Gathering the right information is vital when deciding who to approve for a loan or mortgage. Fortunately, there’s a simple and effective way to collect the data you need—a standard pre qualification form. This form assists lenders in understanding each potential customer's financial history and how they view their current situation, allowing lenders to make informed decisions about loan requests. In this blog post, we'll look at what goes into creating an effective pre qualification form and why its use is essential for today’s lending industry.

| Question | Answer |

|---|---|

| Form Name | Standard Pre Qualification Form |

| Form Length | 7 pages |

| Fillable? | No |

| Fillable fields | 0 |

| Avg. time to fill out | 1 min 45 sec |

| Other names | pre qualification form, sample subcontractor prequalification form, subcontractor prequalification form, qualification form pre |

Standard

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GENERAL INFORMATION |

|

|

|

|

|

|

||||||||

1. Company Name: |

|

|

|

|

|

|

|

|

|

|

|

|

Telephone: |

|

|

|

Fax: |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Street Address: |

|

|

|

|

|

|

|

|

|

|

Mailing Address: |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Web Site: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Contact Person: |

|

|

|

|

|

|

|

|

|

|

Email: |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Telephone: |

|

|

|

|

|

|

|

|

|

|

Fax: |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2. Officers |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Years With Company |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

President: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vice President: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Treasurer: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

3. How many years has your organization been in business under your present firm name? |

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4. Parent Company Name: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

City: |

|

|

|

|

|

|

|

|

State: |

|

Zip: |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Subsidiaries: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5. Under current management since: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6. Contact for Insurance Information: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Title: |

|

|

|

|

|

|

|

|

|

|

Telephone: |

|

|

Fax: |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

7. Insurance Carriers |

|

|

|

|

Type of coverage |

|

|

|

|

|

|

|

|

|

|

Telephone |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

8. Are you self insured for Worker's Compensation Insurance? |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

9. Contact for Requesting Bids: |

|

|

|

|

|

|

|

|

|

|

|

|

Title: |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Telephone: |

|

Fax: |

|

|

|

Email: |

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

10. PQF Completed By: |

|

|

|

|

|

|

|

|

|

Title: |

|

|

|

|

|

Date: |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Telephone: |

|

Fax: |

|

|

|

Email: |

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ORGANIZATION |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

11. Form of Business |

|

Sole Owner |

|

Partnership |

|

Corporation |

|

|

Date and State of Incorporation: |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

12. Percent Minority / Female Owned: |

|

|

EEO Category: |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

13. A. Describe Services Performed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

Construction |

|

|

|

|

|

|

Construction Design |

|

|

|

|

|

|

Original Equipment Manufacturer and Installer |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

Maintenance |

|

|

|

|

|

|

Specialty Maintenance |

|

|

|

|

|

|

Manpower and Resource |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

||||||||||||||||||

|

Original Equipment Manufacturer and Maintenance |

|

|

Service Work (e.g. Janitorial, Clerical, Etc.) |

|

Turnaround |

|||||||||||||||||

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Engineering |

|

|

|

|

|

|

Other |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

Page 1 Rev 2/25/2004 |

|

|

|

|

|

|

|||||||

13. B. Work Categories |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Check the categories in which you are interested in bidding and in which you are qualified to perform work. Attach additional information clarifying your |

|||||||||||||||||

capabilities and specialities. |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

(C) denotes work done by company employees (S) denotes work done by subcontractors |

