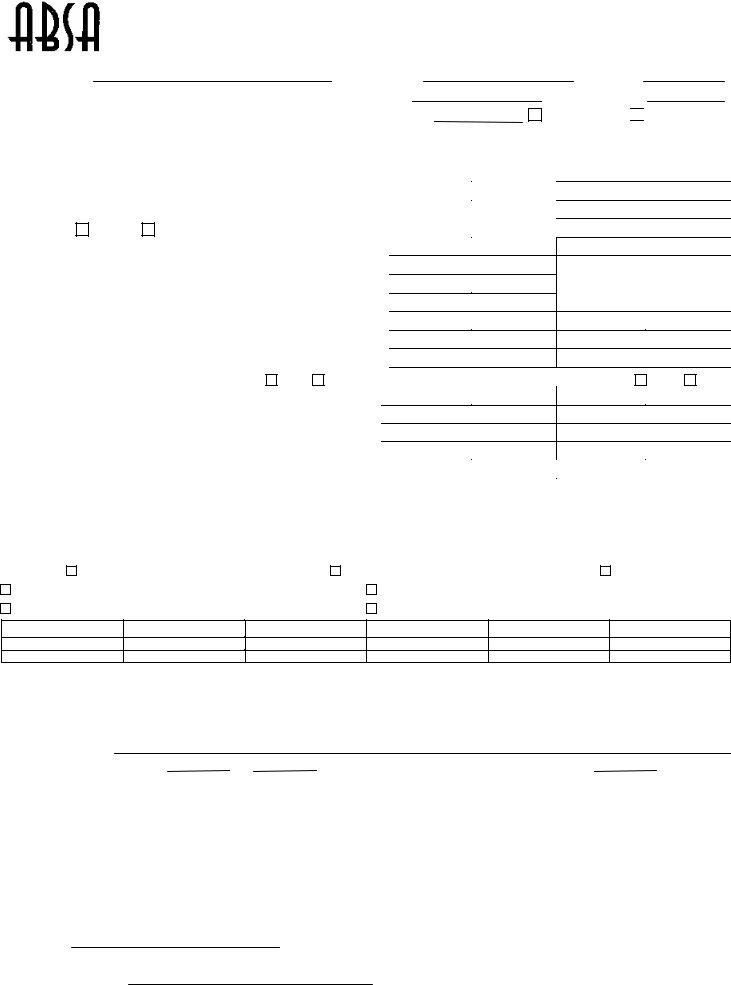

At the core of ensuring safety and competence in the skilled trade of welding, especially within the sphere of pressure equipment safety, lies the Welder Qualification Record (WQR) form, specifically the AB-76A version updated in September 2010. This critical document serves as a comprehensive record, meticulously outlining a welder's adherence to predefined welding procedure specifications (WPS), which detail the steps and methods to be followed during welding operations. Through sections that capture a welder's name, ABSA file number, and extensive details on the test coupon—including base materials used, their thicknesses, and welding processes employed—the form provides an intricate look into the welder's capability and the parameters under which they were tested. Covering testing conditions, qualification limits, and welding variables alongside actual values for welding processes, types, base metals, and filler metals, the form goes on to detail welding positions, progression, gas types used, and results from a plethora of tests including bend tests, macro tests for fusion, and results from nondestructive examination methods like radiographic (R.T.) and ultrasonic testing (U.T.). All these elements are aimed at certifying a welder's proficiency under the demanding standards set by Section IX of the ASME Boiler and Pressure Vessel Code. This record not only validates the skillset of a welder but also serves as a pivotal reference for employers, safety auditors, and regulatory bodies, ensuring that only qualified personnel operate within this high-stakes industry.

| Question | Answer |

|---|---|

| Form Name | Welder Qualification Form |

| Form Length | 1 pages |

| Fillable? | No |

| Fillable fields | 0 |

| Avg. time to fill out | 15 sec |

| Other names | welding certificate format, welding certificate sample, welder performance qualification record word format, welder certificate format in word download |

WELDER QUALIFICATION RECORD (WQR)

the pressure equipment safety authority

Welders Name:ABSA File No.:

Identification of WPS followed by welder during welding of test coupon:

Base material(s) welded: |

|

Thickness: |

Stamp No.:

W.P. Reg. # WP-

Test Coupon Prod. Weld

|

Testing Conditions and Qualification Limits |

||

Welding Variables |

|

Actual Values |

|

|

Welding Process(es) Used: |

|

|

Type of Welding (i.e., Manual, |

|

||

Base Metal P Number: |

To P Number: |

|

|

Plate |

Pipe (enter diameter if pipe or tube): |

|

|

Backing (metal, weld metal,

Filler Metal or Electrode Specification(s) (SFA) (info only):

Filler Metal or Electrode Classification(s) (info only):

Filler Metal or Electrode

Filler Type (solid/metal or flux cored/powder) (GTAW or PAW):

Consumable Insert for GTAW or PAW:

Deposit Thickness for each process or electrode type, etc. (in.):

Range Qualified

Process/Electrode 1: |

3 layers minimum Yes |

No |

Process/Electrode 2: |

3 layers minimum |

Welding Position (2G, 6G, 3F, etc.):

Vertical Progression (Uphill or Downhill):

Fuel Gas for OFW or Inert Gas Backing for GTAW, PAW, GMAW:

Transfer Mode (spray/globular or pulse to short circuit- GMAW):

Yes

No

GTAW Current Type/Polarity (AC, DCEP, DCEN): |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

Results |

|

|

|

|

|

|

|

||

Visual Examination of |

Tack Welds: |

( Length: |

|

Number: |

) |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Root Pass (Describe Discontinuity if Unacceptable): |

|

|

|

|

|

|

|

|

|

|

|

|

||

Completed Weld (Describe defects if unacceptable): |

|

|

|

|

|

|

|

|

|

|

|

|

||

Bend Test: Transverse Root and Face |

Longitudinal Root and Face |

Side |

||||||||||||

Pipe Bend Specimen,

Plate Bend Specimen,

Macro Test for Fusion

Macro Test for Fusion

Type

Result

Type

Result

Type

Result

(For alternative qualification of groove welds by volumetric examination to |

|

|

||||||||||||||||

R.T. Results: |

|

|

|

|

U.T. Results: |

|

|

|

||||||||||

Fillet Weld - Fracture Test (Describe location, nature and size of any crack or tearing of specimen): |

|

|

||||||||||||||||

Length and Per Cent of Defects: |

|

|

|

|

inches |

|

|

|

|

|

|

|

|

|||||

Macro |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

X |

inch. Convexity: |

|

|

inch. or Concavity: |

inch. |

|||||||||||||

Other Tests: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

Record Information |

|

|

|

|

|

|

|

||||

Film or Specimens Evaluated by: |

|

|

|

|

|

|

|

|

Company: |

|

|

|||||||

Welding supervised by: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Mechanical tests conducted by: |

|

|

|

|

|

|

|

Laboratory test no.: |

|

|

|

|||||||

We certify that the statements in this record are correct and that the test coupons were prepared, welded and tested in accordance with the requirements of Section IX of the ASME Boiler and Pressure Vessel Code.

ACCREDITED ORGANIZATION: |

|

AOQP No.: |

|

Expiry Date: |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Certified by: |

|

Examiner File No. |

|

|

|

Date: |

|

|

|||||

P.Q. Card No. (When issued): |

|

|

Performance Test Reference No.: |

||||||||||

Test Coupon I.D. No.: |

|

|

|

Date Coupon is to be retained to: |

|

|

|||||||