Embarking on the installation or maintenance of the XNX Universal Transmitter calls for a thorough understanding of its Quick Start Guide, a document designed to streamline the initial setup and ongoing use of this multifaceted device. From the outset, users are introduced to critical components like mounting considerations, wiring intricacies, and the calibration process, each underpinned by essential warnings and specifications that ensure safety and optimal performance. The guide delves into the specifics of mounting both the transmitter and detectors, highlighting the importance of proper placement and installation techniques. Wiring the transmitter, a task that demands meticulous attention to detail, is covered with guidelines on general considerations, isolation, circuit protection, and load assessments, alongside distance considerations for various installations types. Users are also equipped with instructions for making POD connections, managing 4-20mA output and common connections, and configuring for HART® Communications, foundational for the transmitter's operational integrity. Moreover, the document addresses terminal block connections and the nuances of wiring for different sensor personalities – EC, mV, and IR – ensuring users can adapt the transmitter to a range of scenarios. With a nod to options like local HART® Interface, Relays, Modbus, and Foundation Fieldbus, the guide prepares users for a first-time power-up, navigating the front panel, entering menu structures, and performing gas calibration, a critical step for ensuring accuracy and reliability of readings. Additionally, sensor data information, sensor cartridge replacement, along with troubleshooting tips through warning, fault, and informational messages, are thoroughly covered. This comprehensive approach ensures not only a successful setup but also sustained, efficient operation in diverse environments, making the XNX Universal Transmitter Quick Start Guide an invaluable resource for users.

| Question | Answer |

|---|---|

| Form Name | Xnx Universal Transmitter |

| Form Length | 100 pages |

| Fillable? | No |

| Fillable fields | 0 |

| Avg. time to fill out | 25 min |

| Other names | xnx transmitter wiring xnx xnx transmitter manual pdf download, xnx xnx xnx transmitter wiring video pdf download online, xnx transmitter wiring xnx honeywell, xnx transmitter installation manual 2 |

Quick Start Guide

XNX Universal Transmitter

Table of Contents

1 |

Introduction |

5 |

|

2 |

Warnings |

6 |

|

3 |

Mounting and Location of Detectors |

8 |

|

|

3.1 |

Mounting the XNX Universal Transmitter |

8 |

4 |

Wiring the XNX transmitter |

11 |

|

|

4.1 |

General Wiring Considerations |

11 |

|

|

Loading��������������������������������������������������������������������������� |

11 |

|

|

Isolation �������������������������������������������������������������������������� |

12 |

|

|

Circuit Protection����������������������������������������������������������� |

12 |

|

|

Loads ������������������������������������������������������������������������������ |

12 |

|

4.2 |

Distance Considerations for Installation |

12 |

Types of Installations ���������������������������������������������������� 12 Power Source Selection������������������������������������������������ 12 Wire Selection ���������������������������������������������������������������� 12 Single Transmitter Distances ��������������������������������������� 13

4.3 |

POD Connections |

16 |

4.4 |

16 |

Setting

4.5 |

Terminal Block Connections |

19 |

4.6 |

EC Personality Wiring |

20 |

|

4�6�1 XNX Electrochemical (EC) Sensor Installation ��������� |

22 |

|

4�6�2 XNX EC Sensor Remote Mounting Kit ����������������������� |

23 |

4.7 mV Personality Wiring |

24 |

|

|

4�7�1 mV Remote Sensor Mounting������������������������������ |

27 |

4.8 |

IR Personality Wiring |

29 |

4�8�1 Connecting a Searchpoint Optima Plus or Searchline Excel ���������������������������������������������������������������������� 30

Attaching the Searchpoint Optima Plus to the XNX Universal Transmitter���������������������������������������������������� 30

Searchline Excel and Searchpoint Optima Plus Re- mote Installation ������������������������������������������������������������ 30

Searchpoint Optima Plus or Searchline Excel Wiring Recommendations��������������������������������������������������������� 31