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

S |

1. Air Conditioning / Refrigeration |

|

|

|

C |

S |

|

12. Instrumentation |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Comfort Cooling / HVAC |

|

|

|

|

|

|

|

General |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Process Refrigeration |

|

|

|

|

|

|

|

DCS Control Systems |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

S |

|

2. Buildings |

|

|

|

C |

S |

|

13. |

Insulation |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Remodeling |

|

|

|

|

|

|

|

General |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

New (steel, brick, block, other) |

|

|

|

|

|

|

|

Asbestos Abatement |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

S |

|

3. Cleaning |

|

|

|

C |

S |

|

14. |

Linings/coatings for: |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Industrial |

|

|

|

|

|

|

|

Metal |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Janitorial |

|

|

|

|

|

|

|

Concrete |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

S |

|

4. Civil |

|

|

|

C |

S |

|

15. |

Field Maintenance |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Concrete |

|

|

|

|

|

|

|

General |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Excavation/Grading Paving |

|

|

|

|

|

|

|

Hot Tap/line stops |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- Asphalt |

|

|

|

|

|

|

|

Leak Sealing (online) |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- Concrete |

|

|

|

|

|

|

|

Field Machining |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5. Demolition/Dismantling |

|

|

|

|

|

|

|

Tank/Vessel Code |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

S |

|

6. Electrical |

|

|

|

|

|

|

|

Boiler Code |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

General |

|

|

|

|

|

|

|

Exchanger Retubing |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rotating Equipment |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heat Tracing |

|

|

|

|

|

|

|

Valve |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cathodic Protection |

|

|

|

|

|

|

|

Cooling Tower |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Grounding Systems |

|

|

|

|

|

|

|

High Alloy Welding (list type) |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

C |

|

S |

7. Inspection & Testing |

|

|

|

|

|

|

|

Lead Lining |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

General NDT |

|

|

|

|

|

|

|

Glass Lining |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Radiography |

|

|

|

|

|

|

|

Heat Treating |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Infared Scanning |

|

|

|

|

|

|

|

Nonmetallic materials |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Eddy Current Testing |

|

|

|

|

|

|

|

Pipe Fabrication |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Acoustic Emission |

|

|

|

|

|

|

|

Mobile Equipment Repair |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Column Scanning |

|

|

|

|

|

|

|

16. New Construction |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Civil/Soils |

|

|

|

|

|

|

|

17. |

Painting |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

High Voltage Electrical |

|

|

|

|

|

|

|

18. |

Refractory/Acid Brick |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Electrical Ground Inspection |

|

|

|

|

|

|

|

19. Rigging/Equipment Erection |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fiberglass Inspection |

|

|

|

C |

S |

|

20. Consulting |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

S |

|

|

|

|

|

|

|

|

|

Mechanical |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8. Scaffolding |

|

|

|

|

|

|

|

Electrical |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9. Scale Maintenance |

|

|

|

|

|

|

|

Chemical |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10. Structural Steel Fab/Erection |

|

|

|

|

|

|

|

Metallurgical |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11. Tanks - Field Erection |

|

|

|

|

|

|

|

Controls |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Describe Additional Services Performed: |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

14. A. Do you normally employ |

|

Union Personnel? |

|

|

|

Leased Personnel? |

|||||||||||

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

If union, list trades/locals: |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

B. Average number of employees for last 3 years: |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

15. Annual Dollar Volume for the Past Three Years: |

|

|

Year: |

|

|

|

|

Year: |

|

|

Year: |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

$ |

|

|

|

|

|

|

$ |

|

$ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Page 2 Rev 2/25/2004

16. Largest Job During the Last 3 Years: |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

17. Your Firm's Desired Project Size |

Maximum: $ |

|

|

|

|

|

Minimum: $ |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

18. a.D&B Financial Rating: |

|

18 b. Annual Sales: |

|

|

|

18.c. Net Worth: |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

18.d. DUNS #: |

|

Date: |

|

|

|

18.e. Tax ID #: |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

||

19. Bank Line of Credit $: |

|

|

|

Bonding Capacity $ |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Bank Reference(s): |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

20. Major jobs in progress |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Customer/Location |

Type of Work |

Size |

|

Customer Contact |

Telephone |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

21. Major jobs completed in the past three years |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Customer/Location |

