lift goes to fire alarm floor when input for fire alarm (input 20 main) becomes active.

P17 SHORT DRIVE |

0 - 5 |

Possible setting is from 0 to 5 stations. This function is used with VVVF regulation. I f call is in area of this stations, elevator will start with middle speed and calculate delay for change speed from middle to slow

P18 DELAY SHORT DRIVE |

0,0 - 9,9 sec. |

Possible setting is from 0 to 99 miliseconds |

|

This is delay for slow speed when elevator work with middle speed in short drive function. |

|

P19 TRAVEL TIME - FAST SPEED |

0 - 450 sec. |

Security timer. Timer runs when the lift is in fast speed. W hen t he lift reaches sw it ch for st op in

st at ion t he t imer runs again. The lift must reach next station or stop before this timer reaches zero. I f the timer reaches zero during fast speed all outputs are disabled. Reset is only possible by switching the power off and back on after a few seconds

Timer is disabled when it is set to 0.

P20 TRAVEL TIME - SLOW SPEED |

0 - 450 sec. |

Security timer. Timer runs when the lift is in slow speed. The lift must stop before this timer reaches zero. I f the timer reaches zero during slow speed all outputs are disabled . Reset is only possible by switching the power off and back on after a few seconds

Timer is disabled when it is set to 00.

P21 TRAVEL TIME – TEST SPEED |

0 - 450 sec. |

Security timer. Timer runs when the lift is driven on maintenance ( test ) . The lift must stop before this timer reaches zero. I f the timer reaches zero during maintenance drive all outputs are disabled. Reset is only possible by switching the power off and back on after a few seconds

Timer is disabled when it is set to 00..

P22 SWITCH |

0.0 - 9.0 sec. |

Timer to eliminate double counting because of bad contacts on the switches for counting and positioning. This timer is active on inputs 12, 13, 14, 15 and 16 in main module. After changing the state of these inputs the input is enabled for the period of this timer. The timer runs for each input indep endently.

35 |

291 842 003 |

P23 STABILIZATION TIME |

0.0 - 9.0 sec. |

Timer starts after the end of travel. I n the period of this timer all activities are disabled. After this time expires the next stage starts (opening doors, drive with fast or slow speed etc. )

P24 YEAR

Setting of year in date for real time clock

P25 MONTH

Setting of year in date for real time clock

P26 DAY

Setting of year in date for real time clock

P27 HOUR

Setting of year in date for real time clock

P28 MINUTE

Setting of year in date for real time clock

P29 |

GROUP |

1 |

- 4 |

|

|

Possible setting is 1 to 4 |

|

|

|

|

1 |

one elevator – simplex |

|

|

|

2 |

up to 8 equal elevators |

|

|

|

3 |

reserved ( do not use ) |

|

|

|

4 |

reserved ( do not use ) |

|

|

P30 |

NUMBER OF ELEVATORS IN GROUP |

1 |

- 8 |

|

P31 |

ELEVATOR NUMBER |

1 |

- 8 |

|

Each elevator in group operation must have different number. |

|

|

||

Numbers starts from number one. |

|

|

||

P32 FLOOR SHIFT IN GROUP |

0 |

- 8 |

||

This setting allows group operation with shifted floors. I f the 1st station of the lift is in the level of 2nd or 3rd station of other lift in group, difference can be written in this parameter.

Setting of display PK96 is the same for all elevators in group. I t should be set according to the lift with the

lowest first sta tion. |

|

|

Example for two elevators connected in duplex: |

|

|

Elevator 1 |

with stations C2, C1, G, 1, 2; setting of P32= 0, P4= 5; setting of PK96 is C2, C1, G, 1, 2. |

|

Elevator 2 |

with stations G, 1, 2; setting of P32= 2, P4= 3; setting of PK96 is C2, C1, G, 1, 2. |

|

P33 MAX. FLOORS FOR SINGLE DRIVE |

0 - 48 |

|

Maximal number of floors for single drive. I t should be set in case when traveling time between first and last station is longer than maximal allowed traveling time.