4�8�2 Connecting Generic mA Device ��������������������������������� 32

XNX Universal Transmitter Quick Start Guide |

3 |

Table of Contents (cont’d) |

|

|

5 Options |

36 |

|

5.1 |

Local HART® Interface |

36 |

5.2 |

Relays |

36 |

5.3 Modbus |

37 |

|

5.4 |

Foundation Fieldbus |

38 |

6 Powering the XNX for the First Time |

39 |

|

6.1 |

XNX Units Configured for EC, mV, and IR (except Searchline |

|

Excel) |

39 |

|

6.2 |

XNX IR Units Configured for Searchline Excel |

40 |

6.3 |

Configuring the XNX Universal Transmitter |

42 |

7 The XNX Front Panel |

43 |

|

7.1 |

Controls and Navigation |

43 |

7.2 |

The General Status Screen |

43 |

7.3 |

Entering the Menu Structure |

45 |

7.4 |

Displaying Transmitter Information |

46 |

8 Gas Calibration Menu |

46 |

|

8.1 |

Calibration |

47 |

|

8.1.1 Calibration Procedure |

47 |

|

8.1.2 Zero and Span Calibration for XNX EC Sensors |

49 |

|

8.1.3 Zero and Span Calibration of XNX EC Hydrogen Sulfide (H2S) |

|

|

Sensors |

49 |

|

8.1.4 XNX EC Sensor Operational Life |

50 |

|

8.1.5 Zero and Span Calibration for MPD Sensors |

50 |

|

8.1.6 MPD Flammable Sensor |

52 |

|

8.1.7 Cross Calibration procedure for |

52 |

|

8.1.8 Calibrating the 705/705HT |

55 |

|

8.1.9 Calibrating the Sensepoint/Sensepoint HT |

55 |

8.2 |

Functional Gas Testing (Bump Test) |

56 |

9 Sensor Data |

57 |

|

9.1 |

Operating and Storage Conditions for Performance Tested |

|

EC Cartridges |

57 |

|

9.2 |

EC Sensor Performance Data, Factory Mutual Verified |

58 |

9.3 |

EC Sensor Performance Data, DEKRA EXAM Verified |

59 |

9.4 |

Other EC Sensors |

60 |

10 XNX Catalytic Bead and IR Replacement Sensor Cartridges |

62 |

|

11 Warning Messages |

63 |

|

12 Fault Messages |

70 |

|

13 Informational Messages |

82 |

|

14 Control Drawings |

84 |

|

15 Certification Labels |

91 |

|

16 Specifications |

94 |

|

17 EC Declaration of Conformity |

96 |

|

4 |

XNX Universal Transmitter Quick Start Guide |

1 Introduction

The XNX Quick Start Guide is an abbreviated print reference for the installation, operation, and maintenance of the XNX® Universal Transmitter. Refer to the XNX Universal Transmitter Resource CD (Honeywell part number

Manuals

XNX Technical Manual (1998M0738)

XNX Quick Start Guide

MPD Operating Manual

XNX Safety Manual

XNX Foundation Field bus Technical Manual

Control Drawings

1226E0402 XNX Control Drawing- UL,CSA, XM Approved Model

1226E0454 XNX Control Drawing- UL, INMETRO Approved Models

3000E3159 XNX ECC Cartridge Control Drawing- XNXX***** Series EC Cartridges and Remote Mount Kit.

For other sensor types such as Sensepoint Optima Plus, Searchline Excel, model 705 HT, or Sensepoint sensors, refer to their respective manuals for installation and ordering information.

XNX Universal Transmitter Quick Start Guide |

5 |

2 Warnings

High

•Installation must be in accordance with the recognized standards of the appropriate authority in the country concerned.

•Any work on the interior of the detector must be conducted only by trained personnel.

•Ensure that local regulations and site procedures are followed when carrying out any work. Appropriate standards must be followed to maintain the overall certiication of the detector.

•To reduce the risk of ignition of hazardous atmosphere, disconnect the equipment

from the supply circuit before opening the detector enclosure. Conduit runs must have a seal itting connected within 18 inches (45 cm) of the enclosures. Keep the assembly tightly closed during operation.

•Never open the XNX enclosure under power unless the area is known to be non

•The detector must be earthed/grounded for Intrinsic Safety, electrical safety, and to limit the effects of radio frequency interference. Earth/ground points are provided inside and outside the unit. EMI note for applications using shielded cable: Cable shield terminations must be made at the cable glands with suitable EMI type glands. Avoid terminating cable shields at the Earth ground lug inside the XNX enclosure. In cases where wiring is in pipe, a shielded cable is not required. The external terminal is only a supplemental bonding connection where local authorities permit or require such a connection.

•Take care when handling EC sensor cells as they may contain corrosive solutions.

•Do not tamper with or in any way disassemble the sensor cells.

•Do not expose the transmitter or sensor cells to temperatures outside the recommended range.

•Do not expose the sensor to organic solvents or lammable liquids.

•At the end of their working lives, sensors must be disposed of in an environmentally safe manner. Disposal should be according to local waste management requirements and environmental legislation.