Type of Work |

Size |

|

Customer Contact |

Telephone |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

22. Are there any judgments, claims or suits pending or outstanding against your company? If yes, please attach details. |

|

||||||||||

|

|

|||||||||||

|

|

|

|

|

||||||||

|

23. Are you now or have you ever been involved in any bankruptcy or reorganization proceedings? If yes, please attach details |

|

||||||||||

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SAFETY & HEALTH PERFORMANCE |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

24. Workers Compensation Experience Modification Rate (EMR) Data |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

a. EMR is: |

|

|

b. EMR for three last years |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Interstate rate |

|

|

YEAR |

|

|

|

|

EMR |

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Intrastate rate |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Monopolistic State rate |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dual Rate |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|||||||

c. State of Origin |

|

|

d. EMR Anniversary Date: |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

||

e. Standard Industrial Classification (SIC): |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

25. Injury and Illness Data: |

|

|

|

|

|

|

|

|

|

|

||

a. Total company employee hours worked last three years (excluding subcontractors)

Hours / Year |

Year: |

Year: |

Year: |

Field

Total

b.Provide data (excluding subcontractor) using your OSHA 200 and 300 Forms from the past three (3) years: Notes:

(1) Data should be total company data unless specifically requested by client.

(2) Combine injuries and illnesses from 200 Form as reported on 300 Form

(3) If your company is not required to maintain OSHA 200/300 forms, please provide information from your Worker's Compensation insurance carrier itemizing all claims for the last 3 years.

|

|

|

Year: |

Year: |

|

Year: |

|

||

|

|

|

|

|

|

|

|

|

|

Fatalities |

|

No. |

|

Rate: |

No. |

Rate: |

No. |

Rate: |

|

Rate = Number of Fatalities x 200,000 / Total Employee Hours |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lost workday case injuries and illnesses involving days away from work, or |

|

No. |

|

Rate: |

No. |

Rate: |

No. |

Rate: |

|

days of restricted work activity, or both. |

|

|

|

|

|

|

|

|

|

Rate = Total LW and restricted cases x 200,000 / Total Employee Hours |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lost workday case injuries and illnesses involving days away from work. |

|

No. |

|

Rate: |

No. |

Rate: |

No. |

Rate: |

|

Rate = LW cases** x 200.000 / Total Employee Hours |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Injuries and Illnesses involving medical treatment only. |

|

No. |

|

Rate: |

No. |

Rate: |

No. |

Rate: |

|

Rate = Total Injuries and Illnesses involving medical treatment only x 200, |

|

|

|

|

|

|

|

|

|

000 / Total Employee Hours |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Total OSHA Recordable Injury and Illnesses Rate |

|

No. |

|

Rate: |

No. |

Rate: |

No. |

Rate: |

|

Rate = Total Injuries and Illnesses x 200,000 / Total Employee Hours |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

