With the online editor for PDFs by FormsPal, you're able to fill in or edit qw 484a right here. Our development team is constantly endeavoring to enhance the tool and ensure it is much easier for clients with its extensive functions. Enjoy an ever-evolving experience now! Getting underway is simple! Everything you need to do is adhere to the following simple steps directly below:

Step 1: Press the "Get Form" button above. It'll open up our pdf editor so that you can start filling in your form.

Step 2: The tool grants the capability to customize almost all PDF documents in various ways. Enhance it by including your own text, correct what is already in the PDF, and add a signature - all readily available!

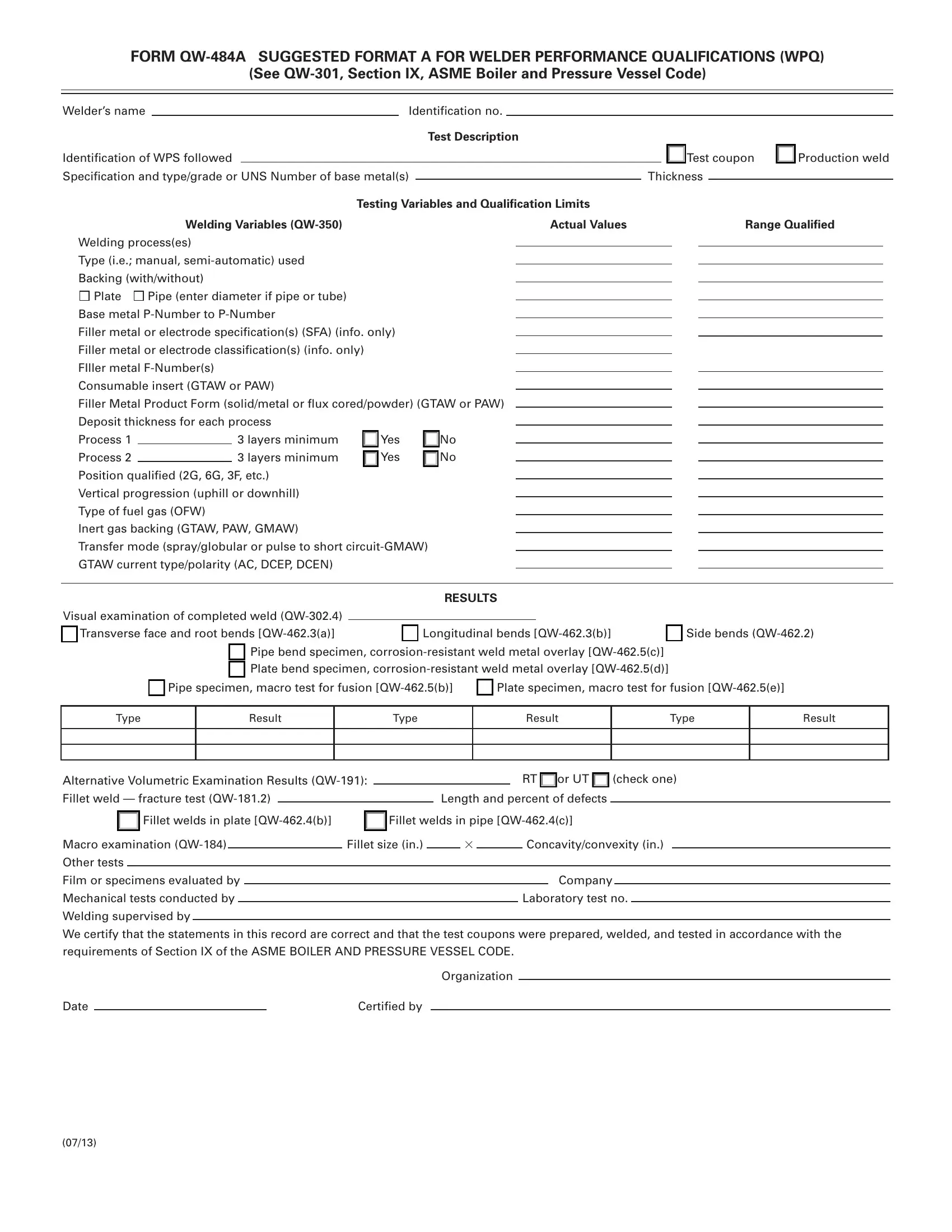

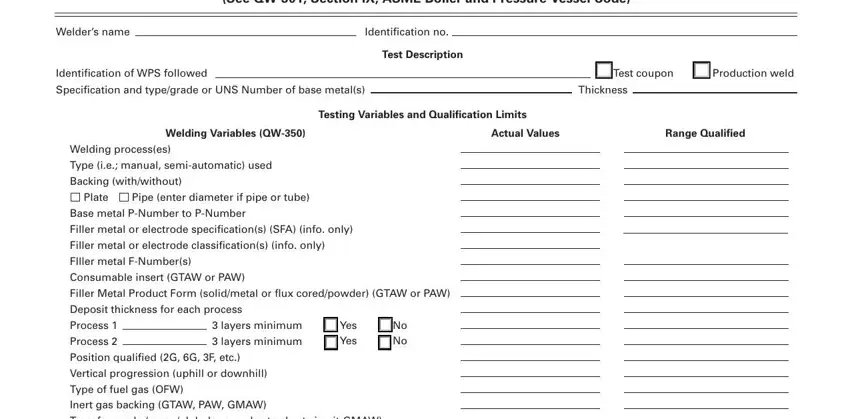

As for the fields of this specific form, here's what you need to do:

1. It is recommended to complete the qw 484a properly, thus pay close attention while filling in the parts comprising all of these blanks:

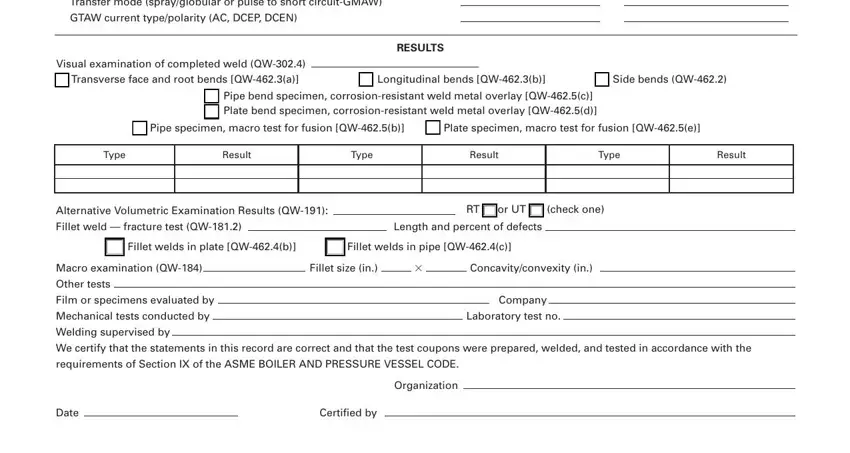

2. The subsequent part is to fill in these particular blanks: Transfer mode sprayglobular or, GTAW current typepolarity AC DCEP, Visual examination of completed, RESULTS, Transverse face and root bends QWa, Longitudinal bends QWb, Side bends QW, Pipe bend specimen, Plate bend specimen, Pipe specimen macro test for, Plate specimen macro test for, Type, Result, Type, and Result.

You can potentially make a mistake when filling in the Transfer mode sprayglobular or, hence make sure that you take another look prior to deciding to finalize the form.

Step 3: Before submitting this form, it's a good idea to ensure that all blanks were filled out as intended. The moment you’re satisfied with it, press “Done." Right after creating a7-day free trial account here, you'll be able to download qw 484a or send it via email immediately. The PDF form will also be readily accessible in your personal account menu with your each and every change. Whenever you work with FormsPal, you can easily fill out documents without stressing about personal data leaks or records getting distributed. Our protected system helps to ensure that your private data is kept safe.