•Alternatively, sensors may be securely packaged, clearly marked for environmental disposal, and returned to Honeywell Analytics.

•Do NOT incinerate electrochemical cells as they may emit toxic fumes.

•Verify all outputs, including display, after installation, after service events, and periodically to ensure the safety and integrity of the system.

•Delays resulting from transmission errors between sensor and transmitter extend response times T90 by more than

•As some test gases are hazardous, exhaust the low housing outlet to a safe area. Do not use the XNX Universal Transmitter in

6 |

XNX Universal Transmitter Quick Start Guide |

Hazardous Locations instaLLation requirements (uL/csa/Fm)

•To reduce the risk of ignition of hazardous atmospheres, conduit runs must have a pour gland installed within 18 inches (457mm) of enclosure.

•All ¾ inch NPT conduit, stopping plugs and adapters must be installed with 5 ¼ threads (minimum) engaged to Maintain Explosion Proof rating.

•The XNX Cover Assembly must be fully seated to enclosure 9 threads (minimum) to maintain Explosion Proof rating.

•Stopping Plugs supplied (Honeywell Part Number

•For units itted with the optional relay module: Relay contact ratings are 250 VAC 5A, 24 VDC 5A Resistive Loads Only.

•Use copper conductors only, 60/75°C. Terminal block screws should be tightened to 4.5 lb/in maximum.

•For models

•

•XNX Universal Transmitters carrying UL/CSA/FM approvals that are conigured

for devices measuring %LEL will not allow adjustments to the full scale value. The range is ixed at 100%.

Hazardous Locations instaLLation requirements (ateX)

•Read and understand Technical Manual 1998M0738 before installation and use.

•Use only Certiied M25 cable glands for installation.

•Shielded armoured cable is required for CE compliance.

•special conditions for safe use

•The following applies to the HART Barrier intrinsically safe circuits: For

installations in which both the Ci and Li of the intrinsically safe apparatus exceeds 1% of the Co and Lo parameters of the associated apparatus (excluding the cable), then 50% of Co and Lo parameters are applicable and

shall not be exceeded, i.e. the Ci of the device plus the C of the cable must be less than or equal to 50% of the Co of the associated apparatus, and the Li of the device plus the L of the cable must be less than or equal to 50% of the Lo of the associated apparatus.

•For circuits connected to the EC barrier in which the capacitance and inductance exceed 1% of the permitted values, then the maximum permitted capacitance is limited to 600nF for group IIC and 1uF for group IIIC.

•The connection to the HART circuit shall be rated a minimum of IP 6X.

XNX Universal Transmitter Quick Start Guide |

7 |

3 Mounting and Location of Detectors

caution

caution

The location of the transmitters and sensors should be made in accordance with any relevant local and national legislation, standards or codes of practice. Always replace detectors with a detector of the same type. The detector should be mounted where the gas is most likely to be present. The following points should be noted when locating gas detectors.

•Consider the possible damage caused by natural events e.g. rain or looding when locating detectors.

•Consider ease of access for functional testing and servicing.

•Consider how escaping gas may behave due to natural or forced air currents.

notes:

The placement of detectors should be determined following the advice of experts having specialist knowledge of gas dispersion, experts having knowledge of the process plant system and equipment involved, safety and engineering personnel. The agreement reached on the location of detectors should be recorded.

CSA certiication does not cover XNX EC cartridges or XNX EC cartridge remote mounting kit,

use of HART®, Modbus, or Foundation Fieldbus used for combustible gas performance. HART®, Modbus, or Foundation Fieldbus may be used only for

data collection or record keeping with regards to combustible gas detection.

FM approved conigurations (see the XNX Universal Transmitter Technical Manual, section 6.3 XNX Certiications by Part Number Series) also limit the

use of HART®, Modbus, or Foundation Fieldbus to use for diagnostics, data collection, or record keeping.

The XNX Universal Transmitter is certiied and designed for installation and use worldwide in hazardous areas.