26. Have you received any regulatory (EPA, OSHA, etc.), civil or criminal |

citations in the last three years? |

|

|

|

||||

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

Page 3 Rev 2/25/2004 |

|

|

|

|

|||

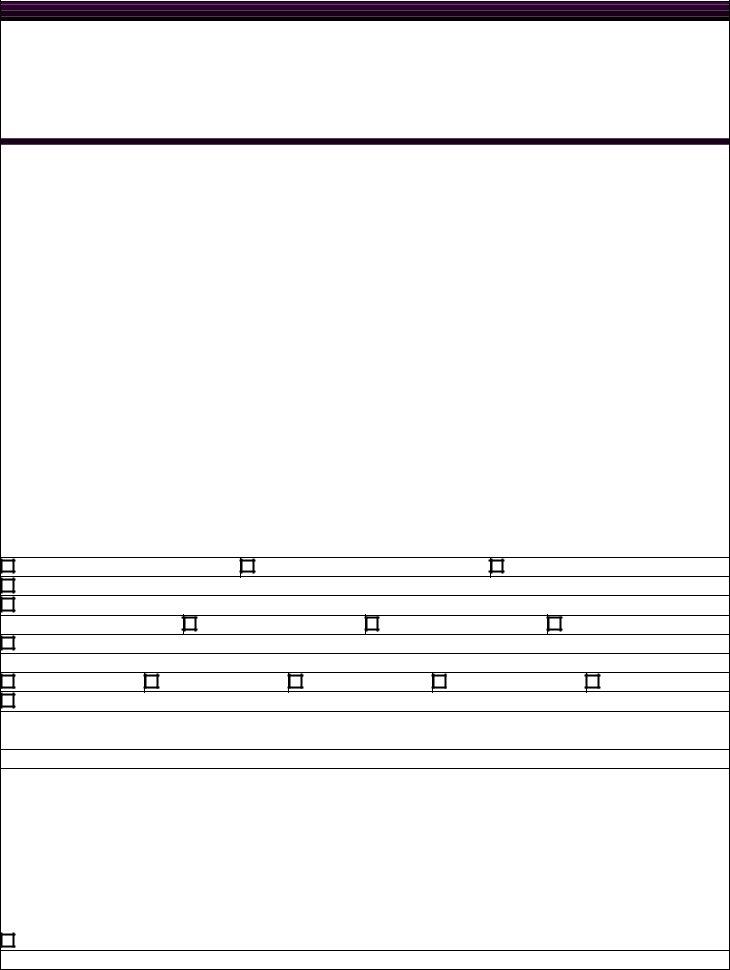

SAFETY, HEALTH & ENVIRONMENTAL MANAGEMENT

27. Name of highest ranking safety/health professional in the company

Name: |

|

|

|

Title: |

|

|

|

|

Certifications: |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Telephone: |

|

|

Fax: |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This person reports to: |

|

|

Title: |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

28. Do you have or provide: |

|

a. Full time Safety/Health Director |

|

b. Full time Site Safety/Health Supervisor |

|

|

c. Full Time Job Safety/Health Coordinator |

||||||

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

29. Do you have or provide: |

|

a. Safety/Health incentive program |

|

b. Company paid safety/health training |

|

||||||||

|

|

|

|||||||||||

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SAFETY, HEALTH & ENVIRONMENTAL PROGRAMS / PROCEDURES |

|||||||||

|

30. a. Do you have a written S, H E Program? |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

b. Does the program address the following key elements? |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

||||||

|

1. |

Management commitment and expectations |

|

|

|

|

2. Employee participation |

|

|||||

|

|

|

|

|

|||||||||

|

3. |

Accountabilities and responsibilities for managers, supervisors, and employees |

|

4. Resources for meeting safety, health |

environmental requirements. |

||||||||

|

|

||||||||||||

|

|

|

|

|

|

||||||||

|

5. |

Periodic safety and health performance appraisals for all employees |

|

|

|

6. Safety, Health Environmental Recognition Program |

|||||||

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

Hazard recognition and control |

|

|

|

|

|

|

|

|

|

|||

|

7. |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

c. Does the program satisfy your responsibility under the law for: |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||||

|

Ensuring your employees follow the safety rules |

|

|

|

|

|

|

|

|

||||

|

1. |

|

|

|

|

|

|

|

|

||||

|

|

|

|

||||||||||

|

Advising owner of any unique hazards presented by the contractors work and of any hazards found by the contractor |

|

|||||||||||

|

2. |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

31. Does the program include work practices and procedures such as |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

||||||

|

a. Equipment Lockout and Tagout (LOTO) |

|

|

|

|

b. Confined Space Entry |

|

||||||

|

|

|

|

|

|

|

|

||||||

|

c. Injury and Illness Recording |

|

|

|

|

d. Fall Protection |

|

||||||

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

||||||

|

e. Personal Protective Equipment |

|

|

|

|

f. Portable Electrical/Power Tools |

|

||||||

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

||||

|

g. Vehicle Safety |

|

|

|

|

|

|

h. Compressed Gas Cylinders |

|

||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|||||||

|

i. Electrical Equipment Grounding Assurance |

|

|

|

|

j.Powered Industrial Vehicles (Cranes, Forklifts, JLGs) |

|||||||

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

||||

|

k. Housekeeping |

|

|

|

|

|

|

l. Accident/Incident Reporting |

|

||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|||||||

|

m. Unsafe Condition Reporting |

|

|

|

|

n. Emergency Preparedness, including evacuation plan |

|||||||

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

||||

|

p. Back Injury Prevention |

|

|

|

|

|

|

q. Hazwoper Training |

|

||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

||||

|

r. Heat Stress Prevention |

|

|

|

|

|

|

s. Scaffold Builing /Scaffold Use |

|

||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

t. General NDTand Radiography |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

32. Do you have written programs for the following: |

|

|

|

|

|

|

|

|

|||||

a. Hearing Conservation

b. Spill prevention and waste minimization

c. Hazard Communuication

d. Program to support contractor requirements of the OSHA Process Safety Management of highly hazardous

e. Respiratory Protection

Where applicable, have employees been: |

Trained? |

Fit tested? |

Medically approved? |

|

33. Do you have a substance abuse program?

If yes, does it include the following?

Random Testing

Testing for Cause

DOT Testing

Post Incident Testing

34. Do your employees read, write, and understand English such that they can perform their job tasks safely without an interpreter?

If no, provide a description of your plan to assure that they can safely perform their jobs.

35. Medical

a. Do you conduct medical examinations for:

|

|

Preplacement Job Capability |

|

Hearing Function (Audiograms) |

|

Pulmonary |

|

Respiratory |

|||||

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

b.Describe how you will provide first aid and other medical services for your employees while |

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||

|

c. Do you have personnel trained to perform first aid and CPR? |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

36. Do you hold site safety, health and environmental meetings for: |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Field Supervisors |

|

|

Frequency: |

|

|

Employees |

|

|

Frequency: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

New Hires |

|

|

Frequency: |

|

|

Subcontractors |

|

|

Frequency: |

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Are the safety, health and environmental meetings documented?

Page 4 Rev 2/25/2004

37. Personal Protection Equipment (PPE) |

|

|

|

|

|

|

|

|

|

|

|

|

a. Is applicable PPE provided for employees? |

|

b. Do you have a program to assure that PPE is inspected and maintained? |

||

|

|

|

|

|

|

|

38. Do you have a corrective action process for addressing individual safety and health performance deficiencies? |

|

|||

|

|

||||

|

|

|

|

|

|

39. Equipment and Materials: |

|

|

|

|

|

|

|

|

|

|

|

|

a. Do you have a system for establishing applicable health, safety, and environmental specifications for acquisition of materials and equipment? |

|

|||

|

|

||||

|

|

|

|

|

|

|

b. Do you conduct inspections on operating equipment e.g., cranes, forklifts, JLGs) in compliance with regulatory requirements? |

|

|||

|

|

||||

|

|

|

|

|

|

|

c. Do you maintain operating equipment in compliance with regulatory requirements? |

|

|||

|

|

||||

|

|

|

|

|

|

|

d. Do you maintain the applicable inspection and maintenance certification records for operating equipment? |

|

|||

|

|

||||

|

|

|

|

|

|

40. Subcontractors |

|

|

|

|

|

|

|

|

|

|

|

|

Do you use subcontractors? (If no, skip to next question) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

a. Do you use safety, health and environmental performance criteria in selection of subcontractors? |

|

|||

|

|

||||

|

|

|

|

||

|

b. Do you evaluate the ability of subcontractors to comply with applicable safety, health and environmental requirements as part of the selection process? |

||||

|

|||||

|

|

|

|

|

|

|

c. Do your subcontractors have a written safety, health and environmental program? |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