3.1 Mounting the XNX Universal Transmitter

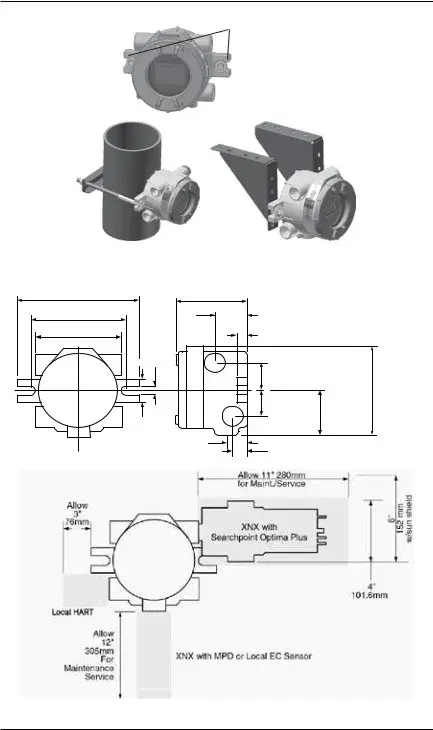

The XNX Universal Transmitter can be mounted in a number of different methods using the integral mounting tabs.

Using the mounting tabs, the XNX can be attached to:

•Flat wall surface

•Unistrut®

With the optional Pipe Mount kit, the XNX can be mounted to pipe of diameter 2 to 6 in (50 to 150mm).

A ceiling mount bracket kit (1226A0358) is also available.

notes:

Agency certiications require that EC and mV sensors face down. Optima sensors must be mounted horizontally.

8 |

XNX Universal Transmitter Quick Start Guide |

Integral Mounting Lugs

Figure 1. Integral mounting lugs and optional pipe and ceiling mounts

7.75"

196.85 mm

6.00"

15.4mm

5.6"

124.24 mm

4.48" |

|

|

113.8 mm |

2.054" |

|

|

|

|

|

52.18mm |

|

|

0.625" |

|

|

15.88mm |

|

0.55" |

|

|

14.35 mm |

|

|

|

1.768" |

|

|

44.90 mm |

|

|

1.768" |

|

|

44.90 mm |

3.176" |

1.67" |

|

80.67 mm |

|

|

|

42.41 mm |

|

|

1.2" |

|

|

31.75mm |

0.945" |

|

|

24mm |

|

6.138"

158.75mm

Figure 2. XNX Universal Transmitter mounting dimensions and clearances

XNX Universal Transmitter Quick Start Guide |

9 |

Warning

Warning

When the XNX is equipped with the optional Remote Mount Kit, the remote sensor MUST be securely mounted to a ixed position. The Remote Sensor Kit is not intended to be used as a

detector.

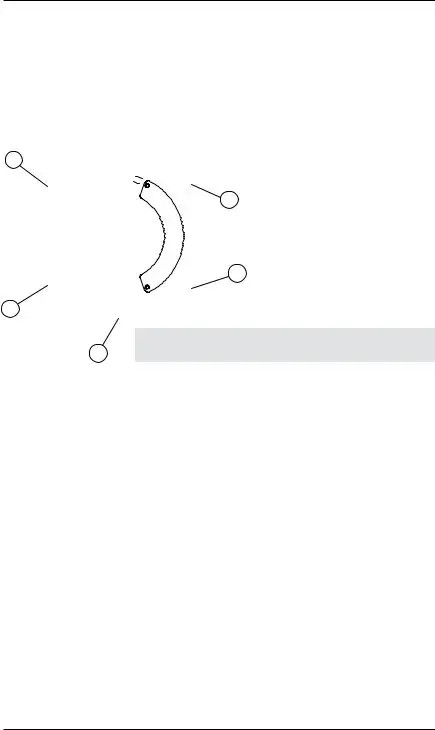

The XNX is conigured with 5 cable/conduit entries built into the housing for wiring and mounting sensors. Figure 3 provides the guidelines to proper installation of the XNX.

A

note

E

While relay wiring can use any available cable/conduit entry in the XNX enclosure, do not use the same cable/ conduit entry for both relay reset and relay signal lines to

D*

avoid electrical noise.

B

C

* Limited access due to IS barrier if equipped with electrochemical cell.

Option |

Position |

|

|

Local HART® Option |

B |

MPD, 705 Series, Sensepoint Series |

C |

|

|

Catalytic Bead Sensor |

C |

|

|

Searchpoint Optima Plus |

A or E |

|

|

Searchline Excel |

Typically C |

|

|

Remote Sensor Connection (except EC ) |

Any remaining |

|

|

Searchpoint Optima Plus - Remote |

Any remaining |

|

|

Modbus® |

Any remaining |

Relays |

Any remaining |

|

|

Foundation Fieldbus |

Any remaining |

|

|

Power |

Any remaining |

|

|

Figure 3. XNX Universal Transmitter cable/conduit entry assignments

10 |

XNX Universal Transmitter Quick Start Guide |