d. Do you include your subcontractors in: |

|

|

|

|

|

|

|

|

|

|

|

|

Safety, Health and Environmental Orientation |

|

Safety, Health and Environmental Inspections |

|

|

|

|

|

|

|

|

|

Safety, Health and Environmental Meeting |

|

Safety, Health and Environmental Audits |

|

|

|

|

|

|||

|

|

|

|

|

|

41. Inspections and Audits |

|

|

|

|

|

|

|

|

|

|

|

|

a. Do you conduct Safety, Health and Environmental inspections? |

|

b. Do you conduct Safety, Health and Environmental program audits? |

||

|

|

|

|

|

|

|

c. Are corrections of deficiencies documented? |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SAFETY, HEALTH & ENVIRONMENTAL TRAINING |

|

|||

|

|

|

|

|

|

42. Safety, Health & Environmental Training |

|

|

|

|

|

|

|

|

|

|

|

|

a. Do you know the regulatory safety, health and environmental training requirements for your employees? |

|

|||

|

|

||||

|

|

|

|

|

|

|

b. Have your employees received the required safety, health and environmental training and retraining and is it documented? |

|

|||

|

|

||||

|

|

|

|

|

|

|

c. Do you have a specific safety, health and environmental training program for supervisors? |

|

|||

|

|

||||

|

|

|

|

|

|

|

d. Are all employees trained in the work practices needed to safely perform his/her job? |

|

|||

|

|

||||

|

|

|

|

||

|

e. Is each employee instructed in the known potential of fire, explosion, or toxic release hazards related to his/her job, the process and the applicable provisions of the |

||||

|

|||||

|

emergency action plan? |

|

|

|

|

|

|

|

|

|

|

|

CRAFT TRAINING AND ASSESSMENT |

|

|||

Data timeframe From: |

To: |

|

|||

|

|

|

|

|

|

Notes |

|

|

|

|

|

1. Data should be the best available applicable for your company's workforce (use average of last twelve months) |

|

||||

2. Training, Skills Assessment Testing and Performance Verification refer to nationally recognized programs such as NCCER, NCCCO and DOL BAT programs. |

|||||

|

|

|

|

|

|

If not applicable, please explain |

|

|

|

|

|

|

|

|

|

||

43. Workforce |

# |

|

% |

||

|

|

|

|

|

|

a. Journeymen |

|

|

|

|

|

|

|

|

|

|

|

b. |

|

|

|

|

|

|

|

|

|

|

|

c. Helpers |

|

|

|

|

|

|

|

|

|

|

|

d. |

|

|

|

|

|

|

|

|

|

|

|

e. |

|

|

|

|

|

|

|

|

|

|

|

f. Supervision (Foremen/General Foremen) |

|

|

|

|

|

|

|

|

|

|

|

g. Professional (Safety/Scheduling/Engineering) |

|

|

|

|

|

|

|

|

|

|

|

h. Administration/Management |

|

|

|

|

|

|

|

|

|

|

|

i. Total Workforce |

|

|

|

|

|

|

|

|

|

|

|

|

44. Do you have written Workforce Development Policies and Procedures? |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

45. Formal Training For |

|

|

|

|

|

|

|

|

|

||

|

a. Do you have and maintain craft training records for employees? |

|

b. Do you provide incentives to trainees to complete formal training? |

||

|

|

|

|||

c. Percent of |

|

||||

|

|

||||

d. Percent of |

|

||||

|

|

|

|

|

|

|

e. Is Company an accredited NCCER Training Sponsor or Unit? |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Page 5 Rev 2/25/2004 |

|

|||

46. Assessments, Upgrade Training & Certification |

|

|

|

|

# |

% |

||||

|

|

|

|

|

|

|

|

|

|

|

a. Journeymen craftsmen who have been assessed through the craft skills assessment process (see note 2) |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

b. Journeyman Craftsmen who have been certified through written skills assessment testing? |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

c. Journeyman Craftsmen who have been certified in more than one craft? |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

d. Journeymen craftsmen with skills deficiencies identified through assessment testing and receiving upgrade training? |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

e. Journeymen craftsmen in upgrade training to improve areas identified through assessment testing? |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

f. Do you provide incentives for journeymen to become certified? |

|

|

g. Do craftsmen have access to upgrade training to improve skills? |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

h. Is Company an accredited NCCER Assessment Center |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

i. When are craftsmen assessed? |

|

|

Within 30 days of hire |

Other: |

|

|||||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

47. Performance Verification |

|

|

|

|

|

|

|

# |

% |

|

|

|

|

|

|

|

|

||||

a. Journeymen craftsmen that have achieved verified performance |

|

|

|

|

|

|

||||

|

|

|

|

|||||||

b. Journeymen craftsmen that have achieved both written certification and verified performance. |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

COMMENTS/EXPLANATIONS |

|

||||||

COMMENTS/EXPLANATIONS |

|

|

|

|

|

|

|

|

|

|

Page 6 Rev 2/25/2004

|

|

INFORMATION SUBMITTAL |

|||||

|

|

|

|

|

|

|

|

Please provide copies of checked items with the completed PQF: |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

EMR documentation from your insurance carrier |

|

Safety, Health |

Environmental Training Schedule (Sample) |

|||

|

|

|

|

|

|

|

|

|

Insurance Certificate(s) |

|

Safety, Health |

Environmental Training for Supervisors (Outline) |

|||

|

|

||||||

|

|

|

|

|

|

||

|

OSHA 200 and 300 Logs (Past 3 Years) |

|

Copy of Louisiana Contractor's Licence |

||||

|

|

||||||

|

|

|

|

|

|

|

|

|

Safety, Health |

Environmental Program |

|

Organization Chart |

|||

|

|

||||||

|

|

|

|

|

|

|

|

|

Safety, Health |

Environmental Incentive Program |

|

List of major equipment (e.g., cranes, JLGs, forklifts) your company has available fo |

|||

|

|

||||||

|

|

|

|

|

|

||

|

Substance Abuse Program (Include Substances Tested Levels) |

|

Equipment Lockout and Tagout (LOTO) |

||||

|

|

||||||

|

|

|

|

|

|

||

|

Hazard Communication Program |

|

Confined Space Entry |

||||

|

|

||||||

|

|

|

|

|

|

||

|

Respiratory Protection Program |

|

Fall Protection, Scaffold use, scaffold building |

||||

|

|

||||||

|

|

|

|

|

|

||

|

Housekeeping Policy |

|

Personal Protective Equipment |

||||

|

|

||||||

|

|

|

|

|

|

||

|

Accident/Incident Investigation Procedure |

|

Portable Electric / Power Equipment |

||||

|

|

||||||

|

|

|

|

|

|

|

|

|

Unsafe Condition Reporting Procedure |

|

Vehicle Safety |

|

|

||

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

Safety, Health |

Environmental Inspection Form |

|

Compressed Gas Cylinders |

|||

|

|

||||||

|

|

|

|

|

|

|

|

|

Safety, Health |

Environmental Audit Procedure or Form |

|

Electrical Equipment Grounding Assurance |

|||

|

|

||||||

|

|

|

|

|

|

|

|

|

Safety, Health |

Environmental Orientation (Outline) |

|

Emergency Preparedness, including evacuation plan |

|||

|

|

||||||

|

|

|

|

|

|

|

|

|

Safety, Health |

Environmental Training Program (Outline) |

|

Waste Disposal |

|||

|

|

||||||

|

|

|

|

|

|

||

|

Example of Employee Safety, Health Environmental Training Records |

|

Back Injury Prevention |

||||

|

|

||||||

|

|

|

|

|

|

||

|

Workforce Development Policies |

|

Heat Stress Prevention |

||||

|

|

||||||

|

|

|

|

|

|

|

|

|

NDT Radiography Program |

|

|

|

|

||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

Fill in below Name & Title of Company Officer responsible for assuring the accuracy of this document: |

|

|

|||||

|

|

|

|

|

|

|

|

Name |

|

Title |

|

|

|

Date |

|

|

|

|

|

|

|

|

|

Page 7 Rev 2/25/2004